Preparation process of camel milk soap

A preparation process, camel milk technology, applied in synthetic soap composition, soap detergent composition, alkali soap/ammonium soap composition, etc., can solve the problems that camel milk antibacterial protein is difficult to function, antibacterial protein is difficult to function, etc. to prevent wound infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

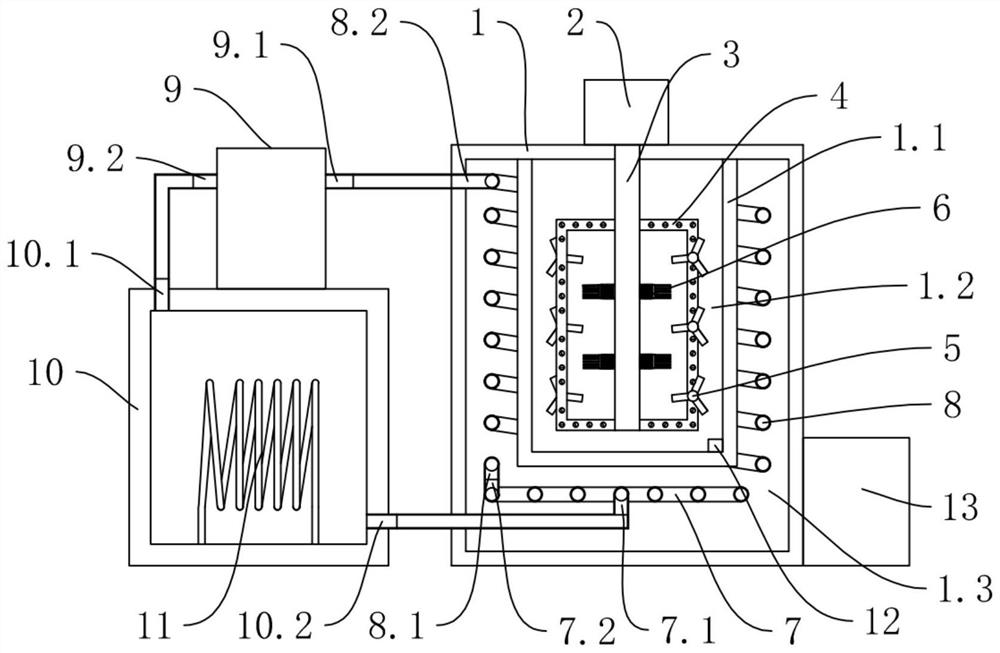

[0057] The preparation process of camel milk soap in this embodiment: (1) filter the newly collected camel milk, then pasteurize it, and then keep stirring until the camel milk returns to room temperature; add to the camel milk obtained in step (1) 10% hydrochloric acid solution, adjust the pH to be 1.5, then add pepsin, and the mass ratio of camel milk and pepsin is 1000:1, stir for 6.5h, and keep the pH at 1.5 during the stirring process; Add 10% sodium hydroxide solution to the camel milk, adjust the pH to 8, then add trypsin, and the mass ratio of camel milk to trypsin is 1000:0.8, stir for 6 hours, keep the pH at 8 during the stirring process, and then again Filtration; (4) Mix the camel milk and glycerin obtained in step (3) according to the weight ratio of 2:1 to obtain the mixed solution I, and add the mixed solution I and sodium hydroxide into the above stirring device according to the weight ratio of 3:1 , stirred at a speed of 400r / min for 7min to obtain the mixed l...

Embodiment 2

[0059] The preparation process of camel milk soap in this embodiment: (1) filter the newly collected camel milk, then pasteurize it, and then keep stirring until the camel milk returns to room temperature; Add 10% hydrochloric acid solution to the milk to adjust the pH to 2, then add pepsin, and the mass ratio of camel milk to pepsin is 1000:0.8, stir for 7 hours, and keep the pH at 2 during the stirring process; (3) to step (2) Add 10% sodium hydroxide solution to the obtained camel milk to adjust the pH to 7.5, then add trypsin, and the mass ratio of camel milk to trypsin is 1000:0.7, stir for 6 hours, and keep the pH during the stirring process 7.5, and then filter again; (4) Mix the camel milk and glycerin obtained in step (3) according to the weight ratio of 2:1 to obtain the mixed solution I, and mix the mixed solution I and sodium hydroxide according to the weight ratio of 3.5:1 Add it into the stirring device, and stir for 6 minutes at a speed of 500r / min to obtain the...

Embodiment 3

[0061] The preparation process of camel milk soap in this embodiment: (1) filter the newly collected camel milk, then pasteurize it, and then keep stirring until the camel milk returns to room temperature; Add 10% hydrochloric acid solution to the milk to adjust the pH to 1.5, then add pepsin, and the mass ratio of camel milk to pepsin is 1000:1, stir for 7.5h, and keep the pH at 1.5 during the stirring process; (3) Add 10% sodium hydroxide solution to the camel milk obtained in step (2), adjust the pH to 8, then add trypsin, and the mass ratio of camel milk and trypsin is 1000:0.6, stir for 6h, and keep pH is 7, and then filtered again; (4) Mix the camel milk and glycerin obtained in step (3) according to the weight ratio of 2:1 to obtain the mixed solution I, and mix the mixed solution I and sodium hydroxide according to the weight ratio of 2.5:1 Add the ratio to the stirring device, and stir at a speed of 300-600r / min for 5-10 minutes to obtain the mixed liquid II; (5) Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com