Method for cleaning animal fibers with supercritical fluid

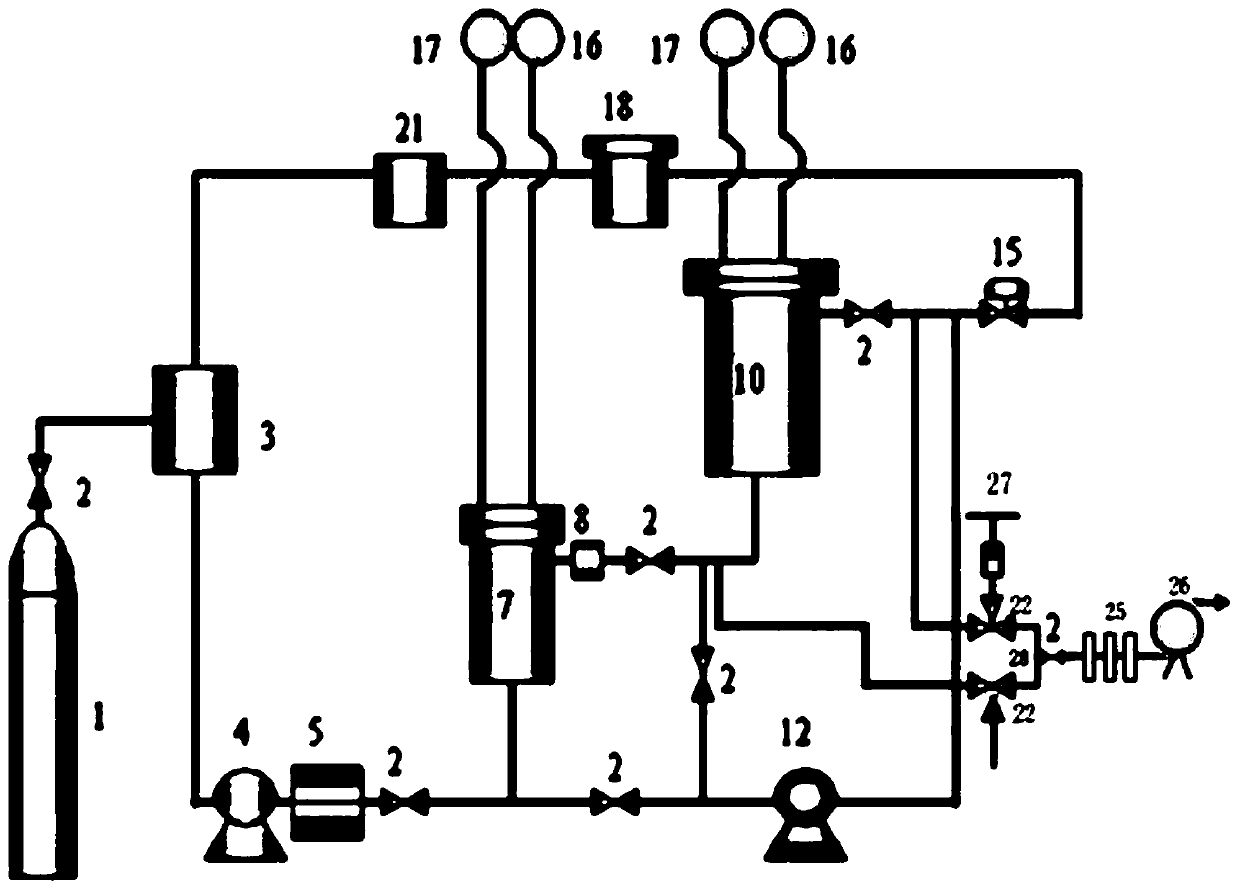

A technology of supercritical fluid and animal fiber, which is applied in the direction of dry cleaning fiber products, textiles and papermaking, and processing textile material containers. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Present embodiment provides a kind of cleaning method of cashmere (wool) fiber in supercritical carbon dioxide fluid, adopts above-mentioned device to carry out, comprises the following steps:

[0046] A. Dissolve about 0.2g of surfactant AOT in 10mL of ethanol solution, and stir until completely dissolved, then add lipase with a concentration of about 1g / L, and then add detergent with a concentration of about 4g / L. The trade name of the white cat detergent, and then stirred until clarified to prepare a mixed working solution,

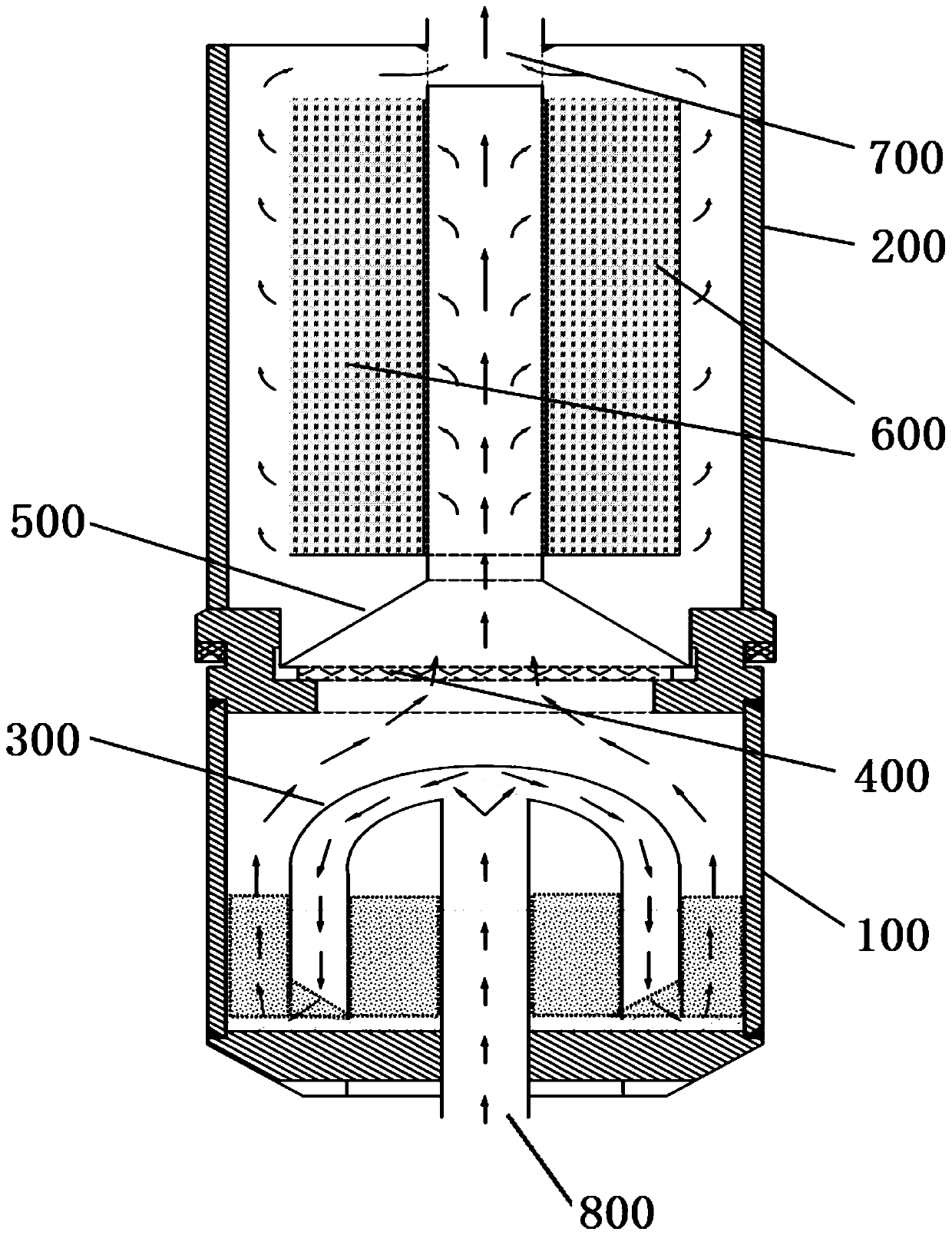

[0047] B. Put the mixed working fluid in the working fluid storage kettle 100, place the sarong 600 containing about 10 g of cashmere fiber in the working kettle 200, and the working fluid storage kettle 100 and the working kettle 200 are sealed and connected to form supercritical carbon dioxide washing cashmere device to ensure that the bottom of the sarong 600 is kept at a distance of 45 cm from the liquid surface of the mixed working fluid, s...

Embodiment 2

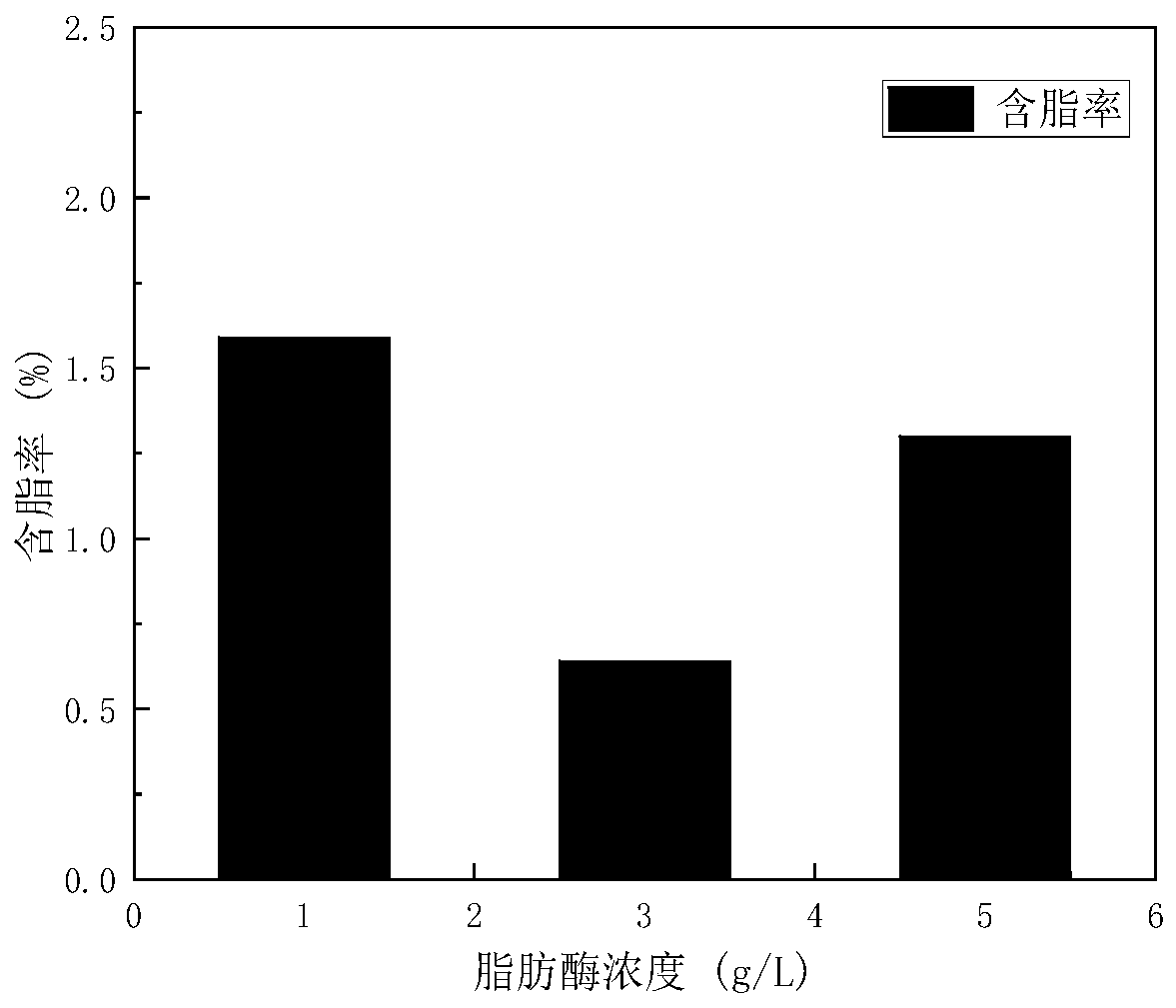

[0071] This embodiment provides a method for cleaning cashmere (wool) fibers in a supercritical carbon dioxide fluid. The cleaning method is basically the same as that described in Embodiment 1, and will not be repeated here. The difference is that the lipase concentration in this example is 3g / L. The fat content, degreasing rate and whiteness test results of the wool products processed by the velvet washing process in this embodiment are: the fat content is 0.64%, the degreasing rate is 83.05%, and the whiteness is 70.76.

Embodiment 3

[0073] This embodiment provides a method for cleaning cashmere (wool) fibers in a supercritical carbon dioxide fluid. The cleaning method is basically the same as that described in Embodiment 1, and will not be repeated here. The difference is that the lipase concentration in this example is 5g / L. The fat content, degreasing rate and whiteness test results of the wool products processed by the velvet washing process in this embodiment are: the fat content is 1.3%, the degreasing rate is 69.53%, and the whiteness is 68.16. .

[0074] By embodiment 1-3 and image 3 , Figure 4 , Figure 5 The effect of lipase concentration in supercritical carbon dioxide fluid on the fat content, degreasing rate, and whiteness of cashmere fiber after treatment can be seen from the figure with the increase of lipase concentration. The fat content rate of cashmere fiber decreases gradually, while the degreasing rate increases gradually. This is because the addition of lipase can obviously remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com