Anti-seepage and anti-crack dry-mixed mortar

A technology for dry-mixing mortar and mixture, applied in the field of mortar composition, can solve the problems of high cost, difficult repair, short effective trial period, etc., and achieve the effects of low price, simple construction and small dry shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

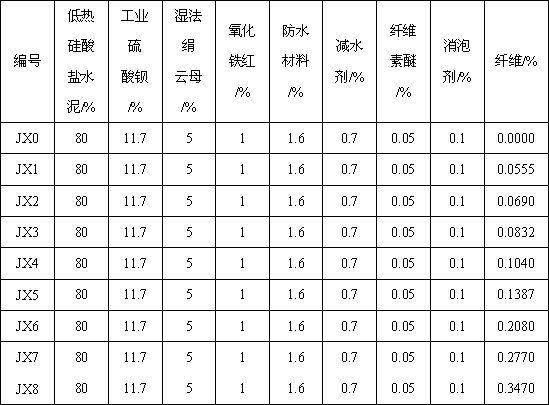

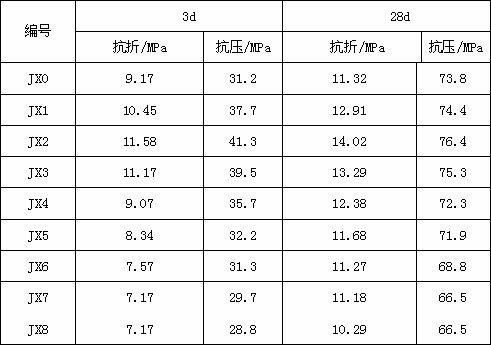

[0031] An anti-seepage and anti-cracking dry-mixed mortar mainly includes (see Table 1 for details): 80% cement, 11.7% barium ore (industrial barium sulfate, or precipitated barium sulfate), 5% wet-process sericite powder, 1.6% Components and mass percentages of waterproof mortar admixture, 1% iron oxide red, 0-0.347% fiber, 0.85% admixture (including 0.7% water reducer, 0.05% cellulose ether and 0.1% defoamer) Each component; put the weighed material into the mixer and mix evenly, and then the anti-seepage and anti-crack dry-mixed mortar is obtained.

[0032]Among them: Jiahua Cement Plant P·LH42.5R low-heat portland cement is used for cement, PCA(Ⅰ) polycarboxylate water reducing agent of Jiangsu Bote New Material Co., Ltd. is used for water reducer, and Kayton Group is used for waterproof mortar admixture For the KMA waterproof mortar admixture (K309) produced by the company, the cellulose ether adopts hydroxypropyl methylcellulose ether HPMC75000S from Longfor Technology C...

Embodiment 2

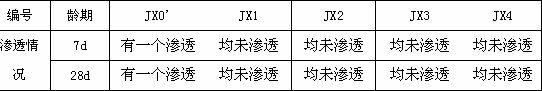

[0042] An anti-seepage and anti-cracking dry-mixed mortar, the cementing material of the blank sample is Lafarge P.O42.5R ordinary Portland cement, the waterproof material is replaced by 70-140 mesh quartz sand, and the other ingredients are the same as Table 1, according to the standard JGJ / T 70-2009 "Standard for Test Methods of Basic Properties of Building Mortar" to measure the influence of low-heat Portland cement, waterproof material and fiber on the impermeability of mortar. The results are shown in Table 4.

[0043] Table 4: Mortar penetration test results:

[0044]

[0045] It can be seen from Table 4 that compared with the blank sample JX0', the use of low-heat Portland cement, adding waterproof materials, and polyvinyl alcohol fiber mortar has better impermeability. It meets the requirements of anti-seepage pressure in the building materials industry standard JC / T 984-2005 (7d >1MPa, 28d<1.5MPa).

Embodiment 3

[0047] An anti-seepage and anti-cracking dry-mixed mortar, the blank sample precipitated barium sulfate is replaced by 70-140 mesh quartz sand, other components are the same as in Table 1, and low-background multi-channel energy gamma spectrometer 40 K, 232 Th, 226 Ra specific activity was measured to study the effect of precipitated barium sulfate on the radioactive shielding effect of mortar, and the results are shown in Table 5.

[0048] Table 5: Radiation shielding effect test:

[0049] Numbering

[0050] It can be seen from Table 5 that compared with the blank sample JX0, after adding precipitated barium sulfate, the shielding rate of mortar to gamma rays has been improved to a certain extent. When the amount of precipitated barium sulfate is 11.7wt%, the shielding rate is increased by 13.49% . This is mainly because barite contains a large amount of heavy element barium. When gamma rays pass through the substance, three main effects can occur in the interac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com