Low-slag-rate metal smelting technology

A metal smelting and slag technology, which is applied in the field of aluminum alloy material preparation, can solve the problems of increasing the difficulty and workload of smelting operations, high slag content, and incomplete melting of pure element materials, so as to avoid incomplete melting of feeding materials. Thoroughly, reduce the amount of slag, reduce the workload and the effect of work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

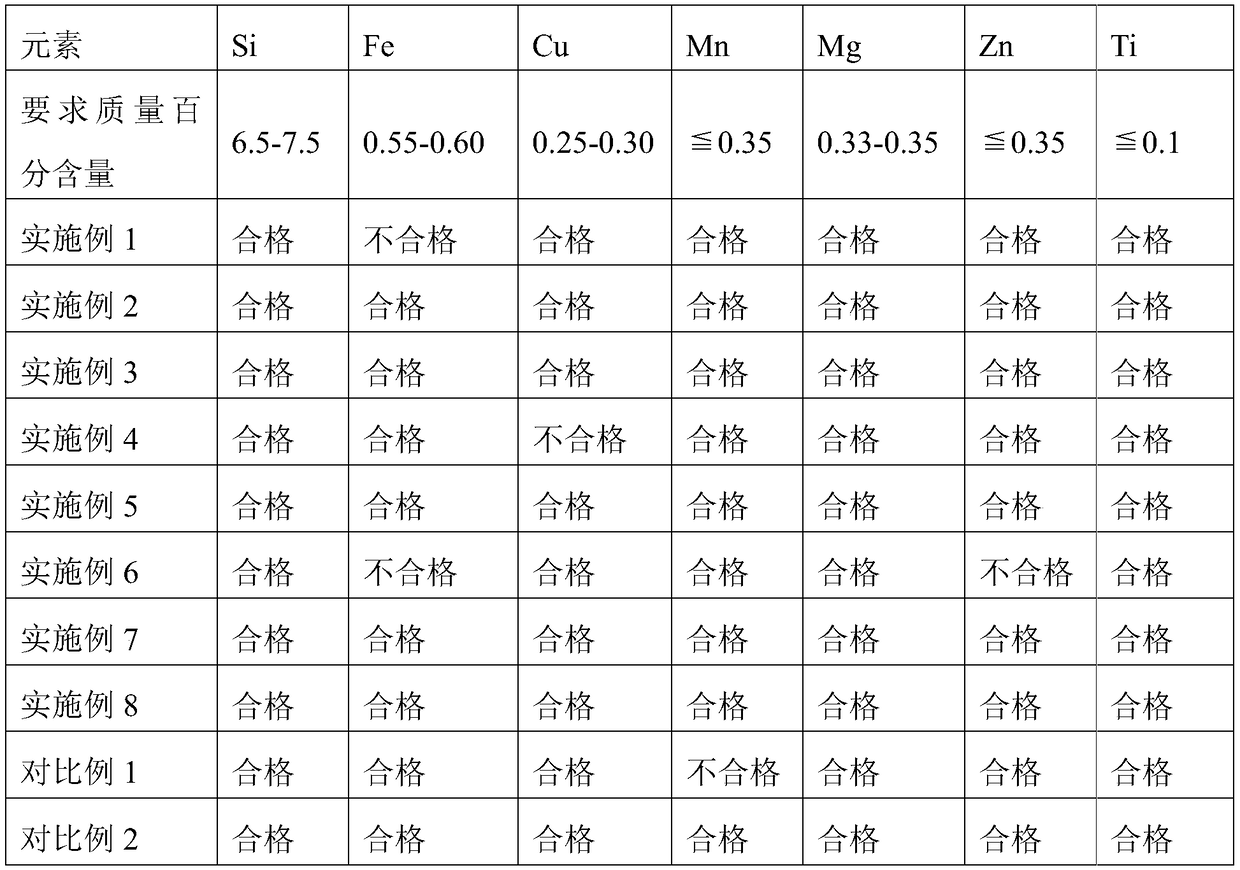

Examples

Embodiment 1

[0029] S1: Add 15000kg of A00 aluminum ingot and 530kg of 533 silicon material into the melting furnace, ignite and heat up to melt, and control the temperature in the melting furnace between 730-750°C. When feeding, small materials that are easy to oxidize, such as silicon and iron, are added to the bottom of the furnace, and large materials that are not easy to oxidize, such as aluminum ingots, are added to the upper part. When adding silicon material, place the feeding platform at the furnace mouth, pour metal silicon on the feeding platform, slowly push the silicon into the aluminum water with a rake, and stir fully so that the silicon is completely immersed in the aluminum water. Stir the liquid to confirm whether the metal silicon is completely melted.

[0030] S2: After part of the A00 aluminum ingot is melted, when the A00 aluminum ingot is not completely melted, add 340kg of copper wire into the melting furnace to immerse it in the aluminum liquid, continue to heat up...

Embodiment 2

[0038] S1: Add 14090kg of A00 aluminum ingot and 500kg of 533 silicon material into the melting furnace, ignite and heat up to melt, and control the temperature in the melting furnace between 730-750°C. When feeding, small materials that are easy to oxidize, such as silicon and iron, are added to the bottom of the furnace, and large materials that are not easy to oxidize, such as aluminum ingots, are added to the upper part. When adding silicon material, place the feeding platform at the furnace mouth, pour metal silicon on the feeding platform, slowly push the silicon into the aluminum water with a rake, and stir fully so that the silicon is completely immersed in the aluminum water. Stir the liquid to confirm whether the metal silicon is completely melted.

[0039] S2: After part of the A00 aluminum ingots are melted, when the A00 aluminum ingots are not completely melted, add 350kg of copper wire into the melting furnace to immerse it in the molten aluminum, continue to hea...

Embodiment 3

[0047]S1: Add 14900kg of A00 aluminum ingot and 530kg of 533 silicon material into the melting furnace, ignite and heat up to melt, and control the temperature in the melting furnace between 730-750°C. When feeding, small materials that are easy to oxidize, such as silicon and iron, are added to the bottom of the furnace, and large materials that are not easy to oxidize, such as aluminum ingots, are added to the upper part. When adding silicon material, place the feeding platform at the furnace mouth, pour metal silicon on the feeding platform, slowly push the silicon into the aluminum water with a rake, and stir fully so that the silicon is completely immersed in the aluminum water. Stir the liquid to confirm whether the metal silicon is completely melted.

[0048] S2: After part of the A00 aluminum ingot is melted, when the A00 aluminum ingot is not completely melted, add 340kg of copper wire into the melting furnace to immerse it in the aluminum liquid, continue to heat up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com