Patents

Literature

43results about How to "Improve antimicrobial properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing composite Ag-Ti oxide antibacterial film by magnetron sputtering

InactiveCN101717920AImprove uniformityStrong adhesionVacuum evaporation coatingSputtering coatingIntermediate frequencyOxide composite

The invention discloses a method for preparing a composite Ag-Ti oxide antibacterial film by magnetron sputtering, mainly comprising the steps of: 1) carrying out pretreatment on the surface of film carrier base material, sequentially washing by more than two organic solvents and deionized water under the condition of ultrasonic wave, the washing time by using the organic solvents and the deionized water being 5-15min, and finally, drying at 15-85 DEG C for 0.5-3h under the vacuum condition; 2) arranging a metal Ti target and a metal Ag target on a magnetron sputtering device, taking argon as working gas, filling reaction gas containing oxygen into a vacuum chamber of the magnetron sputtering device, sputtering the metal Ti by an intermediate frequency magnetron sputtering power supply of the magnetron sputtering device, sputtering the Ag by the magnetron sputtering power supply, and obtaining Ag-Ti metal oxide composite coating film. The method is simple and efficient, and the obtained film has high uniformity, good dispersibility and strong adhesive force, so as to be taken as antibacterial material which has the advantages of broad spectrum, high efficiency, permanent antibacterial performance, safety and environmental protection.

Owner:ZHEJIANG UNIV

Antimicrobial Coating

InactiveUS20110182960A1Reduces adherence and colonisationImprove antimicrobial propertiesBiocideSurgeryGelatin productCoated surface

The invention relates to methods for applying coatings comprising recombinant gelatin and an antimicrobial agent to a surface. In particular, the invention is concerned with methods for coating medical devices. The invention is also concerned with coated surfaces and medical devises, and compositions comprising gelatin and an antimicrobial agent.

Owner:FUJIFILM MFG EURO

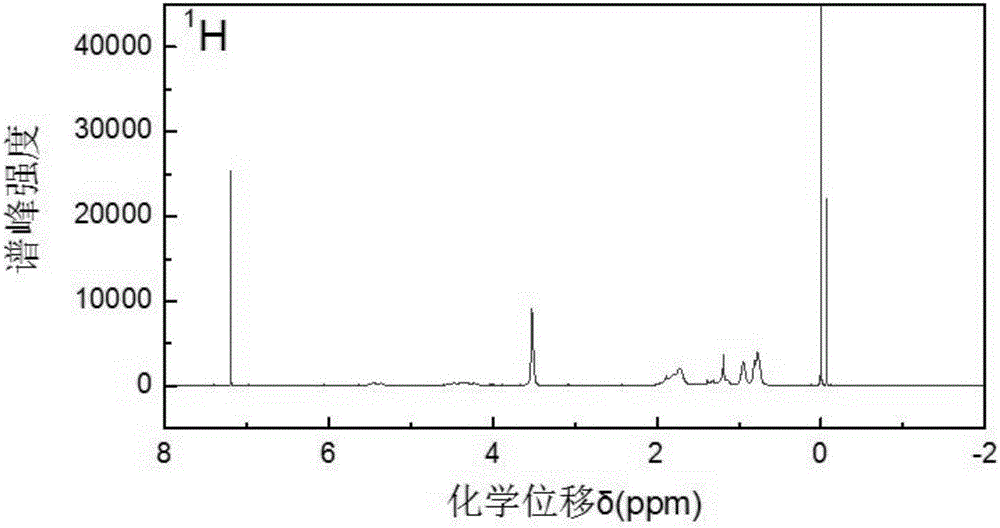

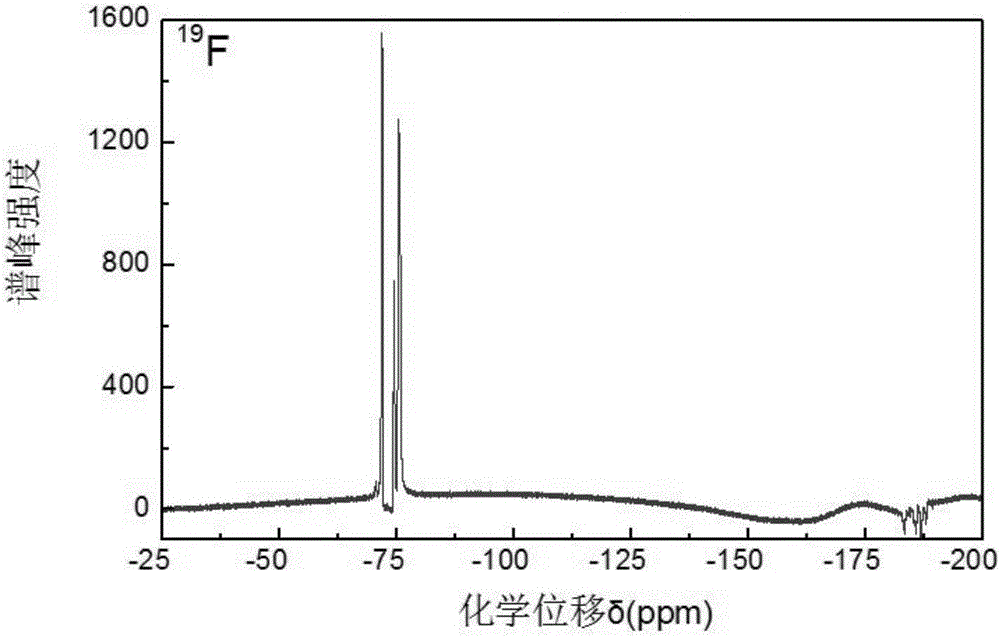

Amphiphilic fluorine-containing block copolymer antibacterial material and preparation method thereof

The invention discloses an amphiphilic fluorine-containing block copolymer antibacterial material and a preparation method thereof. The preparation method of the antibacterial material comprises the following steps that 1, fluorine-containing acrylate monomers are polymerized; 2, the product obtained in the first step and acrylate monomers are copolymerized; 3, the product obtained in the second step and methacrylic acid glycidyl ester monomers are copolymerized; 4, epoxide cleavage in the product obtained in the third step is combined with 5,5-dimethylhydantoin, a hydantoin loop is converted into hydantoin halamine, and the antibacterial material is obtained. According to the amphiphilic fluorine-containing block copolymer antibacterial material and the preparation method thereof, the antibacterial material contains fluorine-containing perssad and hydantoin halamine perssad, the fluorine-containing perssad can resist protein adsorption and bacterial adhesion, the hydantoin halamine perssad can conduct sterilization and bacteriostasis, after the hydantoin halamine perssad releases active halogens to make bacteria inactivated, the hydantoin halamine perssad can be restored to the hydantoin loop structure, and under the action of the active halogens, the hydantoin loop structure can be regenerated into the hydantoin halamine perssad. The antibacterial material can be applied to the fields of water-based antibacterial coatings, marine organism antifouling and biomedical materials.

Owner:广东洁科膜分离技术有限公司

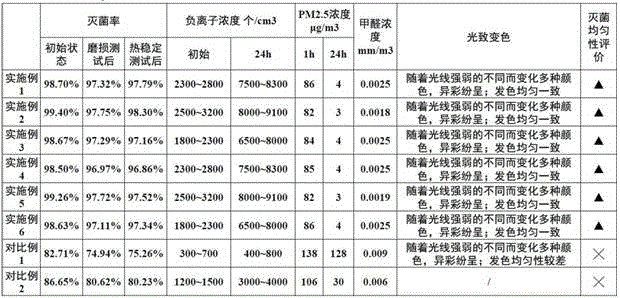

Photo chromic ceramic glaze and preparation method thereof

InactiveCN106336119AIngredients ScienceReasonably preparedMaterial nanotechnologyGrapheneFritCalcite

The invention discloses a photo chromic ceramic glaze and a preparation method thereof. The preparation method comprises the steps of preparation of photo chromic glaze, glazing, sintering of ceramic glaze, wherein the method for preparing photo chromic glaze comprises the steps of preparing the mixed powder, by mass, mixed with 25-35% of low temperature frit, 30-40% of potash feldspar, 10-20% of quartz, 3-6% of calcite, 3-6% of speck stone, 2-5% of calcium orthophosphate, 1-5% of kaolin, 5-10% of calcined clay, adding the function agent into the mixed powder and uniform mixing. The addition of the function agent is 1-8% of the mass of the mixed powder. The glaze is prepared by fine grinding and water adding, so that the photo chromic ceramic glaze is obtained. Compared with the existing ceramic glaze, the ceramic glaze of the invention has the advantages of scientific ingredients, reasonable preparation, stable performance, without toxic substances such as lead and cadmium. The ceramic glaze also has the advantages of antibacterial properties of uniform persistent spectrum, air purification and photo chromic function, thereby further broadening the scope of application of ceramic glaze.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Antimicrobial dressing

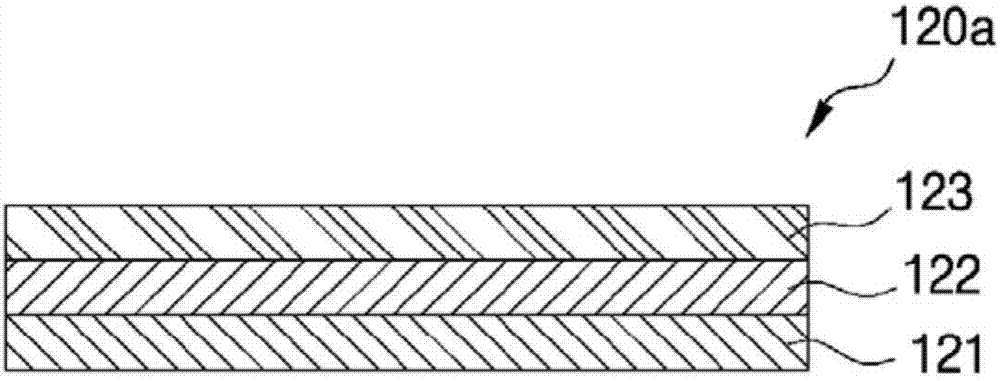

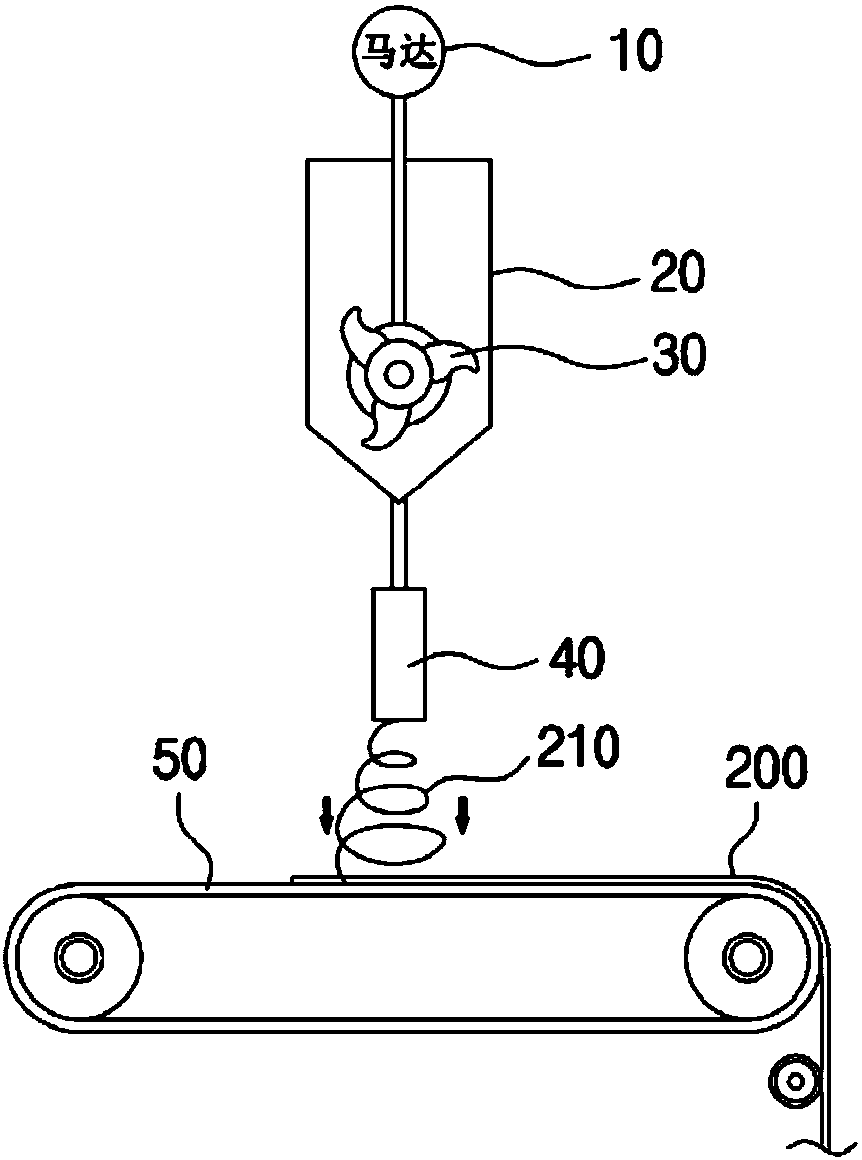

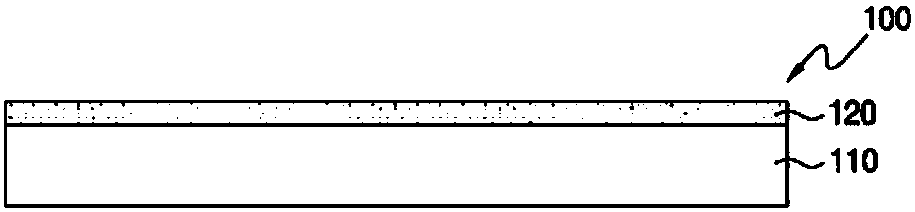

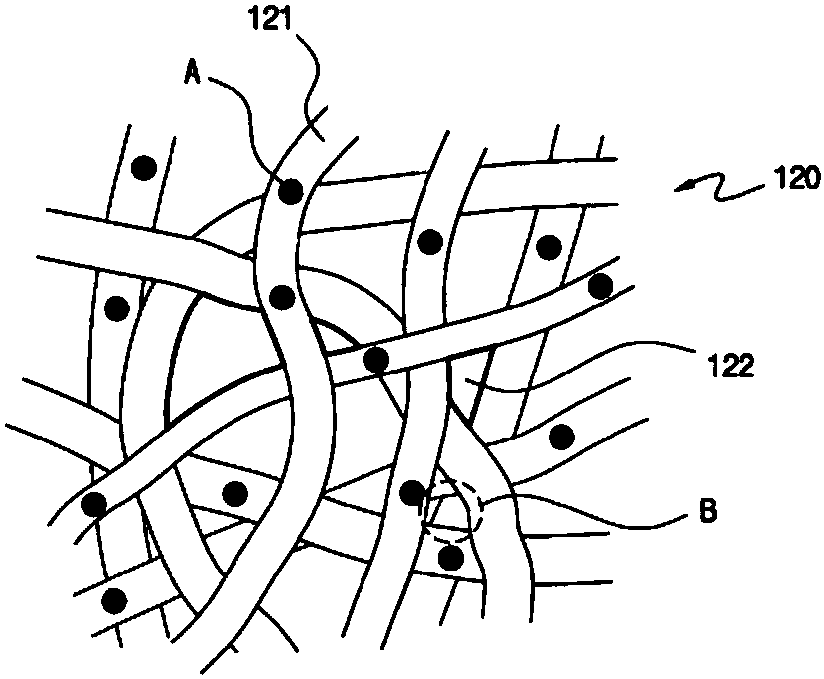

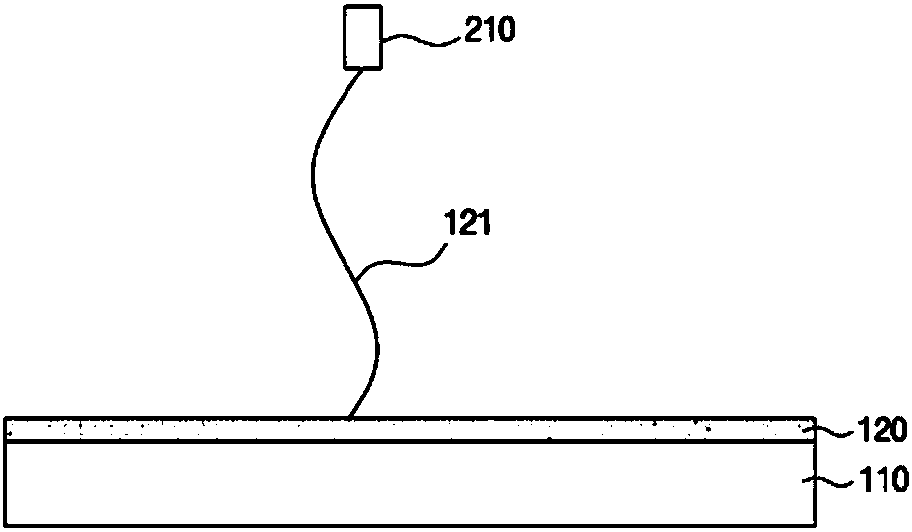

ActiveCN107427390ALight in massRelieve painNon-adhesive dressingsPharmaceutical delivery mechanismNanofiberDissolution

The present invention relates to an antimicrobial dressing, the antimicrobial dressing comprising: a first cover member which has a plurality of pores formed thereon and makes contact with a wound; an antimicrobial membrane which is laminated to the first cover member, has a plurality of pores formed thereon, and is made by the accumulation of nanofibers containing synthetic polymers, water-soluble polymers that dissolve in an exudate secreting from the wound, and antimicrobial substances released by the dissolution of the water-soluble polymers; and a second cover member which is laminated to the antimicrobial membrane, has a plurality of pores formed thereon, and is exposed to outside air.

Owner:AMOGREENTECH CO LTD

Antistatic health care ceramic and preparation method thereof

The invention discloses an antistatic health care ceramic and a preparation method thereof. The preparation method comprises the steps of: A, preparation of glaze slurry: by mass percentage, mixing 10-15% of zinc oxide, 0.4-0.5% of barium carbonate, 0.3-0.4% of talc powder, 58-65% of borax, 10-12% of silicon oxide, 12-20% of boron oxide, and 2-7% of a functional agent to obtain mixed powder, adding alumina ball-milling balls and distilled water, and performing ball milling; then adding tourmaline and cordierite, further performing ball milling, and controlling the slurry at 300-350 mesh, thus obtaining a glaze slurry, wherein the tourmaline and cordierite respectively account for 3-8% and 1-5% of the mass of the mixed powder; B, glaze slurry impregnation: impregnating ceramic in the glaze slurry, and then performing first firing; and C, glaze slurry spraying: spraying glaze slurry and conducting second firing, thus obtaining health care ceramic. Compared with existing ceramic, the ceramic prepared by the method provided by the invention has the characteristics of scientific compounding, reasonable preparation, and stable performance, does not contain lead, cadmium or other extremely toxic substances, and also has uniform and lasting spectral antimicrobial characteristics, air purification and antistatic functions, thus further broadening the application scope of the ceramic.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

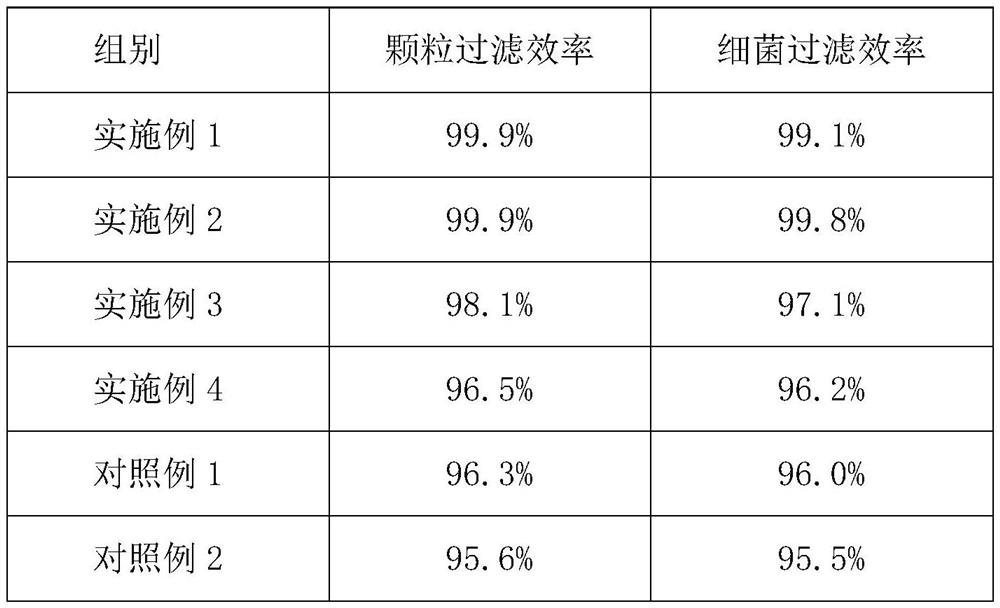

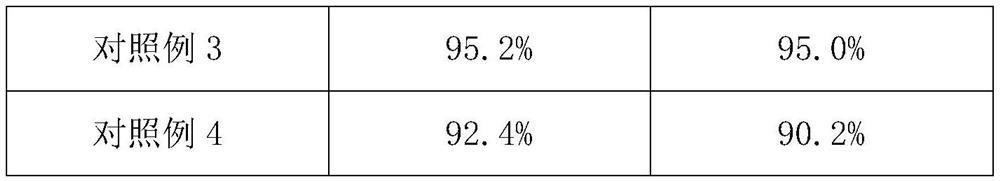

Manufacturing method for novel filter material

ActiveCN111974088AImprove antibacterial propertiesImprove antioxidant capacityDispersed particle filtrationBiochemical fibre treatmentPolymer scienceNonwoven fabric

The invention relates to a manufacturing method for a novel filter material. The manufacturing method comprises the steps: firstly melt blending is conducted on a ferulic acid-chitosan grafted copolymer, polycaprolactone and polypropylene according to a mass part ratio of (1-5):(1-10):(70-90), a spray melting technology is adopted, and a non-woven fabric layer is obtained; secondly, surface modification treatment is conducted on the obtained non-woven fabric layer through polyvinylpyrrolidone and an ammonium persulfate solution, and silver-loaded nano titanium dioxide powder is loaded on the surface of the non-woven fabric layer; then a polytetrafluoroethylene microporous membrane with the thickness of not more than 1 mm is prepared, and hot-pressing compositing is conducted on the polytetrafluoroethylene microporous membrane and the non-woven fabric layer obtained in the step 2 to obtain a composite filter layer; corona treatment is conducted on the obtained composite filter layer, wherein the storage charge density is 3*10<-4> to 5.7*10<-3> C / m2; and finally, a waterproof non-woven fabric layer and a spunlace non-woven fabric layer are composited on the two sides of the obtainedcomposite filter layer correspondingly. The filter material is good in filtering effect and good in air permeability, and fibers have great chemical stability, thermal stability, hydrophilicity and antibacterial property.

Owner:GUANGZHOU TRACE ELEMENTS BIOLOGICAL TECH CO LTD

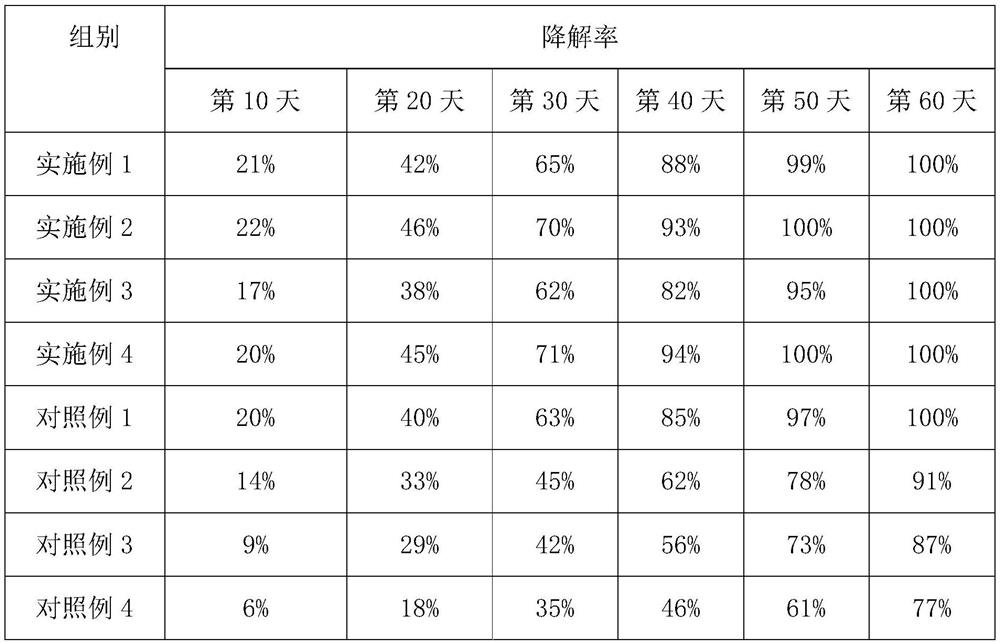

Noctilucent deodorant ceramic glaze and preparation method thereof

The invention discloses a noctilucent deodorant ceramic glaze and a preparation method thereof. The preparation method comprises the steps of: firstly preparing a noctilucent deodorant glaze slurry, and then conducting glazing and sintering to obtain ceramic glaze. Specifically, the preparation method of the noctilucent deodorant glaze slurry consists of: by mass percentage, mixing 25-35% of low temperature frit, 30-40% of potassium feldspar, 10-20% of quartz, 3-6% of calcite, 3-6% of talc, 2-5% of calcium phosphate, 1-5% of kaolin, and 5-10% calcined soil to obtain mixed powder, adding a functional agent accounting for 3-10% of the mass of the mixed powder into the mixed powder and mixing the substances evenly, performing fine grinding, and adding water to obtain the glaze slurry, i.e. noctilucent deodorant ceramic glaze slurry. Compared with existing ceramic glazes, the ceramic glaze prepared by the invention has the characteristics of scientific compounding, reasonable preparation, stable performance, and no lead, cadmium or other extremely toxic substances, also has uniform and lasting spectral antibacterial properties, deodorizing properties and noctilucent function, thus further broadening the application scope of ceramic glaze.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

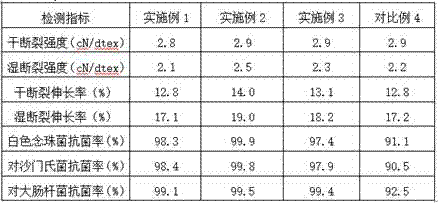

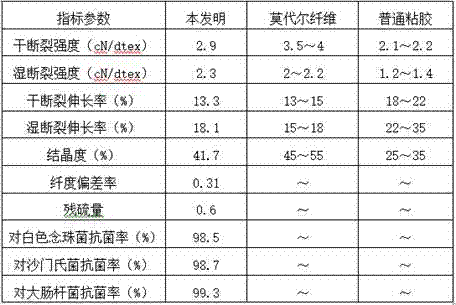

Beauty maintaining and young keeping sea cucumber cellulose fiber and making method thereof

ActiveCN107268097AEliminates hyperpigmentationStay flexibleAntibacterial agentsCosmetic preparationsWrinkle skinSlurry

The invention provides a beauty maintaining and young keeping sea cucumber cellulose fiber. The dry fracture strength is not less than 2.8 cN / dtex, the wet fracture strength is not less than 2.1 cN / dtex, the sea cucumber collagen content is not less than 2%, the dry breaking elongation is 12-14%, and the wet breaking elongation is 17-19%. The invention also provides a making method of the beauty maintaining and young keeping sea cucumber cellulose fiber. The method comprises a step of preparation of a sea cucumber slurry, and the sea cucumber slurry preparation step comprises desalting, pulping, chemical water treatment and heating. An under product made of the beauty maintaining and young keeping sea cucumber cellulose fiber can repair human face tissues, and collagens contained in the fiber can make skins keep elastic, prevent and reduce wrinkles and eliminate face pigment deposition, so the fiber is a good raw material for making face masks, breast masks and wet wipes.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

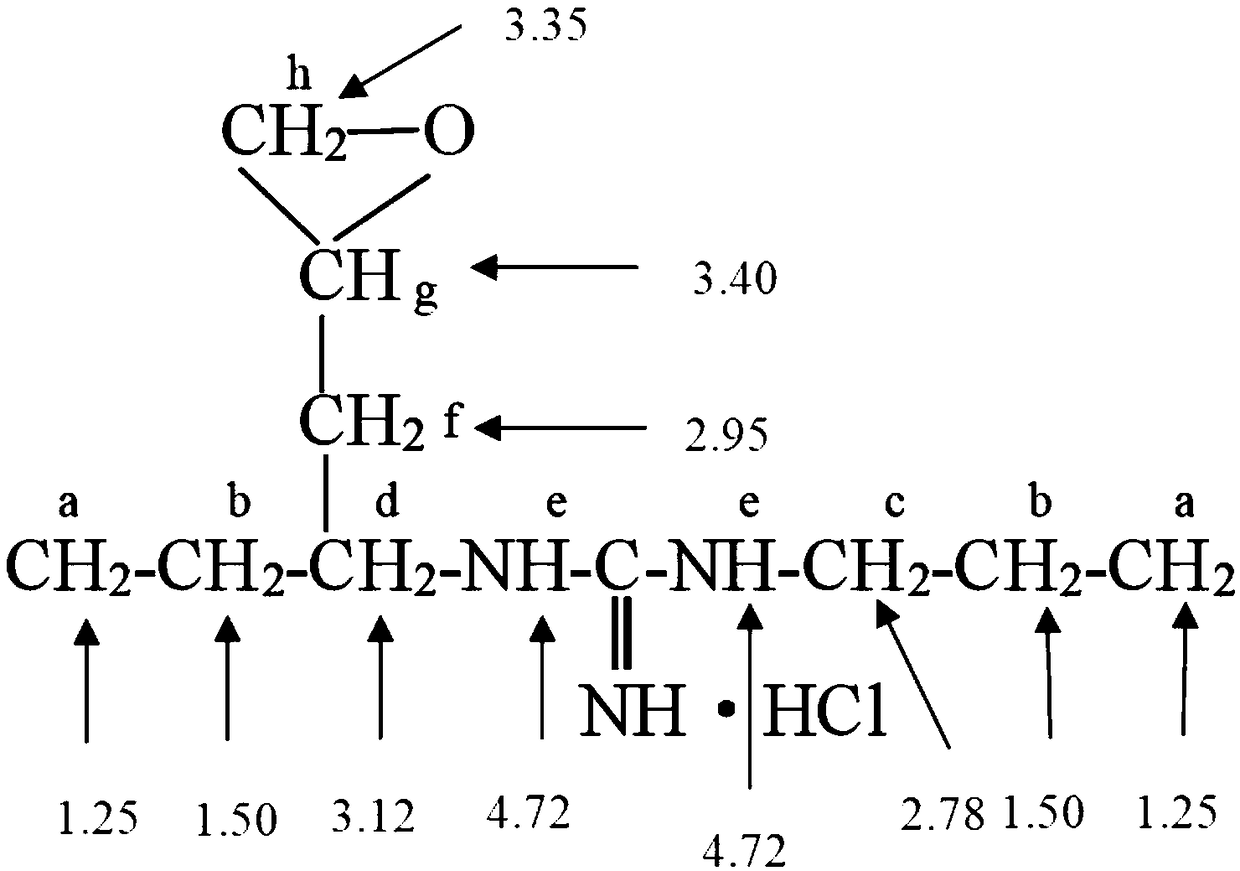

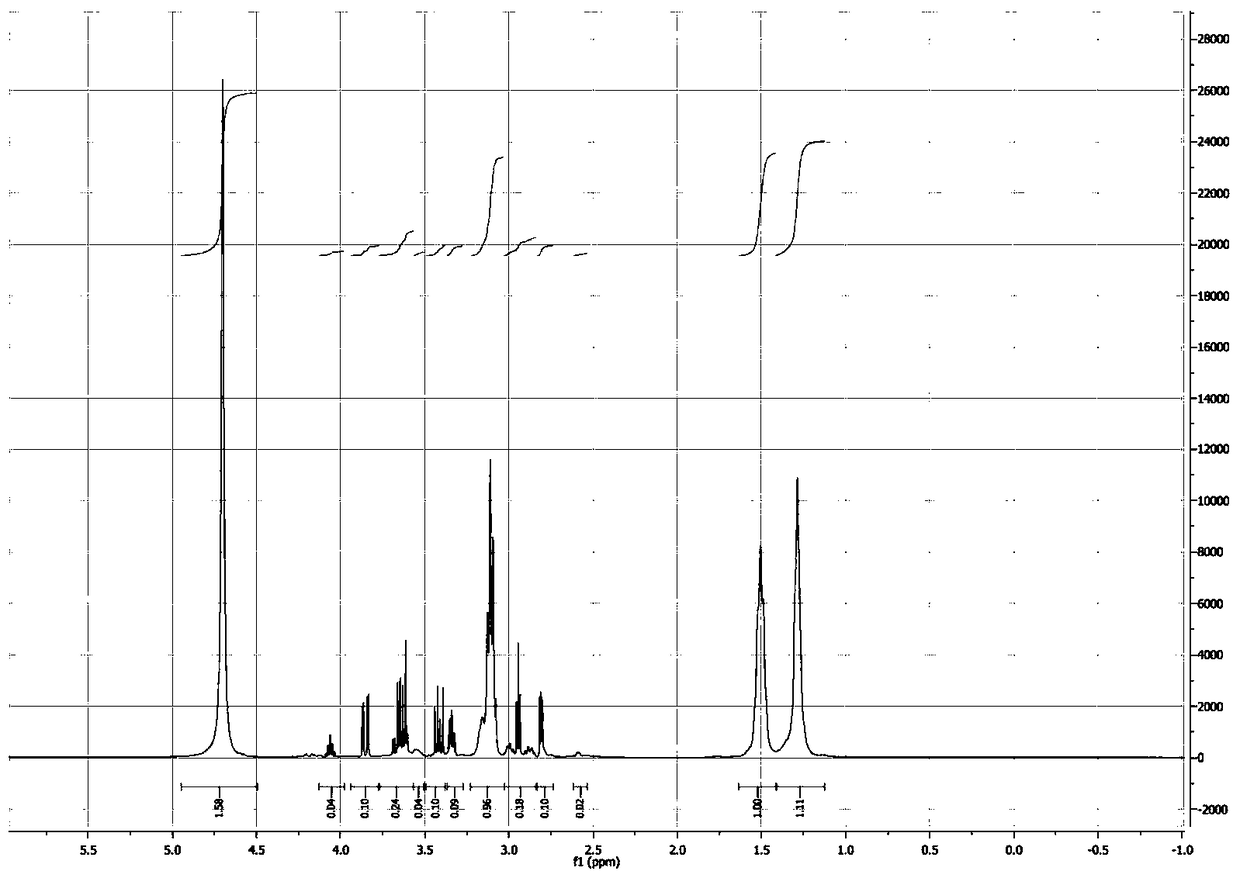

Polyepoxypropylhexylguanidine hydrochloride and preparation method thereof

InactiveCN109503832AImprove antibacterial propertiesRapid sterilizationPolyethylene terephthalatePolyvinyl chloride

The invention belongs to the technical field of plastic antibacterial agents, and particularly relates to polyepoxypropylhexylguanidine hydrochloride and a preparation method thereof. The preparationmethod of the polyepoxypropylhexylguanidine hydrochloride has the advantages that the technology is simple, and the cost is low. The polyepoxypropylhexylguanidine hydrochloride prepared by the preparation method has the advantages that the purity is high, and the yield rate can stably reach 90.0% to 95.0%; the sterilizing effect is excellent, and the poison and irritation are avoided; the polyepoxypropylhexylguanidine hydrochloride can be used as an antibacterial agent to be added into PP (polypropylene), PE (polyethylene), PET (polyethylene terephthalate), PVC (polyvinyl chloride) and other plastics to further prepare the antibacterial plastics, and the influence on the appearance, transparency, plasticity, hardness and other properties of the plastic is avoided; the polyepoxypropylhexylguanidine hydrochloride and the plastic can generate grafting copolymerizing reaction at the temperature of 160 DEG C, and the polyepoxypropylhexylguanidine hydrochloride cannot be dissolved out by thewater-based and oil-based solvents after combining, so that the prepared antibacterial plastic can realize lasting antibacterial characteristic.

Owner:上海高聚生物科技有限公司

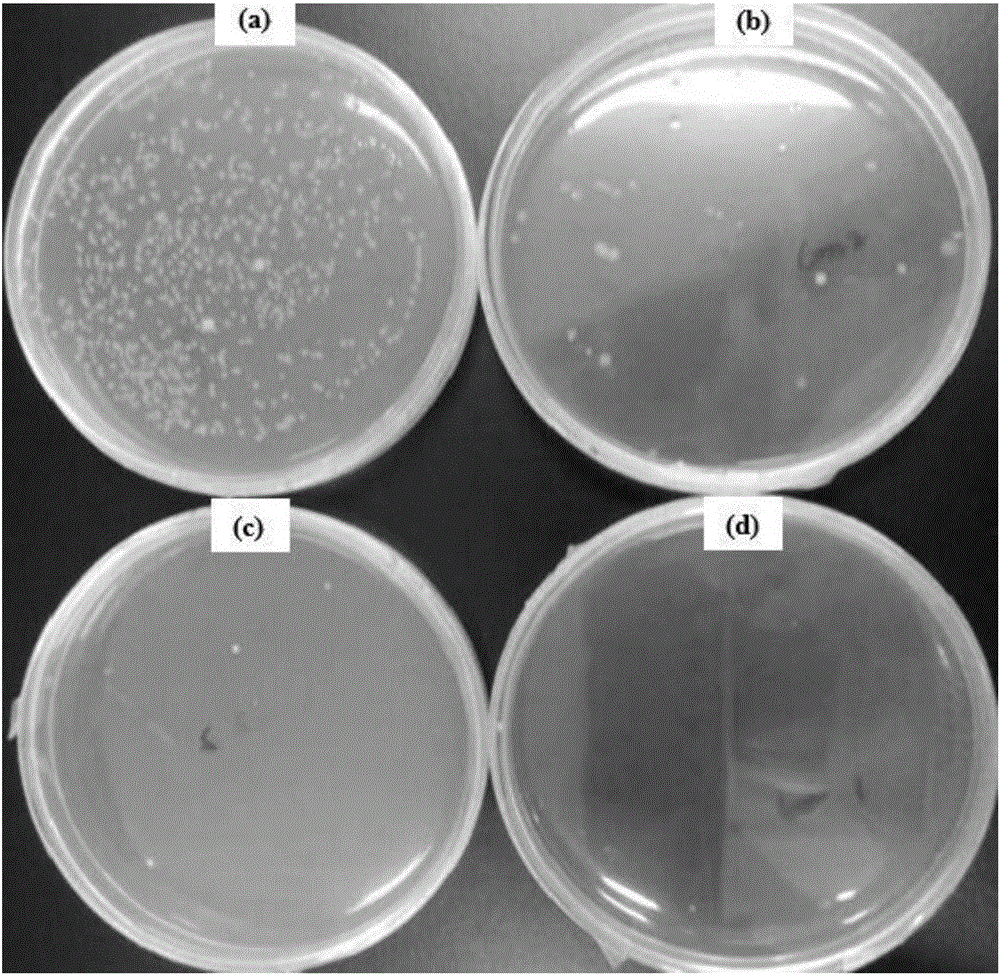

Photochromic health care ceramic and preparation method thereof

The invention discloses a photochromic health care ceramic and a preparation method thereof. The preparation method comprises the steps of: A, glaze slurry preparation: by mass percentage: mixing 10-15% of zinc oxide, 0.4-0.5% of barium carbonate, 0.3-0.4% of talc powder, 58-65% of borax, 10-12% of silicon oxide, 12-20% of boron oxide and 5-8% of a functional agent to obtain mixed powder, then adding alumina ball-milling balls and distilled water to conduct ball milling; then adding tourmaline and cordierite to further perform ball milling, and controlling the slurry at 300-350mesh, thus obtaining the glaze slurry, wherein the tourmaline and cordierite respectively account for 3-8% and 1-5% of the mass of the mixed powder; step B, glaze slurry impregnation: conducting impregnation of the glaze slurry and then performing first firing; and C, glaze slurry spraying: spraying the glaze slurry and then conducting second firing so as to obtain health care ceramic. Compared with the existing ceramics, the ceramic prepared by the method provided by the invention has the characteristics of scientific compounding, reasonable preparation, stable performance, no lead, cadmium or other extremely toxic substances, and also has uniform and lasting spectral antibacterial properties, photochromic and anti-radiation functions, thus further broadening the application scope of ceramics.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Antibacterial radiation-resisting ceramic glaze and preparation method thereof

InactiveCN106746653AIngredients ScienceReasonably preparedBiocideDead animal preservationCalcium biphosphateFrit

The invention discloses antibacterial radiation-resisting ceramic glaze and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing antibacterial radiation-resisting glaze slip, and then glazing and sintering to obtain the ceramic glaze. The preparation method of the antibacterial radiation-resisting ceramic glaze slip comprises the following steps: mixing the following materials in percentage by mass: 25 to 35 percent of low temperature frit, 30 to 40 percent of potassium feldspar, 10 to 20 percent of quartz, 3 to 6 percent of calcite, 3 to 6 percent of talc, 2 to 5 percent of calcium phosphate, 1 to 5 percent of kaolin and 5 to 10 percent of calcined clay to obtain mixed powder; adding a functional additive into mixed powder, and uniformly mixing, wherein the adding amount of the functional additive is 3 to 8 percent of the mass of the mixed powder; finely grinding, and adding water to obtain the glaze slip, thus obtaining the antibacterial radiation-resisting ceramic glaze. Compared with existing ceramic glaze, the ceramic glaze prepared by the preparation method disclosed by the invention is scientific in material burdening, reasonable in preparation and stable in performance; in addition, the antibacterial radiation-resisting ceramic glaze does not contain extremely toxic substances such as lead and cadmium; meanwhile, the antibacterial radiation-resisting ceramic glaze also has uniform and persistent antibacterial characteristic, air purifying characteristic and radiation-resisting function, and further the application range of the ceramic glaze is widened.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

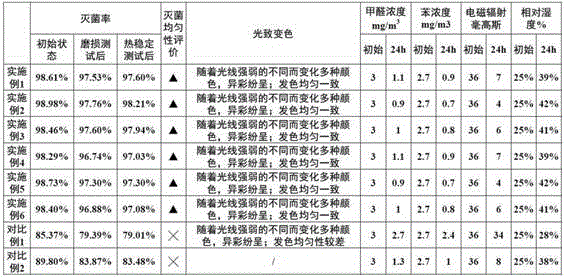

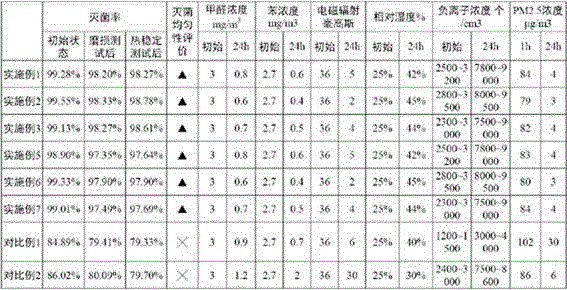

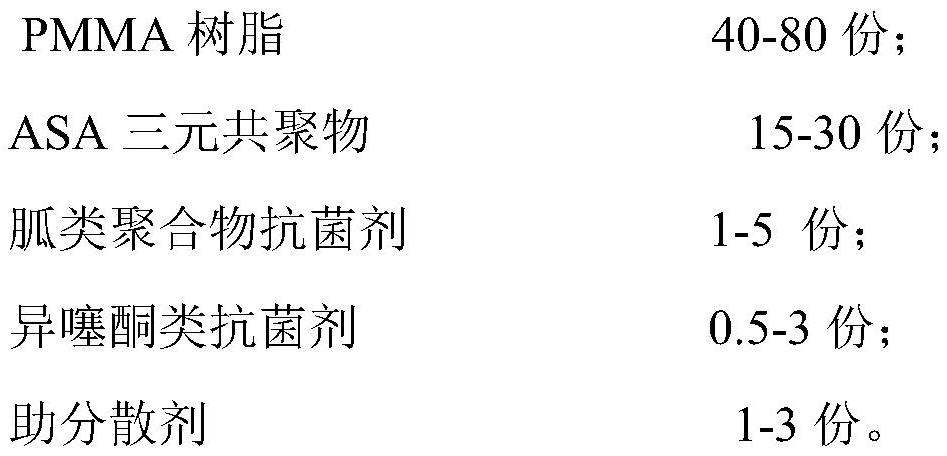

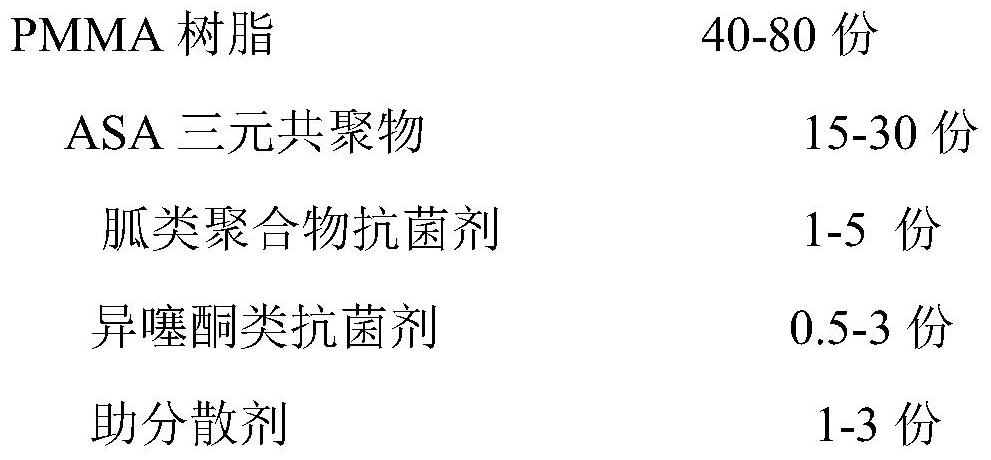

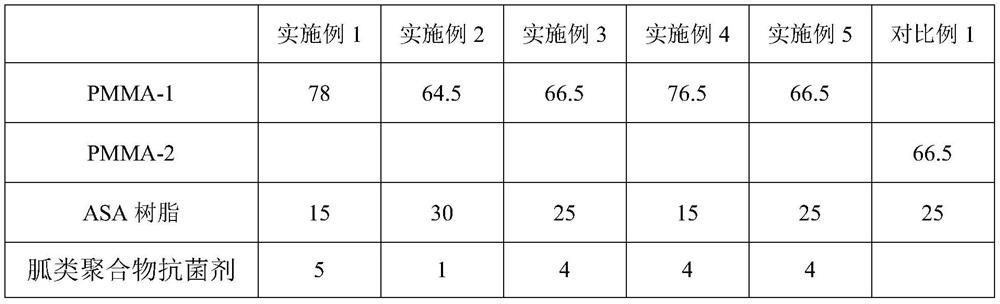

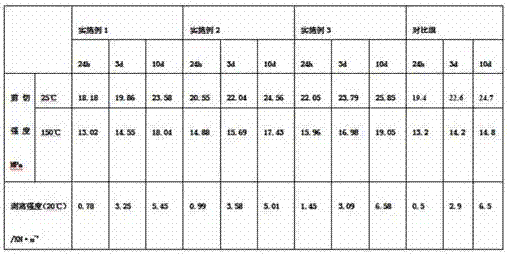

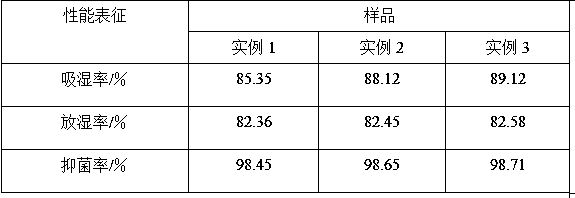

High-stability and broad-spectrum antibacterial PMMAASA alloy material based on molecular online self-assembly technology and preparation method thereof

PendingCN113667254AGuaranteed Dispersion ExtrusionAchieve decentralizationPolymer sciencePolymethyl methacrylate

The invention relates to a high-stability and broad-spectrum antibacterial PMMAASA alloy material based on a molecular online self-assembly technology and a preparation method thereof, and the high-stability and broad-spectrum antibacterial PMMAASA alloy material specifically comprises the following raw materials by weight: 40-80 parts of polymethyl methacrylate resin, 15-30 parts of an acrylonitrile-styrene-acrylate terpolymer, 1-5 parts of a guanidine polymer antibacterial agent, 0.5-3 parts of an isothiazone antibacterial agent, and 1-3 parts of a dispersing aid. According to the preparation method, online molecular self-assembly of active substances of an isothiazone antibacterial agent with excellent antibacterial performance and a guanidine polymer antibacterial agent with excellent antifungal performance is realized through a tandem type double-order extrusion modification process method, and then secondary online melting and mixing with a PMMA resin matrix, a dispersing aid and the like are performed. The molecular self-assembly technology based on polar groups can ensure the high activity, broad spectrum and stability of the antibacterial system, and the adopted double-order online melt extrusion process can also well avoid inactivation, degradation, failure and other unstable conditions caused by water cooling or contact with the external environment of the active antibacterial system.

Owner:华合新材料科技股份有限公司

Environment-friendly polyurethane antibiosis adhesive and preparation method thereof

InactiveCN106977687AImprove antimicrobial propertiesBroaden the field of applicationNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemistryIsocyanate compound

The invention discloses an environment-friendly polyurethane antibiosis adhesive and a preparation method thereof. The environment-friendly polyurethane antibiosis adhesive is prepared from the following raw materials in parts by weight: 10-30 parts of hexamethylene diisocyanate, 0.5-5 parts of antibacterial zeolite, 0.5-5 parts of tetrahydrofuran-ethylene oxide copolymerization glycol, 5-15 parts of dibutyl phthalate, 0.10-0.20 part of dibutyltin dilaurate, 0.2-2.0 parts of polyoxyethylene polyoxy propyl alcohol amidogen ether, 0.10-0.20 part of p-methyl benzol sulfonyl isocyanate, 0.10-0.20 part of gamma-glycidyl 3-(trimethoxysilyl)propyl ether and 0.10-0.30 part of triethylene glycol bis-[3-(3-tertiary butyl-4-hydroxy-5-methylphenyl) propionate]. According to the environment-friendly polyurethane antibiosis adhesive, the antibacterial property of the polyurethane adhesive is effectively improved, the application field of the polyurethane adhesive is widened, and the polyurethane antibiosis adhesive performs an active promotion function for the industrial production of the high-performance polyurethane adhesive and the wide application of the high-performance polyurethane adhesive in national industries.

Owner:JIUSHENG WOOD

Biomedical Devices

InactiveUS20090122260A1Improve antimicrobial propertiesReduce accumulationProsthesisOptical partsDevice formBiomedical equipment

Biomedical devices are provided herein which are formed from a polymerization product of a monomeric mixture comprising (a) one or more esterified aminoalcohol monomers; and (b) one or more biomedical device-forming monomers.

Owner:BARCLAYS BANK PLC AS SUCCESSOR AGENT

Method for preparing antibacterial mould-proof zeolite-based humidity controlling material

ActiveCN109095945AImprove antimicrobial propertiesImprove moisture absorption performanceCeramicwareLong actingEnzyme

The invention relates to a method for preparing an antibacterial mould-proof zeolite-based humidity controlling material and belongs to the technical field of humidity controlling materials. Accordingto the technical scheme of the invention, water soluble alkaloids are extracted and loaded into a high water absorbing gel material, and the alkaloids are uniformly dispersed and pressurized and loaded into inner walls of pores of a zeolite material. Since the inner walls of the pores of the material are in a high pressure environment, the gel material effectively permeates and coats to the surface of the inner walls of pores of the zeolite, the pore structure is effectively reinforced due to effective coating after curing, the moisture-absorbing water-soluble antibacterial enzyme-inhibitoryalkaloids are obtained, effective long-acting bacteria inhibition is realized, and the antibacterial property of the zeolite-based humidity controlling material is improved.

Owner:南京金德瑞环保科技有限公司

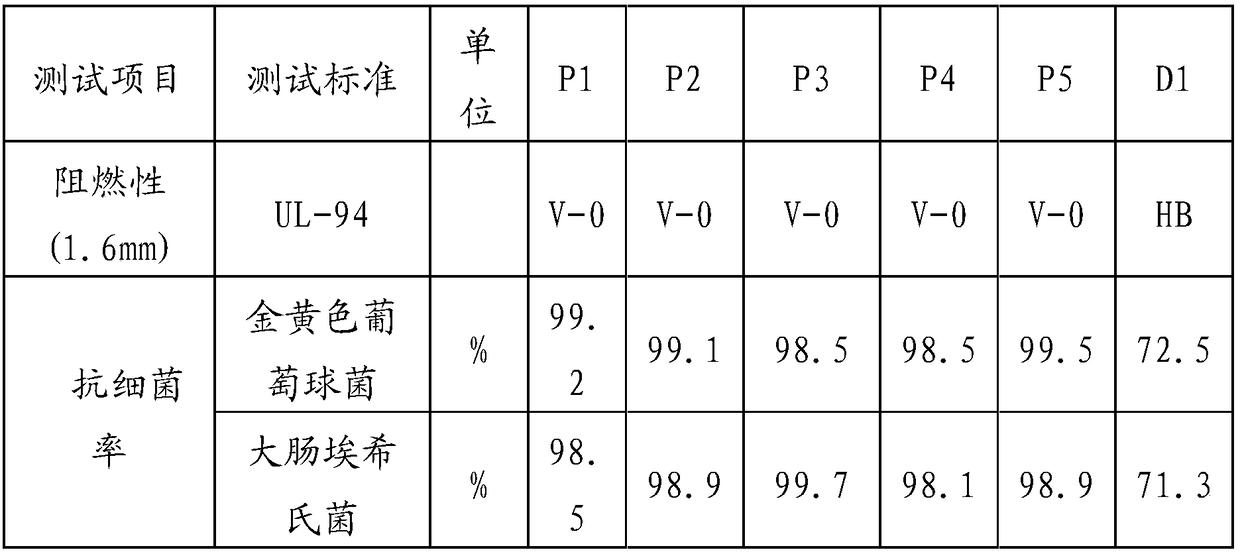

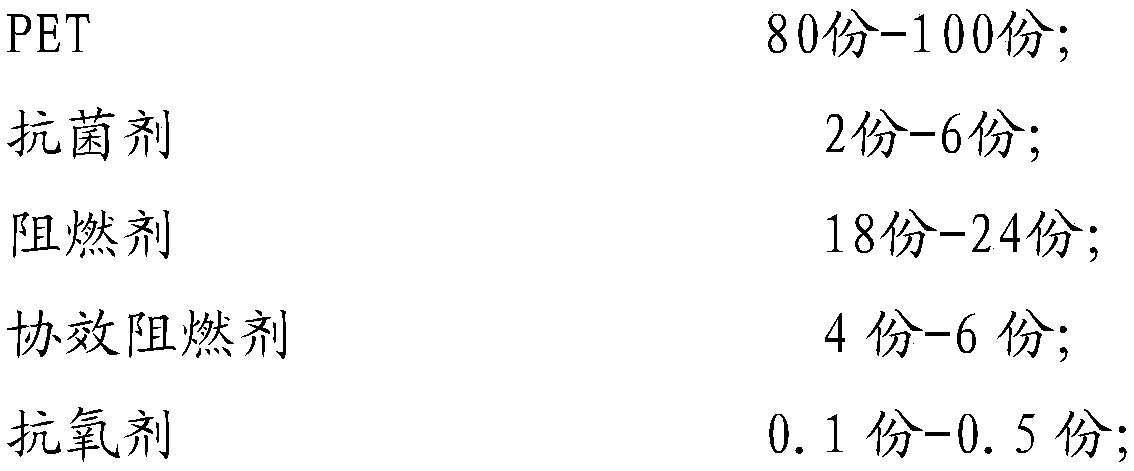

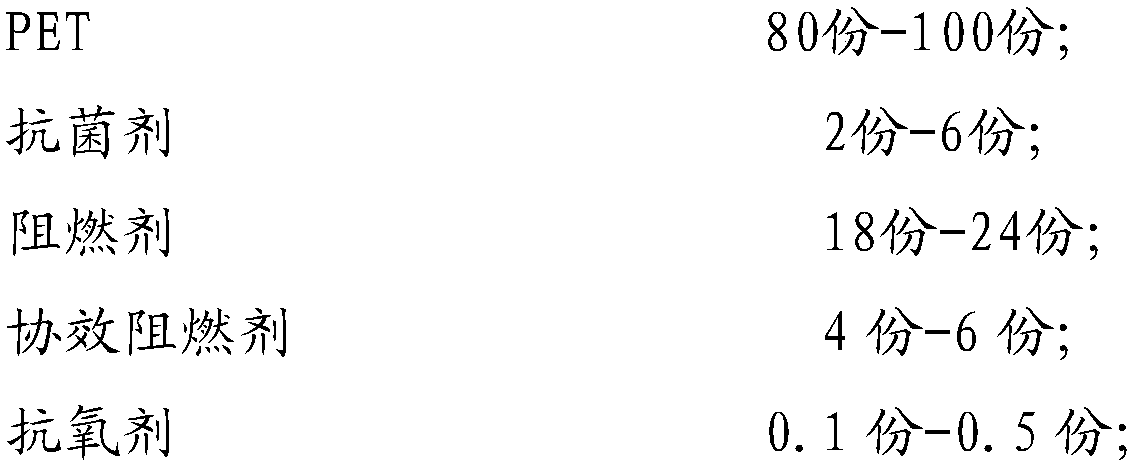

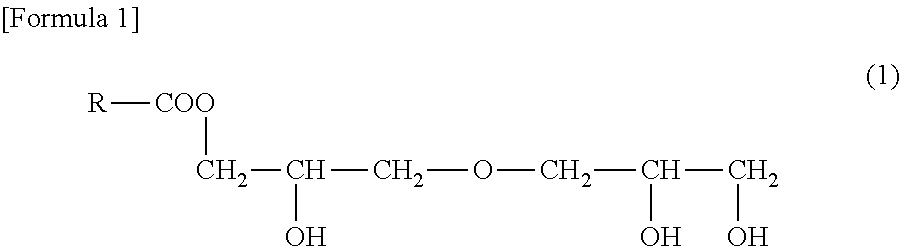

Antibacterial flame-retardant PET composite material and preparation method thereof

InactiveCN109294176AImprove antimicrobial propertiesImprove flame retardant propertiesFire retardantNano tio2

The invention relates to an antibacterial flame-retardant PET composite material and a preparation method thereof. The material consists of the following components in parts by weight: 80 parts-100 parts of PET; 2 parts-6 parts of an antibacterial agent; 18 parts-24 parts of a flame retardant; 4 parts-6 parts of a synergistic flame retardant; and 0.1 parts-0.5 parts of an anti-oxidant; wherein theantibacterial agent is a copper-loaded kaolin antibacterial agent. The technical scheme firstly uses a mixture of nano TiO2 and zinc hydroxystannate as the synergistic flame retardant, which improvesthe flame retardant performance of the PET composite material; The PET composite material prepared by the technical scheme has excellent flame retardant performance and antibacterial property, and makes up for the deficiency of the existing products, and has great popularization value.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

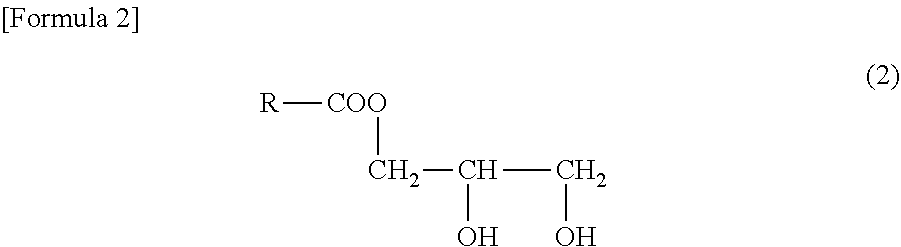

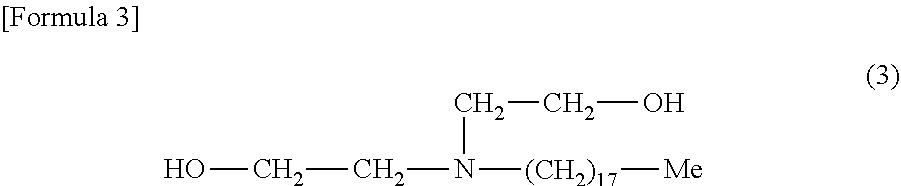

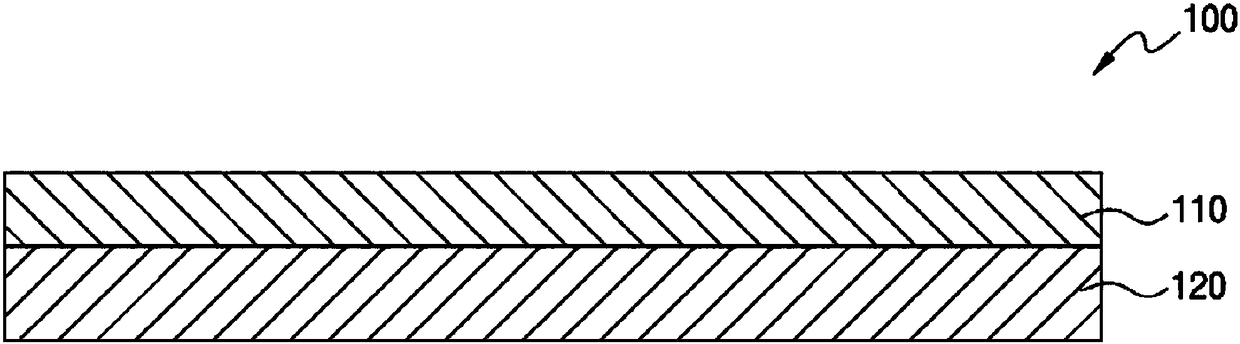

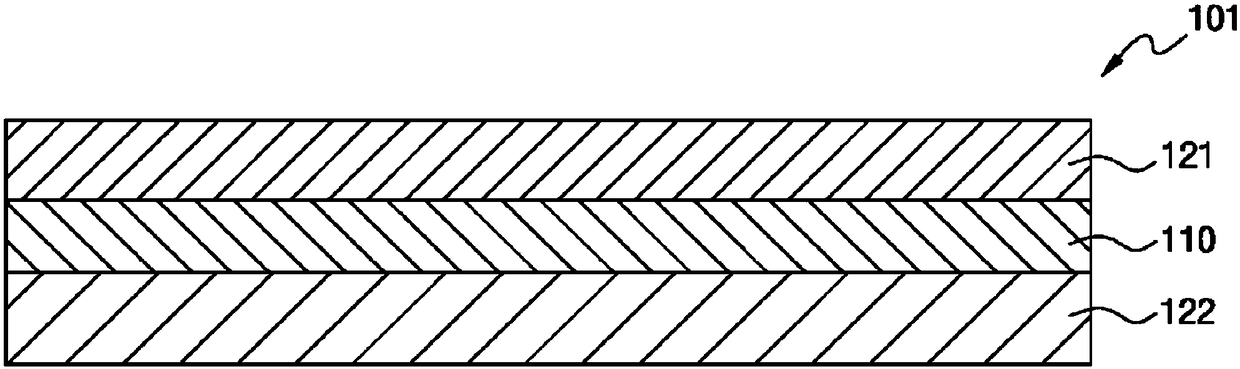

Freshness-retentive film

PendingUS20210120812A1Improve antimicrobial propertiesBiocideFruit and vegetables preservationPolymer scienceGlycerol

Owner:MITSUI CHEM TOHCELLO INC

Dry-type pad

ActiveCN108135861AReduce the amount of antimicrobial substancesReduce painNon-adhesive dressingsPeptide/protein ingredientsFiberPolymer science

The present invention relates to a dry-type pad comprising: a wound membrane which is made by accumulating fibers containing a hydrophobic polymer, a hydrophilic polymer that swells by means of an exudate secreting from a wound, and a dry-type wound healing agent that is released by means of the swelling of the hydrophilic polymer and is difficult to store in a liquid phase; and a first release member which is a support on which the fibers are accumulated, and is separable from the wound membrane.

Owner:AMOLIFESCI CO LTD

Adsorptive membrane

InactiveCN107666952AImprove adsorption efficiencyGuaranteed liquidityMembranesSemi-permeable membranesAdsorptive membranePhysical chemistry

The present invention relates to an adsorptive membrane characterized by comprising: a support member provided with a plurality of first pores; and a first adsorptive member which is laid on the support member, has a plurality of second pores, and is formed by accumulating ion-exchange nanofibers for adsorbing foreign substances.

Owner:AMOGREENTECH CO LTD

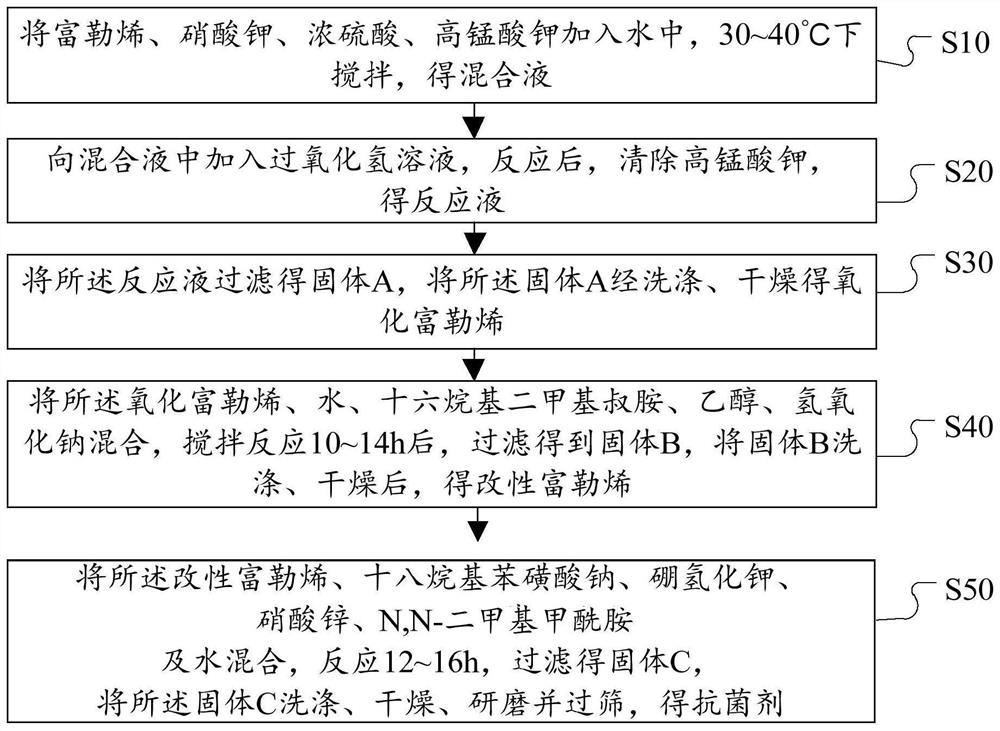

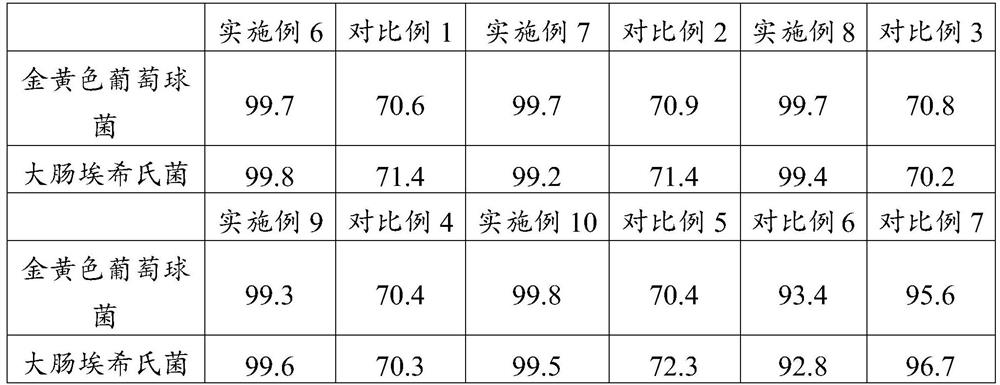

Preparation method of antibacterial agent, thermoplastic resin composite material and preparation method thereof

ActiveCN113519552AImprove antimicrobial propertiesGood antibacterial propertiesBiocideDisinfectantsComposite materialPotassium manganate

The invention discloses a preparation method of an antibacterial agent, a thermoplastic resin composite material and a preparation method thereof, and relates to the technical field of high polymer materials. The preparation method of the antibacterial agent comprises the following steps: adding fullerene, potassium nitrate, concentrated sulfuric acid and potassium permanganate into water, and stirring at 30-40 DEG C to obtain a mixed solution; adding a hydrogen peroxide solution into the mixed solution, reacting, and removing potassium permanganate to obtain a reaction solution; filtering the reaction liquid to obtain a solid A, and washing and drying the solid A to obtain fullerene oxide; mixing fullerene oxide, water, hexadecyl dimethyl tertiary amine, ethanol and sodium hydroxide, stirring and reacting for 10-14 hours, filtering to obtain a solid B, and washing and drying the solid B to obtain modified fullerene; and mixing the modified fullerene, sodium octadecyl benzene sulfonate, potassium borohydride, zinc nitrate, N, N-dimethylformamide and water, reacting for 12-16 hours, filtering to obtain a solid C, and washing, drying, grinding and sieving the solid C to obtain the antibacterial agent. The antibacterial agent prepared by the method can obviously improve the antibacterial effect.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Anti-bacterial luminous low-temperature ceramic ink for ink jet and preparation method thereof

The invention discloses an anti-bacterial luminous low-temperature ceramic ink for ink jet and a preparation method thereof. The preparation method comprises the following steps: A, mixing and grinding 25-38% of pigment, 0.5-5% of anti-bacterial compound, 1-5% of luminous compound, and 15-20% of drier of low-temperature frit; B, weighing 3-8% of a dispersant, 2-5% of a surface additive, 0.1-0.3% of a flatting agent, 0.3-0.8% of an antifoaming agent, 0.5-1% of a binding agent, and 0.08-0.1% of an anti-settling agent, adding a solvent into a homogenizer to disperse and grind, filtering, and obtaining an ink finished product. Compared with the current low-temperature ceramic ink, the manufactured low-temperature ceramic ink has the characteristics of scientific ingredients, and the low-temperature frit without the extremely toxic substances, such as lead and cadmium, is used so that the ceramic ink can guarantee the color development performance while the ceramic ink is fired in the low temperature. The luminous compound and anti-bacterial compound are rationally matched for the synergistic effect, so the ceramic ink also has the durable spectral anti-bacterial character, the pollution-preventing and self-cleaning functions and the luminous character, the application range of the low-temperature ceramic ink is further widened.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

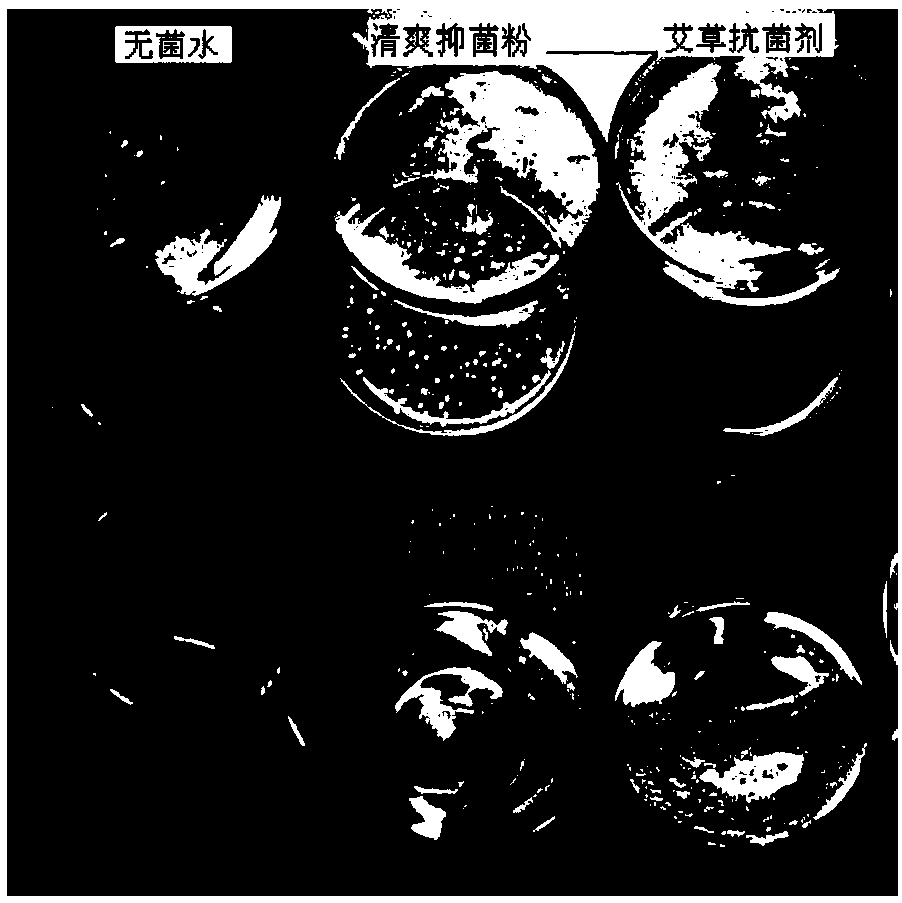

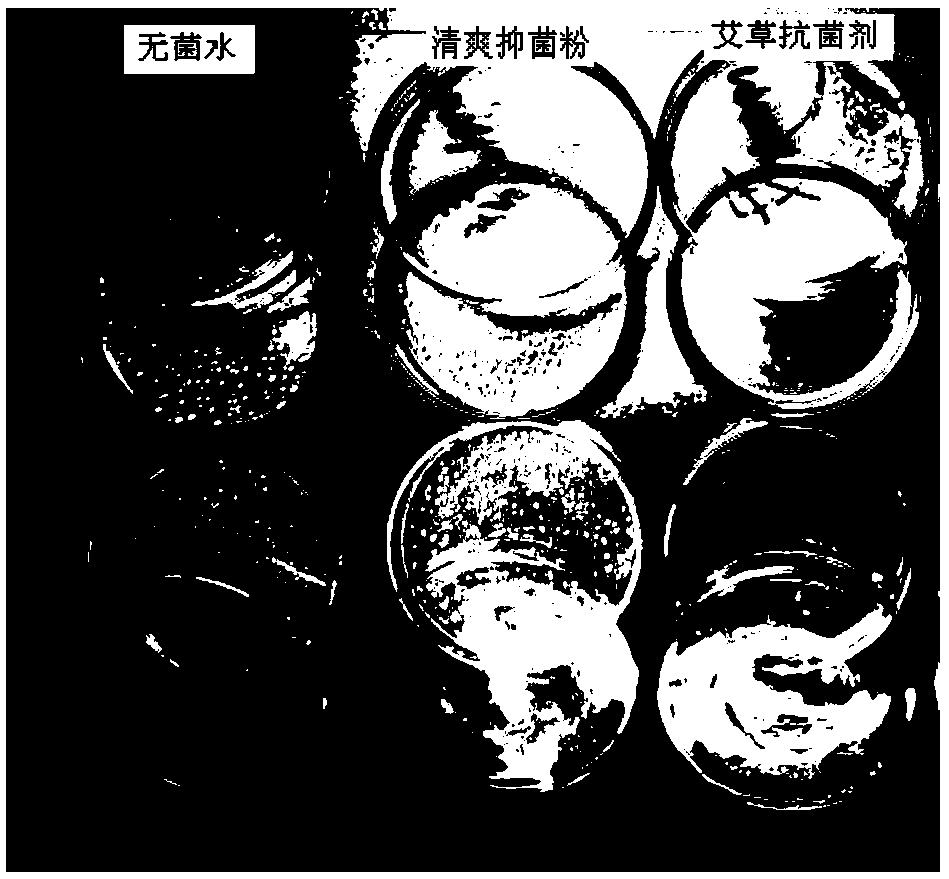

Wormwood antibacterial agent and preparation method thereof

The invention discloses a wormwood antibacterial agent and a preparation method thereof. The preparation method of the wormwood antibacterial agent includes the steps: pretreating wormwoods to obtainwormwood extracts; heating, mixing and cooling the wormwood extracts and salicylic acid; adding boric acid and benzoic acid, mixing, stirring, standing and sub-packaging the materials to obtain the wormwood antibacterial agent. The preparation method of the wormwood antibacterial agent is simple, low in cost, free from irritation and toxic and side effects, suitable for large-scale production andwide in application prospect. The wormwood antibacterial agent is free from any toxic and harmful chemical components, toxic and side effects, chemical residues and any toxicity, low in cost, non-irritating to human bodies and good in stability, can be used and preserved for a long time, has high antibacterial properties and also has sterilization and bacteriostasis functions.

Owner:湖南省健缘医疗科技有限公司

Preparation process of camel milk soap

InactiveCN112029597AGood effectWith sterilizationSoap detergents with organic compounding agentsBioreactor/fermenter combinationsBiotechnologyGlycerol

The invention discloses a preparation process of camel milk soap, and relates to the technical field of cleaning products. The preparation process of the camel milk soap, which comprises the followingsteps: carrying out filtration and pasteurization on newly collected camel milk, adding pepsase in an environment with a pH value of 1-2 to hydrolyze for 6-8 hours, then adding trypsin in an environment with a pH value of 1-2 to hydrolyze for 6-8 hours, putting into a special stirring device, then adding glycerol and sodium hydroxide, adding the mixed grease into a stirring device, adding the superfine powder of the mirabilitum praeparatum and the essence of the mirabilitum praeparatum, and continuously stirring to carry out saponification reaction, so as to obtain a pasty saponification solution; and adding the saponification liquid into a mold, performing standing for 2-3 days, demolding, and drying to obtain the camel milk soap. The camel milk soap prepared by the preparation process of the camel milk soap has good effects of sterilization, acarus killing, virus resistance and the like, is small in irritation, and can effectively prevent wound infection; the camel milk soap provided by the invention is simple in preparation process and strong in operability, and the steps supplement each other.

Owner:内蒙古沙漠之神生物科技有限公司

A method of making a filter material

ActiveCN111974088BImprove antibacterial propertiesImprove antioxidant capacityDispersed particle filtrationBiochemical fibre treatmentPolymer sciencePyrrolidinones

The invention relates to a method for making a filter material. First, ferulic acid-chitosan graft copolymer, polycaprolactone and polypropylene are melt-blended at a mass ratio of 1-5:1-10:70-90 , adopting melt-blowing technology to obtain a non-woven fabric layer; secondly, using polyvinylpyrrolidone and ammonium persulfate solution to carry out surface modification treatment on the obtained non-woven fabric layer, and loading silver-loaded nano-titanium dioxide powder on the surface of the non-woven fabric layer; Then prepare a polytetrafluoroethylene microporous membrane with a thickness no more than 1mm, and heat-compress the polytetrafluoroethylene microporous membrane with the non-woven fabric layer obtained in step 2 to obtain a composite filter layer; corona is performed on the obtained composite filter layer process, storing a charge density of 3 x 10 ‑4 ~5.7×10 ‑3 C / m 2 ; Finally, the waterproof non-woven fabric layer and the spunlace non-woven fabric layer are respectively composited on both sides of the obtained composite filter layer. The filter material of the present application has good filtering effect, good air permeability, and the fiber has good chemical stability, thermal stability, hydrophilicity and antibacterial property.

Owner:GUANGZHOU TRACE ELEMENTS BIOLOGICAL TECH CO LTD

Antibacterial wormwood compound as well as preparation method and application thereof

InactiveCN109430297AImprove antibacterial propertiesHigh sterilization rateBiocideFungicidesBenzoic acidSalicylic acid

The invention discloses an antibacterial wormwood compound as well as a preparation method and application thereof. The antibacterial wormwood compound is prepared from the following components by weight: 150 to 350 g of wormwoods, 500 to 3,000 g of salicylic acid, 500 to 2,000 g of boric acid and 500 to 2,000 g of benzene formic acid. The antibacterial wormwood compound disclosed by the invention, which is prepared from the wormwoods, the salicylic acid, the boric acid and the benzoic acid, has a remarkable antibacterial effect, high bactericidal rate and good inhibitory effect on common bacteria, yeasts and molds. The wormwoods have better bactericidal and bacteriostatic effects, synergistically sterilize with the salicylic acid, the boric acid and the benzoic acid to enhance the killingeffect, and also prevent occurrence of some common diseases in life. The antibacterial wormwood compound does not contain any toxic and harmful chemical components, has no toxic and side effects andno chemical residues, has low cost and no toxicity, is not irritating to a human body and can be used for a long time; furthermore, the antibacterial wormwood compound has good stability, is still relatively high in antibacterial property after being stored for a long time and has dual effects of sterilization and bacteriostasis.

Owner:湖南省健缘医疗科技有限公司

Anionic waterborne UV light curing ceramic ink-jet ink and preparation method thereof

The invention discloses anionic waterborne UV light curing ceramic ink-jet ink and a preparation method thereof. The preparation method comprises the following steps that 1, 20%-30% of waterborne acrylate, 1%-20 % of a solvent and 0.5%-3% of an ink auxiliary are fully mixed, 20%-38% of ceramic pigments are added while the mixture is stirred, dispersing is conducted, 10%-20% of waterborne epoxy acrylate and 0.1%-5% of an anionic complex are added, the materials are mixed to be uniform, 0%-5% of an antibacterial complex is added, and the materials are mixed to be uniform to obtain a mixed material; 2, the mixed material is ground and dispersed till the fineness reaches to be smaller than 1 micrometer; 3, 0.5%-4% of a waterborne photoinitiator is added, and after the materials are dispersed to be uniform, the finished product is obtained. Compared with existing light curing ceramic ink-jet ink, the ink prepared through the method is scientific in material proportioning, reasonable in preparation, stable in performance and free of poison and irritation, has a durable antibacterial property, an antifouling self-cleaning function and an air purification property through the synergistic effect of the anionic complex and an antibacterial composite material and widens the application range of the light curing ceramic ink-jet ink.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

Manufacturing method of antibacterial deodorizing polyester fiber

ActiveCN102965760BWashableLong-lasting antibacterial and deodorant functionFilament/thread formingConjugated synthetic polymer artificial filamentsPolyethylene terephthalate glycolAntibacterial agent

Owner:RONGSHENG PETROCHEM

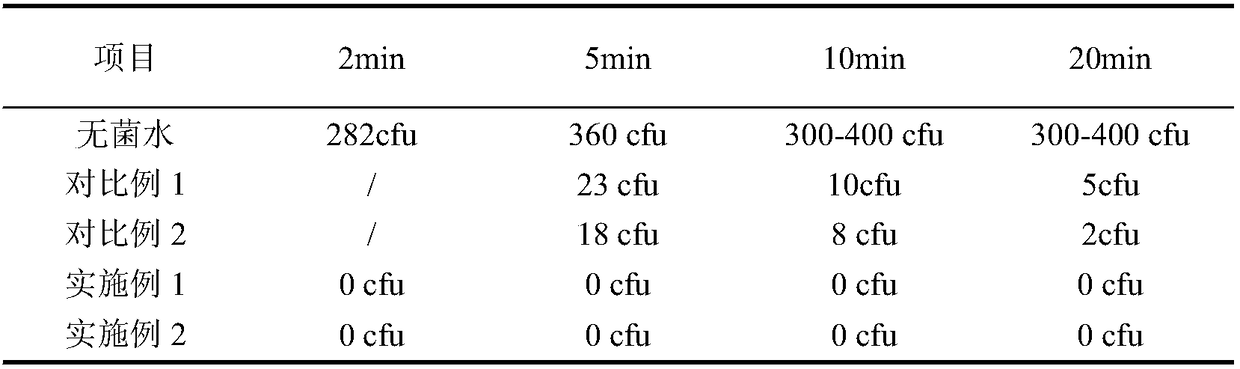

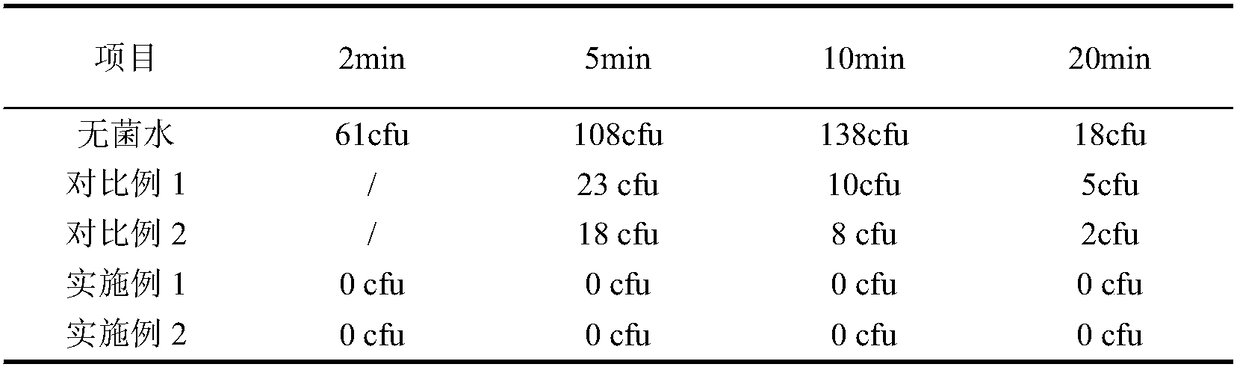

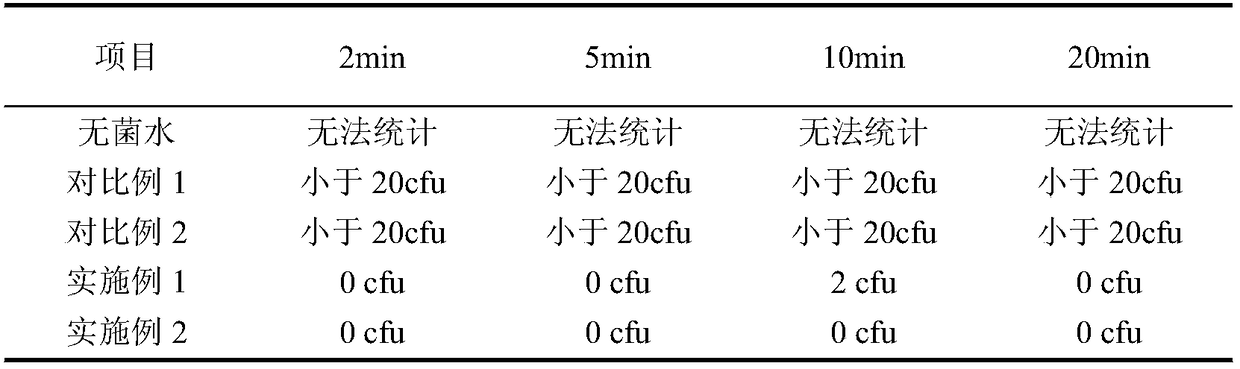

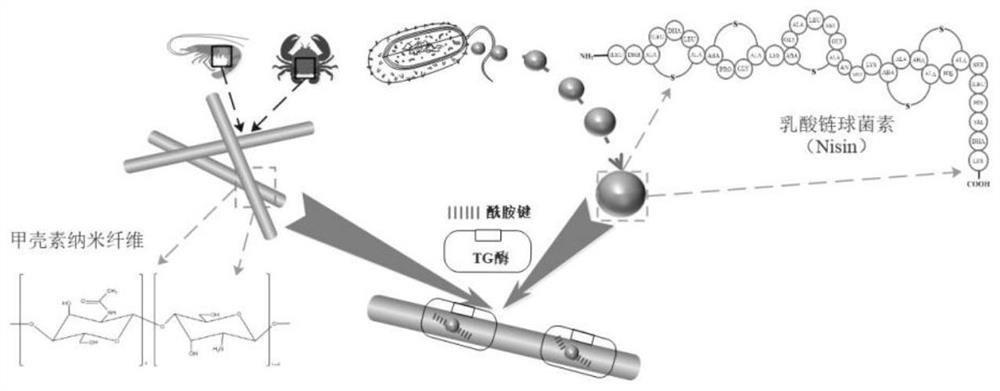

Chitin nanofiber/Nisin composite preservative based on transglutaminase induced crosslinking and preparation method

PendingCN112544686ASafeDegradableClimate change adaptationBiochemical treatment with enzymes/microorganismsPolymer scienceBinding site

The invention provides a chitin nanofiber / Nisin composite preservative based on transglutaminase induced crosslinking and a preparation method of the chitin nanofiber / Nisin composite preservative. Thepreparation method comprises the following steps of S1, preparing chitin nanofibers; and S2, adding Nisin and transglutaminase into a chitin nanofiber solution dissolved in acetic acid, and carryingout stirring, water bath oscillation and pH value adjustment, so as to finally obtain the chitin nanofiber / Nisin composite preservative based on transglutaminase induced cross-linking. According to the preparation method, the transglutaminase is used for inducing the chitin nanofibers and the Nisin to be crosslinked to form a stable covalent bond, so that the stability of the Nisin is improved; and besides, due to the high surface volume ratio of the chitin nanofibers, more binding sites can be provided for carrying out nano adsorption on the Nisin, and synergistic antibiosis is carried out byutilizing the film-forming property and the antibacterial activity of nanoscale chitin and the antibacterial property of the Nisin, so that breeding and reproduction of most microorganisms are inhibited. Experimental results show that the preservative prepared by the invention has excellent antibacterial and bacteriostatic ability, and can greatly prolong the preservation time of seafood.

Owner:FUJIAN AGRI & FORESTRY UNIV

A kind of preparation method of fish gelatin antibacterial film

The invention discloses a method for preparing a fish gelatin antibacterial film, which is characterized in that it comprises the following steps: (1) preparing a fish gelatin-γ-polyglutamic acid mixed solution, the fish gelatin-γ-polyglutamic acid mixed solution It is a mixed solution of fish gelatin and γ-polyglutamic acid; (2) adding evening primrose oil, tea tree essential oil, sodium starch octenyl succinate, glycerin to the mixed solution of fish gelatin-γ-polyglutamic acid and sorbitol to prepare a fish gelatin antibacterial film solution; (3) carry out ultrasonic degassing treatment to the fish gelatin antibacterial film solution, dry and sterilize after degassing to obtain the fish gelatin antibacterial film. The invention can effectively improve the melting temperature of the fish gelatin antibacterial film, improve the process of replacing the mammalian gelatin antibacterial film with the fish gelatin antibacterial film, improve the antibacterial properties of the fish gelatin antibacterial film at the same time, and overcome the traditional antibacterial agent in the prior art by adding the fish gelatin antibacterial film Insufficient antimicrobial properties.

Owner:JIANGXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com