Method for synthesizing copper-based perovskite powder by low-temperature solvent method

A solvent method and perovskite technology, applied in chemical instruments and methods, copper compounds, inorganic chemistry, etc., can solve the problems of lack of powder synthesis process, etc., and achieve low cost of growth equipment, short manufacturing cycle, and few process steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]All inorganic copper-based perovskite powder Cs3Cu2I5Preparation method and steps

[0026]Step 1: Weigh 15.558g (ie 0.06mol) of cesium iodide (99.5%) and 7.618g (ie, 0.04mol) of copper iodide (98%), and put the two drugs into a 250ml beaker.

[0027]Step 2: First transfer 16ml of N,N-dimethylformamide to a 250ml beaker with a pipette, and then transfer 4ml of dimethylsulfoxide to a 250ml beaker (ie DMF:DMSO=4:1 ).

[0028]Step 3: Put the stirring rotor into the above-mentioned 250m beaker and seal it with a parafilm.

[0029]Step 4: Place the beaker on a magnetic stirrer and stir for 5 hours at a constant temperature at a temperature of 60 degrees Celsius and a rotation speed of 750 r / s to fully dissolve and react the medicine.

[0030]Step 5: Take a clean 100ml beaker and filter the precipitated powder in the solution with qualitative filter paper.

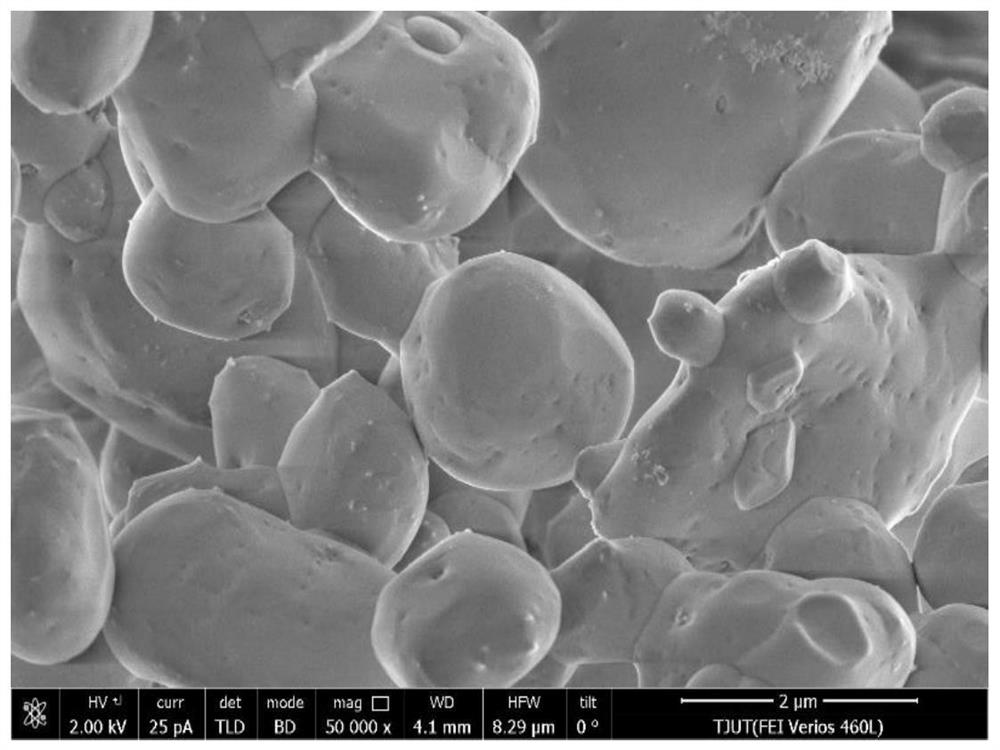

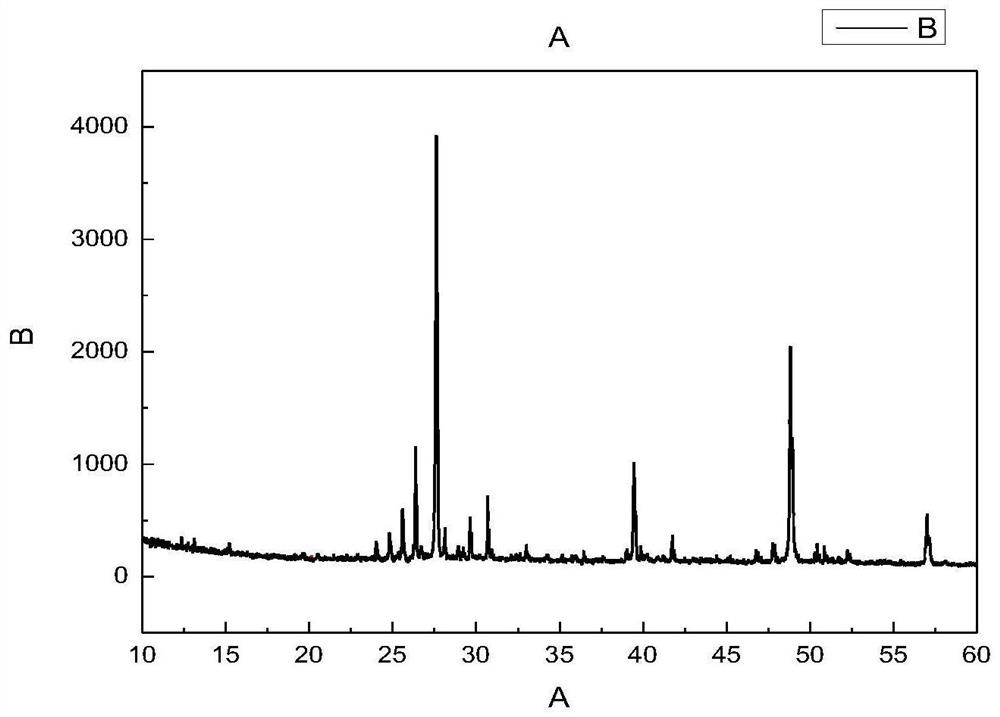

[0031]Step 6: Dry the filtered powder, grind it thoroughly with a grinder, take a small amount of powder for XRD detection, and store the remaini...

Embodiment 2

[0037] All inorganic copper-based perovskite powder Cs 3 Cu 2 Br 5 Preparation method and steps:

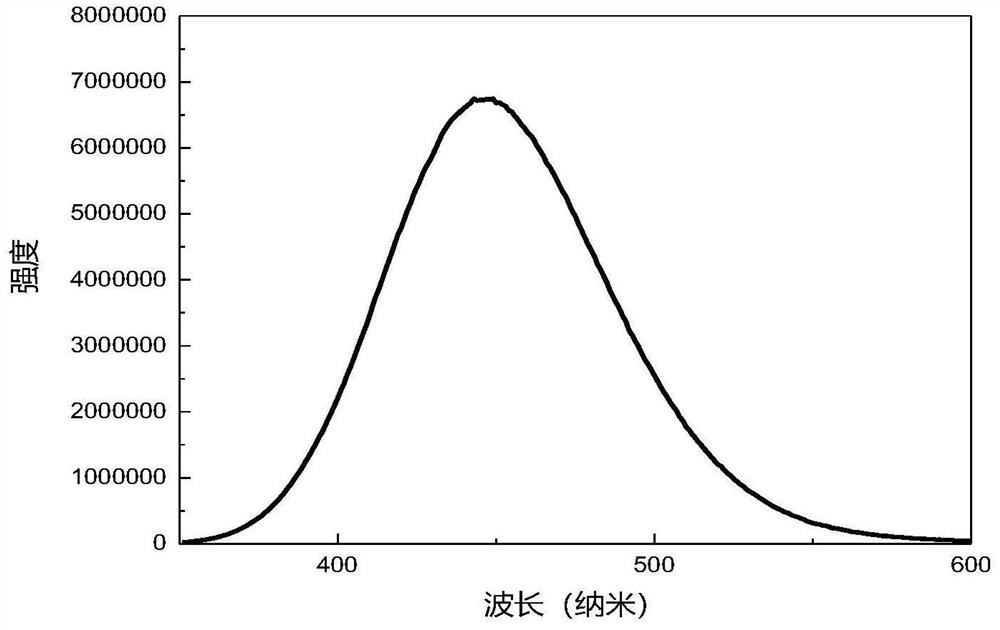

[0038] The other steps are the same as in Example 1, except that cesium iodide is replaced with cesium bromide; the solvents N,N-dimethylformamide and dimethylsulfoxide are replaced with separate N,N-dimethylformamide . The obtained product powder has good luminescence properties.

Embodiment 3

[0040] All inorganic copper-based perovskite powder Cs 3 Cu 2 Cl 5 Preparation methods and steps.

[0041] The other steps are the same as in Example 1, except that cesium iodide is replaced with cesium chloride; the solvents N,N-dimethylformamide and dimethyl sulfoxide are replaced with separate γ-butyrolactone. The resulting product has good light-emitting properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com