Environment-friendly polyurethane antibiosis adhesive and preparation method thereof

A polyurethane and antibacterial adhesive technology, applied in the direction of adhesive additives, non-polymer adhesive additives, etc., can solve problems such as few reports, and achieve the effects of improving antibacterial properties, broadening application fields, and superior bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

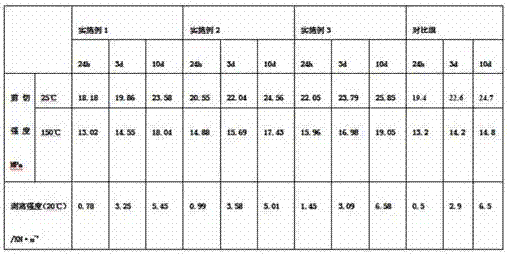

Examples

Embodiment 1

[0035] Embodiment 1: environment-friendly polyurethane antibacterial adhesive, made of the following raw materials by weight: 12 parts of hexamethylene diisocyanate, 1.3 parts of antibacterial zeolite, 1.3 parts of tetrahydrofuran-ethylene oxide copolyethylene glycol, diphthalate 12 parts of butyl ester, 0.15 parts of dibutyltin dilaurate, 1.25 parts of polyoxyethylene polyoxypropanol amine ether, 0.15 parts of p-toluenesulfonyl isocyanate, 0.15 parts of γ-glycidyl etheroxypropyl trimethoxysilane, trimethoxysilane Glycol bis-[3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate] 0.2 parts.

[0036] Concrete preparation steps are:

[0037] 1) Weigh tetrahydrofuran-ethylene oxide copolyethylene glycol according to the weight ratio and put it into the reaction kettle, stir and heat to 80-100°C, vacuumize and dehydrate for 3-4 hours;

[0038] 2) Add polyoxyethylene polyoxypropanol amine ether to tetrahydrofuran-ethylene oxide copolymer glycol that has been dehydrated and cooled to...

Embodiment 2

[0042] Embodiment 2: environment-friendly polyurethane antibacterial adhesive, made of the following raw materials by weight: 25 parts of hexamethylene diisocyanate, 3.6 parts of antibacterial zeolite, 3.5 parts of tetrahydrofuran-ethylene oxide copolyethylene glycol, diphthalate 8 parts of butyl ester, 0.11 part of dibutyltin dilaurate, 0.6 part of polyoxyethylene polyoxypropanolamine ether, 0.14 part of p-toluenesulfonyl isocyanate, 0.18 part of γ-glycidyl etheroxypropyl trimethoxysilane, 0.14 parts of triethylene glycol bis-[3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate].

[0043] Concrete preparation steps are:

[0044] 1) Weigh tetrahydrofuran-ethylene oxide copolyethylene glycol according to the weight ratio and put it into the reaction kettle, stir and heat to 80-100°C, vacuumize and dehydrate for 3-4 hours;

[0045] 2) Add polyoxyethylene polyoxypropanol amine ether to tetrahydrofuran-ethylene oxide copolymer glycol that has been dehydrated and cooled to room te...

Embodiment 3

[0049] Embodiment 3: An environment-friendly polyurethane antibacterial adhesive, made of the following raw materials in parts by weight: 18 parts of hexamethylene diisocyanate, 2.5 parts of antibacterial zeolite, 1.5 parts of tetrahydrofuran-ethylene oxide copolyethylene glycol, phthalate 8 parts of dibutyl formate, 0.12 parts of dibutyltin dilaurate, 1.6 parts of polyoxyethylene polyoxypropanolamine ether, 1.4 parts of p-toluenesulfonyl isocyanate, 0.13 parts of γ-glycidyl etheroxypropyl trimethoxysilane Parts, triethylene glycol bis-[3-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate] 0.16 parts.

[0050] Concrete preparation steps are:

[0051] 1) Weigh tetrahydrofuran-ethylene oxide copolyethylene glycol according to the weight ratio and put it into the reaction kettle, stir and heat to 80-100°C, vacuumize and dehydrate for 3-4 hours;

[0052] 2) Add polyoxyethylene polyoxypropanol amine ether to tetrahydrofuran-ethylene oxide copolymer glycol that has been dehydrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com