Amphiphilic fluorine-containing block copolymer antibacterial material and preparation method thereof

A technology of block copolymers and antibacterial materials, which is applied in the field of amphiphilic fluorine-containing block copolymer antibacterial materials and its preparation, and can solve the problems of being unable to be directly immobilized, unable to form non-eluting antibacterial materials, and limited application range, etc. problems, to achieve the effect of sterilization and inhibition of bacterial reproduction, reproducible antibacterial properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

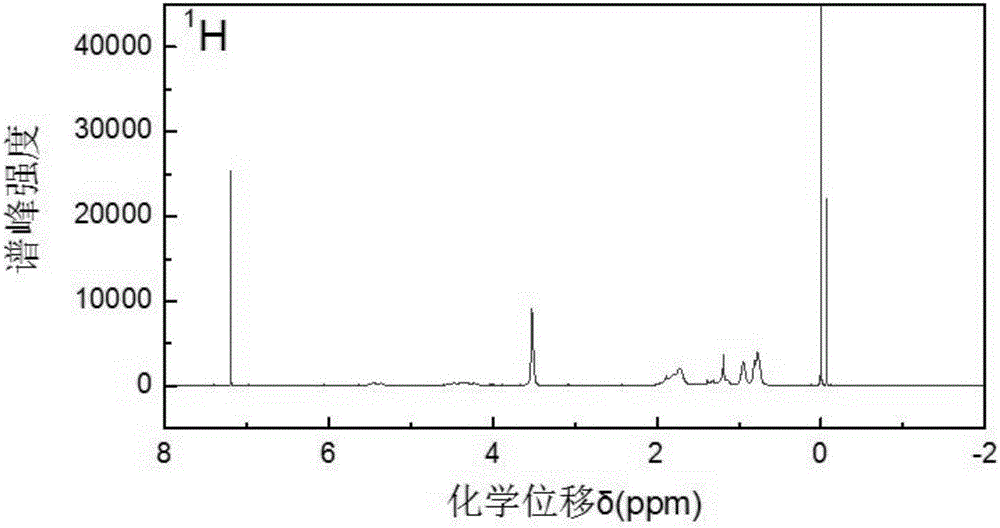

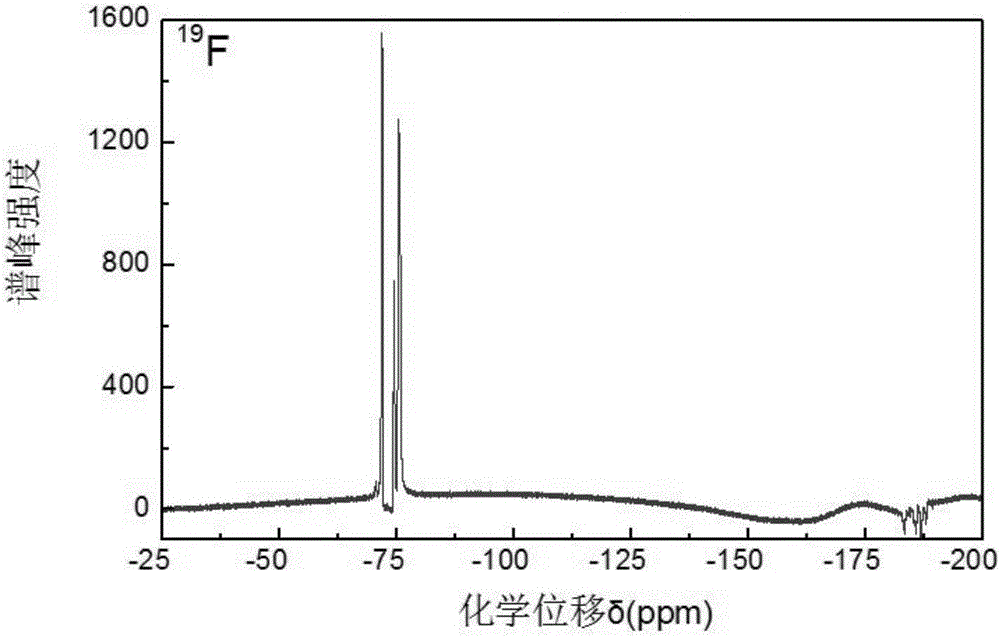

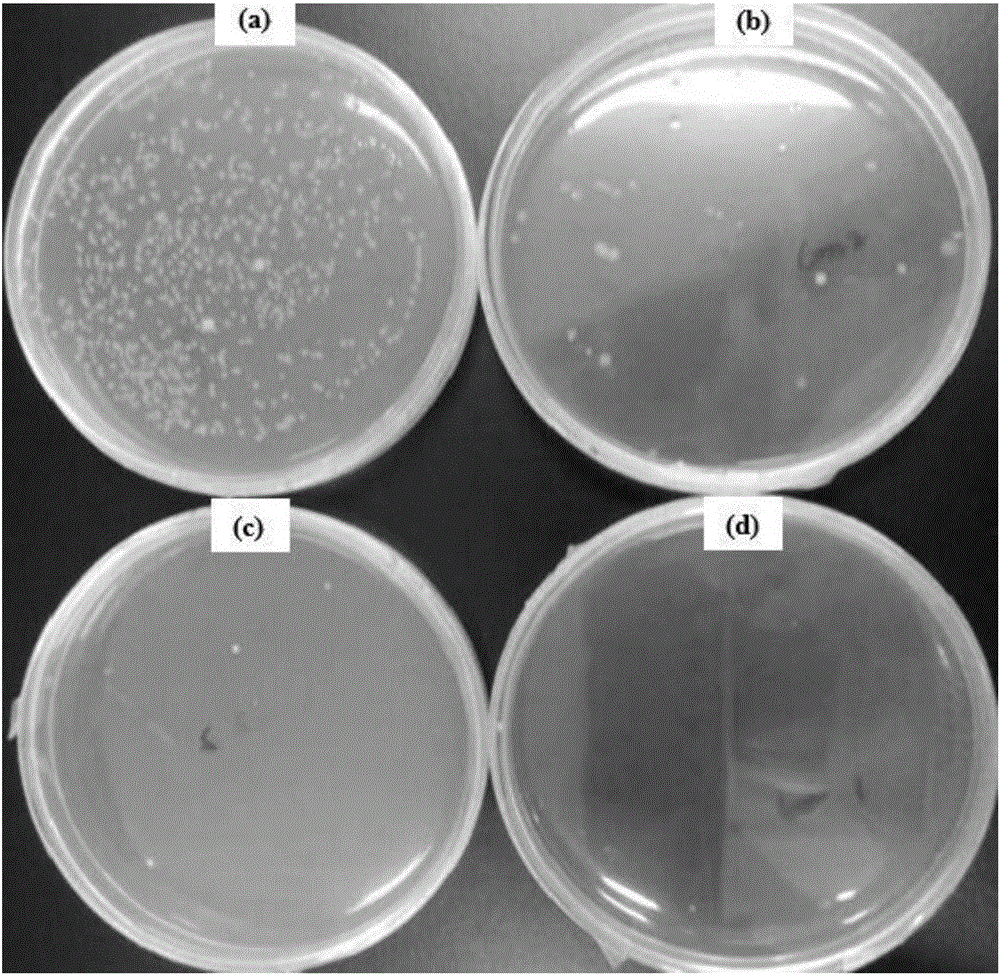

Examples

preparation example Construction

[0039] The preparation method of the amphiphilic fluorine-containing block copolymer antibacterial material corresponding to the above general formula comprises the following steps:

[0040] 1) Add fluorine-containing acrylate monomer, catalyst, initiator and solvent I into the polymerization bottle, remove oxygen, pass in protective gas, fully react, purify and dry, and obtain product A;

[0041] 2) Add product A, acrylate monomer, catalyst and solvent I into the polymerization bottle, deoxygenate, pass through protective gas, fully react, purify and dry, and obtain product B;

[0042] 3) Add product B, glycidyl methacrylate, catalyst and solvent I into the polymerization bottle, deoxygenate, pass through protective gas, fully react, purify and dry, and obtain product C;

[0043] 4) Add product C, 5,5-dimethylhydantoin, basic catalyst and solvent II into the polymerization bottle, fully react, put the product into an active halogen solution after purification, soak it, then w...

Embodiment 1

[0064] 1) After mixing 18.9mmol hexafluorobutyl methacrylate and 10ml cyclohexanone, blow nitrogen to exhaust oxygen; add 0.1mmol cuprous chloride, 0.3mmol bipyridine and 10ml cyclohexanone into the polymerization bottle, seal And evacuated, filled with nitrogen three times; then inject the hexafluorobutyl methacrylate monomer solution with a syringe, and add 0.1mmol initiator α-ethyl bromopropionate, freeze in liquid nitrogen-thaw-vacuumize three times, and finally pass Protected by nitrogen gas, heated to 80° C. under 300 rpm magnetic stirring, reacted for 8 hours, and cooled to room temperature in an ice-salt bath to terminate the reaction. The product was dissolved in tetrahydrofuran, neutral alumina was passed through the column to remove impurities, and precipitated in a mixed solvent of methanol / water (1:1, v / v), and the precipitate was vacuum-dried at 40°C to constant weight;

[0065] 2) Add the product of step 1), 94.3mmol butyl methacrylate, 0.78mmol cuprous chloride...

Embodiment 2

[0069] 1) After mixing 5mmol dodecafluoroheptyl methacrylate with 10ml toluene, blow nitrogen to exhaust oxygen; add 0.05mmol cuprous chloride, 0.15mmol pentamethyldiethylenetriamine and 10ml toluene to the polymerization bottle , sealed and evacuated, and filled with nitrogen three times; then inject the dodecafluoroheptyl methacrylate monomer solution with a syringe, and add 0.05mmol initiator α-bromoisobutyrate ethyl ester, liquid nitrogen freezing-thawing-vacuumizing Three times, finally pass nitrogen protection, heat to 100°C under 400rpm magnetic stirring, react for 8 hours, and cool to room temperature in an ice-salt bath to terminate the reaction. The product was dissolved in tetrahydrofuran, neutral alumina was passed through the column to remove impurities, and precipitated in a mixed solvent of methanol / water (1:1, v / v), and the precipitate was vacuum-dried at 40°C to constant weight;

[0070] 2) Add the product of step 1), 94.3mmol ethyl methacrylate, 0.5mmol cupro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com