Method for detecting content of barium carbonate in witherite

A detection method, witherite technology, applied in the field of chemical detection, can solve the problems of high analysis results, separation of barium sulfate and silicate, etc., and achieve the effect of large detection range, simple and easy-to-learn detection method, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

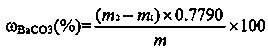

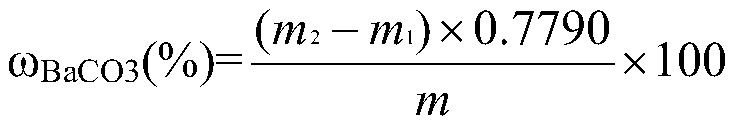

Image

Examples

Embodiment 1

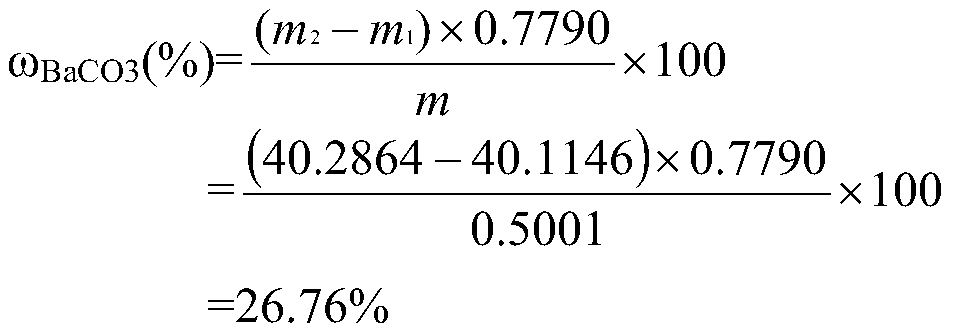

[0037] Determination of barium carbonate content in witherite 1# sample

[0038] A. Sample preparation: crush and grind witherite 1# to a particle size of ≤0.125mm, and dry in an oven at a constant temperature of 135°C±5°C for 1.5h;

[0039] B. Prepare the following reagents and solutions: 1+1 hydrochloric acid solution, potassium dichromate solution with a concentration of 20g / L, acetic acid-ammonium acetate buffer solution with pH=4~5, 0.1% methyl red indicator, concentration 100g / L L sodium hydroxide solution, silver nitrate solution with a concentration of 17g / L; the reagents and water used, unless otherwise specified, refer to analytical reagents and third-grade water not lower than those specified in GB / 6682; test The reagents and solutions used in the test are all prepared according to the provisions of GB / T603-2002 "Preparation of Preparations and Products Used in Chemical Reagent Test Methods";

[0040] C. Determination:

[0041] 1) Sample dissolution: Weigh 0.5001g...

Embodiment 2

[0054] Determination of barium carbonate content in witherite 2# sample

[0055] A. Sample preparation: crush and grind witherite 2# to a particle size of ≤0.125mm, and dry in an oven at a constant temperature of 135°C±5°C for 1.8h;

[0056] B. Prepare the following reagents and solutions: 1+1 hydrochloric acid solution, potassium dichromate solution with a concentration of 20g / L, acetic acid-ammonium acetate buffer solution with pH=4~5, 0.1% methyl red indicator, concentration 100g / L L sodium hydroxide solution, silver nitrate solution with a concentration of 17g / L; the reagents and water used, unless otherwise specified, refer to analytical reagents and third-grade water not lower than those specified in GB / 6682; test The reagents and solutions used in the test are all prepared according to the provisions of GB / T603-2002 "Preparation of Preparations and Products Used in Chemical Reagent Test Methods";

[0057] C. Determination:

[0058] 1) Sample dissolution: Weigh 0.5000g...

Embodiment 3

[0071] Determination of barium carbonate content in witherite 3# sample

[0072] A. Sample preparation: crush and grind witherite 3# to a particle size of ≤0.125mm, and dry in an oven at a constant temperature of 135°C±5°C for 2 hours;

[0073] B. Prepare the following reagents and solutions: 1+1 hydrochloric acid solution, potassium dichromate solution with a concentration of 20g / L, acetic acid-ammonium acetate buffer solution with pH=4~5, 0.1% methyl red indicator, concentration 100g / L L sodium hydroxide solution, silver nitrate solution with a concentration of 17g / L; the reagents and water used, unless otherwise specified, refer to analytical reagents and third-grade water not lower than those specified in GB / 6682; test The reagents and solutions used in the test are all prepared according to the provisions of GB / T603-2002 "Preparation of Preparations and Products Used in Chemical Reagent Test Methods";

[0074] C. Determination:

[0075] 1) Sample dissolution: Weigh 0.50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com