Preparation method of antibacterial agent, thermoplastic resin composite material and preparation method thereof

A technology of thermoplastic resin and composite material, which is applied in the preparation of antibacterial agent, thermoplastic resin composite material and its preparation field, can solve the problems such as poor antibacterial effect, achieve good antibacterial performance and improve antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

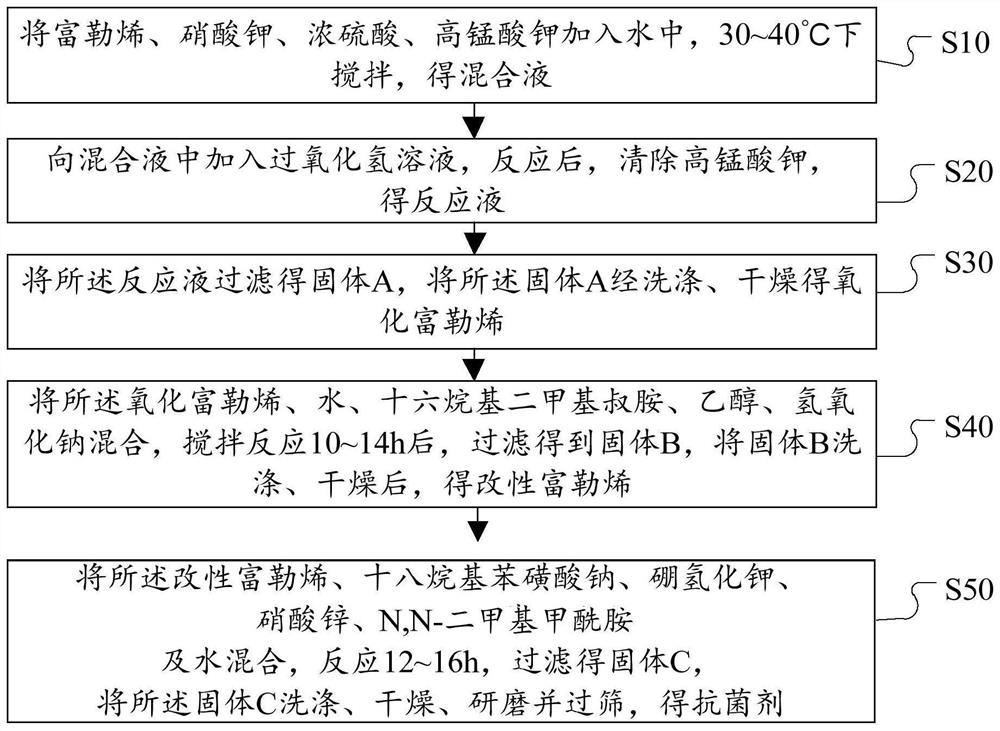

[0033] see figure 1 , the preparation method of the antibacterial agent that the present invention proposes, comprises the following steps:

[0034] S10. Add fullerene, potassium nitrate, concentrated sulfuric acid, and potassium permanganate into water, and stir at 30-40° C. to obtain a mixed solution.

[0035] In this step, concentrated sulfuric acid and potassium permanganate are used as oxidants to oxidize and modify the surface of fullerene, potassium nitrate combines with hydrogen ions in the solution to form nitric acid to enhance the oxidation effect, and water is used as a dispersion medium to provide a solution for the reaction The environment is conducive to the carrying out of the reaction. The water is preferably deionized water, which can effectively prevent the impact of impurity ions in the water on the reaction.

[0036] The proportioning of fullerene, potassium nitrate, concentrated sulfuric acid, potassium permanganate is not limited in the present inventio...

Embodiment 1

[0072] (1) Add 400g fullerene, 100g potassium nitrate, 1000g concentrated sulfuric acid and 60g potassium permanganate into 1600g water, stir at 30°C for 6h to obtain a mixed solution;

[0073] (2) Add hydrogen peroxide solution to the mixed solution, after the reaction, remove potassium permanganate to obtain a reaction solution, filter the reaction solution to obtain solid A, wash the solid A, and dry at 40°C for 6 hours to obtain fullerene oxide;

[0074] (3) Mix 300g fullerene oxide, 1800g water, 2g hexadecyl dimethyl tertiary amine, 100g ethanol, and 60g sodium hydroxide, stir and react for 10h, filter to obtain solid B, wash solid B, and heat at 70°C Dry for 10 hours to obtain modified fullerene;

[0075] (4) Mix 400g modified fullerene, 1g sodium octadecylbenzenesulfonate, 6g potassium borohydride, 200g zinc nitrate, 60g N,N-dimethylformamide and 2000g water, react for 12h, and filter to obtain Solid C, the solid C was washed, dried at 70°C for 10 hours, ground and pa...

Embodiment 2

[0077] (1) Add 500g fullerene, 120g potassium nitrate, 1200g concentrated sulfuric acid and 80g potassium permanganate into 2000g water, stir at 40°C for 8h to obtain a mixed solution;

[0078] (2) Add hydrogen peroxide solution to the mixed solution, after the reaction, remove potassium permanganate to obtain a reaction solution, filter the reaction solution to obtain solid A, wash the solid A, and dry at 60°C for 8 hours to obtain fullerene oxide;

[0079] (3) Mix 400g fullerene oxide, 2400g water, 4g hexadecyl dimethyl tertiary amine, 180g ethanol, and 80g sodium hydroxide, stir and react for 14 hours, filter to obtain solid B, wash solid B, and heat at 90°C Dry for 12 hours to obtain modified fullerene;

[0080] (4) Mix 500g modified fullerene, 3g sodium octadecylbenzenesulfonate, 8g potassium borohydride, 300g zinc nitrate, 100g N,N-dimethylformamide and 2400g water, react for 16h, and filter to obtain Solid C, the solid C was washed, dried at 90°C for 12 hours, ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com