Acidification roasting method for efficiently treating aluminum electrolysis solid waste

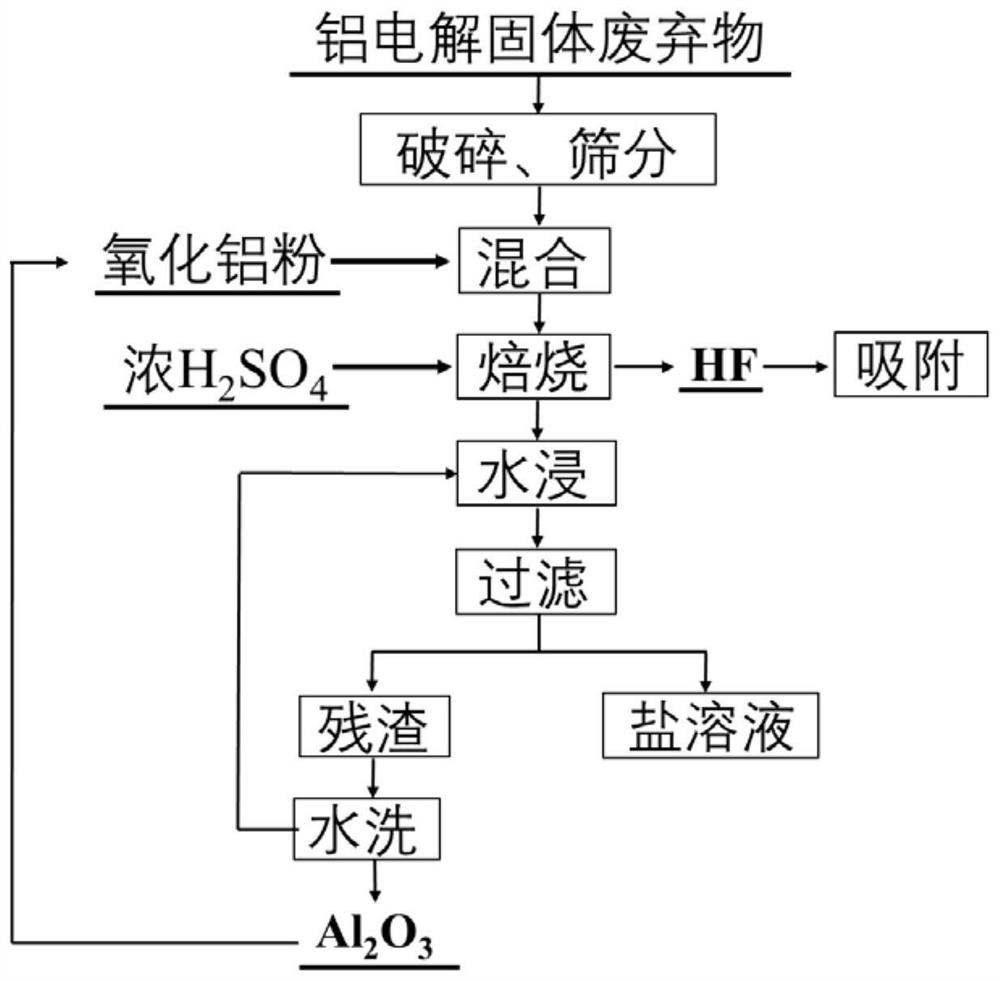

A solid waste, acidification roasting technology, applied in the direction of alumina/hydroxide preparation, hydrogen fluoride, fluorine/hydrogen fluoride, etc., can solve the problems such as the conversion rate of fluoride that is not mentioned, and achieve thorough and efficient roasting reaction, convenient operation, The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An acidification and roasting method for efficiently treating aluminum electrolytic solid waste, the specific operation is as follows:

[0026] Take 20g of pure cryolite and prepare it in the form of particles less than 200 mesh; mix it with alumina at a mass ratio of 1:1; prepare sulfuric acid with a concentration of 98%: mix the mixed material with concentrated sulfuric acid at a mass ratio of 1 : 4 mixed into the crucible, placed in a roasting device, at a temperature of 250°C, with a stirring speed of 500r / min, roasted for 2h; during the roasting process, use aluminum hydroxide to absorb the hydrogen fluoride gas generated by the reaction; after the roasting reaction is completed and cooled , add 400ml of deionized water to the roasted product, stir and react at room temperature for 1h, filter to obtain the filtrate and filter residue; the filter residue is washed and dried; the obtained filtrate is a solution containing sodium sulfate and aluminum sulfate, and the f...

Embodiment 2

[0029] An acidification and roasting method for efficiently treating aluminum electrolytic solid waste, the specific operation is as follows:

[0030] Take 20g of waste solid aluminum electrolyte, crush, ball mill, and sieve to make it standby in the form of particles smaller than 200 mesh; mix it with alumina at a mass ratio of 2:1; prepare sulfuric acid with a concentration of 98%: mix the The uniform material and concentrated sulfuric acid are mixed into the crucible at a mass ratio of 1:1, placed in a roasting device, and roasted for 1 hour at a temperature of 150°C with a stirring speed of 500r / min; during the roasting process, aluminum hydroxide, adsorption reaction Generated hydrogen fluoride gas; after the roasting reaction is finished and cooled, add 400ml of deionized water to the roasted product, stir and react at room temperature for 1h, filter to obtain the filtrate and filter residue; wash and dry the filter residue; the obtained filtrate It is a sulfate solution...

Embodiment 3

[0032] An acidification and roasting method for efficiently treating aluminum electrolytic solid waste, the specific operation is as follows:

[0033] Take 20g of waste solid aluminum electrolyte, crush, ball mill, and sieve to make it ready for use in the form of particles smaller than 200 mesh; mix it with alumina at a mass ratio of 1:1; prepare sulfuric acid with a concentration of 98%: put the mixed The uniform material and concentrated sulfuric acid are mixed into the crucible at a mass ratio of 1:3, placed in a roasting device, and roasted for 2 hours at a temperature of 250°C with a stirring speed of 500r / min; during the roasting process, aluminum hydroxide, adsorption reaction Generated hydrogen fluoride gas; after the roasting reaction is finished and cooled, add 400ml of deionized water to the roasted product, stir and react at room temperature for 1h, filter to obtain the filtrate and filter residue; wash and dry the filter residue; the obtained filtrate It is a sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com