Preparation method of hydroxy methionine salt and compound

A technology of hydroxymethionine salt and complex, applied in the field of compound food or feed additive, can solve the problems of not conforming to the experimental facts, increased production cost, waste of raw materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: magnesium hydroxymethionine (Mg(C 5 h 9 o 3 S) 2 ) preparation

[0046] In an airtight, corrosion-resistant reaction vessel, add dehydrated alcohol (dehydrated alcohol: magnesium hydroxide=25, molar ratio), hydroxymethionine (MHA) and magnesium hydroxide (Mg(OH) in a molar ratio of 2:1 ) 2 ), 80 ° C stirring reaction 2.0h. The product was filtered by suction, washed with alcohol (the filtrate was recovered for use), and dried to obtain the product. Its chemical reaction equation is as follows:

[0047]

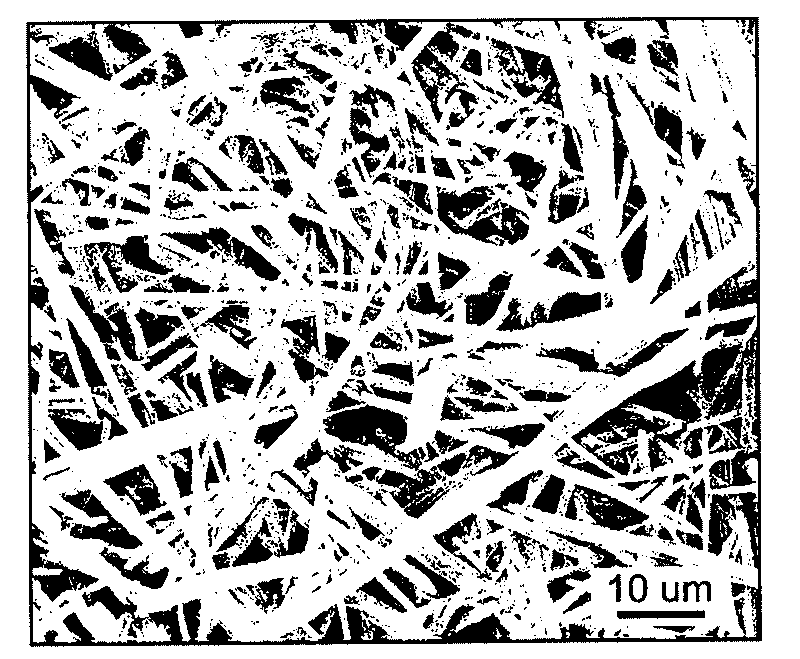

[0048] The analytical data of the prepared magnesium hydroxymethionine are shown in Table 1, and the product morphology is shown in Figure 1.

Embodiment 2

[0049] Embodiment 2: magnesium hydroxymethionine (Mg(C 5 h 9 o 3 S) 2 ) preparation

[0050] In sealable, corrosion-resistant reaction vessel, add the reclaimed ethanol (reclaimed ethanol: magnesium hydroxide=25, mol ratio) among the embodiment 1, the hydroxymethionine (MHA) of 2: 1 and magnesium hydroxide ( Mg(OH) 2 ), 80 ° C stirring reaction 2.0h. The product was filtered by suction, washed with alcohol (the filtrate was recovered for use), and dried to obtain the product.

[0051] The analytical data of the prepared magnesium hydroxymethionine are shown in Table 1, and the product morphology is shown in Figure 1.

[0052] The analytical data of the magnesium hydroxymethionine prepared by the present invention of table 1

[0053]

[0054] a. Measured according to the method described in the national standard GB / T 21034-2007, take the average value of three measurements of the sample; b. See attached drawing 1, the diameter of the submicron wire is 0.5-1.5um, and t...

Embodiment 3

[0055] Embodiment 3: Hydroxymethionine calcium (Ca(C 5 h 9 o 3 S) 2 ) preparation

[0056] In an airtight, corrosion-resistant reaction vessel, add dehydrated alcohol (dehydrated alcohol: calcium hydroxide=15, molar ratio), hydroxymethionine (MHA) and calcium hydroxide (Ca(OH) in a molar ratio of 2:1 ) 2 ), kept stirring at 85°C for 0.5h. The product was filtered by suction, washed with alcohol (the filtrate was recovered for use), and dried to obtain the product. Its chemical reaction equation is as follows:

[0057]

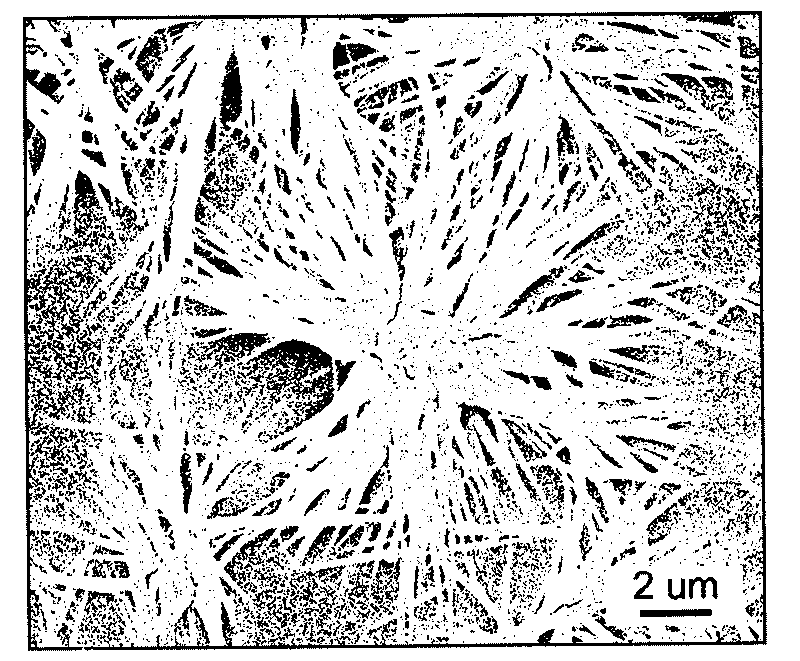

[0058] The analytical data of the prepared calcium hydroxymethionine are shown in Table 2, and the morphology of the product is shown in Figure 2.

[0059] The analytical data of the calcium hydroxymethionine prepared by the present invention of table 2

[0060]

[0061] a. Measured according to the method described in the national standard GB / T 21034-2007, the average value of the three measurements of the sample is taken; b. Referring to Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com