Technology for solid barium chloride acidification section

A technology of barium chloride and working section, which is applied in the field of barium chloride production technology, can solve the problems of H2S pollution and high cost, and achieve the effect of no H2S pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

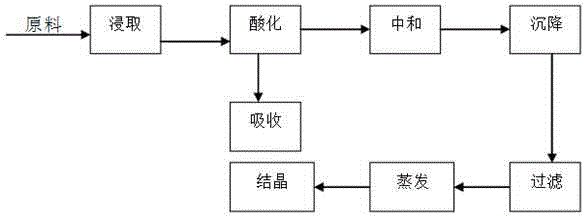

[0014] Such as figure 1 , a solid barium chloride acidification section process, comprising the following steps:

[0015] A. The witherite is pulverized by a pulverizer, and then the large particle of barium powder is soaked in water to achieve a paste state;

[0016] B. Pour the soaked slurry into the acidification tank through the slurry pump, and add a certain amount of hydrochloric acid with a concentration of 31% regularly, and stir quickly to make the acidification reaction occur;

[0017] C. After the acidification is completed, the solution is added to the neutralizer, and a 31% concentration of caustic soda solution is added to the neutralizer for neutralization reaction to remove magnesium ions and iron ions;

[0018] D. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com