High-stability and broad-spectrum antibacterial PMMAASA alloy material based on molecular online self-assembly technology and preparation method thereof

A self-assembly technology and high-stability technology, applied in the field of polymer materials, can solve the problems of poor broad-spectrum of inorganic antibacterial agents, lack of antibacterial properties of materials, poor antibacterial stability, etc., to achieve apparent viscosity reduction, Increased impact strength, long-lasting and stable effect

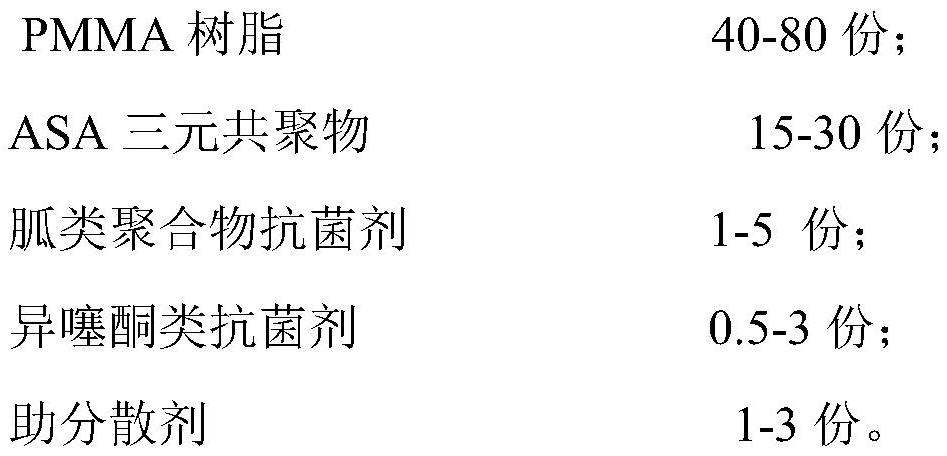

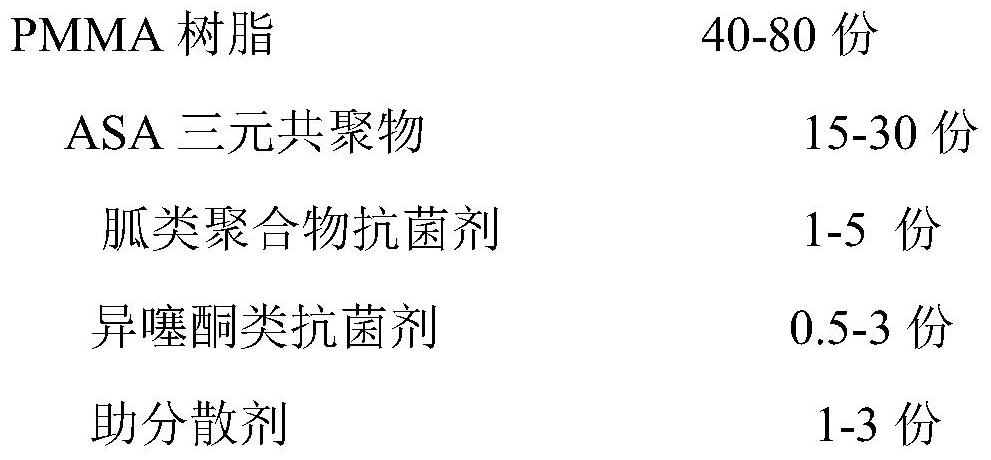

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

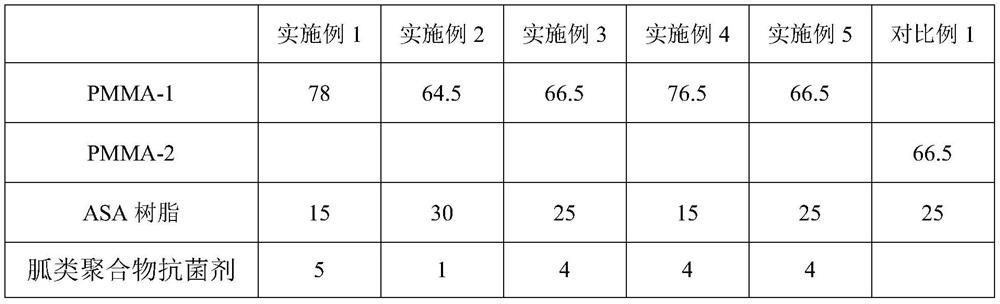

Embodiment 1

[0037] Take by weighing ASA terpolymer, guanidine polymer antibacterial agent by the data of embodiment 1 shown in table 1 and mix homogeneously, obtain mixed raw material A; Take PMMA resin, auxiliary dispersant by described weight fraction, mix homogeneously , to obtain mixed raw material B.

[0038] The mixed raw material A is fully dried, and then placed in the main feeding bin of a closely meshing co-rotating twin-screw extruder, and fed into the barrel of the extruder through the feeding screw, and the isothilones antibacterial agent The aqueous solution is delivered to the barrel of the extruder through the feeding hole of the second section of the barrel through the high-precision liquid metering pump; the diameter of the twin-screw extruder used is 35mm, the length-to-diameter ratio L / D is 56, and the main barrel is fed from The temperature settings of each zone from the mouth to the outlet of the machine head are: 160°C, 200°C, 210°C, 215°C, 220°C, 220°C, 220°C, 220°...

Embodiment 2

[0041] Take by weighing ASA terpolymer, guanidine polymer antibacterial agent by the data of embodiment 2 shown in table 1 and mix homogeneously, obtain mixed raw material A; Take PMMA resin, auxiliary dispersant by described weight, mix homogeneously , to obtain mixed raw material B.

[0042] The mixed raw material A is fully dried, and then placed in the main feeding bin of a closely meshing co-rotating twin-screw extruder, and fed into the barrel of the extruder through the feeding screw, and the isothilones antibacterial agent The aqueous solution is delivered to the barrel of the extruder through the feeding hole of the second section of the barrel through the high-precision liquid metering pump; the diameter of the twin-screw extruder used is 35mm, the length-to-diameter ratio L / D is 56, and the main barrel is fed from The temperature settings of each zone from the mouth to the outlet of the machine head are: 160°C, 200°C, 210°C, 215°C, 220°C, 220°C, 220°C, 220°C, 220°C,...

Embodiment 3

[0048] Take by weighing ASA terpolymer, guanidine polymer antibacterial agent by the data of embodiment 3 shown in table 1 and mix homogeneously, obtain mixed raw material A; Take by weighing PMMA resin, co-dispersant by described weight, mix homogeneously , to obtain mixed raw material B.

[0049] The mixed raw material A is fully dried, and then placed in the main feeding bin of a closely meshing co-rotating twin-screw extruder, and fed into the barrel of the extruder through the feeding screw, and the isothilones antibacterial agent The aqueous solution is delivered to the barrel of the extruder through the feeding hole of the second section of the barrel through the high-precision liquid metering pump; the diameter of the twin-screw extruder used is 35mm, the length-to-diameter ratio L / D is 56, and the main barrel is fed from The temperature settings of each zone from the mouth to the outlet of the machine head are: 160°C, 200°C, 210°C, 215°C, 220°C, 220°C, 220°C, 220°C, 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com