A continuous ring-opening production process for epoxy-terminated polyether

A capped polyether, production process technology, applied in the field of continuous ring-opening production process of epoxy-capped polyether, can solve the problem of limited capping report, no more than 90%, and achieve stable and controllable product quality High effect with few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

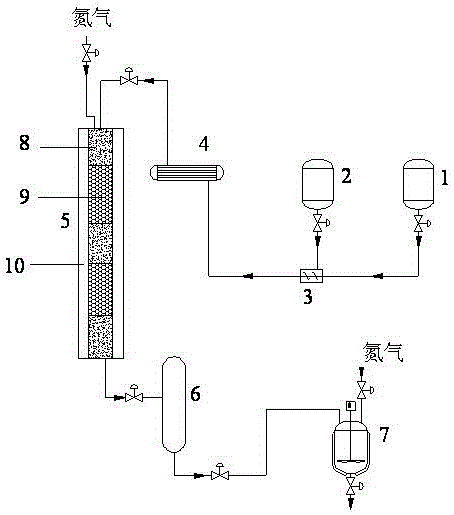

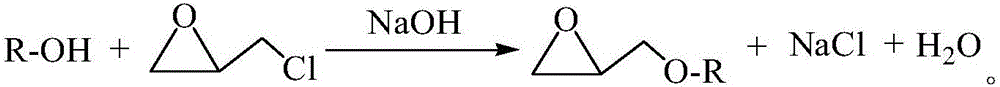

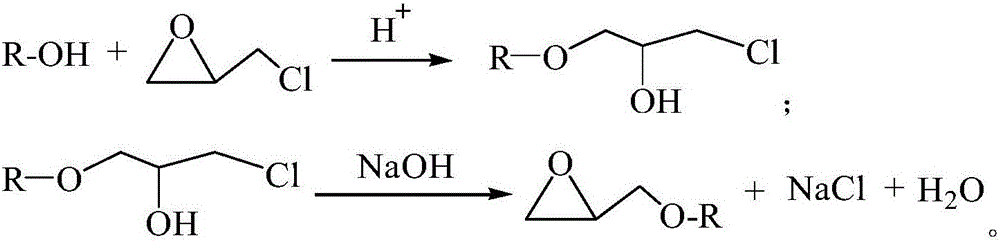

[0050] This embodiment is a continuous ring-opening production process of epoxy-terminated allyl alcohol polyoxyethylene ether, using allyl alcohol polyoxyethylene ether and epichlorohydrin as raw materials, and using solid super acid WO 3 / Al 2 o 3 As a catalyst, its basic synthesis route is as follows:

[0051] (1) Fill the solid superacid catalyst into the bed layer at the upper and lower ends of the continuous flow fixed bed reactor, replace the air with nitrogen, and the allyl alcohol polyoxyethylene ether and epichlorohydrin are metered into the mixer by the metering pump and mixed , and heated to a certain temperature with a heater, the heated material is continuously added from the upper end of the fixed bed reactor, and the reaction liquid is continuously collected in the collection tank at the lower end of the reactor to obtain the intermediate product of chlorohydrin ether;

[0052] (2) metering the reaction solution in the collection tank in step (1) into the rea...

Embodiment 2

[0069] Dissolve 2.1g of ammonium metatungstate in 11g of deionized water and add to 35g of γ-Al 2 o 3 In the 80-90 ℃ oscillating oil bath, shake and impregnate for 24 hours, then add 1.1g pseudoboehmite and 0.7g 10wt% dilute nitric acid while stirring, and add an appropriate amount of deionized water, knead and knead to form a semi-wet It is most suitable that the shape can be smoothly extruded into strips, extruded into strips with a diameter of 3mm in a single-screw extruder, then dried at 110°C, roasted in an air atmosphere of 750°C for 3 hours, and sieved to obtain 18-24 mesh three Catalyst with 5 wt% tungsten oxide content.

Embodiment 3

[0071] Dissolve 7.7g of ammonium metatungstate in 11g of deionized water and add to 35g of γ-Al 2 o 3 In the 80-90 ℃ oscillating oil bath, shake and impregnate for 24 hours, then add 1.1g pseudoboehmite and 0.7g 10wt% dilute nitric acid while stirring, and add an appropriate amount of deionized water, knead and knead to form a semi-wet It is most suitable that the shape can be extruded into strips smoothly, extruded into strips with a diameter of 3mm in a single-screw extruder, then dried at 110°C, roasted in an air atmosphere of 750°C for 3 hours, and sieved to obtain 18-24 mesh tungsten Catalyst at 18% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com