Method for preparing antibacterial mould-proof zeolite-based humidity controlling material

An antibacterial, mildew-proof and wet material technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of building damage, health hazards, and mildew of humidity-conditioning materials, and achieve the improvement of antibacterial performance and moisture absorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

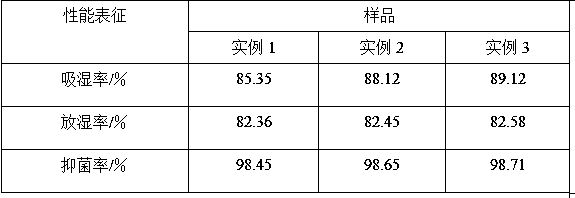

example 1

[0021] Wash the rattan vine, vacuum freeze-dry, grind and disperse, collect the dispersed particles and mix the dispersed particles with a mass fraction of 5% ethanol solution at a mass ratio of 1:10, collect the mixed solution and place it under reflux at 55°C for 3 hours , collect the reflux solution and place it at 45°C for rotary evaporation to 1 / 10 of the original volume, obtain the extract solution and adjust the pH to 3.5 with 1% hydrochloric acid in mass fractions, collect the modified solution and convert the modified solution according to the mass ratio of 1:10. The liquid and petroleum ether were mixed and extracted for 3 times, the extract was collected and the volume ratio was 1:5, the extract was stirred and mixed with n-butanol for 3 times, the n-butanol was recovered by distillation under reduced pressure and the dry matter was collected, ground and pulverized to obtain Modified powder; then weigh 45 parts of deionized water, 10 parts of acrylic acid, 0.5 parts ...

example 2

[0023] Wash the rattan vine, vacuum freeze-dry, grind and disperse, collect the dispersed particles and mix the dispersed particles with a mass fraction of 5% ethanol solution at a mass ratio of 1:10, collect the mixed solution and place it under reflux at 57°C for 4 hours , collect the reflux liquid and place it at 47°C for rotary evaporation to 1 / 10 of the original volume, obtain the extract and adjust the pH to 3.5 with 1% hydrochloric acid in mass fractions, collect the modified liquid and convert the modified liquid to a mass ratio of 1:10 Liquid and petroleum ether were mixed and extracted 4 times, the extract was collected and the volume ratio was 1:5, the extract was stirred and mixed with n-butanol and extracted 4 times, n-butanol was recovered by vacuum distillation and the dry matter was collected, ground and pulverized to obtain a modified 4 parts of deionized water, 12 parts of acrylic acid, 0.7 parts of N,N'-methylenebisacrylamide, 4 parts of lignin and 0.2 parts ...

example 3

[0025]Wash the white hair rattan, vacuum freeze-dry, grind and disperse, collect the dispersed particles and mix the dispersed particles with a mass fraction of 5% ethanol solution at a mass ratio of 1:10, collect the mixed solution and heat to reflux at 65°C for 5h , collect the reflux liquid and place it at 50°C for rotary evaporation to 1 / 10 of the original volume, obtain the extract and adjust the pH to 3.5 with 1% hydrochloric acid in mass fractions, collect the modified liquid and convert the modified liquid to a mass ratio of 1:10. The liquid and petroleum ether were mixed and extracted 5 times, the extract was collected and the volume ratio was 1:5, the extract was stirred and mixed with n-butanol for 5 times, the n-butanol was recovered by distillation under reduced pressure and the dry matter was collected, ground and pulverized to obtain Modified powder; then weigh 50 parts of deionized water, 15 parts of acrylic acid, 1.0 parts of N,N'-methylenebisacrylamide, 5 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com