Patents

Literature

48 results about "Cupric bromide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper(II) bromide, also known as cupric bromide, is a chemical compound. Its chemical formula is CuBr2. It has copper and bromide ions in it. The copper is in its +2 oxidation state.

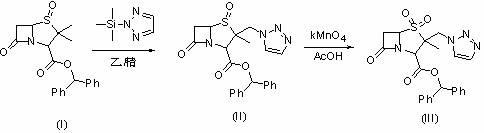

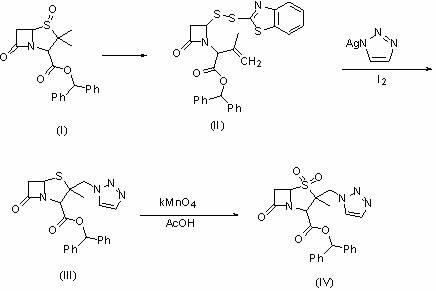

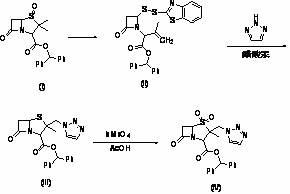

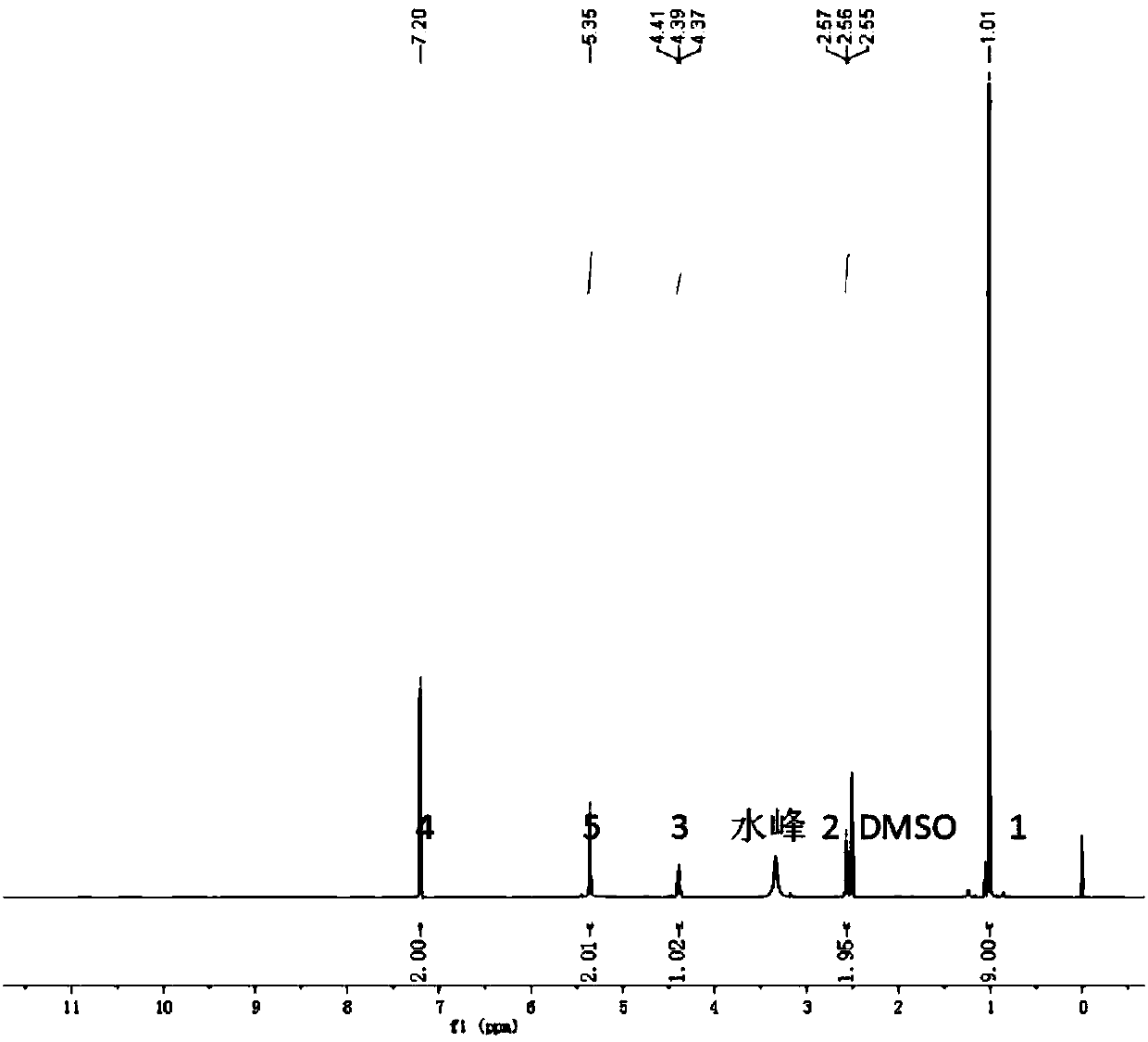

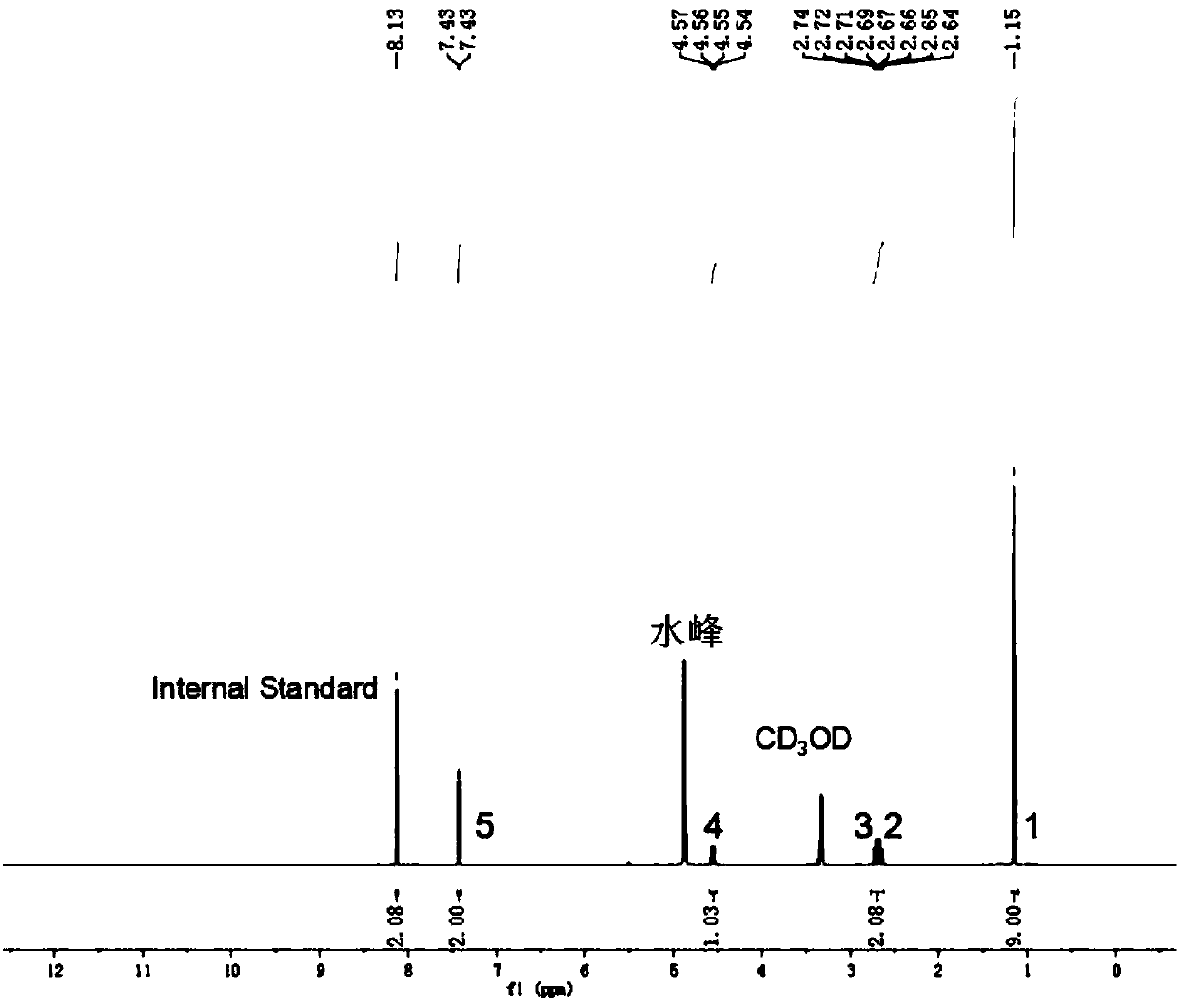

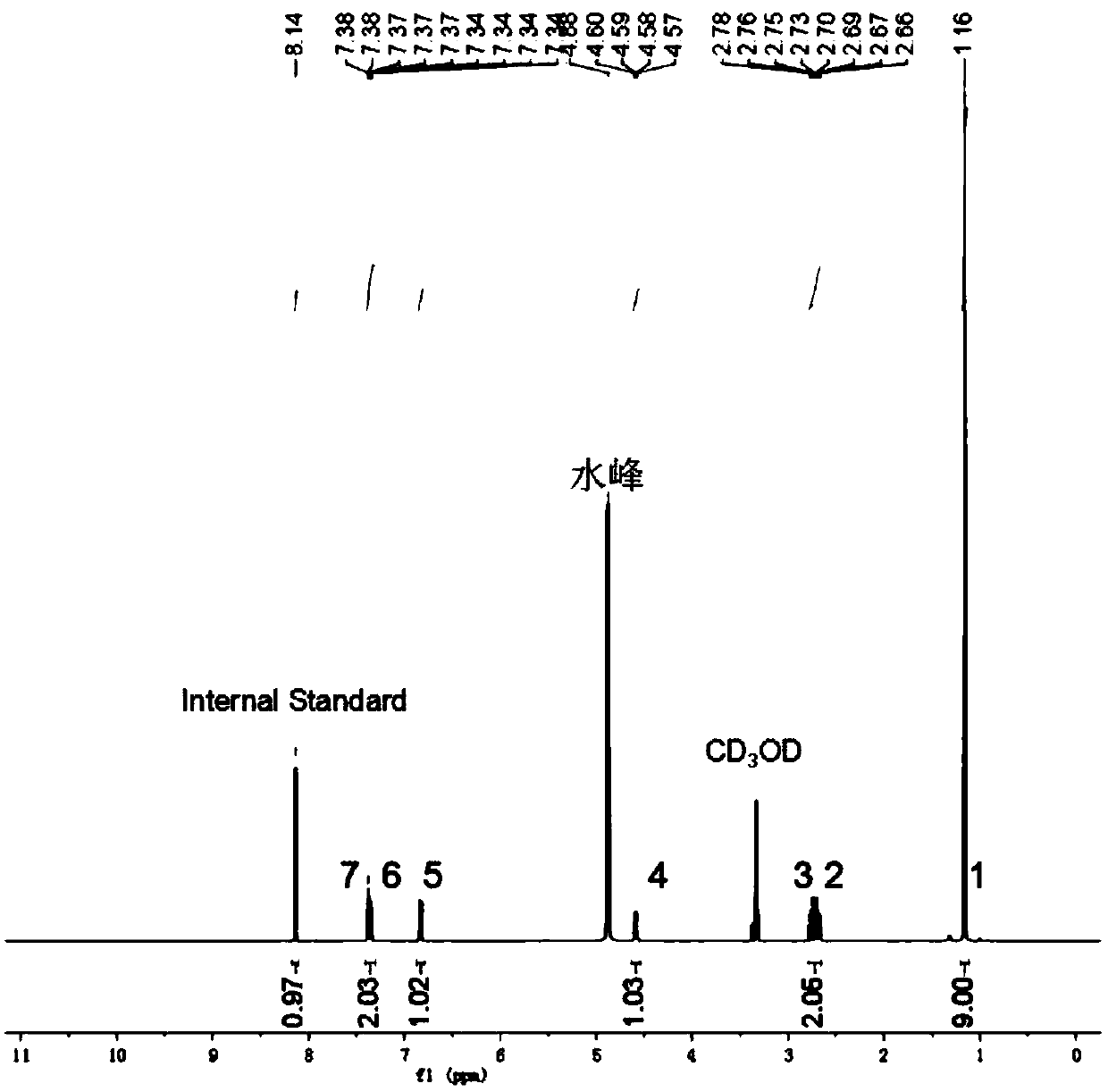

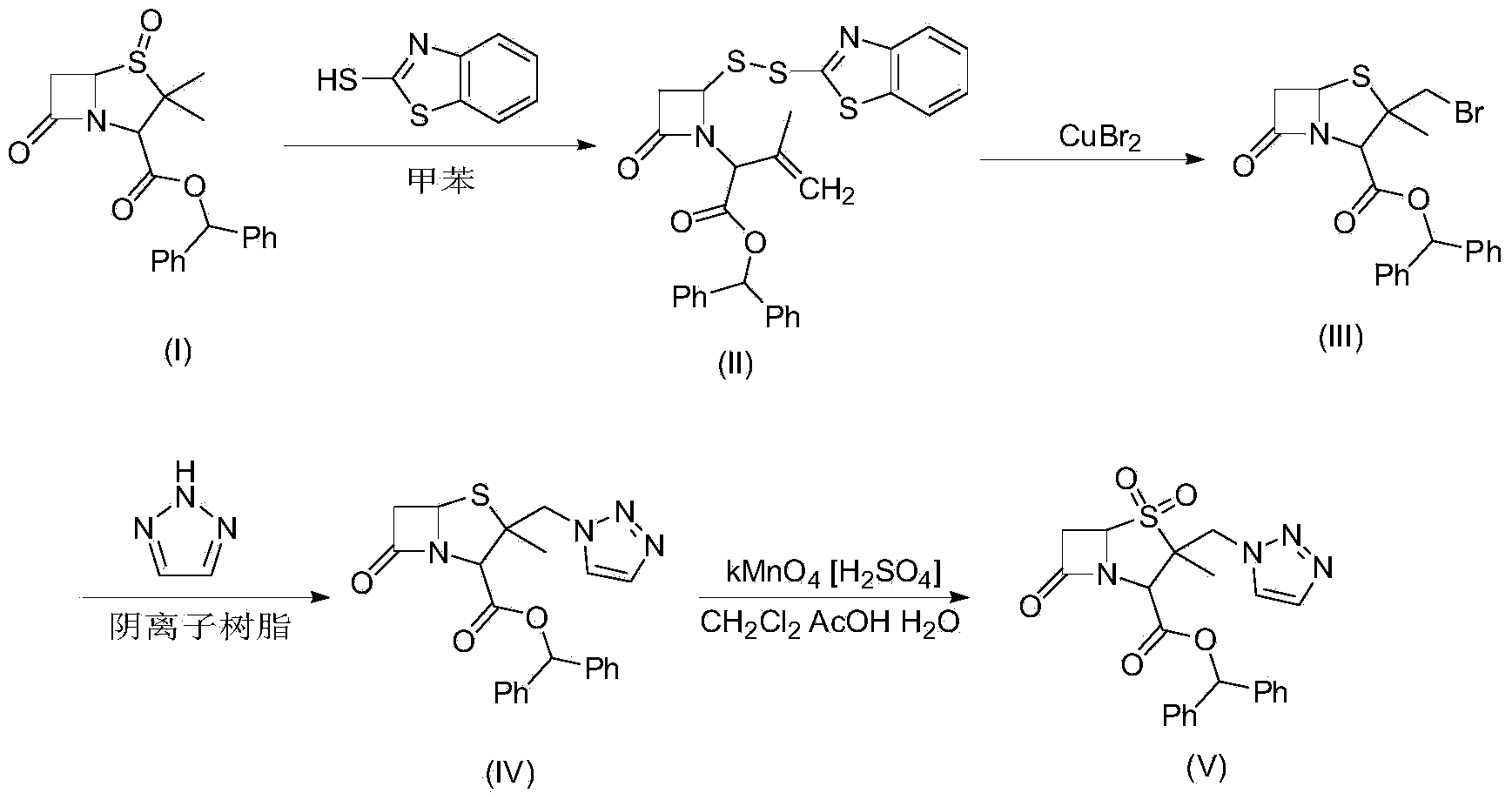

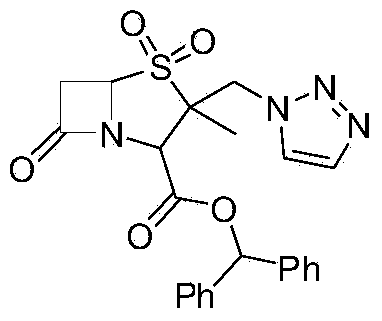

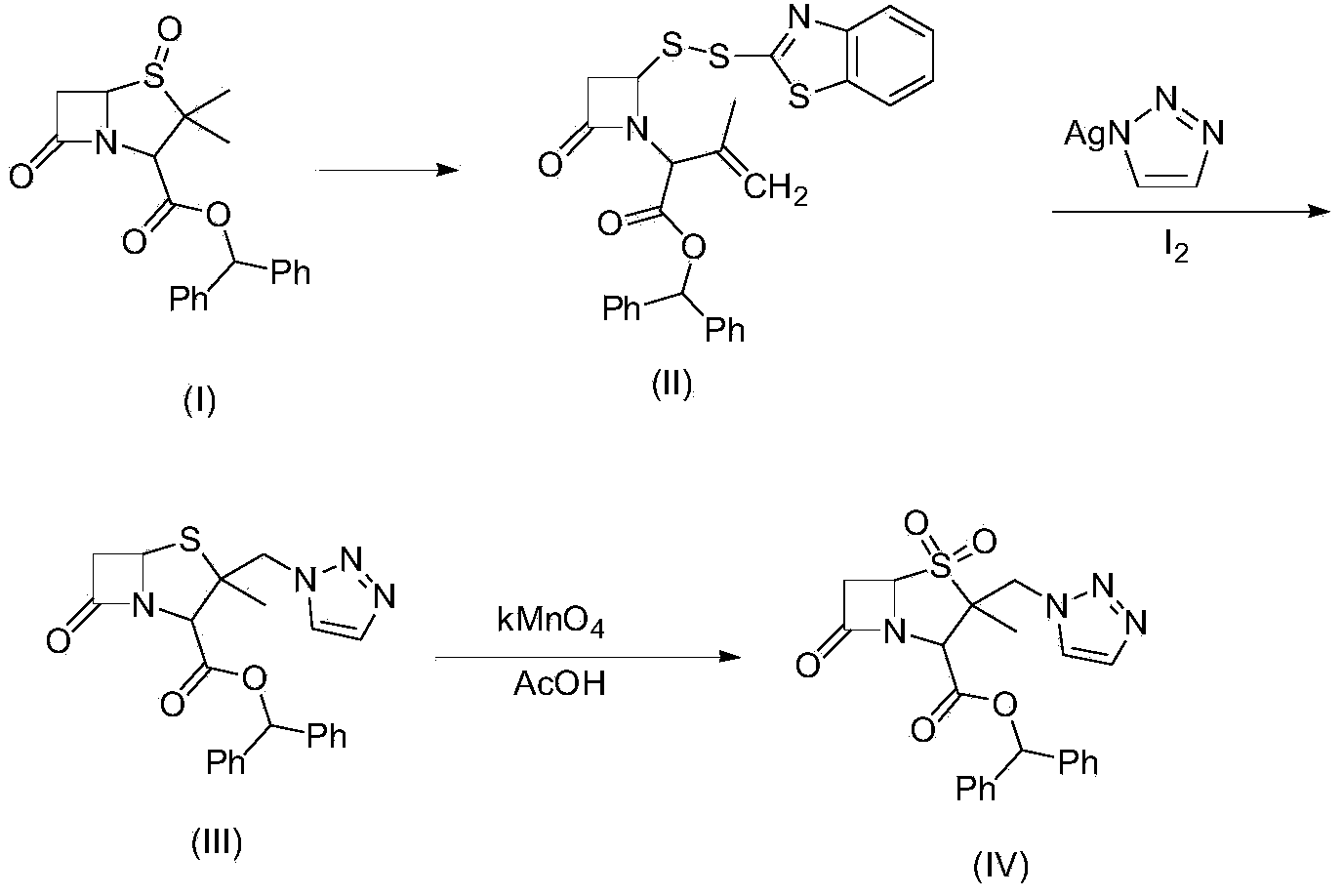

Method for preparing 2 beta-methyl penicillanate benzhydryl dioxide

ActiveCN102304139AIncreased nucleophilic reactivityReduce pollutionOrganic chemistryAcetic acidCupric bromide

The invention provides a method for preparing a 2 beta-methyl penicillanate benzhydryl dioxide, which is to prepare the 2 beta-methyl penicillanate benzhydryl dioxide by four-step reactions. In the method, hydrobromic acid and sodium nitrite or cupric bromide serving as a brominating agent and other methods are adopted, especially bromide is generated by using adsorption of anionic resin, and water is a side product, so that the method is safe and environmentally friendly; the resin can be used repeatedly; the reaction molar yield can be remarkably improved, reaching over 75 percent; and dichloromethane, water, little glacial acetic acid, particularly as well as a catalytic amount of concentrated sulfuric acid are used to replace massive glacial acetic acid serving as a solvent, so that massive glacial acetic acid is removed. The method has unique process, stable product quality, mild process condition and easy control, the traditional azidation reaction and ethynylation reaction are eliminated, the production cost is reduced, the environmental pollution is greatly reduced, and no special equipment is required. The method is suitable for industrial generation in scale.

Owner:JIANGXI FUSHINE PHARMA CO LTD

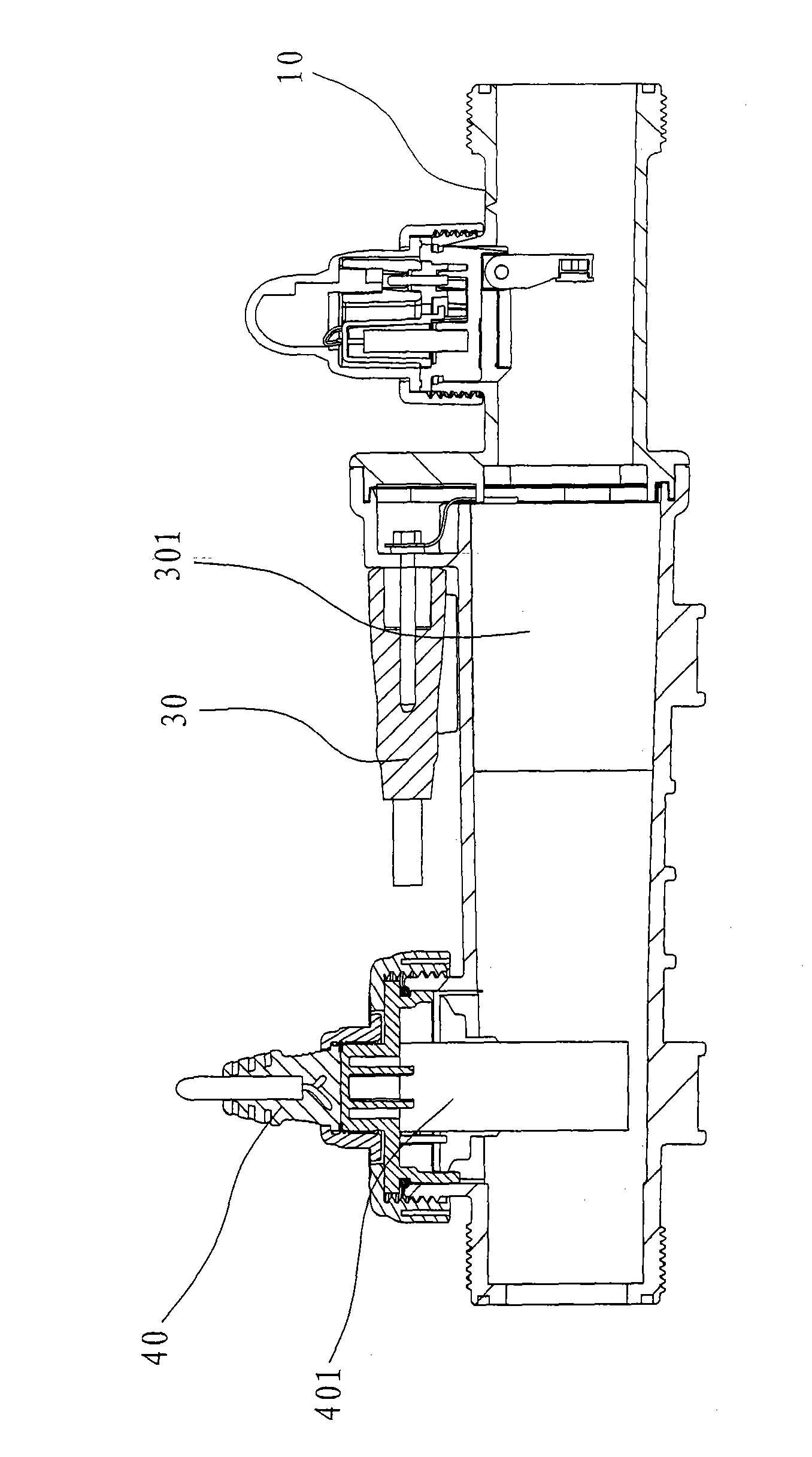

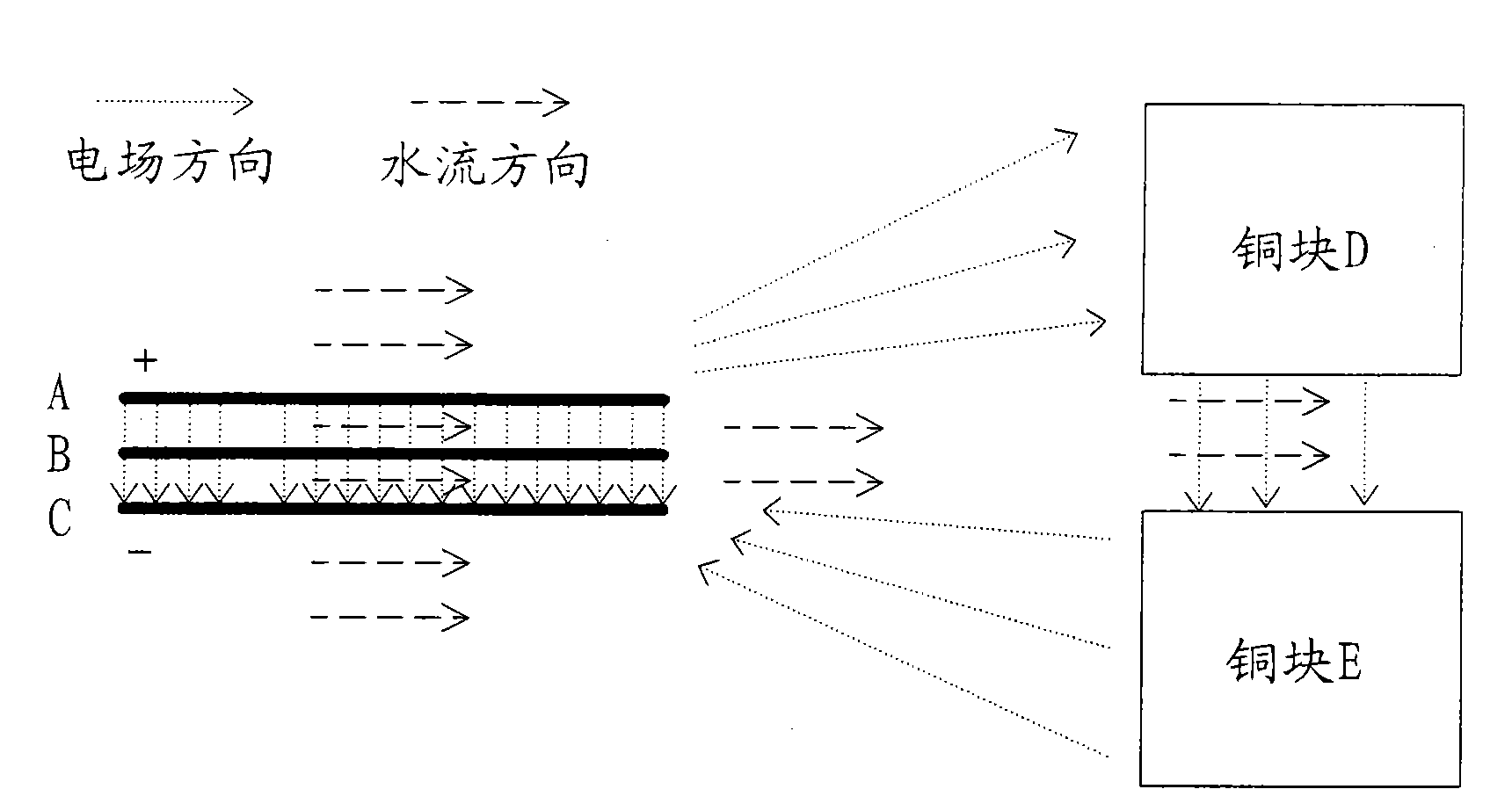

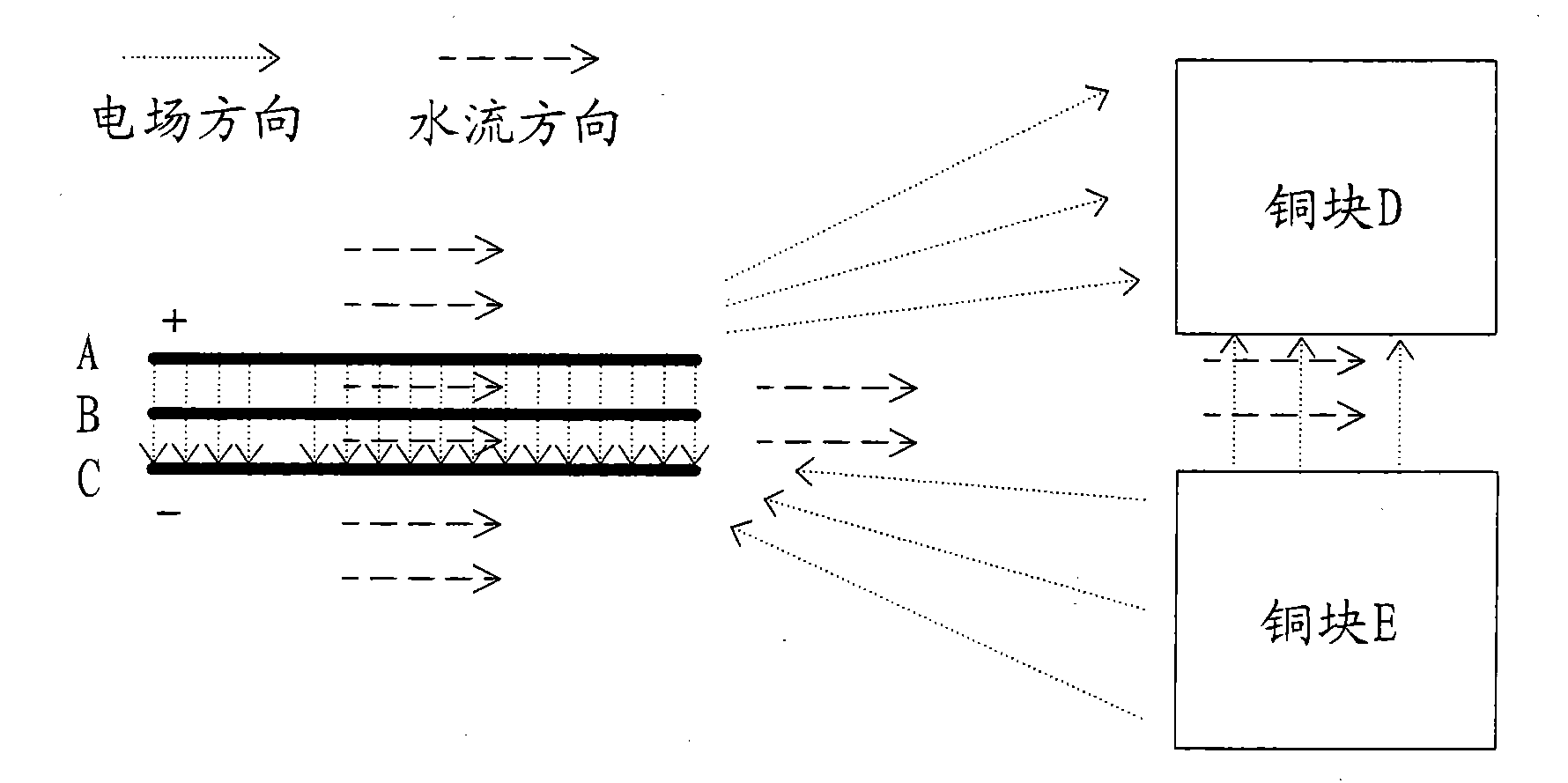

Two-in-one cupric chloride/cupric bromide disinfecting apparatus for swimming pool and control method thereof

ActiveCN101993135AInhibition releaseThe amount of release is controllableWaste water treatment from bathing facilitiesGymnasiumCupric bromideGraphite electrode

The invention discloses a control method of a two-in-one cupric chloride / cupric bromide disinfecting apparatus for a swimming pool, comprising the following steps of: when copper is released, periodically inverting an anode and a cathode of a copper block and allowing an anode and a cathode of titanium plate / graphite electrode plate to be in a suspending state simultaneously; and when chloride / bromide is released, periodically inverting the anode and the cathode of the titanium plate / graphite electrode plate and short connecting the anode and the cathode of the copper plate simultaneously and then connecting the copper block with the cathode of the titanium plate / graphite electrode plate or applying the voltage lower than the voltage of the titanium plate / graphite electrode plate. In the method, by short connecting the copper block when not in work with the cathode of the titanium plate / graphite electrode plate or applying the voltage lower than the voltage of the cathode, the release amount of copper ions can be controlled, the volume of the disinfecting apparatus can be reduced and the corrosion between the anode and the cathode of the copper block is balanced. The invention also discloses the two-in-one cupric chloride / cupric bromide disinfecting apparatus for the swimming pool.

Owner:INTEX IND (XIAMEN) CO LTD

Method for preparing ethyl bromodifluoroacetate

InactiveCN107573242AAvoid damageLess investmentOrganic compound preparationCarboxylic acid esters preparationCupric bromidePotassium fluoride

The invention provides a method for preparing ethyl bromodifluoroacetate and relates to a preparation method of a chemical reagent. The method takes trichloro ethylene as a raw material, and comprisesthe following steps: under the action of ultraviolet light of a catalytic medium, an oxidation reaction happens between trichloro ethylene and oxygen in a reactor to synthesize dichloracetyl chloride; an amination reaction happens between dichloracetyl chloride and diethylamine under the action of a catalyst to synthesize dichloroacetyl diethylamine; a fluorination reaction happens between dichloroacetyl diethylamine and anhydrous potassium fluoride under the action of a solvent and a phase transfer catalyst to synthesize difluoroacetyl diethylacetamide; difluoroacetyl diethylacetamide is esterified to synthesize ethyl difluoroacetate; and by taking cupric bromide as a brominating agent, ethyl difluoroacetate is bromized to prepare the end product (ethyl bromodifluoroacetate). The methodhas the characteristics that the equipment investment is low, reaction conditions are mild, the method is safely implemented at normal pressure, and after-treatment is simple.

Owner:盐城顺恒化工有限公司

Ultralow-mercury catalyst used for acetylene hydrochlorination

ActiveCN105032455AHigh activityImprove stabilityMolecular sieve catalystsPreparation by halogen halide additionZinc bromideCupric bromide

The invention discloses an ultralow-mercury catalyst, and particularly relates to a catalyst with the ultralow content of mercuric chloride and suitable for acetylene hydrochlorination to synthesize chloroethylene. The catalyst comprises a main activity component, auxiliary component A metal bromide, auxiliary component B metal bromide and carriers, wherein the main activity component is mercuric chloride, and the content of the mercuric chloride accounts for 0.5-4% of the total mass of the catalyst carriers; the auxiliary component A metal bromide includes one or more of cupric bromide, cobaltous bromide, manganous bromide, nickel bromide and zinc bromide, and the metal element content of the auxiliary component A metal bromide accounts for 0.1-15% of the total mass of the catalyst carriers; the auxiliary component B metal bromide includes one or more of potassium bromide, barium bromide, sodium bromide and lithium bromide, and the metal element content of the auxiliary component B metal bromide accounts for 0.01-10% of the total mass of the catalyst carriers; the carriers include activated carbon with the specific surface area of 300-2500 m<2> / g and molecular sieve, or silica gel, or zeolite or kieselguhr. While activity and stability of the ultralow-mercury catalyst are ensured, the mercury resource in the catalyst is brought into full play to reach the maximum use efficiency, and the novel ultralow-mercury catalyst is environmentally friendly.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD

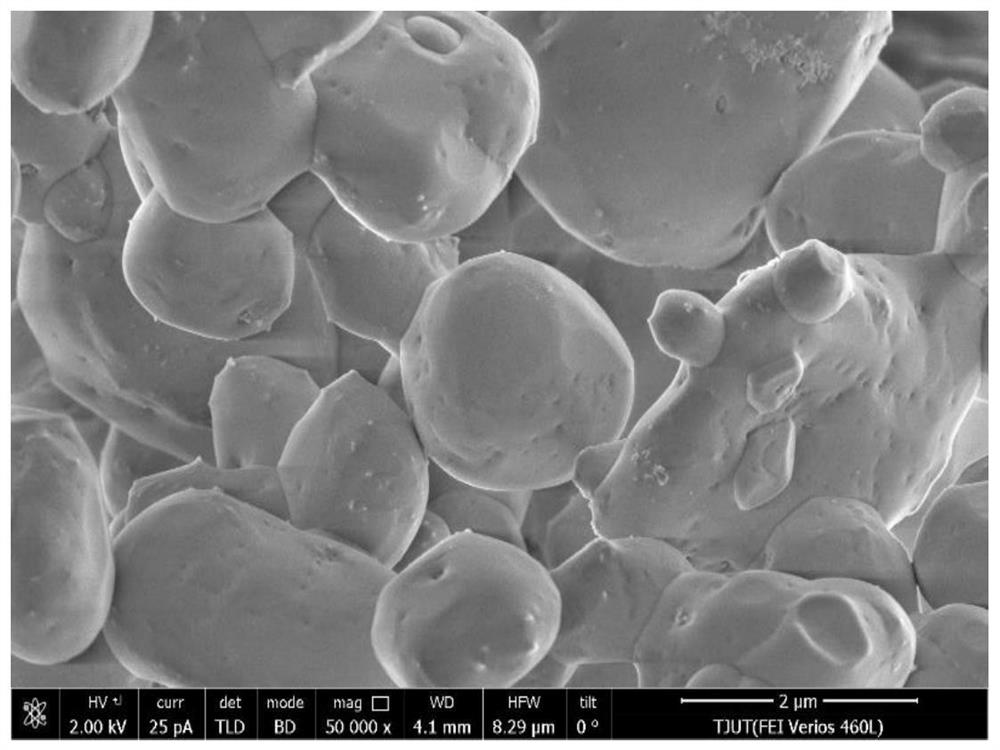

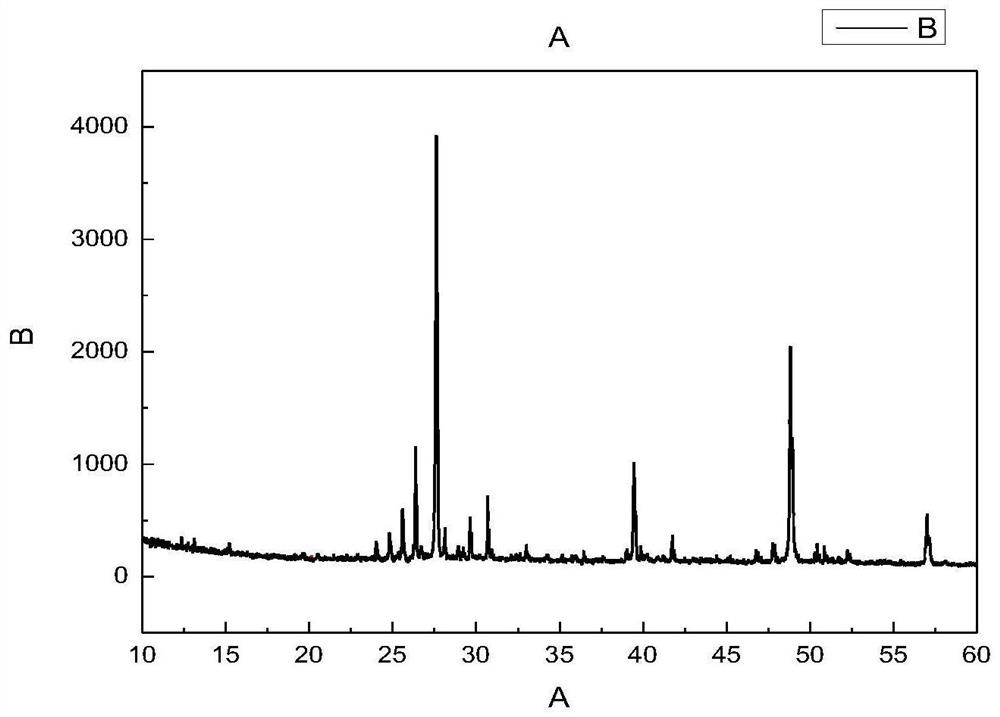

Method for synthesizing copper-based perovskite powder by low-temperature solvent method

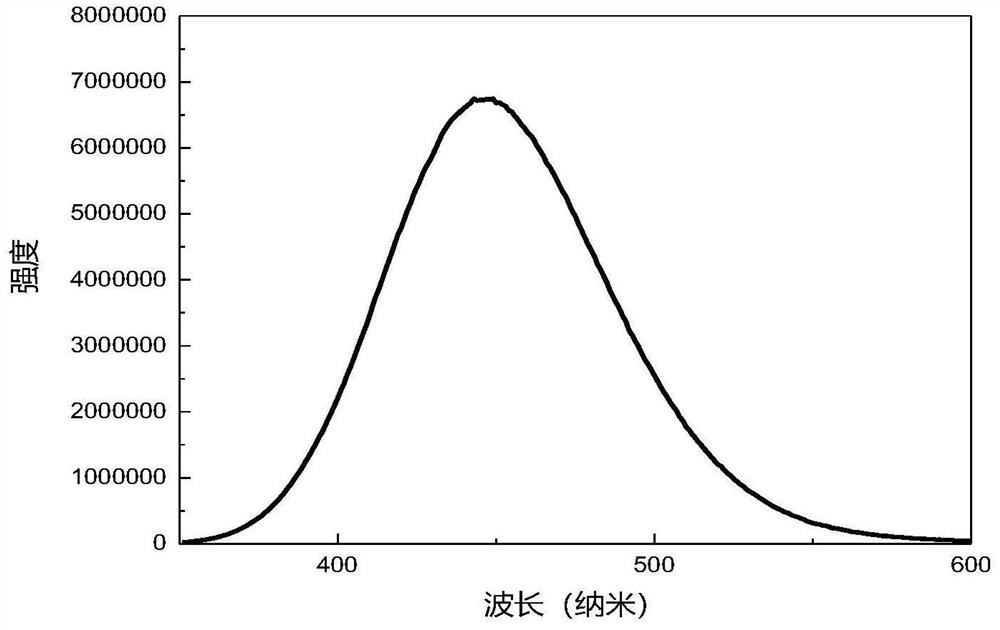

InactiveCN112280555ALow costShort preparation cycleCopper compoundsLuminescent compositionsCupric bromideCopper chloride

The invention relates to a method for synthesizing copper-based perovskite powder by a low-temperature solvent method. The method comprises the following steps: adding CsX and CuX into a polar organicmixed solution, and stirring for 4-6 hours at 40-70 DEG C, wherein the polar organic mixed solution is a mixed solution of N, N-dimethylformamide (DMF)and dimethyl sulfoxide (DMSO), the CsX is cesiumchloride, cesium bromide or cesium iodide, and the CuX is copper chloride, copper bromide or copper iodide. According to the synthesis process, constant-temperature growth on a hot plate is not needed, synthesis is directly conducted on a magnetic stirrer, the synthesis process has the advantages of being short in manufacturing period, low in cost, simple in growth step, environmentally friendlyand the like, and Cs3Cu2X5 powder with high crystallization quality is separated out within 5 hours.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Isoquinoline compound as well as preparation method and application thereof

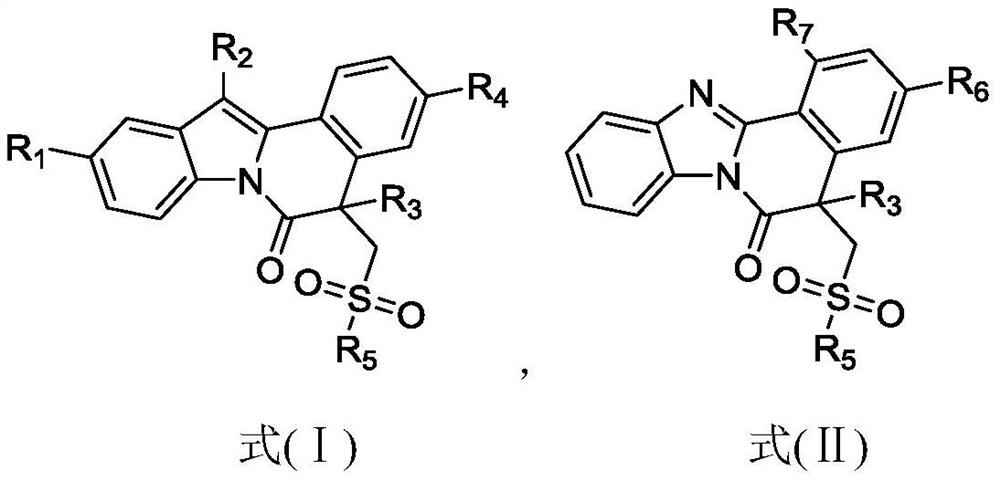

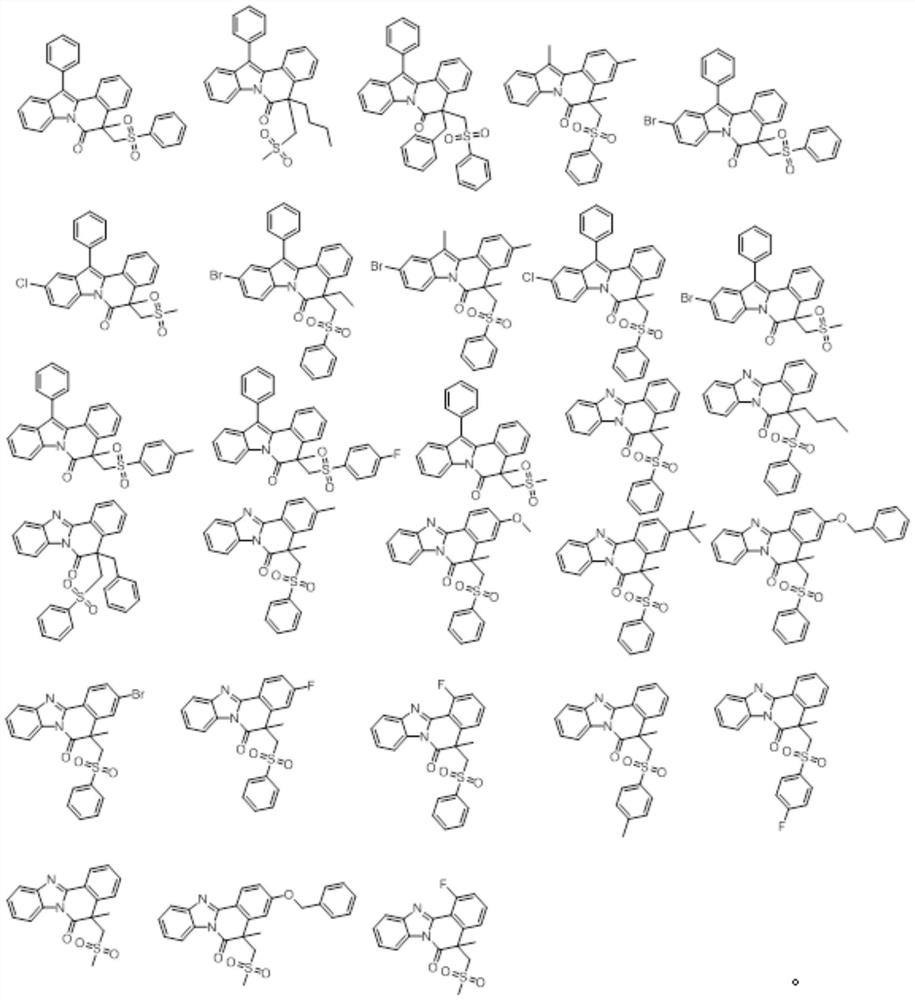

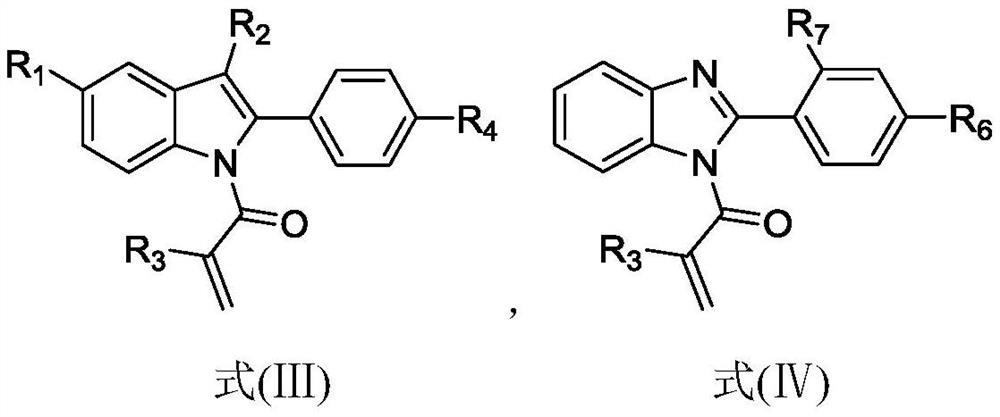

ActiveCN113698399AAntiproliferative activityThe reaction system is simple and safeOrganic chemistryAntineoplastic agentsBenzoic acidChemical synthesis

The invention discloses an isoquinoline compound as well as a preparation method and application thereof, and relates to the technical field of chemical synthesis. The isoquinoline compound is an indolo [2, 1-a] isoquinoline compound or a benzimidazo [2, 1-a] isoquinoline-6 (5H) ketone compound, and the preparation method comprises the following steps: dissolving a 1-(2, 3-diphenyl-1H-indole-1-yl)-2-methyl propenyl-1-ketone compound or a 1-methyl acryloyl-2-aryl-benzimidazole compound and an S-phenyl phenyl thiosulfonate compound in an organic solvent, adding tert-butyl benzoate oxide and a catalytic amount of copper bromide, and reacting at 110 DEG C to obtain the isoquinoline compound. The synthesis process does not need diazo compounds, has the characteristics of cheap and easily available raw materials, mild reaction conditions, simplicity and convenience in operation, high regioselectivity and high yield, and is beneficial to industrial production.

Owner:ZHEJIANG PROVINCIAL PEOPLES HOSPITAL

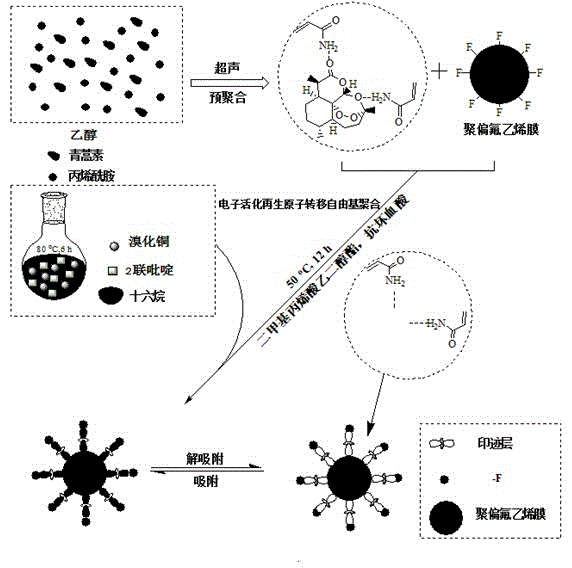

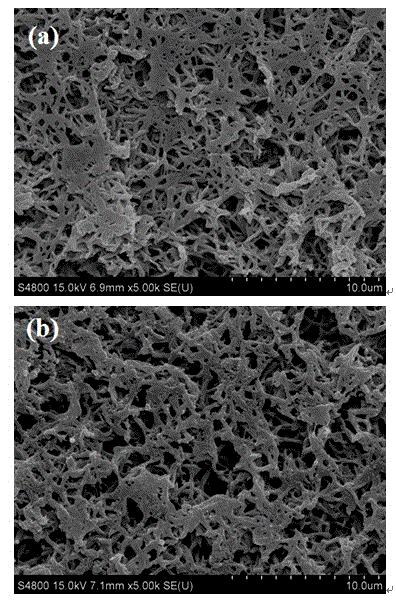

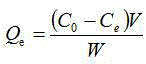

Artemisinin molecular imprinting film, preparation method and applications thereof

InactiveCN104004218AHigh selectivityEasy to separateSemi-permeable membranesOther chemical processesMethacrylateCupric bromide

The present invention relates to an artemisinin molecular imprinting composite film, a preparation method and applications thereof, and belongs to the technical field of environmental material preparation. The present invention especially relates to a method comprising the following steps: adopting a polyvinylidene fluoride membrane as a substrate, firstly activating the surface of the polyvinylidene fluoride membrane, then making up a combination of cupric bromide and 2, 2-bipyridine as a catalyst system, selecting artemisinin as a template molecule, acrylamide as a functional monomer and ethylene glycol dimethacrylate as a crosslinking agent, conducting activator generated by electron transfer for atom transfer radical polymerization, and synthesizing the artemisinin molecular imprinting composite film by one-step method. The adsorption balance, dynamics and selective recognition performance of the imprinting film prepared in the present invention is studied by static adsorption experiments, the results show that the imprinting film prepared in the present invention has very rapid absorption dynamic properties and superior artemisinin molecular recognition performance, and can be used for selective recognition and separation of artemisinin.

Owner:JIANGSU UNIV

Method for synthesizing aliphatic propargylamines

InactiveCN101575294ALow costRaw materials are easy to obtainPreparation by reductive alkylationAmino compound preparation by condensation/addition reactionsCupric bromideIodide

The invention relates to a method for synthesizing aliphatic propargylamines, belonging to the field of the synthesis of aliphatic compounds. The method comprises the following steps: acetylene, aliphatic amine and formaldehyde are synthesized into the aliphatic propargylamines under normal pressure and a certain temperature according to a certain proportion, DMSO or N, N-DMF is used as a reactive solvent, cupric salt is used as a catalyst, and hydrochloric acid is used as a cocatalyst, wherein the cupric salt catalyst is one of cuprous chloride, cuprous bromide, cuprous iodide, cuprous oxide, cupric chloride, cupric bromide and cupric sulfate; the cocatalyst is the hydrochloric acid; the solvent is the DMSO or the N, N-DMF; and the aliphatic amine contains 3 to 30 carbon atoms. The invention has the advantages of low reaction cost, high yield, little side reactions, low difficulty of a reaction technology, simple operation, easy subsequent-separation operation of a product, reaction time shortening and obvious enhancement of the economical efficiency.

Owner:北京理工亘元科技有限公司 +1

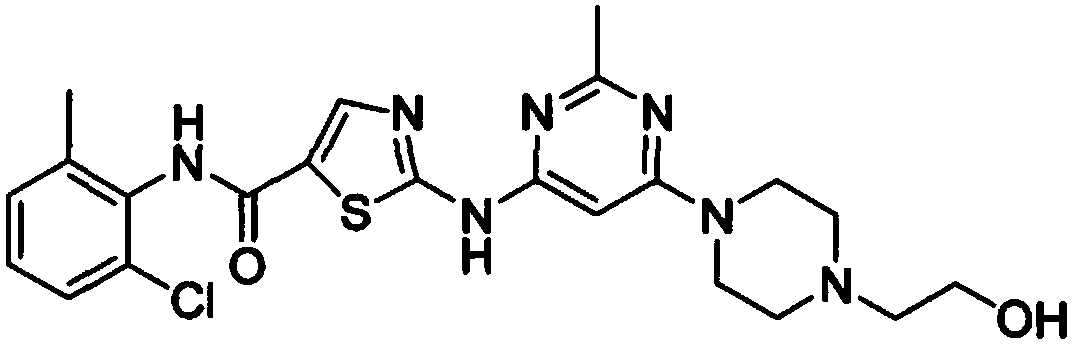

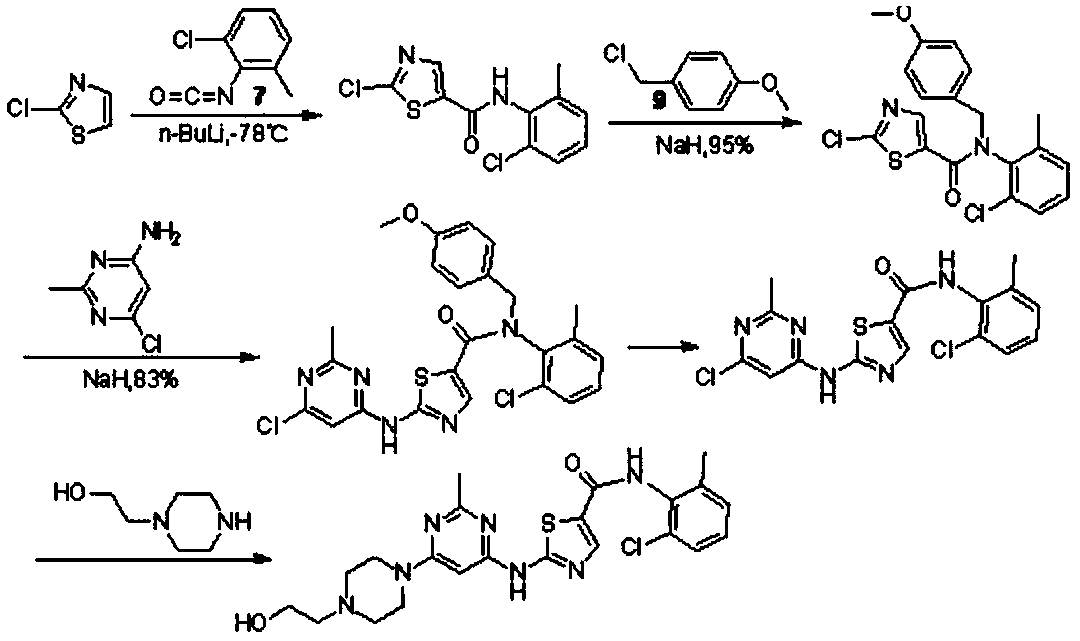

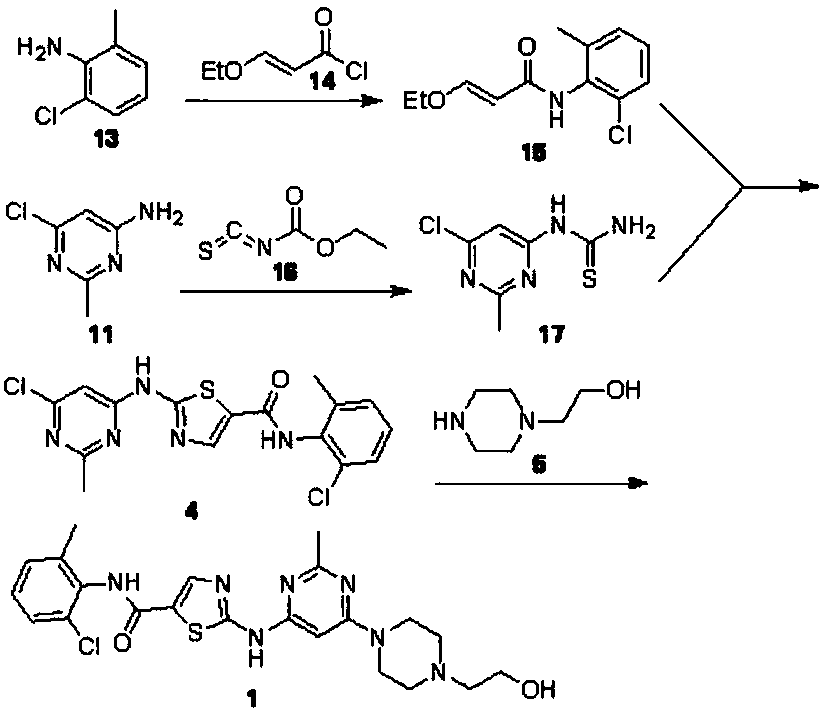

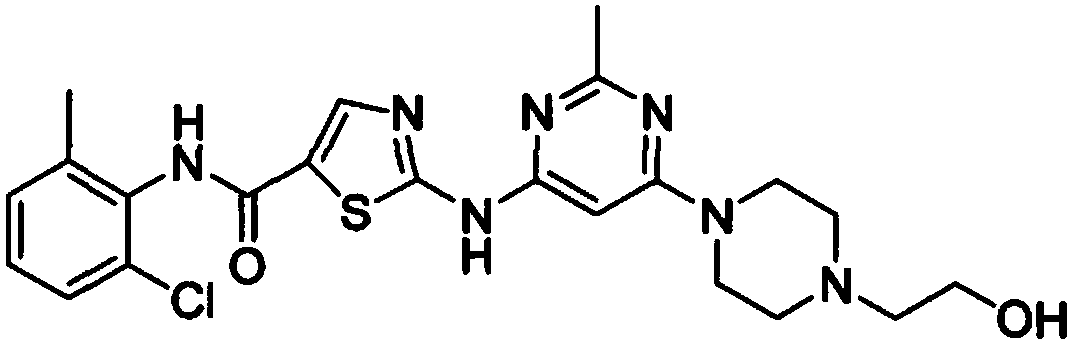

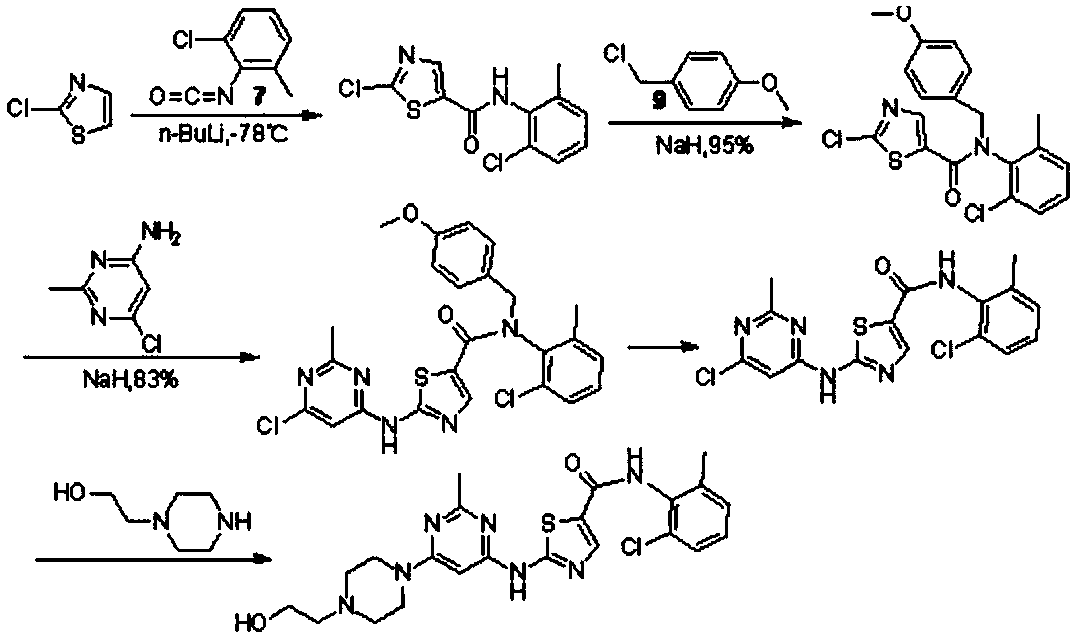

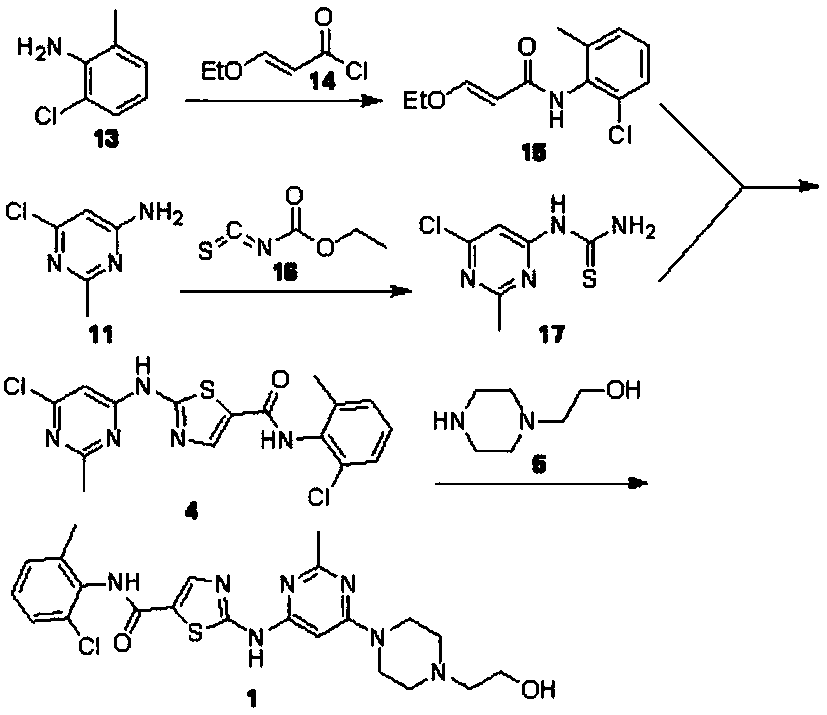

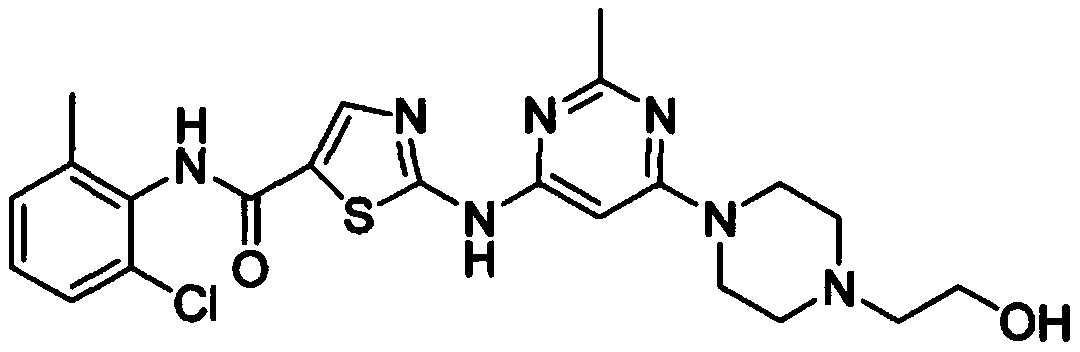

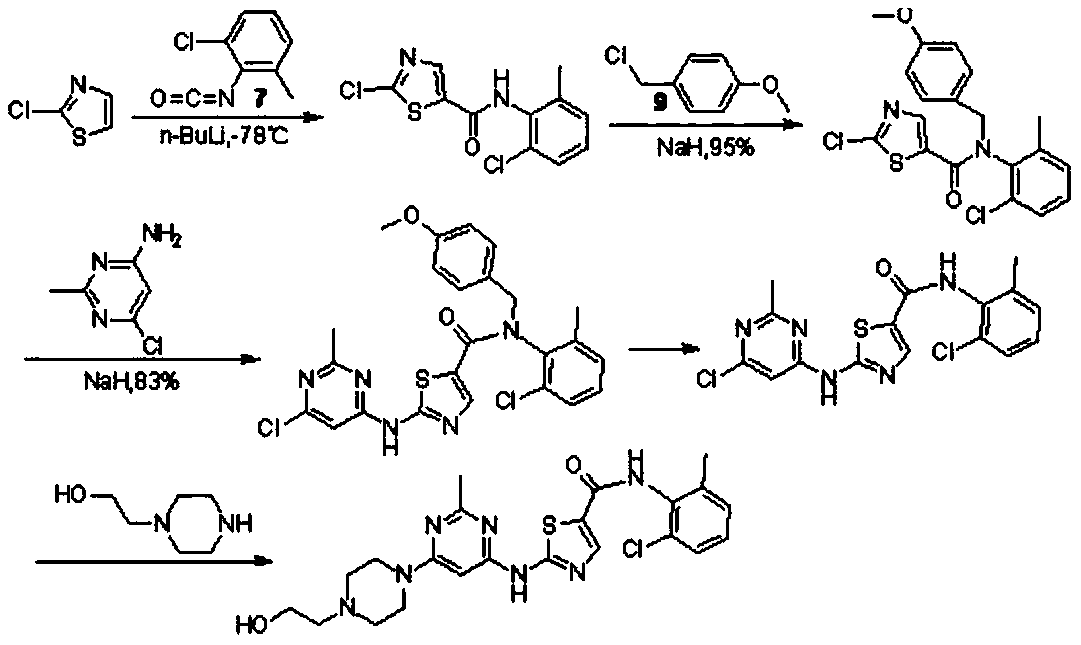

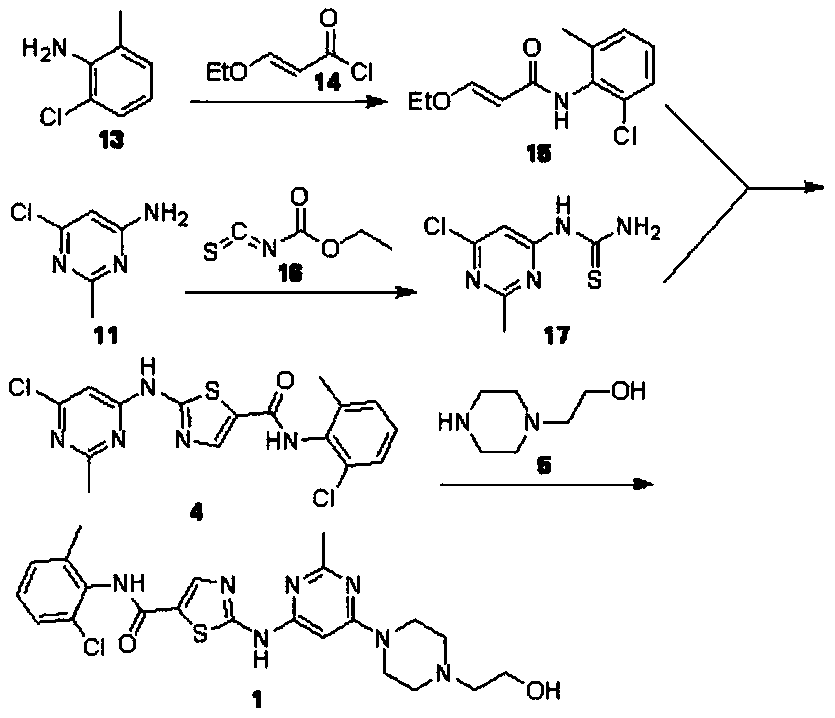

Method for preparing dasatinib tablets

The invention relates to a method for preparing dasatinib tablets. The method comprises the following steps: enabling 3-oxo-ethyl propionate to react with 2-chlorine-6-methylaniline under an alkali condition, further adding a solvent in which cupric bromide is dissolved to carry out a reaction, further adding thiourea, and cyclizing with a catalyst so as to obtain 2-amino-N-(2-chlorine-6-methyphenyl)thiazole-5-formamide; further synthesizing dasatinib tablets from 4,6-dichloro-2-methyl pyrimidine, N-ethoxy piperazine and 2-amino-N-(2-chlorine-6-methyphenyl)thiazole-5-formamide according to a one-pot method under the action of an alkali and an ionic liquid 1-butyl-3-methylimidazole glycinate. The method is mild in condition, simple in step, environmentally friendly, high in yield and applicable to industrial production.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD +2

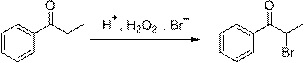

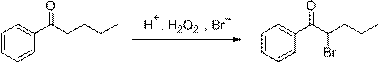

Preparation method of alpha-bromo aromatic ketone compounds

InactiveCN108276264AExperiment operation is simpleReduce manufacturing costOrganic compound preparationCarbonyl compound preparationBromineSolvent free

The invention discloses a high-efficiency and green preparation method of alpha-bromo aromatic ketone compounds. The preparation method comprises that under a certain temperature, alpha-H of aromaticketone compounds is brominated to prepare the alpha-bromo aromatic ketone compounds in an acidic medium with hydrogen peroxide as an oxidant and an inorganic bromide as a bromine source under the condition of an alcoholic solvent or solvent-free. The main features of the method are that bromination reagents such as bromine, bromine dioxane, 2,4,4,6-tetrabromocycloketone, perbrominated quaternary ammonium salts, C5H5N.HBr.Br, NBS, dibromohydantoin, copper bromide and cuprous bromide are not used as the bromine source, so that production cost is reduced, and environmental pollution caused by heavy metal bromination reagents is avoided; and in addition, the method uses hydrogen peroxide and inorganic bromide reagents to prepare the alpha-bromo aromatic ketone compounds in situ, the reaction conditions are mild, the experimental operation is simple, the selectivity is good, and the product is single, and therefore, the preparation method has very high applicability and universality, and has a very broad application prospect.

Owner:NINGXIA PAGODA CHEM CENT LAB CO LTD

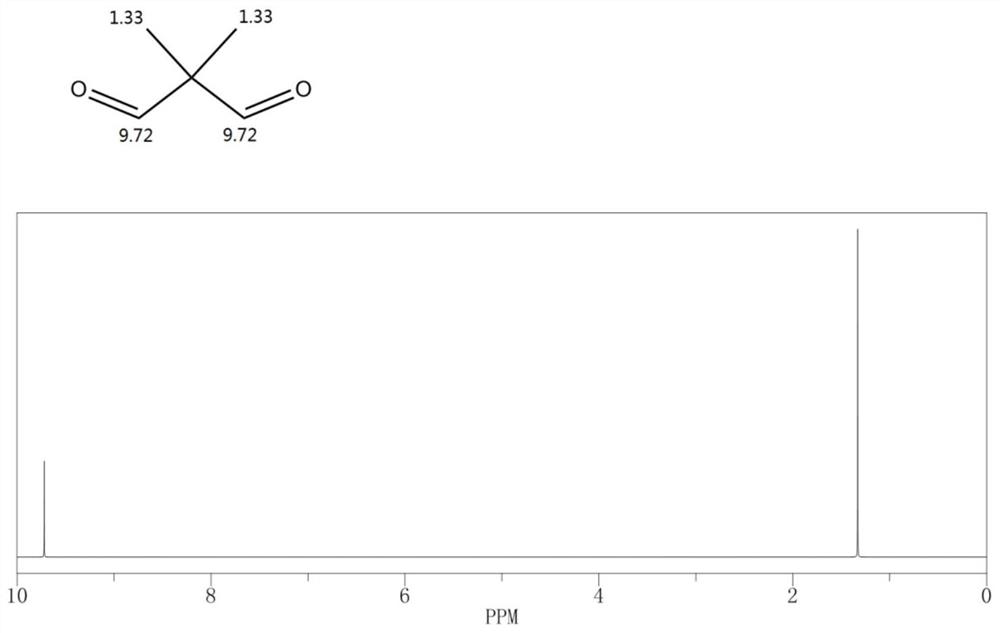

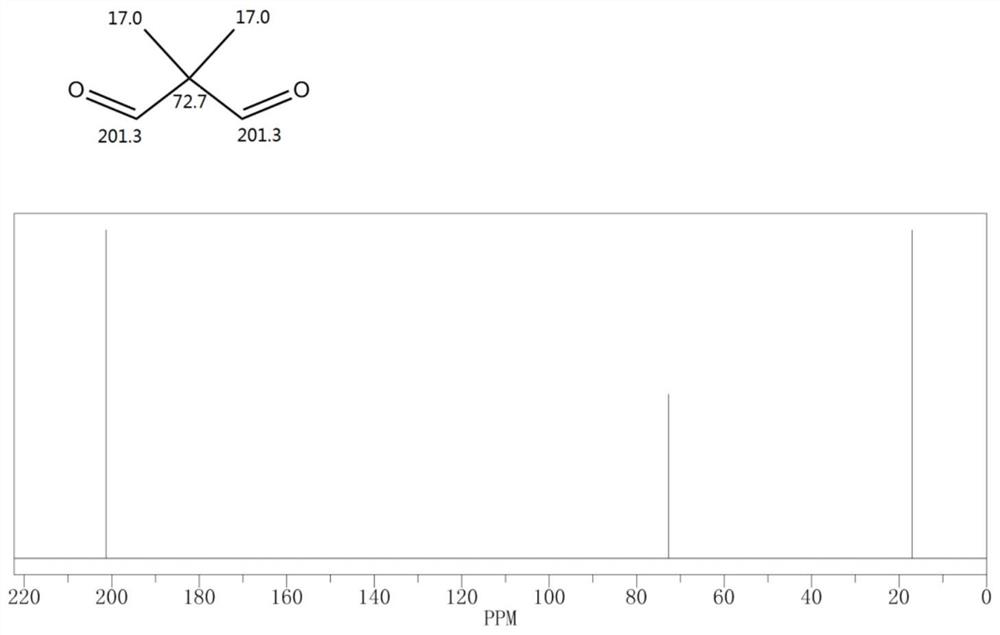

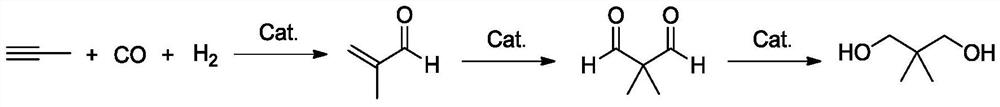

Carbonylation reaction catalyst composition and method for preparing neopentyl glycol

ActiveCN111822050AHigh yieldAtom utilization is highOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCupric bromide

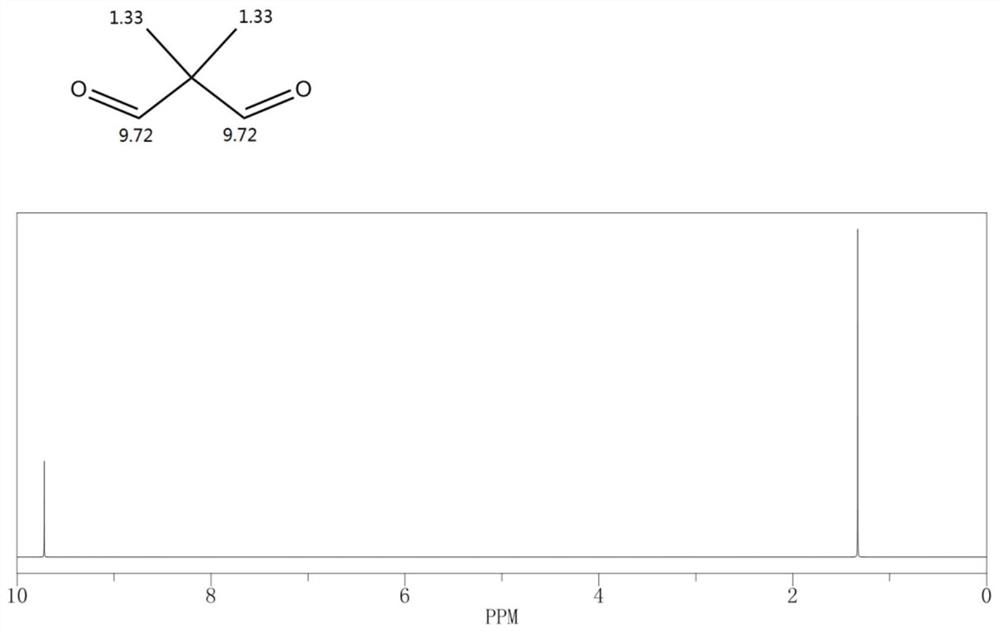

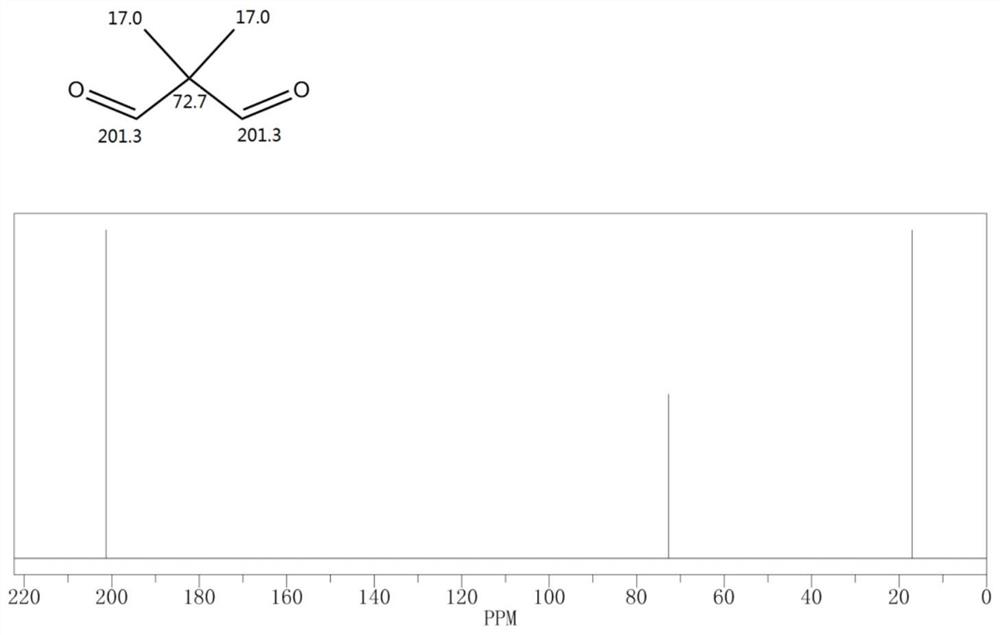

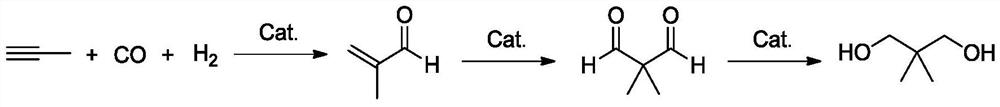

The invention provides a carbonylation reaction catalyst composition and a method for preparing neopentyl glycol. The catalyst composition comprises one or more of a palladium or rhodium-containing compound, diphenylphosphine pyrrole, triphenylphosphine pyrrole, diphenylphosphine-naphthalene sulfonic acid and triphenylphosphine-naphthalene sulfonic acid, and one or more of copper bromide, p-toluenesulfonic acid, boron trifluoride and lanthanum trifluoromethanesulfonate. The method for preparing neopentyl glycol comprises the following steps: (1) carrying out carbonylation on propyne to preparemethylacrolein; (2) under the action of a catalyst composition, methylacrolein is subjected to carbonylation to prepare dimethyl malonaldehyde; and (3) preparing neopentyl glycol by hydrogenation. The catalyst composition can be used for efficiently catalyzing the carbonylation reaction of the alpha, beta-unsaturated carbonyl compound. The method for preparing neopentyl glycol is good in atom economy, low in raw material cost, free of wastewater generation and relatively good in yield.

Owner:WANHUA CHEM GRP CO LTD

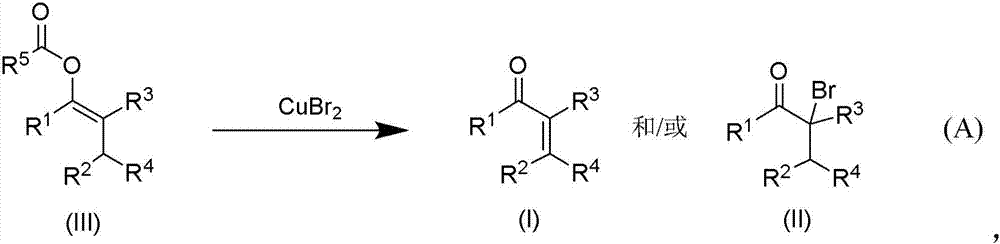

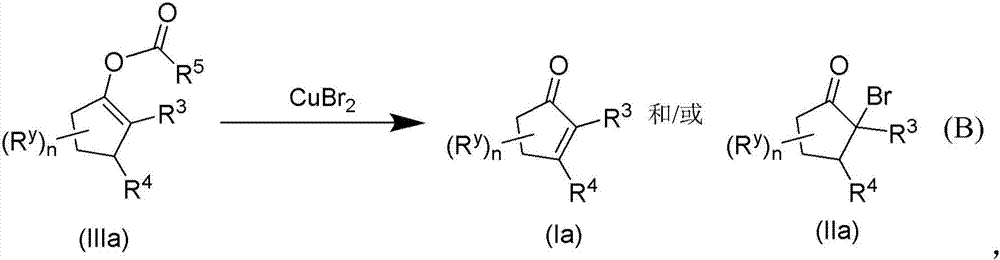

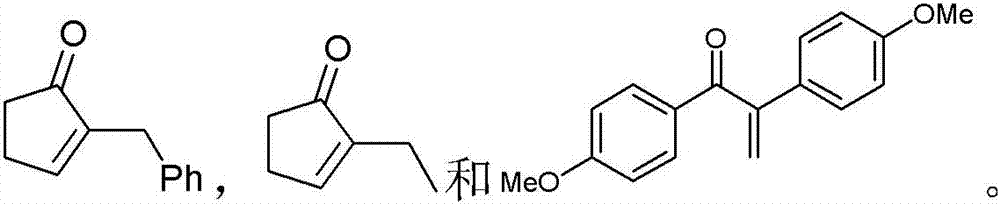

Methods of preparing alpha,beta-unsaturated or alpha-halo ketones and aldehydes

InactiveCN106986768AEasy to understandOrganic compound preparationPreparation by dehydrogenationCupric bromideCombinatorial chemistry

Copper (II) bromide mediated oxidation of acylated enol and use of the reaction in the synthesis of alpha,beta-unsaturated or alpha-bromo ketones or aldehydes are disclosed. A method provides an efficient and practical process for manufacturing dehydrohedione (DHH) and many other versatile alpha,beta-unsaturated or alpha-bromo ketones or aldehydes in large scales to avoid using precious metal compounds.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Modified carbon-based adsorbent as well as preparation method and application thereof

ActiveCN113713769AReduce usageLarge adsorption capacityGas treatmentOther chemical processesCupric bromideModified carbon

The invention discloses a modified carbon-based adsorbent as well as a preparation method and application thereof. According to the method, activated carbon is used as a carrier, cuprous chloride, copper chloride, ferric chloride, calcium chloride, copper bromide, ferrous bromide, calcium bromide, cuprous iodide, ferrous iodide, calcium iodide and the like are loaded as activators, and a modified carbon-based material is successfully prepared through normal-temperature mechanical ball milling activation and used as an adsorbent for fixed removal of mercury in flue gas. The method is simple in process, easy to operate and short in consumed time; operation can be carried out at normal temperature without high-temperature roasting, and energy consumption is low; no wastewater or waste residue is generated in a modification process, the consumption of water and raw materials is small, and cost is remarkably reduced; and the modified carbon-based adsorbent is large in mercury adsorption capacity and high in adsorption rate, and a product obtained after mercury removal is environmentally friendly and free of secondary pollution.

Owner:CENT SOUTH UNIV

Preparation process of dasatinib

ActiveCN109678853ANot easy to saveAvoid synthetic volatileOrganic chemistryMethylanilinePropanoic acid

The invention relates to a preparation process of dasatinib. The method comprises the following steps: enabling 3-oxopropionic acid ethyl ester to react firstly with 2-chlo-6-methylaniline under an alkaline condition, then adding a solvent dissolved with cupric bromide, and reacting to obtain a compound 3; cyclizing the compound 3 and thiourea in solvent water to obtain 2-amino-N-(2-chlo-6-methylphenyl)thiazole-5-formamide; and then synthesizing dasatinib from 4,6-dichloro-2-methyl pyrimidine, N-ethoxyl piperazine, and 2-amino-N-(2-chlo-6-methyl phenyl)thiazole-5-formamide through a one-pot method under the actions of an alkali K3PO4 and a catalyst 1-butyl-3-methylimidazole glycinate. The conditions are mild, the steps are simple, and the preparation process is environmentally-friendly, high in yield and suitable for industrial production.

Owner:SHANDONG LUOXIN PHARMA GRP CO LTD +2

Preparation method of 5-bromo-2-chlorobenzoic acid

PendingCN111620778AHigh purityImprove responseOrganic compound preparationCatalystsBenzoic acidCupric bromide

The invention relates to a preparation method of 5-bromo-2-chlorobenzoic acid, which is characterized by comprising the following steps: reacting 2-chlorobenzotrichloride used as a raw material with abromination reagent under the catalytic action of a first catalyst to generate 2-chloro-5-bromobenzotrichloride, adding water and a hydrolysis catalyst into the 2-chloro-5-bromobenzotrichloride, andcarrying out after-treatment and purification to obtain 5-bromo-2-chlorobenzoic acid, wherein the first catalyst is prepared by compounding iron bromide, ferrous bromide, copper bromide, (ferrocene methyl) trimethyl ammonium bromide and brominated ferrocene. The invention further discloses the 5-bromine-2-chlorobenzoic acid prepared according to the preparation method of the 5-bromine-2-chlorobenzoic acid. According to the preparation method of 5-bromine-2-chlorobenzoic acid disclosed by the invention, the traditional preparation process conditions are optimized and innovated, so that the product purity, the reaction conversion rate and the production efficiency are effectively improved, the preparation cost is low, the environmental pressure is low, the synthesis route is short, the operation is simple and feasible, the emission of three wastes is reduced, and the reaction yield is high.

Owner:吴赣药业(苏州)有限公司

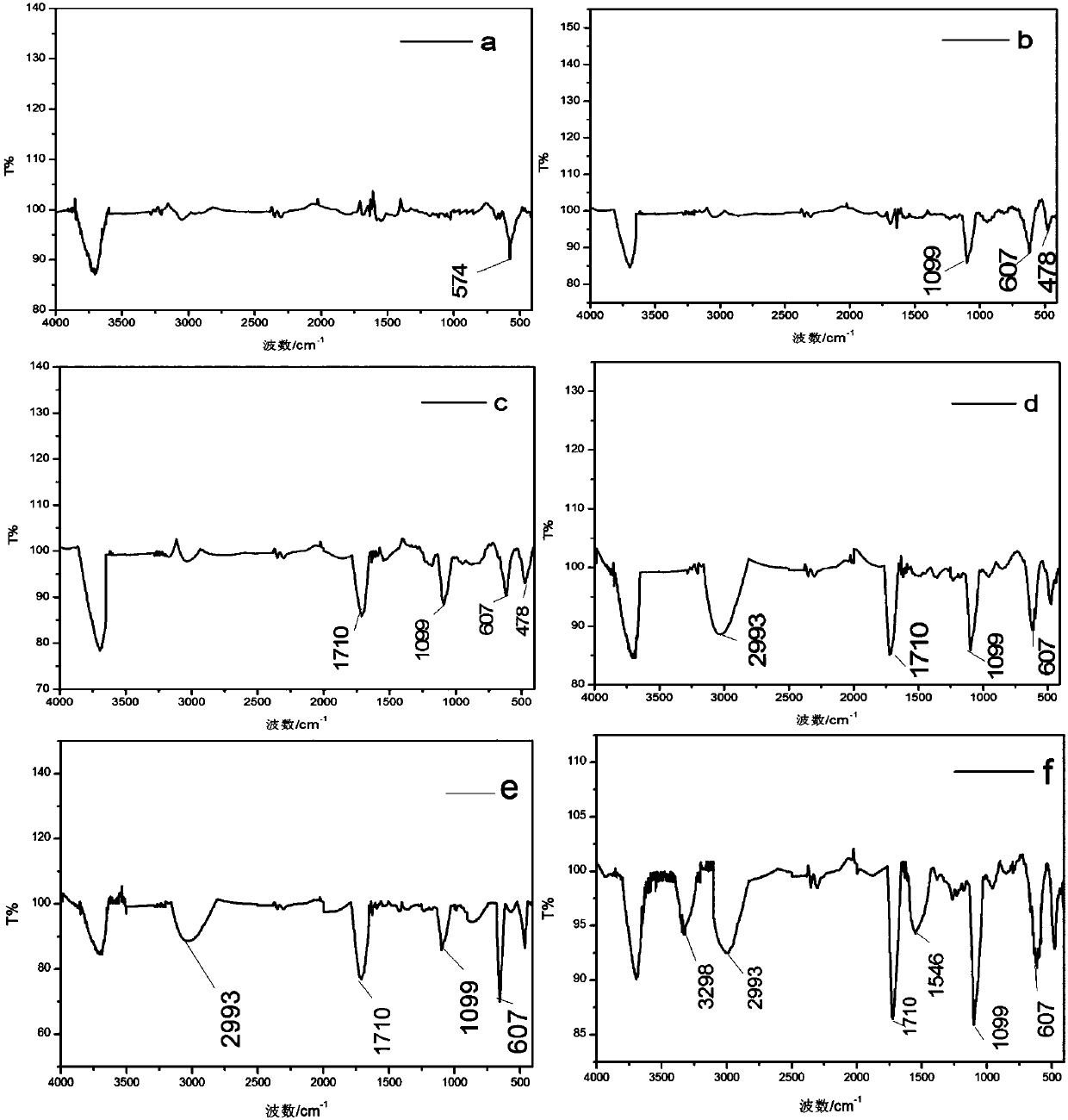

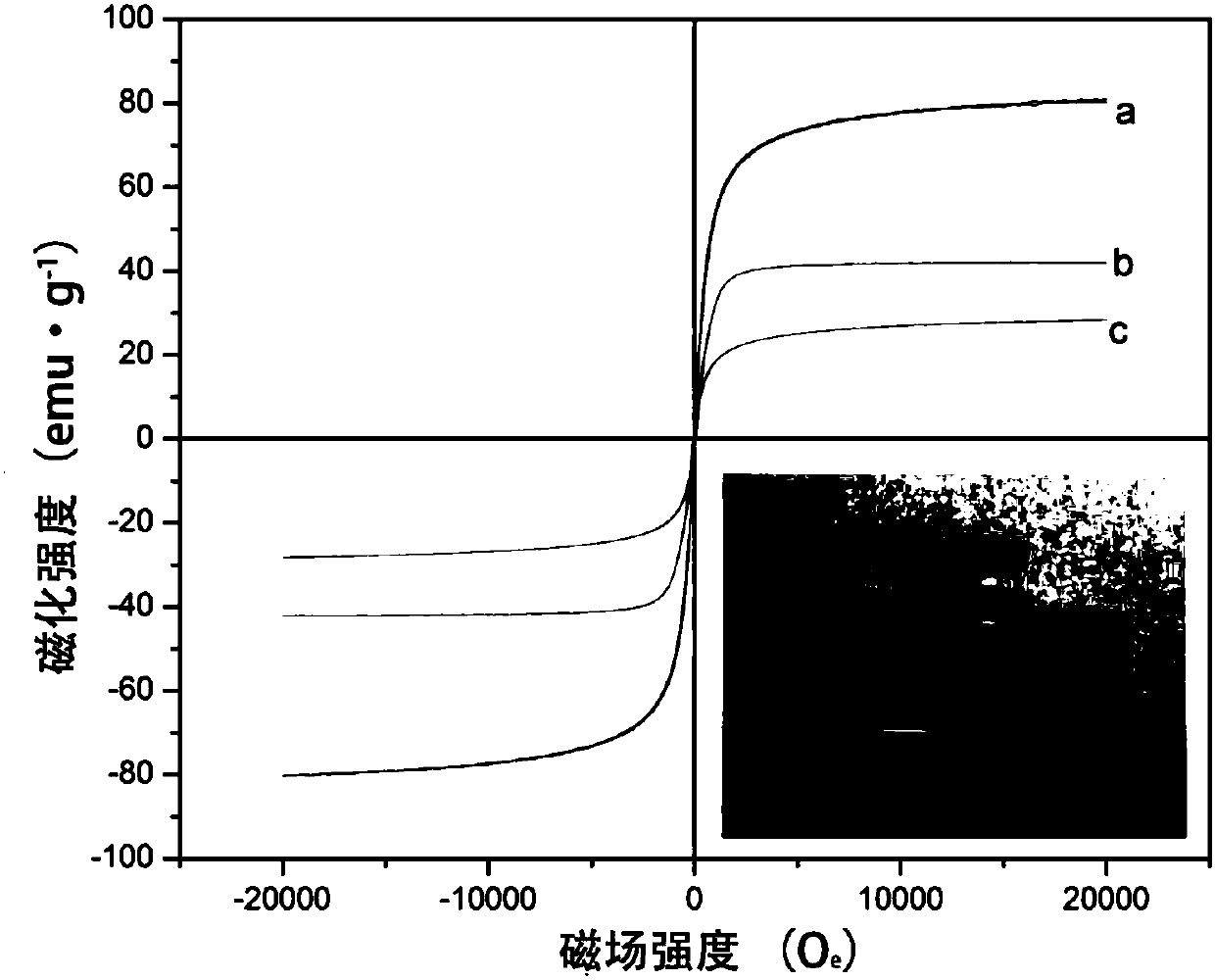

Silibinin magnetic core-shell type imprinting material and preparation method thereof

ActiveCN107840922AEnrich and develop extraction and separation methodsHigh affinityOther chemical processesAlkali metal oxides/hydroxidesDiethylenetriamineNitrogen gas

The invention relates to a silibinin magnetic core-shell type imprinting material and a preparation method thereof. The preparation method comprises the following steps: putting template molecules, namely silibinin, a monomer, namely, methacrylic acid and a pore forming agent, namely acetonitrile, into a reaction container, implementing a reaction, after a pre-reaction, respectively putting a cross-linking agent, namely ethylene glycol dimethacrylate, an initiator, namely azodiisobutyronitrile, a magnetic core, namely Fe3O4&SiO2-<MPS, catalysts, namely pentamethyl diethylenetriamine and cupricbromide, introducing nitrogen, performing reactions in the presence of nitrogen, thoroughly drying an obtained surface imprinting polymer in a drying oven of 60 DEG C, repeatedly eluting, removing residual acetic acid in the material with ethanol, performing vacuum drying on the eluted imprinting material, and performing material discharge. By adopting the method, multiple defects that a conventional extraction separation technique is low in efficiency, serious in material waste, long in time, poor in specificity and the like in the field of natural products, are overcome, and in addition, the target imprinting material is good in selective adsorption upon silibinin, convenient to separate, simple and easy to clean and high in recycling rate.

Owner:NANHUA UNIV

Preparation of tetrabromobisphenol A bis(2,3-dibromopropyl)ether

The invention provides a preparing method of tetrabromobisphemol A bi(2, 3-dibromopropyl)ether. In a chloroform solvent, the bromine adding reaction of tetrabromobisphemol A diene propyl ether and bromine is carried out under the catalyzing influence of calcium bromide, zinc bromide, aluminium bromide, nickelous bromide, iron bromide, ammonium bromide, cupric bromide, tetrabutyl ammonium bromide,tetraethyl ammonium bromide or triethyl benzyl ammonium bromide and the like. The chloroform solvent in the obtained tetrabromobisphemol A bi(2, 3-dibromopropyl)ether chloroform saturated solution can be eliminated after being directly heated by pulverized vapor, and granulation or milling processes can be finished simultaneously. After the processes of centrifuge dripping, drying and the like, the powder or graininess tetrabromobisphemol A bi(2,3-dibromopropyl)ether with limited particle size distribution can be obtained. The recovery rate of the chloroform solvent is more than 97 percent.

Owner:HUAIHAI INST OF TECH

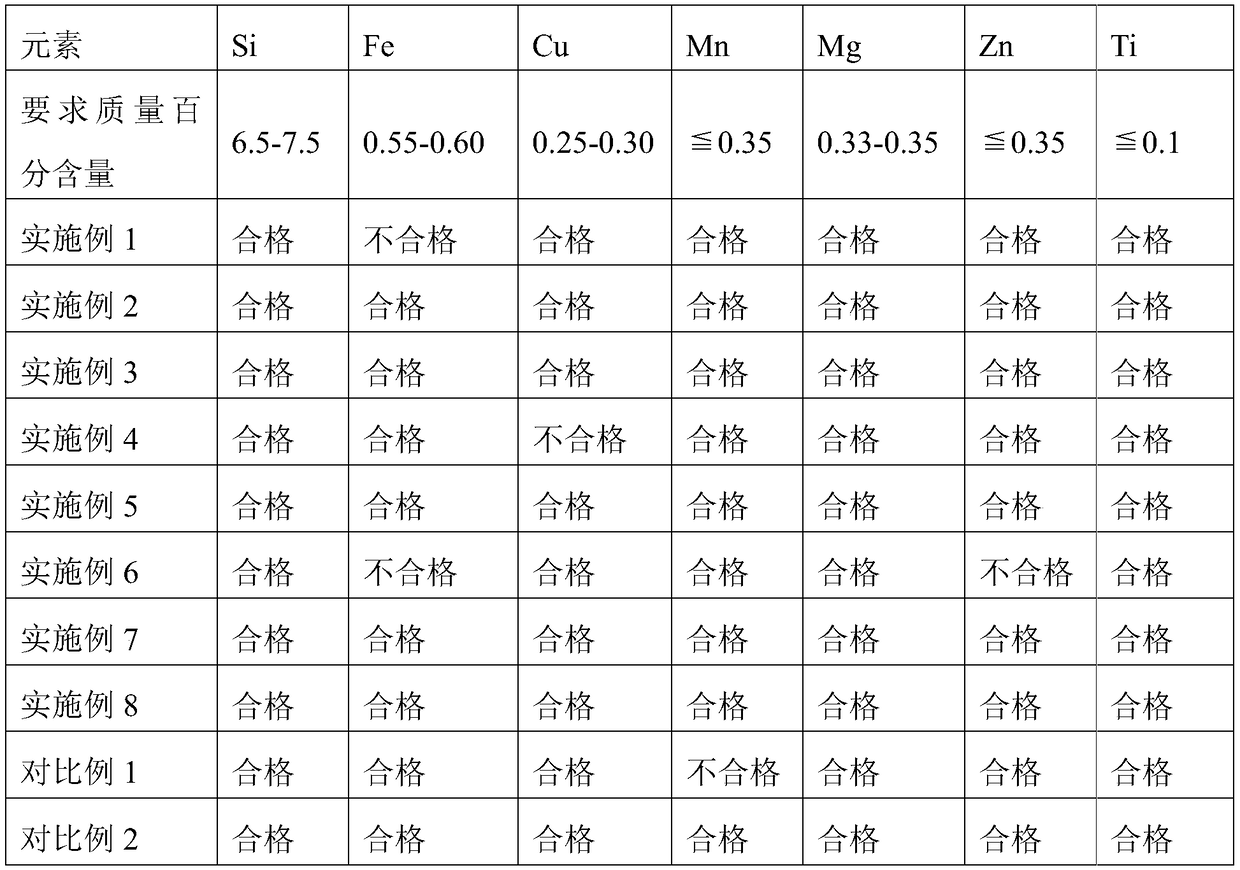

Low-slag-rate metal smelting technology

The invention relates to the technical field of aluminum alloy material preparation, in particular to a low-slag-rate metal smelting technology. The slag rate generated when an alloy material is supplemented in the alloy smelting process can be effectively decreased, and the workload and the working difficulty in the smelting process can be reduced. The low-slag-rate metal smelting technology is characterized by comprising the steps that 1, aluminum ingots and silicon materials are added into a smelting furnace, and igniting is conducted for temperature rising and smelting; 2, copper wires areadded into the smelting furnace, and temperature rising and smelting continue being conducted; 3, after all the aluminum ingots are smelted, the silicon materials and an aluminum-strontium alloy areadded; 4, after all the materials are smelted, first-time slagging-off operation is conducted; 5, after first-time slagging-off operation is completed, molten aluminum is taken for component detection, and the alloy material containing corresponding elements and cupric bromide are supplemented according to a detection result; 6, when the molten aluminum components meet the requirements, a refiningagent is added for refining; 7, second-time slagging-off operation is conducted on the refined molten aluminum; and 8, after second-time slagging-off operation is completed, the molten aluminum is mixed and stirred to be uniform, and a sample can be cast.

Owner:湖北新金洋资源股份公司

Phenylethanolamine-based beta receptor agonist synthesis method

ActiveCN109912434AThe synthesis method is simpleRaw materials are cheap and easy to getCarboxylic acid nitrile preparationOrganic compound preparationM-aminoacetophenoneCupric bromide

The invention discloses a phenylethanolamine-based beta receptor agonist synthesis method, which comprises: S1: dissolving 4-aminoacetophenone in an organic solvent, carrying out a halogenation reaction with an electrophilic substitution reagent at a benzene ring to generate a halobenzene intermediate, and carrying out a nucleophilic substitution reaction on the halobenzene intermediate and a cyaniding agent in an organic solvent or water under the catalysis of a metal catalyst to generate an acetophenone intermediate; S2, carrying out a carbonyl alpha bromination reaction on the acetophenoneintermediate and cupric bromide in an organic solvent to generate an alpha-bromoacetophenone intermediate; S3, carrying out a reaction on the alpha-bromoacetophenone intermediate and tert-butylamine or isopropylamine in an organic solvent to generate an acetophenone amine intermediate; and S4, carrying out a reaction on the acetophenone amine intermediate and a reducing hydrogenation reagent in anorganic solvent to generate a phenylethanolamine-based beta receptor agonist. According to the present invention, the synthesis method has characteristics of simpleness, high efficiency, inexpensiveand easily-available raw materials and high atom utilization rate, the chemical purity of the synthesized product is more than 99%, and the food safety testing requirements are met.

Owner:上海安谱璀世标准技术服务有限公司

Method for preparing 2 beta-methyl penicillanate benzhydryl dioxide

The invention provides a method for preparing a 2 beta-methyl penicillanate benzhydryl dioxide, which is to prepare the 2 beta-methyl penicillanate benzhydryl dioxide by four-step reactions. In the method, hydrobromic acid and sodium nitrite or cupric bromide serving as a brominating agent and other methods are adopted, especially bromide is generated by using adsorption of anionic resin, and water is a side product, so that the method is safe and environmentally friendly; the resin can be used repeatedly; the reaction molar yield can be remarkably improved, reaching over 75 percent; and dichloromethane, water, little glacial acetic acid, particularly as well as a catalytic amount of concentrated sulfuric acid are used to replace massive glacial acetic acid serving as a solvent, so that massive glacial acetic acid is removed. The method has unique process, stable product quality, mild process condition and easy control, the traditional azidation reaction and ethynylation reaction are eliminated, the production cost is reduced, the environmental pollution is greatly reduced, and no special equipment is required. The method is suitable for industrial generation in scale.

Owner:JIANGXI FUSHINE PHARMA CO LTD

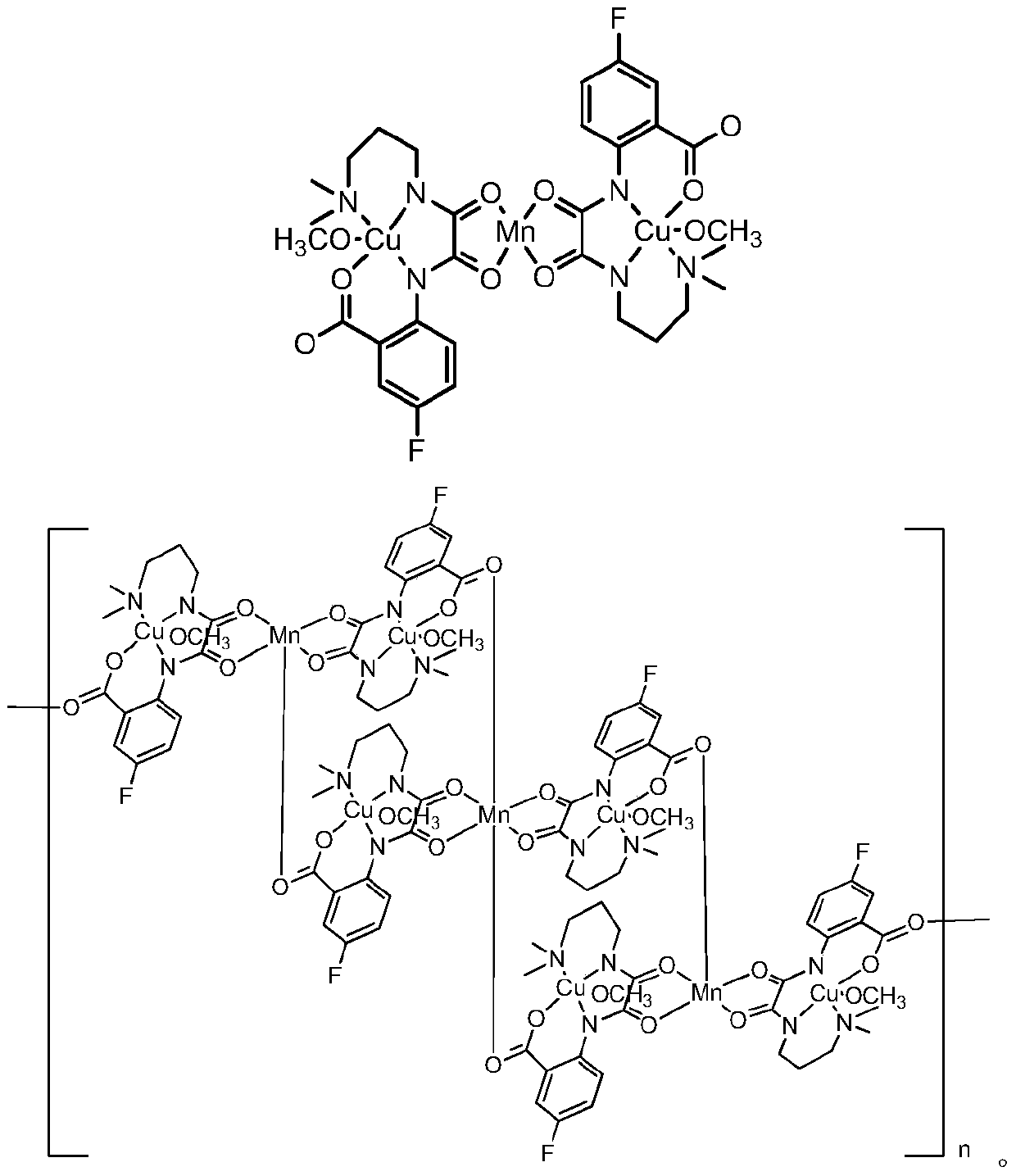

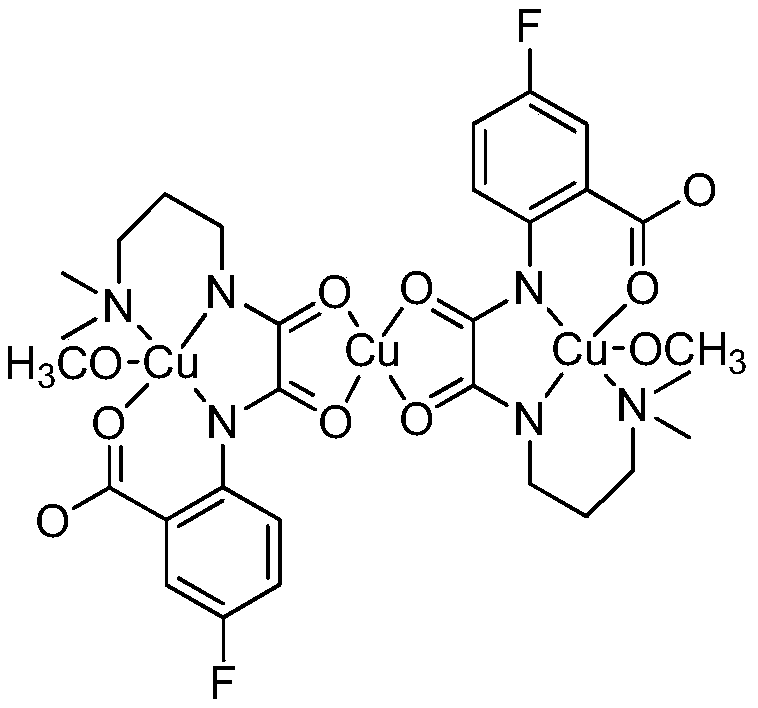

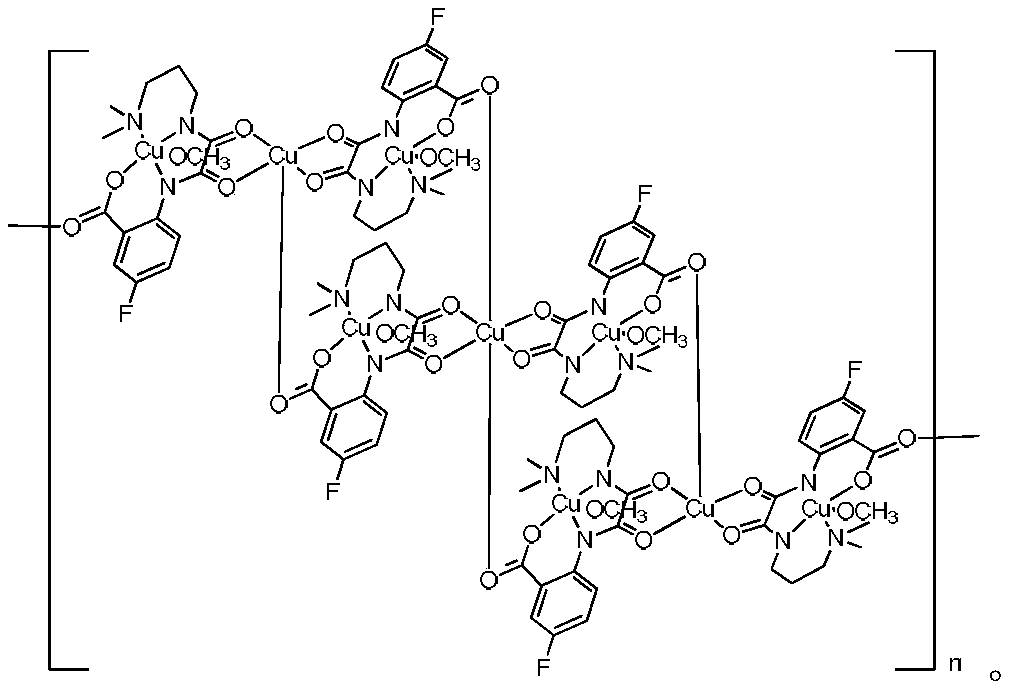

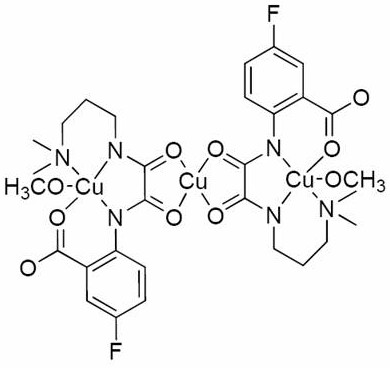

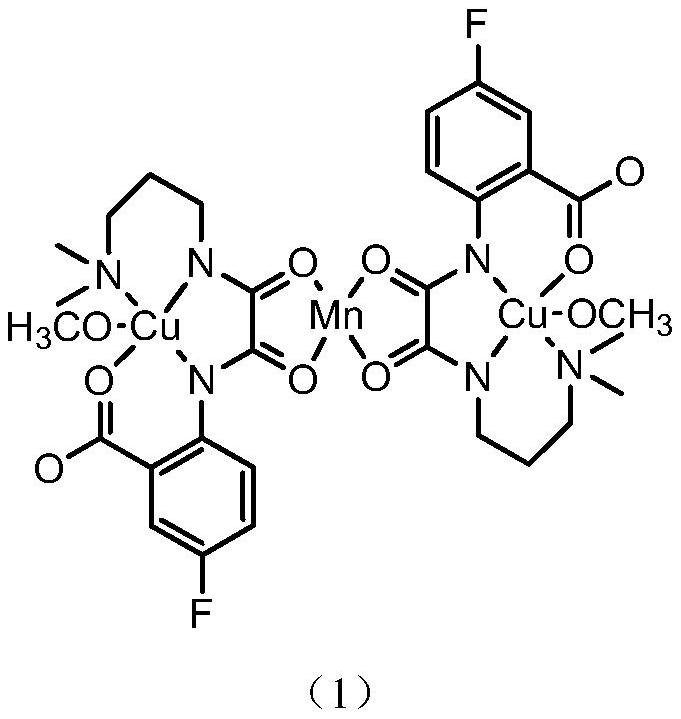

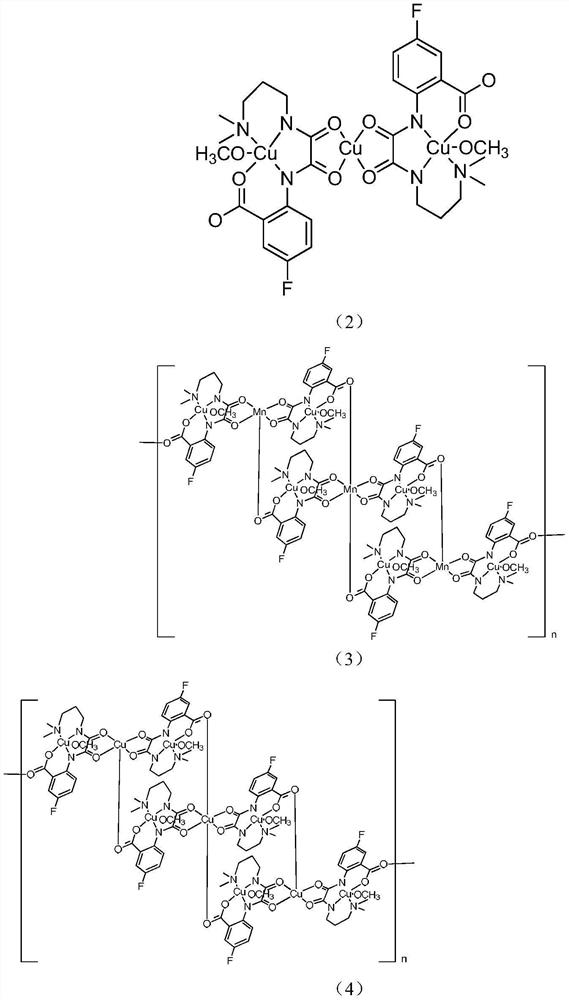

Preparation method and application of oxamide homonuclear/heteronuclear compound containing fluorine

ActiveCN109776623AHigh anticancer activityHigh activityBiocideOrganic chemistryCupric bromideManganese

Owner:WEIFANG UNIV OF SCI & TECH +1

Preparation method and application of a kind of fluorine-containing oxamide homo/heteronuclear compound

ActiveCN109776623BHigh anticancer activityHigh activityBiocideOrganic chemistryBulk crystalCupric bromide

The invention discloses a fluorine-containing oxamide homo / heteronuclear compound and its preparation method and application. The structural formula of the monomer and coordination polymer is as follows. The preparation method is as follows: dissolving 2 mmol of the oxamide mononuclear copper ligand in 10-20 ml In methanol, dissolve 1 mmol of the metal salt in 5-10 ml of methanol, add it to the solution of the above-mentioned mononuclear copper ligand, reflux at 60°C for 5 hours, filter, and slowly volatilize the filtrate for 1 week to obtain blue blocky crystals. It is the heteronuclear compound of fluorine-containing oxamide, the metal salts are manganese salts and copper salts, and the manganese salts are: manganese perchlorate, manganese nitrate, manganese bromide, manganese sulfate, manganese chloride, etc.; the copper The salts are: copper perchlorate, copper chloride, copper bromide, copper sulfate, etc. Compared with the platinum anti-cancer commonly used at present, the compound of the present invention has the characteristics of high anti-cancer activity, low cost, simple preparation method and the like. At the same time, it is the first time that the synthesized compound has been found to be toxic and active against Aedes albopictus, which provides a new way for the development of insecticides for related purposes.

Owner:WEIFANG UNIV OF SCI & TECH +1

A kind of carbonylation reaction catalyst composition and method for preparing neopentyl glycol

ActiveCN111822050BHigh yieldAtom utilization is highOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCupric bromidePtru catalyst

Owner:WANHUA CHEM GRP CO LTD

A kind of preparation technology of dasatinib

ActiveCN109369638BNot easy to saveAvoid synthetic volatileOrganic chemistryMethylanilineCupric bromide

The invention relates to a process for preparing dasatinib. The process includes steps of carrying out heating reflux on 3-oxo-propionic acid ethyl ester and 2-chlorine-6-methylaniline under alkalineconditions, adding cupric bromide, carrying out temperature-rise reflux, adding thiourea and a catalyst heteropoly acid salt, and carrying out room-temperature stirring reaction to obtain 2-amine-N-(2-chlorine-6-methyl phenyl)thiazole-5-formamide; carrying out 'one-pot reaction' on the 2-amine-N-(2-chlorine-6-methyl phenyl)thiazole-5-formamide, 4, 6-dichloro-2-methylpyrimidine and N-hydroxyethyl piperazine under the effects of catalysts to obtain the dasatinib. The process has the advantages of mild condition, simple step, environmental friendliness, high yield and applicability to industrialproduction.

Owner:SHANDONG LUOXIN PHARMA GRP CO LTD +2

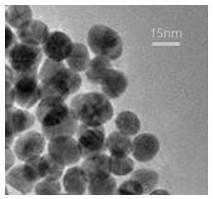

Nickel ion and solvent regulated interface rapid controllable preparation method of cuprous bromide nanocrystal material

InactiveCN110983426AFast preparationEasy to makePolycrystalline material growthFrom normal temperature solutionsCupric bromidePhysical chemistry

The invention provides a nickel ion and solvent regulated interface rapid controllable preparation method of a cuprous bromide nanocrystal material. According to the method, a volatile liquid is usedas a solvent of a copper bromide solution, nickel chloride is added into a copper bromide solution as a regulating agent, the surface of a copper foil is uniformly coated with the copper bromide solution, and a spontaneous reaction is performed to prepare the cuprous bromide crystal material. According to the invention, by adding nickel ions and adjusting the types of solvents, cuprous bromide crystals with amorphous, polyhedral, cake-shaped and sheet-shaped structures are directly prepared on a copper foil substrate, so that the cuprous bromide crystal material is rapidly prepared, the reaction time is greatly shortened, the reaction process is not limited in a solution any more, the field of cuprous bromide preparation methods is expanded, reaction additives are reduced, and the method has the characteristics of simple preparation, low cost and easiness in industrial batch production.

Owner:YANCHENG TEACHERS UNIV

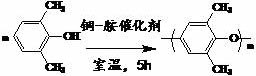

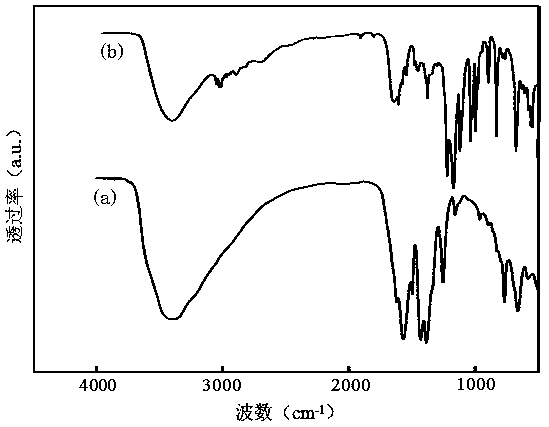

A kind of preparation method of polyphenylene ether

The invention provides an efficient, environment-friendly and low-cost preparation method for an engineering material, namely polyphenyl ether (PPO). According to the preparation method, cuprous bromide nanoparticles are prepared from copper bromide, organic amine and nano-scale cuprous bromide are taken as a copper amine catalyst, and tetrahydrofuran is taken as a solvent, so that high cost caused due to the use of oxygen or hydrogen peroxide is saved in a whole-process air introduction manner, the polymerization reaction of 2,6-dimethylaminophenol is realized, the yield is substantially increased, the environmental influence is minimized, and the production cost is greatly lowered.

Owner:HUAIHAI INST OF TECH

Method for fixing noble metal nano particles on single-crystal silicon surface polymer brush

InactiveCN102173865BHigh aggregation densityControl degree of aggregationCupric bromideCuprous chloride

The invention relates to a method for fixing noble metal nano particles on a single-crystal silicon surface polymer brush, which comprises the following steps: soaking a single-crystal silicon wafer in a hydrofluoric acid solution to obtain a silicon wafer A; dropwisely adding 4-vinylbenzyl chloride onto the surface, radiating, rinsing with acetone, drying, and adding into a monomer-containing solvent; adding copper bromide or copper chloride, cuprous bromide or cuprous chloride and ligand into the solvent to carry out surface-initiated atom transfer and free radical polymerization, thus obtaining a silicon wafer C; putting the silicon wafer C in a dichloromethane solution of trifluoroacetic acid, and stirring to obtain a carboxyl-containing polymer brush; and sufficiently soaking the polymer brush in a solution containing noble metal ions, then taking out, and finally reacting in a sodium borohydride solution, thus fixing the noble metal nano particles on the single-crystal silicon surface polymer brush. The invention achieves the following technical effects: the activity is controllable in the polymerization process, the graft polymerization density is high; the polymer chain isprevented from falling off the substrate; and the controllable fixation of the noble metal nano particles is effectively implemented.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

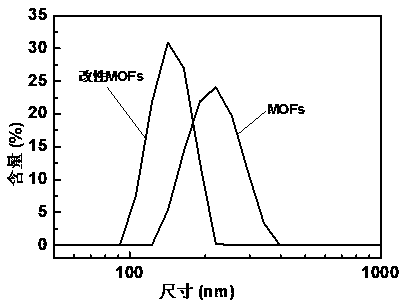

A kind of modification method of metal organic framework compound

The invention provides a method for modifying a metal-organic framework compound, belonging to the technical field of metal-organic frameworks. The invention is to solve the problem of limit of application fields of UiO-66 due to insolubilization of the UiO-66 in water. The method provided by the invention comprises the following steps: step 1, dispersing a metal-organic framework compound namelyUiO-66-NH2 in an organic solvent; step 2, adding an organic solvent solution of 2-bromoisobutyryl bromide and an organic solvent solution of triethylamine, and carrying out a reaction under heating under the protection of nitrogen; step 3, carrying out washing, then carrying out soaking with methanol, and carrying out cleaning, centrifugal separation and drying; step 4, dispersing an obtained material and sodium p-styrenesulfonate in water, adding a tris[2-(dimethylamino)ethyl]amine solution of copper bromide and a sodium ascorbate solution, carrying out a reaction, and carrying out centrifuging so as to obtain a clear liquid; and step 5, carrying out concentration, carrying out washing with methanol, repeatedly carrying out washing and concentration, and carrying out freeze-drying. The method provided by the invention increases the water solubility and surface charges of the UiO-66, and is applied to the fields of drug sustained release, pollutant adsorption, etc.

Owner:HARBIN INST OF TECH AT WEIHAI +1

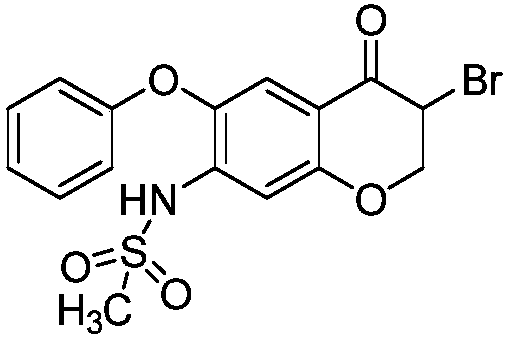

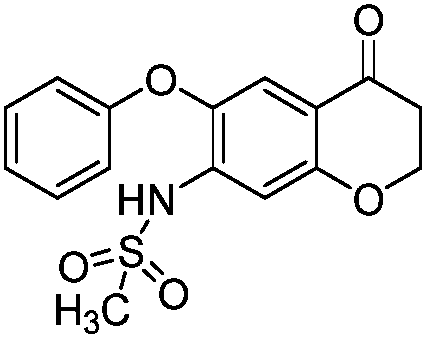

Method for preparing high-yield and high-purity Iguratimod intermediate

The invention discloses a method for preparing an Iguratimod intermediate, i.e., 3-bromo-7-methsulfonamido-6-phenoxy-4H-1-benzo-2,3-dihydropyran-4-one. The method comprises the following steps: (1) dissolving cupric bromide in ethyl acetate and C1-C4 lower alkanol, and carrying out stirring for at least 30 minutes; (2) adding a dichloromethane solution of 7-sulfonamido-6-phenoxy-4H-1-benzo-2,3-dihydropyran-4-one into the solution obtained in the step (1), heating the temperature of the mixture to 20 DEG C to 50 DEG C with stirring, and performing a reaction for 2 to 6 hours; (3) carrying out filtering, washing filter liquor with an aqueous solution of sodium thiosulfate, and concentrating an organic phase, so as to obtain a crude product of the intermediate; and (4) carrying out refining with dichloromethane and petroleum ether, thereby obtaining a refined intermediate. The method is convenient in operation, high in conversion ratio and high in product purity, and the purity can reach96% or more.

Owner:YANGTZE RIVER PHARM GRP CO LTD

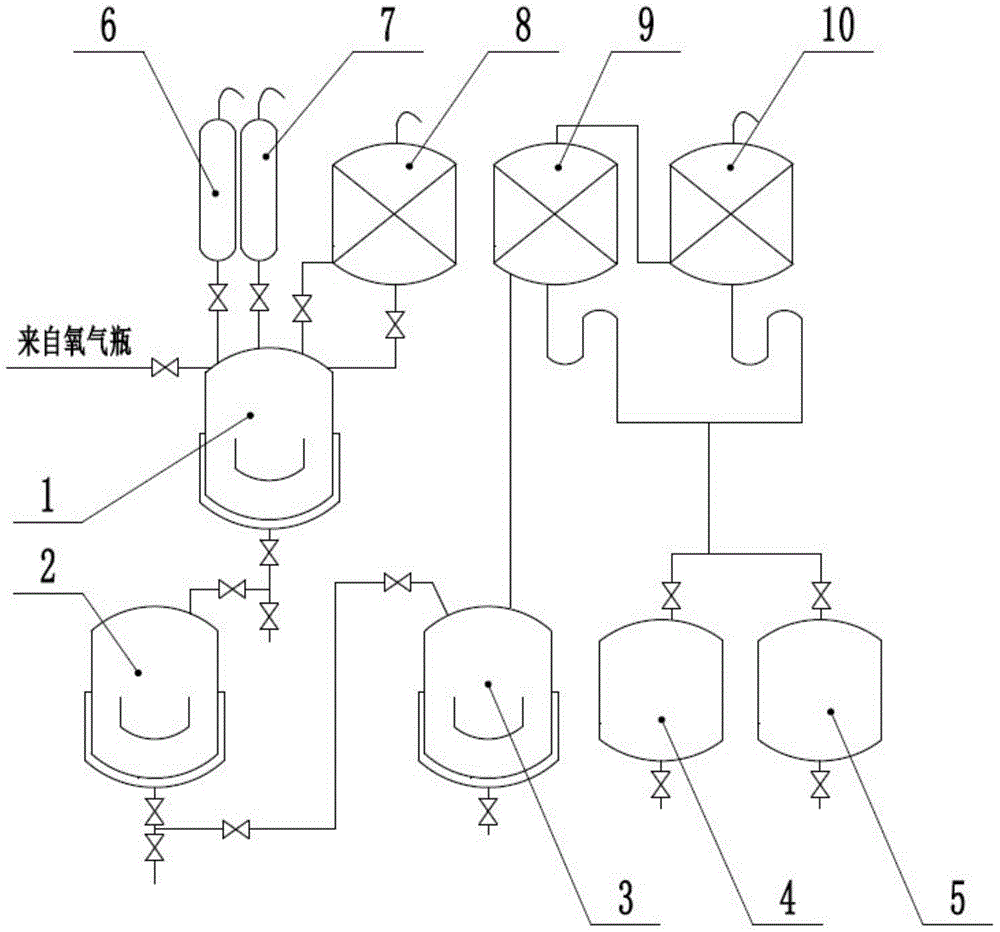

Air catalytic oxidation hydrogen bromide method for preparing 2,3,5-tribromo thiophene

The invention relates to an air catalytic oxidation hydrogen bromide method for preparing 2,3,5-tribromo thiophene. The air catalytic oxidation hydrogen bromide method is characterized by including the following specific steps: chloroform or petroleum ether, thiophene and cupric bromide or sodium nitride or iron bromide or cobalt bromide or ruthenium bromide are put into a reaction kettle (1) to be stirred, wherein the volume ratio of the chloroform or the petroleum ether to the thiophene is 2 to 1, and the cupric bromide or the sodium nitride or the iron bromide or the cobalt bromide or the ruthenium bromide comprises, by mass, 1% of thiophene; then bromine is dropwise added into the reaction kettle (1) through a first dropwise-adding tank (6) for reacting, and cooling is carried out; then an 0.05-mol / L-sodium-hydroxide ethanol solution with the volume a half of the volume of the bromine is dropwise added into the reaction kettle (1) through a second dropwise-adding tank (7); the reaction mixture is placed into a water washing kettle (2), water with the volume the same as the volume of the chloroform or the petroleum ether is added, sufficient stirring and standing are carried out, the mixture in the organic phase is charged into a distillation kettle (3) for atmospheric distillation, solvents and front cut fractions are recycled into a solvent recycling tank (4), then reduced pressure distillation is carried out, and 112-DEG C-116-DEG C / 15 mmHg cut fractions are collected into a product collecting tank (5) to obtain the colorless liquid 2,3,5-tribromo thiophene. The air catalytic oxidation hydrogen bromide method is low in production cost and small in environment pollution, and the bromine use rate is higher than 85%.

Owner:白银摩尔化工有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com