Ternary-core quaternary-shell cathode material, preparation method and use

A technology of positive electrode material and core-shell structure, which is applied in the field of positive electrode material precursors, can solve the problems of poor cycle performance and electrochemical stability, high production cost of lithium cobalt oxide, and low specific energy of the battery, so as to avoid particle shape and Effect of performance, elimination of oxygen defects, effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

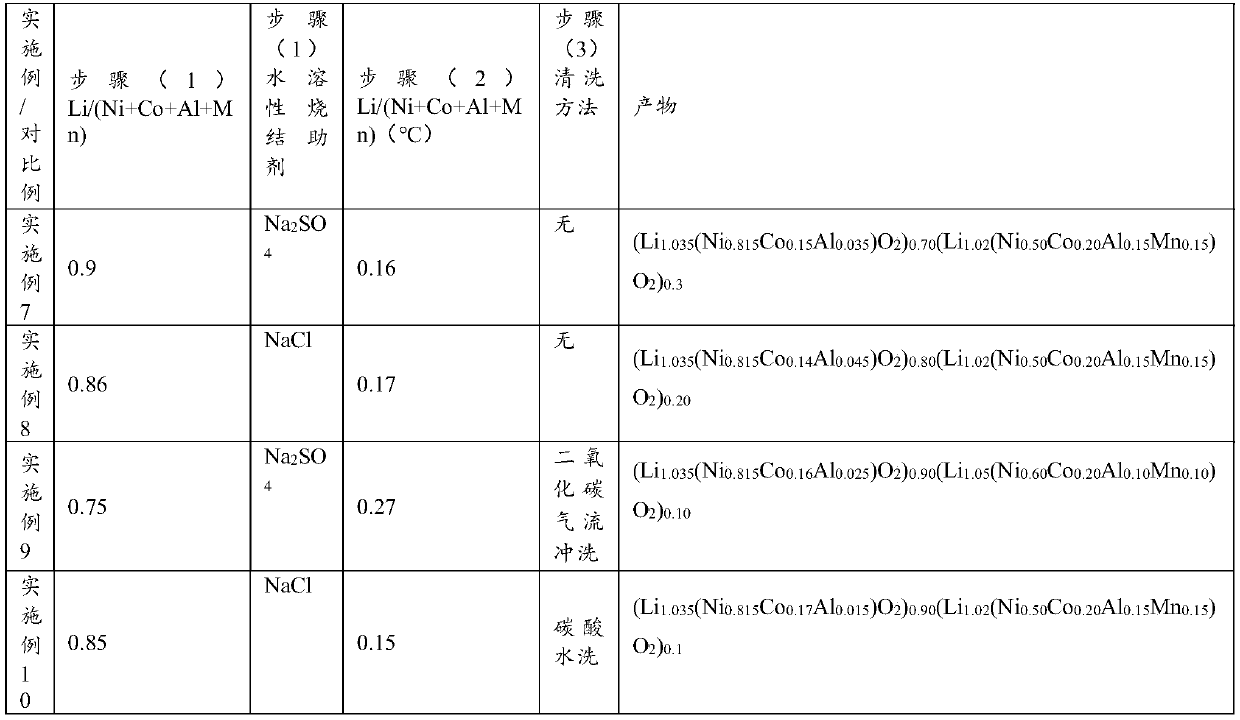

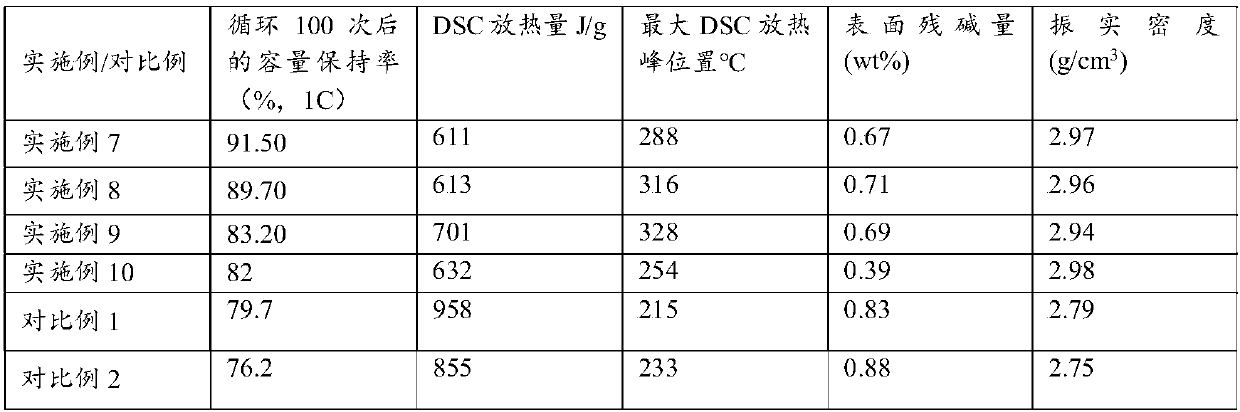

Embodiment 1

[0058] A positive electrode material precursor, the positive electrode material precursor

[0059] It is a core-shell structure with a core-shell molar ratio of 0.7:0.3

[0060] The material chemical formula of the core is Ni 0.815 co 0.15 Al 0.035 (OH) 2 , the material chemical formula of the shell is Ni 0.50 co 0.20 Al 0.15 mn 0.15 CO 3 , its preparation method is:

[0061] Step (a), precursor nucleus Ni 0.815 co 0.15 Al 0.035 (OH) 2 preparation of

[0062] Calculate and weigh soluble nickel salt, soluble cobalt salt, soluble aluminum salt and soluble manganese salt according to the molar ratio of each element Ni: Co: Al=0.815:0.15:0.035; add them together in deionized water and mix to prepare 1mol / the first solution A of L;

[0063] Mix the first solution A, ammonia water, and sodium carbonate solution, control PH=7, and react at a constant temperature at 60°C for 3h, cool to 30°C, filter, wash, and dry the precipitate to obtain the precursor core Ni 0.815 ...

Embodiment 2

[0066] A positive electrode material precursor, the positive electrode material precursor is a core-shell structure, and the core-shell molar ratio is 0.8:0.2

[0067] The material chemical formula of the core is Ni 0.815 co 0.14 Al 0.045 (OH) 2 , the material chemical formula of the shell is Ni 0.50 co 0.20 Al 0.15 mn 0.15 (OH) 2 , its preparation method is:

[0068] Step (a), precursor nucleus Ni 0.815 co 0.14 Al 0.045 (OH) 2 preparation of

[0069] Calculate and weigh soluble nickel salt, soluble cobalt salt, soluble aluminum salt and soluble manganese salt according to the molar ratio of each element Ni: Co: Al=0.815:0.14:0.045; add them together in deionized water and mix to prepare 1mol / the first solution A of L;

[0070] Mix the first solution A, ammonia water, and sodium carbonate solution, control PH=7, and react at a constant temperature at 60°C for 3h, cool to 30°C, filter, wash, and dry the precipitate to obtain the precursor core Ni 0.815 co 0.14 ...

Embodiment 3

[0073] A positive electrode material precursor, the positive electrode material precursor is a core-shell structure, the core-shell molar ratio is 0.9:0.1, and the material chemical formula of the core is Ni 0.815 co 0.16 Al 0.025 CO 3 , the material chemical formula of the shell is Ni 0.60 co 0.20 Al 0.10 mn 0.10 (OH) 2 , its preparation method is:

[0074] Step (a), precursor nucleus Ni 0.815 co 0.16 Al 0.025 (OH) 2 preparation of

[0075] According to the molar ratio of each element Ni:Co:Al=0.815:0.16:0.025

[0076] Calculate and weigh soluble nickel salt, soluble cobalt salt, soluble aluminum salt and soluble manganese salt; add them together to deionized water and mix to prepare the first solution A of 1mol / L;

[0077] Mix the first solution A, ammonia water, and sodium carbonate solution, control PH=7, and react at a constant temperature at 60°C for 3h, cool to 30°C, filter, wash, and dry the precipitate to obtain the precursor core Ni 0.815 co 0.16 Al 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com