New-type super thermophilic esterase catalyzed prepn of poly-epsilon-caprolactone

A technology for catalytic preparation of caprolactone, which is applied in the field of synthetic polymers to achieve the effects of simple operation, easy recycling and reuse, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

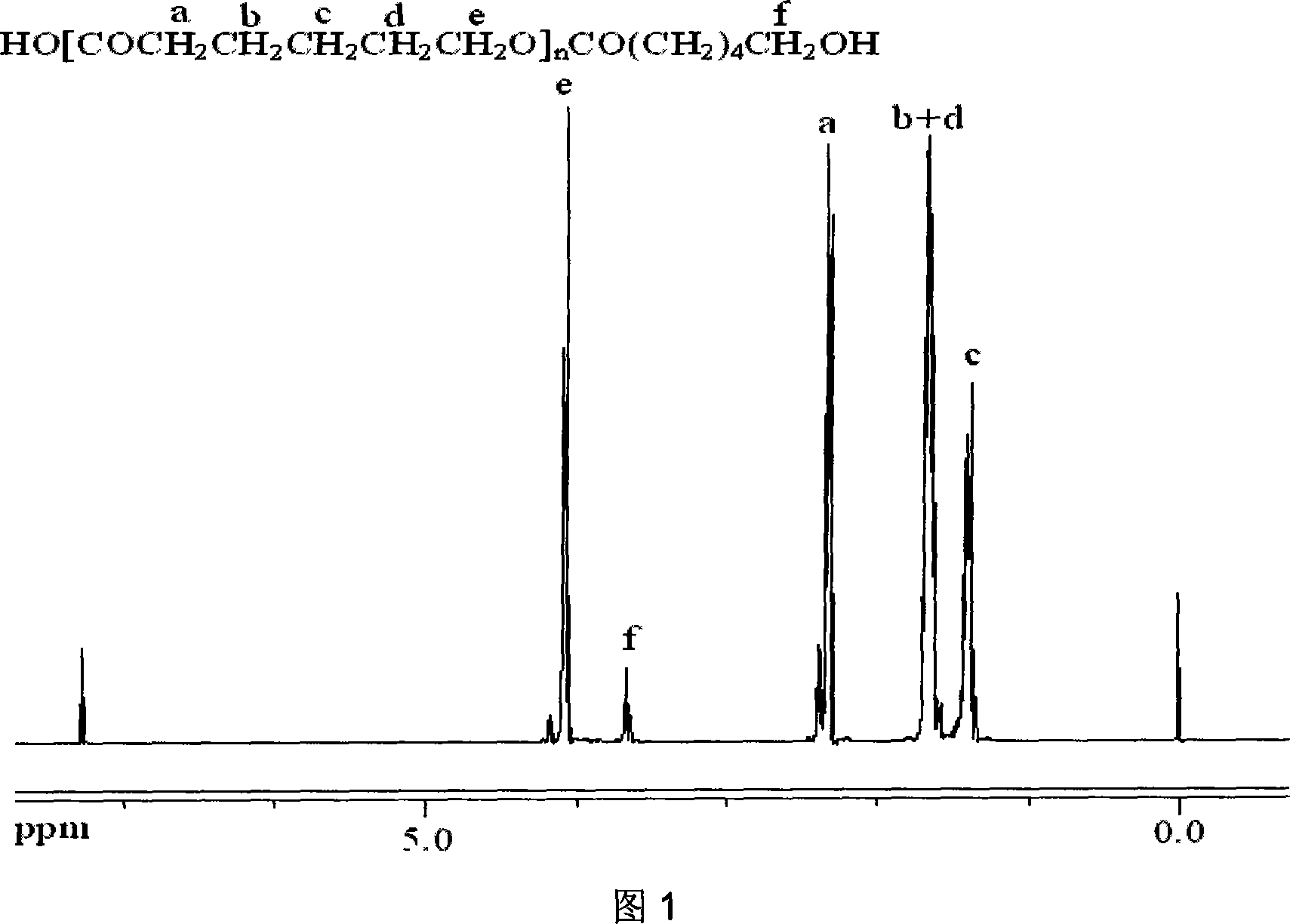

Image

Examples

Embodiment 1

[0021] Preparation of hyperthermophilic esterase preparation AFEST

[0022] The culture medium of hyperthermophilic esterase engineering bacteria is as follows: 1% yeast powder, 1.6% peptone, 0.5% sodium chloride, pH 7.0, sterilized at 115° C. for 20 minutes. The seed solution was enlarged step by step, the inoculum size was 1%, and the culture volume was 10 liters. Cultivate at 37°C until the growth turbidity of the culture is at OD 600 Reached 1.8. Then, IPTG was added for induction (final concentration: 1 mM), and culture was continued at 37° C. for 3 h. The fermentation broth was centrifuged at 5000r / min for 20min to collect the bacteria. The bacteria were repeatedly frozen and thawed twice at -20°C and room temperature, and 50 mmol / L phosphate buffer (pH 8.0) was added at a ratio of 1:6 (w / v), mixed evenly and ultrasonically disrupted for 20 min. The cell disruption solution was incubated at 80°C for 30 minutes to denature and precipitate E. coli miscellaneous proteins....

Embodiment 2

[0024] Mix 200 μL (215 mg) ε-caprolactone (purity ≥ 99%) with 600 μL toluene, add 20 mg of hyperthermophilic esterase AFEST as a catalyst, shake the reaction at 80 ° C for 72 hours, dissolve the product with 10 mL of dichloromethane, filter The enzyme was removed, and the monomer conversion rate of the filtrate was determined by gas chromatography (GC) to be 99.97%. The filtrate was concentrated in vacuo, ice-cold methanol was added to the residue to precipitate at minus 20°C, the precipitate was collected by centrifugation at 8000r / min for 15min, and dried under reduced pressure for 16h to obtain the polymer product. The product was determined by gel permeation chromatography (GPC), with a number average molecular weight of 1768 g / mol and a polydispersity of 1.21.

Embodiment 3

[0026] Mix 200 μL (215 mg) ε-caprolactone (purity ≥ 99%) with 600 μL cyclohexane, add 20 mg of hyperthermophilic esterase AFEST as a catalyst, shake the reaction at 80 ° C for 72 hours, and dissolve the product with 10 mL of dichloromethane , The enzyme was removed by filtration, and the monomer conversion rate of the filtrate was determined by gas chromatography (GC) to be 95.29%. The filtrate was concentrated in vacuo, ice-cold methanol was added to the residue to precipitate at minus 20°C, the precipitate was collected by centrifugation at 8000r / min for 15min, and the polymer product was obtained by drying under reduced pressure for 16h. The product was determined by gel permeation chromatography (GPC), with a number average molecular weight of 2238 g / mol and a polydispersity of 1.46.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com