Preparation method and application of plant polyphenol based rubber accelerator

A rubber accelerator and plant polyphenol technology, which is applied in the field of preparation of plant polyphenol-based rubber accelerators, can solve the problems of easy precipitation, single function, low molecular weight, etc., and achieve long scorch time, less reaction by-products, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

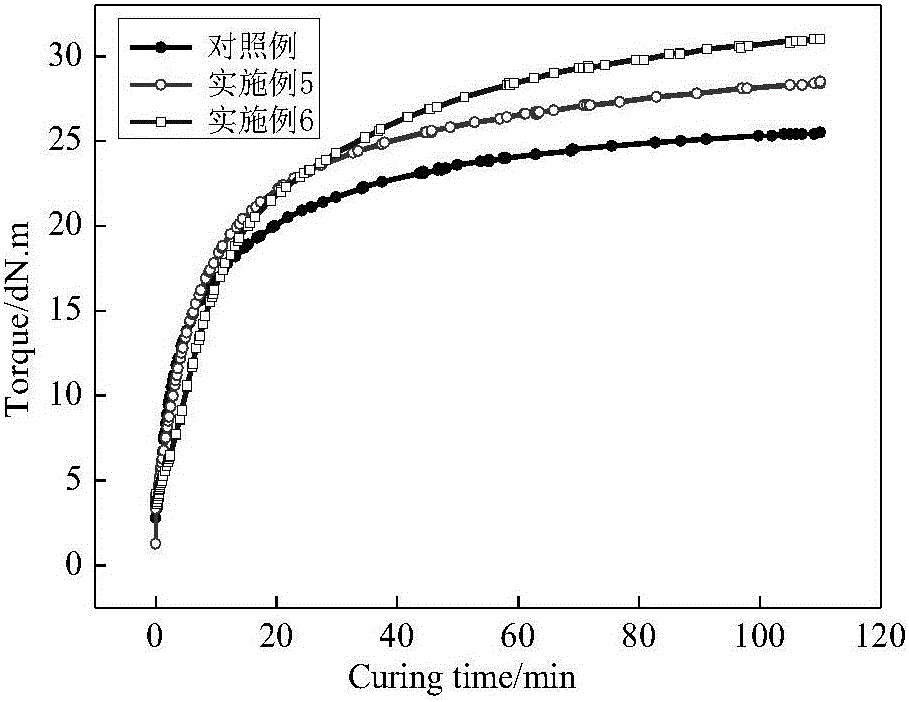

Examples

Embodiment 1

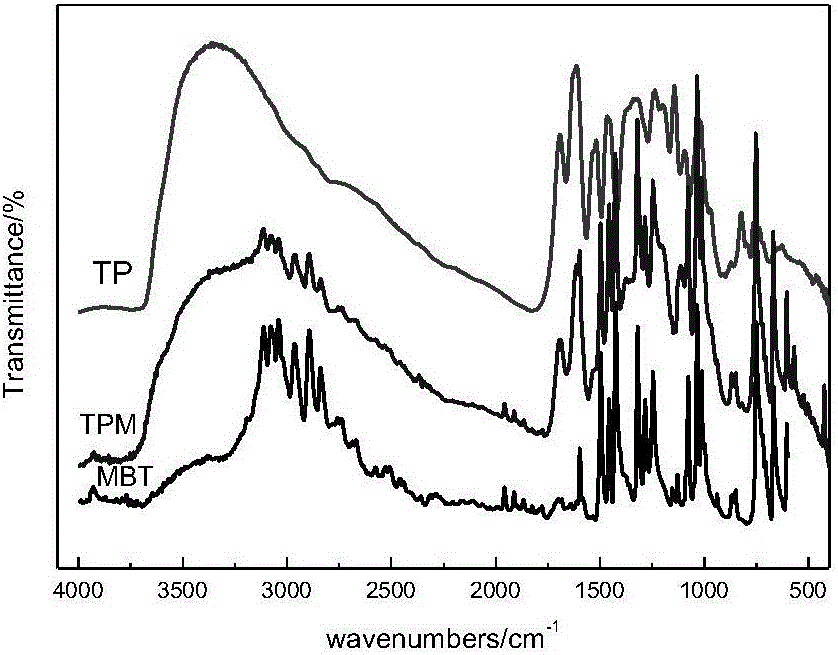

[0041] The preparation of embodiment 1 plant polyphenol-based rubber accelerator TPM

[0042]A preparation method of plant polyphenol-based rubber accelerator, specifically comprising the steps of:

[0043] (1) Weigh 10g of 2-mercaptobenzothiazole (MBT), dissolve in 50ml of formaldehyde in ethanol solution, and stir at room temperature for 10min;

[0044] (2) Adjust PH=3 with hydrochloric acid, reflux and stir in a water bath at 70°C for 6 hours;

[0045] (3) Add 10 g of plant polyphenols into 50 ml of absolute ethanol, adjust the pH to 3 with hydrochloric acid, and oscillate ultrasonically for 5 minutes;

[0046] (4) Add the plant polyphenol ethanol solution in step (3) to the solution prepared in step (2), and continue to react at 70°C for 9 hours;

[0047] (5) The reaction product was left at -10°C for 2 days at low temperature to precipitate unreacted MBT, and filtered;

[0048] (6) The filtrate was added to distilled water, and the plant polyphenol-based multifunctiona...

Embodiment 2

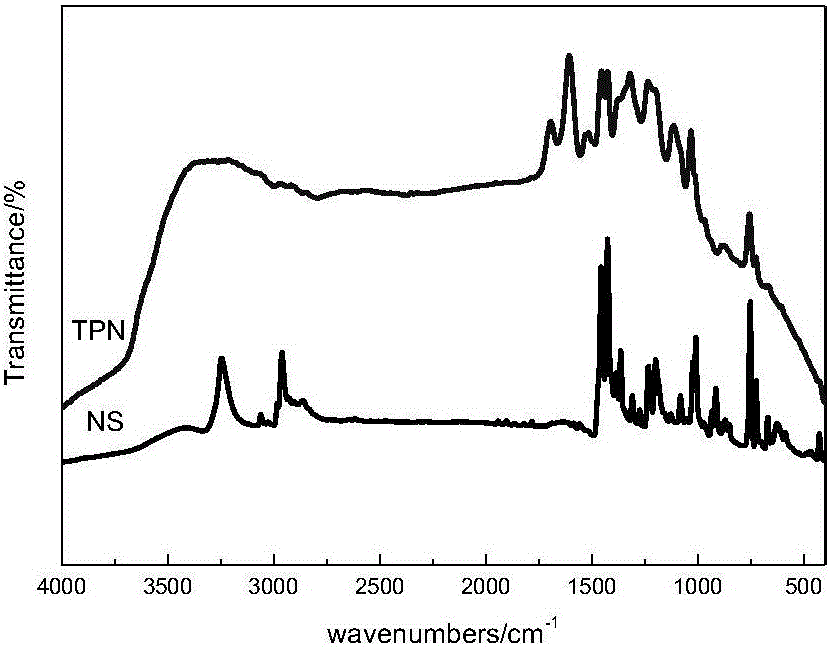

[0049] The preparation of embodiment 2 plant polyphenol-based rubber accelerator TPN

[0050] A preparation method of plant polyphenol-based rubber accelerator, specifically comprising the steps of:

[0051] (1) Weigh 10g of N-tert-butyl-2-benzothiazolesulfenamide (NS), dissolve in 100ml of formaldehyde in ethanol solution, and stir at room temperature for 10min;

[0052] (2) Adjust PH=4 with hydrochloric acid, reflux and stir in 80°C water bath for 3h;

[0053] (3) Add 10 g of plant polyphenols into 100 ml of absolute ethanol, adjust the pH to 4 with hydrochloric acid, and oscillate ultrasonically for 5 minutes;

[0054] (4) Add the plant polyphenol ethanol solution in step (3) to the solution prepared in step (2), and continue to react at 80° C. for 5 h;

[0055] (5) The reaction product was left at -10°C for 2 days at low temperature to precipitate unreacted NS, and filtered;

[0056] (6) The filtrate was added to distilled water, and the plant polyphenol-based multifunc...

Embodiment 3

[0057] The preparation of embodiment 3 plant polyphenol-based rubber accelerator TPM

[0058] A preparation method of plant polyphenol-based rubber accelerator, specifically comprising the steps of:

[0059] (1) Weigh 10g of 2-mercaptobenzothiazole (MBT), dissolve in 100ml of formaldehyde in ethanol solution, and stir at room temperature for 10min;

[0060] (2) Adjust PH=6 with hydrochloric acid, reflux and stir in a water bath at 90°C for 3 hours;

[0061] (3) Add 10 g of plant polyphenols into 100 ml of absolute ethanol, adjust the pH to 6 with hydrochloric acid, and oscillate ultrasonically for 5 minutes;

[0062] (4) Add the plant polyphenol ethanol solution in step (3) to the solution prepared in step (2), and continue to react at 90° C. for 3 hours;

[0063] (5) The reaction product was left standing at a low temperature at -10°C for 3 days to precipitate unreacted MBT, and filtered;

[0064] (6) The filtrate was added to distilled water, and the plant polyphenol-base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com