Antistatic health care ceramic and preparation method thereof

An anti-static and ceramic technology, applied in the field of ceramics, can solve problems such as unsatisfactory effects, lack of multiple functions, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

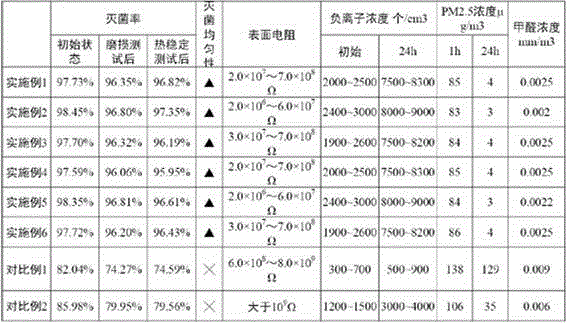

Examples

Embodiment 1

[0036] An antistatic health-care ceramic and a preparation method thereof, the preparation method comprising the steps of:

[0037] Step A, preparation of glaze slurry: 11.2% zinc oxide, 0.4% barium carbonate, 0.4% talcum powder, 60% borax, 10% silicon oxide, 16% boron oxide and 2% functional agent are mixed to obtain a mixed powder by mass percentage , add to the ball milling pot containing alumina balls and distilled water, fix the ball milling pot on the GM-3B high-speed vibrating ball mill, and rotate and ball mill for 30 minutes; then add tourmaline and cordierite, continue to rotate and ball mill for 50 minutes, and control the slurry 300 ~ 350 meshes to prepare glaze slurry; wherein, the tourmaline and cordierite respectively account for 3% and 5% of the mixed powder mass; the mass ratio of the alumina balls to distilled water is 1:2;

[0038] Step B, impregnating the glaze slurry: impregnating the porous ceramics with the glaze slurry → vacuuming → pressurizing cycle t...

Embodiment 2

[0050] An antistatic health-care ceramic and a preparation method thereof, the preparation method comprising the steps of:

[0051] Step A, preparation of glaze slurry: 10% zinc oxide, 0.45% barium carbonate, 0.35% talcum powder, 58% borax, 10% silicon oxide, 16.2% boron oxide and 5% functional agent are mixed to obtain a mixed powder by mass percentage , add to the ball milling pot containing alumina balls and distilled water, fix the ball milling pot on the GM-3B high-speed vibrating ball mill, and rotate and ball mill for 30 minutes; then add tourmaline and cordierite, continue to rotate and ball mill for 50 minutes, and control the slurry 300 ~ 350 meshes to prepare glaze slurry; wherein, the tourmaline and cordierite respectively account for 5% and 3% of the mixed powder mass; the mass ratio of the alumina balls to distilled water is 1:2;

[0052] Step B, impregnating the glaze slurry: impregnating the porous ceramics with the glaze slurry → vacuuming → pressurizing cycle...

Embodiment 3

[0064] An antistatic health-care ceramic and a preparation method thereof, the preparation method comprising the steps of:

[0065]Step A, prepare the glaze slurry: by mass percentage, mix 10% zinc oxide, 0.5% barium carbonate, 0.3% talcum powder, 60.2% borax, 10% silicon oxide, 12% boron oxide and 7% functional agent to get mixed powder , add to the ball milling pot containing alumina balls and distilled water, fix the ball milling pot on the GM-3B high-speed vibrating ball mill, and rotate and ball mill for 30 minutes; then add tourmaline and cordierite, continue to rotate and ball mill for 50 minutes, and control the slurry 300 ~ 350 meshes to prepare glaze slurry; wherein, the tourmaline and cordierite respectively account for 8% and 1% of the mixed powder mass; the mass ratio of the alumina ball milling ball to distilled water is 1:2;

[0066] Step B, impregnating the glaze slurry: impregnating the porous ceramics with the glaze slurry → vacuuming → pressurizing cycle tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com