Adsorptive membrane

A technology of adsorption film and pores, applied in the field of adsorption film, can solve the problems of large filter size, large pores of non-woven fabrics, inability to filter harmful dust, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, specific contents for implementing the present invention will be described with reference to the drawings.

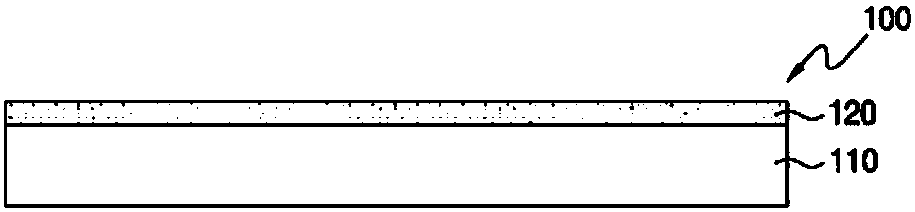

[0044] refer to figure 1 , The adsorption film 100 of the first embodiment of the present invention is characterized in that it includes: a support member 110 having a plurality of first pores; and an adsorption member 120 stacked on the support member 110 and having a plurality of second pores formed by Ion-exchange nanofibers for absorbing foreign matter are stacked.

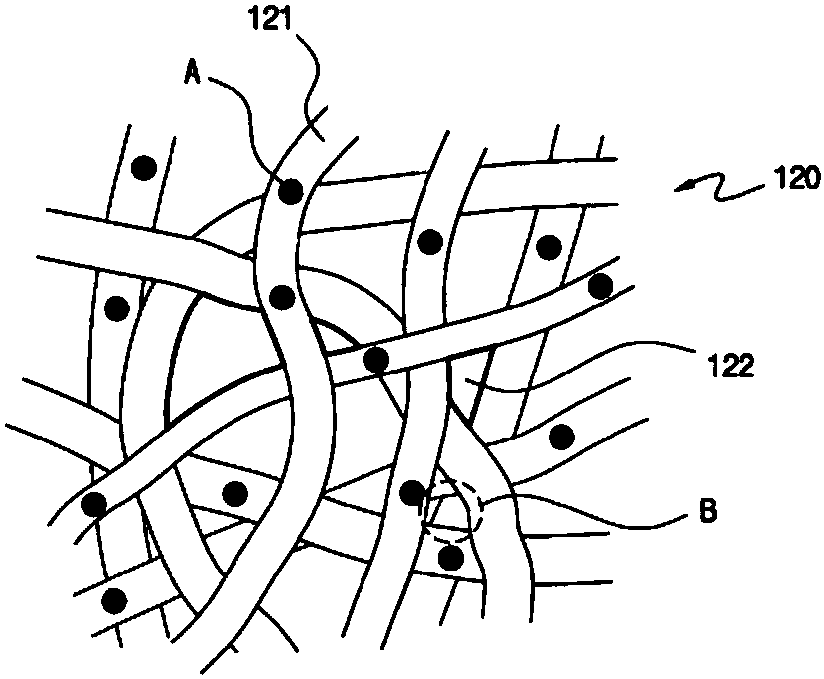

[0045] In this adsorption membrane 100, the ion-exchange nanofibers of the adsorption member 120 adsorb and filter ionic foreign matter, and the foreign matter (dust, Dust, granules, particles, etc.) are physically filtered to improve the removal efficiency of foreign matter.

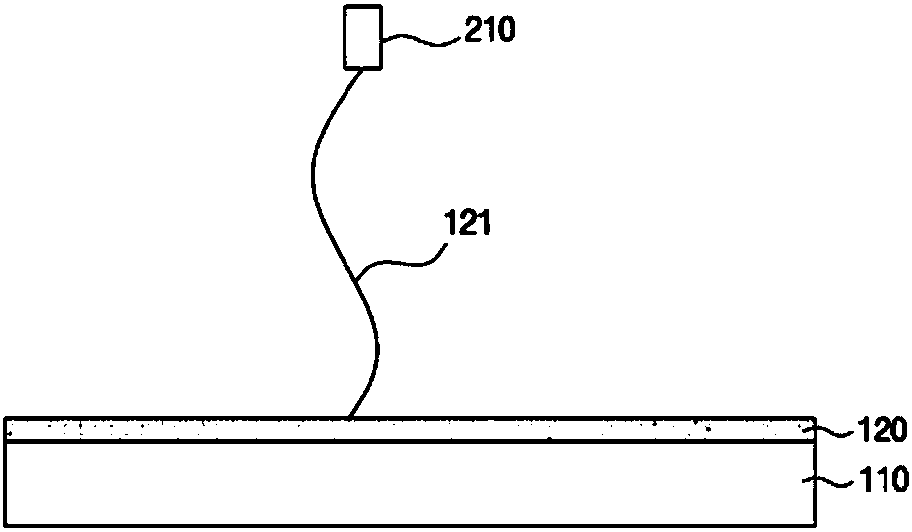

[0046] That is, if figure 2 As shown, when the gas or liquid passes through the adsorption membrane 100, the ion-exchange nanofibers 121 of the adsorption member 120 adsorb the ionic foreign matter A conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com