Temperature-resistant and corrosion-resistant building glass ceramic

A glass-ceramic and corrosion-resistant technology, applied in the field of temperature-resistant and corrosion-resistant architectural glass-ceramics, can solve the problems of poor fire resistance and limited applicability, and achieve the effects of long service life, wide range and excellent temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

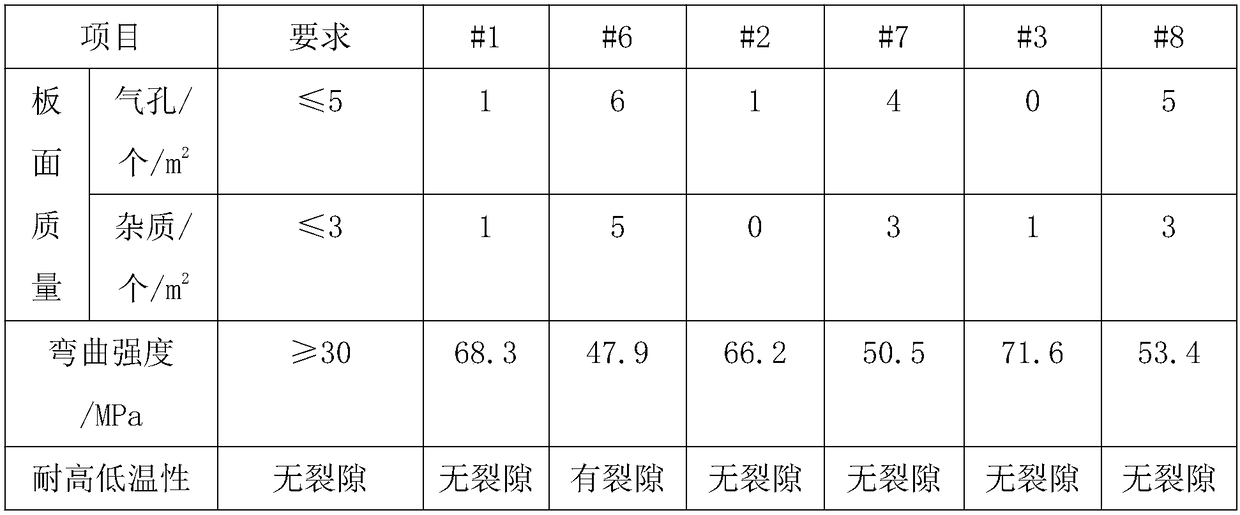

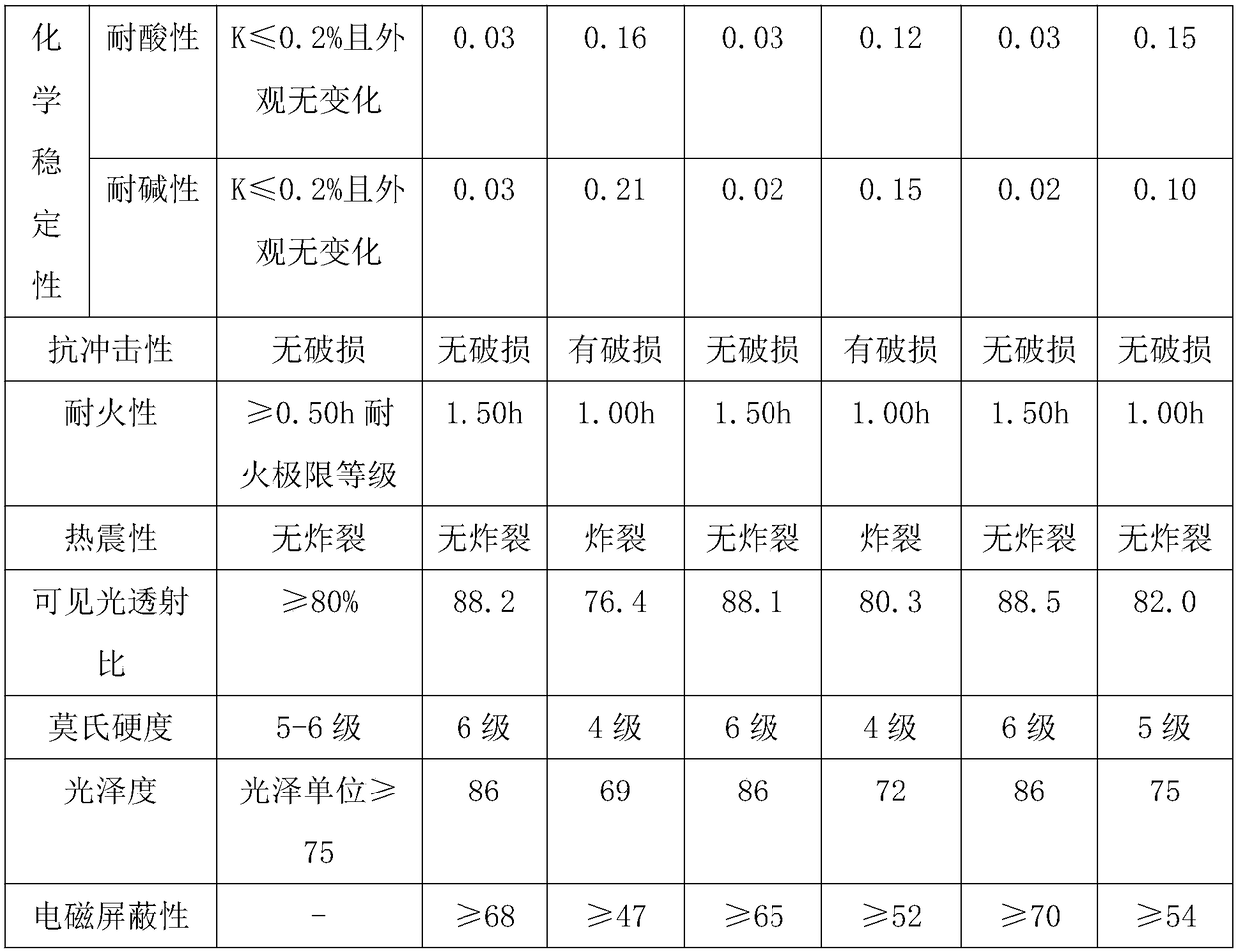

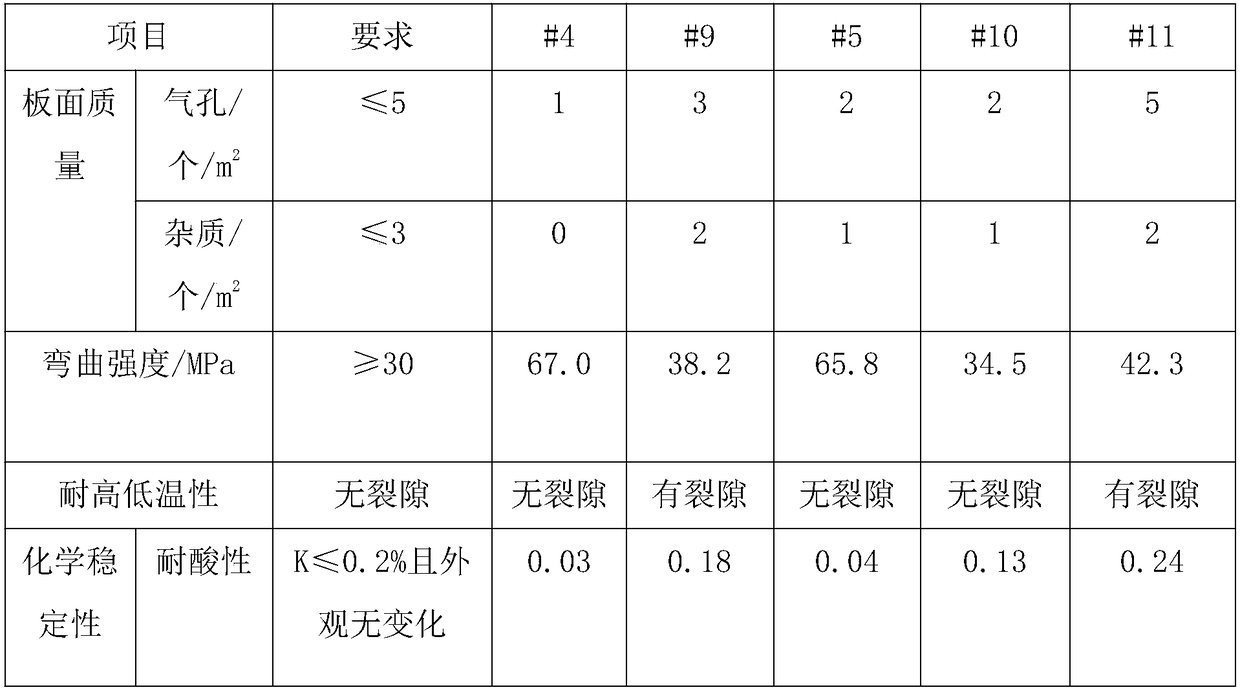

Examples

Embodiment 1

[0067] This embodiment relates to a heat-resistant and corrosion-resistant architectural glass-ceramic and its preparation process. The glass-ceramic is composed of the following raw materials in parts by weight:

[0068] 68 parts of siliceous shale;

[0069] 37 pieces of Yuliang stone;

[0070] 24 parts of vanadium-lead flotation tailings;

[0071] 27 parts limestone;

[0072] 18 parts of witherite;

[0073] 15 parts broken glass;

[0074] Na 2 CO 3 10 parts of powder;

[0075] Yb 2 o 3 6 parts of powder;

[0076] 3 parts of compound clarifying agent;

[0077] The above-mentioned composite clarifying agent is obtained by combining sodium nitrate, calcium sulfate, strontium chloride, and antimony-doped tin dioxide according to the mass ratio of 3:4:1:2.

[0078] The preparation process of this kind of glass-ceramic is generally carried out according to the following steps:

[0079] (1) Prepare raw materials: obtain raw materials according to the proportioning by we...

Embodiment 2

[0087] This embodiment relates to a heat-resistant and corrosion-resistant architectural glass-ceramic and its preparation process. The glass-ceramic is composed of the following raw materials in parts by weight:

[0088] 72 parts of siliceous shale;

[0089] 40 parts of Yuliang stone;

[0090] 28 parts of vanadium-lead flotation tailings;

[0091] 29 parts limestone;

[0092] 20 parts of witherite;

[0093] 18 parts broken glass;

[0094] Na 2 CO 3 12 parts of powder;

[0095] Yb 2 o 3 7 parts of powder;

[0096] 4 parts of compound clarifying agent;

[0097] The above composite clarifier is obtained by combining sodium nitrate, calcium sulfate, strontium chloride and antimony-doped tin dioxide according to the mass ratio of 3.5:4.5:1.5:2.5.

[0098] The preparation process of this kind of glass-ceramic is generally carried out according to the following steps:

[0099] (1) Prepare raw materials: obtain raw materials according to the proportioning by weight, and p...

Embodiment 3

[0107] This embodiment relates to a heat-resistant and corrosion-resistant architectural glass-ceramic and its preparation process. The glass-ceramic is composed of the following raw materials in parts by weight:

[0108] 75 parts of siliceous shale;

[0109] 43 pieces of Yuliang stone;

[0110] 30 parts of vanadium-lead flotation tailings;

[0111] 31 parts of limestone;

[0112] 22 parts of witherite;

[0113] 20 parts broken glass;

[0114] Na 2 CO 3 13 parts of powder;

[0115] Yb 2 o 3 8 parts of powder;

[0116] 5 parts of compound clarifying agent;

[0117] The above-mentioned composite clarifying agent is obtained by combining sodium nitrate, calcium sulfate, strontium chloride, and antimony-doped tin dioxide according to the mass ratio of 4:5:2:3.

[0118] The preparation process of this kind of glass-ceramic is generally carried out according to the following steps:

[0119] (1) Prepare raw materials: obtain raw materials according to the proportioning by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com