SCR (Semiconductor Control Rectifier) catalyst and preparation method thereof

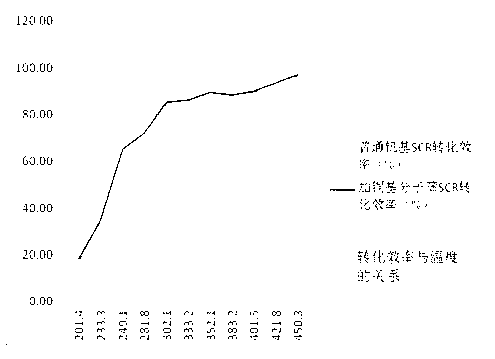

A technology of SCR catalyst and weight percentage, which is applied in the field of SCR catalyst and its preparation, can solve the problems of poor low-temperature activity, achieve high-temperature activity, large tail gas catalytic reaction area, and improve low-temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The SCR catalyst of the present invention mainly comprises: copper acetate of 30.30% by weight, cerium nitrate of 15.15% by weight, metatungstic acid of 18.9% by weight, metavanadic acid of 7.57% by weight, oxalic acid of 18.9% by weight and Percentage 9.18% titanium dioxide.

[0024] In order to further improve the low-temperature activity of the SCR catalyst, 3% to 8% of copper, 2% to 5% of vanadium, 4% to 8% of tungsten, 5% to 8% of cerium, 15% to 20% titanium, using copper, vanadium, titanium, tungsten as active components, cerium as additives, to achieve.

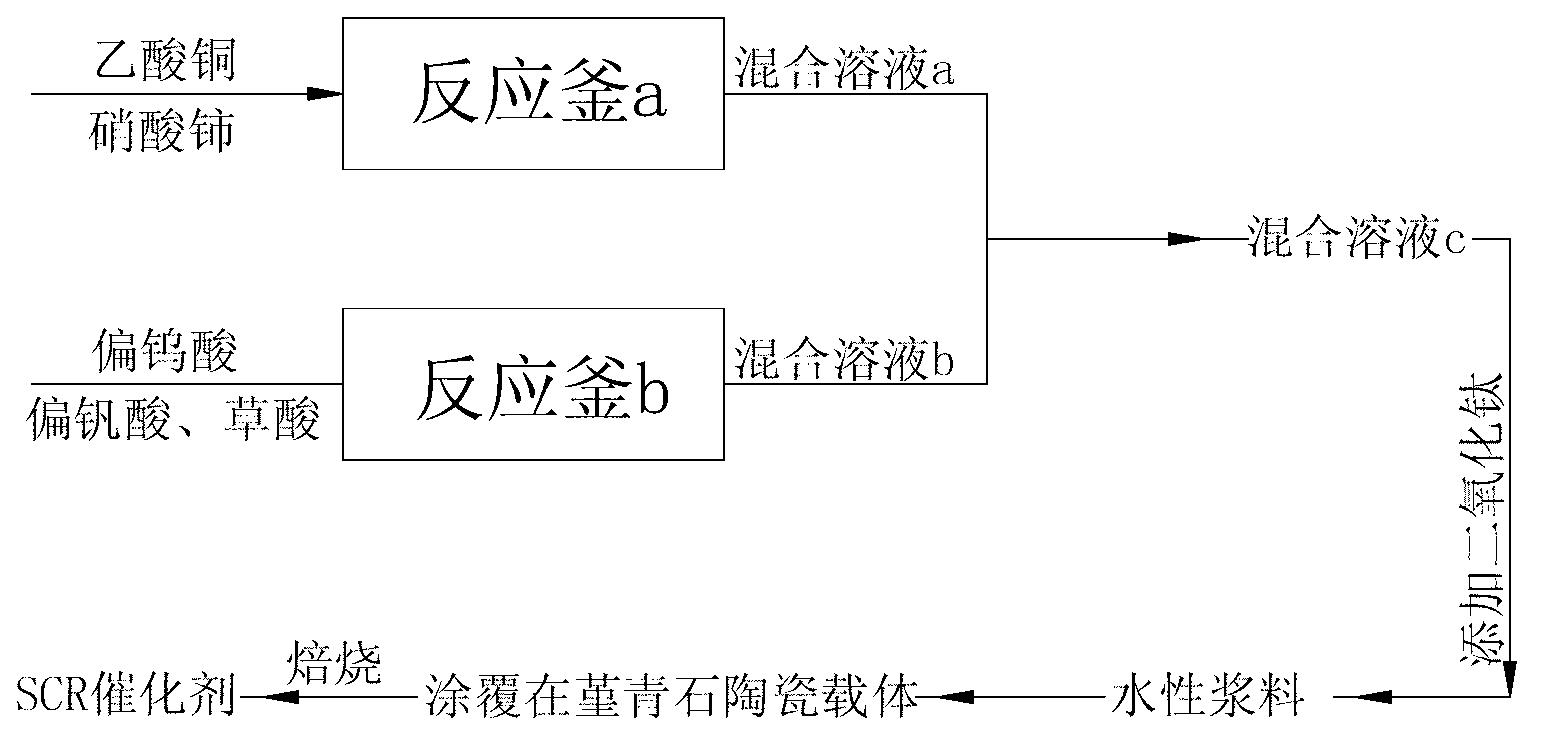

[0025] The preparation method of SCR catalyst comprises the steps:

[0026] a) Put copper acetate and cerium nitrate in the reaction kettle a according to the above weight ratio, and mix them uniformly to obtain a mixed solution a;

[0027] b) Put metatungstic acid, metavanadic acid and oxalic acid in the reaction kettle b according to the above weight ratio, and mix them uniformly to obtain a mixed soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com