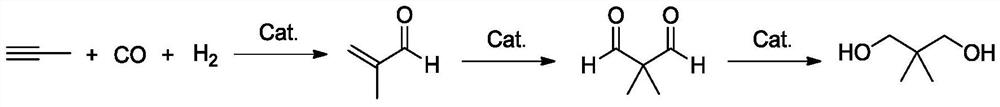

A kind of carbonylation reaction catalyst composition and method for preparing neopentyl glycol

A carbonylation reaction and neopentyl glycol technology, which is applied in the field of carbonylation reaction catalysts and the preparation of neopentyl glycol, can solve problems such as metal catalyst deactivation, and achieve the effect of increasing yield and improving atom utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

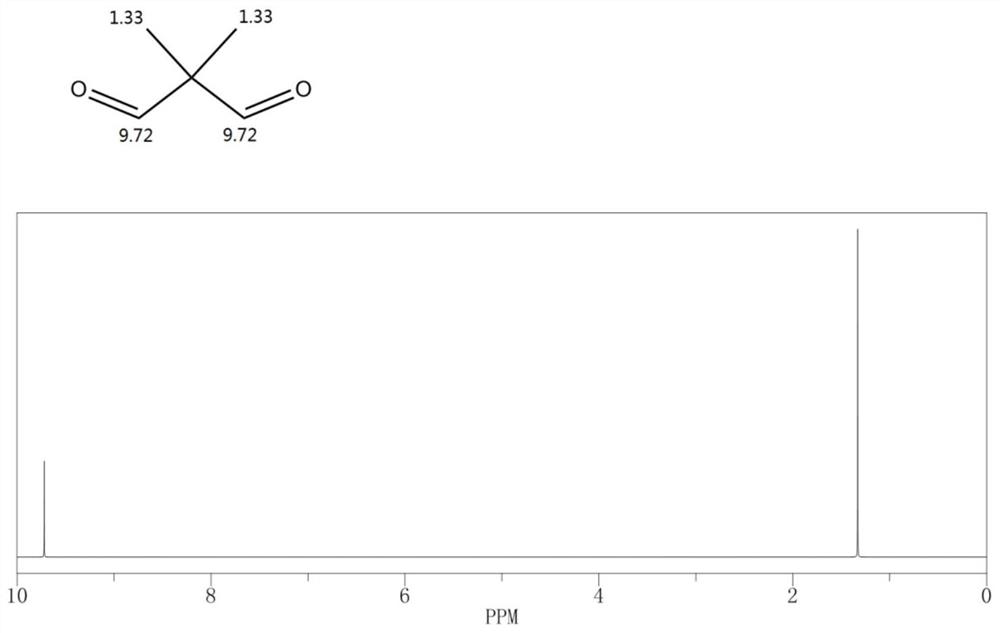

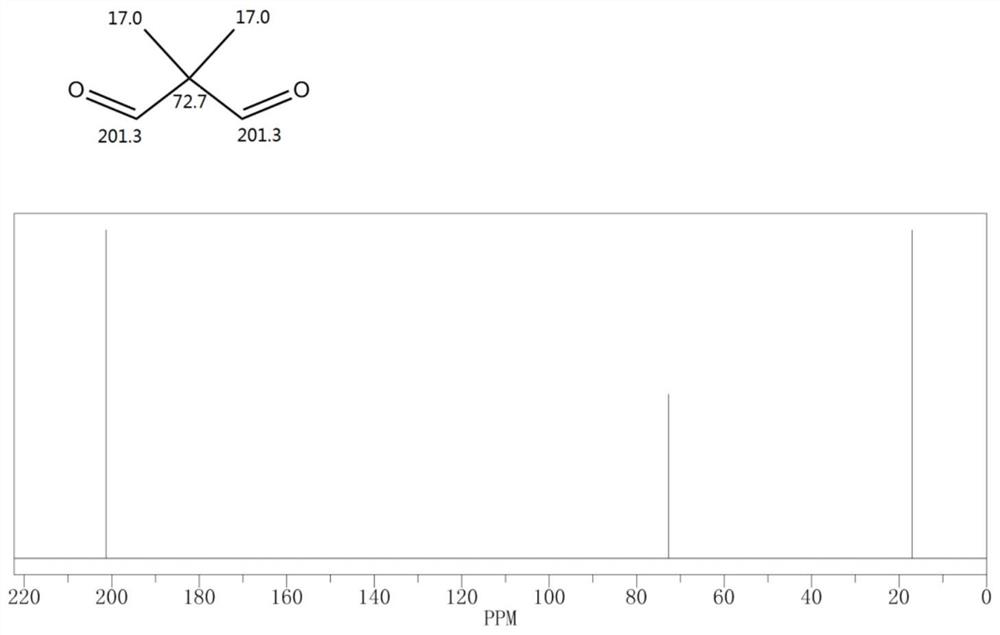

Image

Examples

Embodiment 1

[0055] Add 0.35g palladium acetate, 2.5g triphenylphosphine pyrrole, 1.0g lanthanum trifluoromethanesulfonate to the 1L high-pressure stirring kettle; after replacing the gas phase space of the reaction kettle with nitrogen, pressurize it with nitrogen to 2MPaG, then pass through the reaction kettle Add 350g of propyne liquid, mix evenly; after the mixed liquid in the reaction kettle is heated to 80 ℃, feed H 2 : The synthesis gas with a CO mol ratio of 1:1 reaches a pressure of 5 MPaG, and the reaction is stirred. When the pressure in the reaction kettle drops, the synthesis gas is replenished to 5 MPaG, and the temperature and pressure in the reaction kettle are kept constant, and the reaction is completed for 3h to obtain reaction solution A; Gas chromatography analysis showed that the conversion of propyne was 99.2%, and the selectivity of methacrolein was 98.6%.

[0056] Continue to heat up the reaction solution A to 130°C, feed the synthesis gas to a pressure of 20 MPaG ...

Embodiment 2

[0059] 0.11g of carbonyl rhodium, 2.2g of diphenylphosphine-naphthalenesulfonic acid and 1.1g of boron trifluoride were added to the 1L high-pressure stirred kettle; Pour in 350g of propyne liquid and mix it evenly; after heating the mixed liquid in the reaction kettle to 100°C, pass in H 2 The synthesis gas with a CO molar ratio of 1:1 was 9MPaG to a pressure of 9MPaG, and the reaction was stirred. When the pressure in the reaction kettle dropped, the synthesis gas was replenished, and the temperature and pressure in the reaction kettle were kept constant, and the reaction solution A was obtained after 3.5h of reaction. Through gas chromatography analysis, the conversion rate of propyne was 99.5%; the selectivity of methacrolein was 98.3%.

[0060] Continue to heat up the reaction solution A to 120°C, feed the synthesis gas to a pressure of 16 MPaG, and start the reaction. When the pressure in the reaction kettle drops, replenish the synthesis gas, and react for 12 h to obtai...

Embodiment 3

[0063] Add 0.4 rhodium acetylacetonate, 1.85 g triphenylphosphine-naphthalene sulfonic acid, 0.65 g copper bromide to the 1L high-pressure stirred kettle; after replacing the gas phase space of the reactor with nitrogen, pressurize it to 2MPaG with nitrogen, then pass through the reactor Add 350g of propyne liquid and mix evenly; after the mixed liquid in the reaction kettle is heated to 65°C, add H 2 The synthesis gas with a CO molar ratio of 1:1 reaches a pressure of 6 MPaG, and the reaction is stirred. When the pressure in the reaction kettle drops, the synthesis gas is replenished, and the temperature and pressure in the reaction kettle are kept constant, and the reaction solution A is obtained after the reaction is completed for 2 h. Through gas chromatography analysis, the conversion rate of propyne was 99.3%; the selectivity of methacrolein was 98.8%.

[0064] Continue to heat up the reaction solution A to 145°C, feed the synthesis gas to a pressure of 22 MPaG to start ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com