Manufacturing method for novel filter material

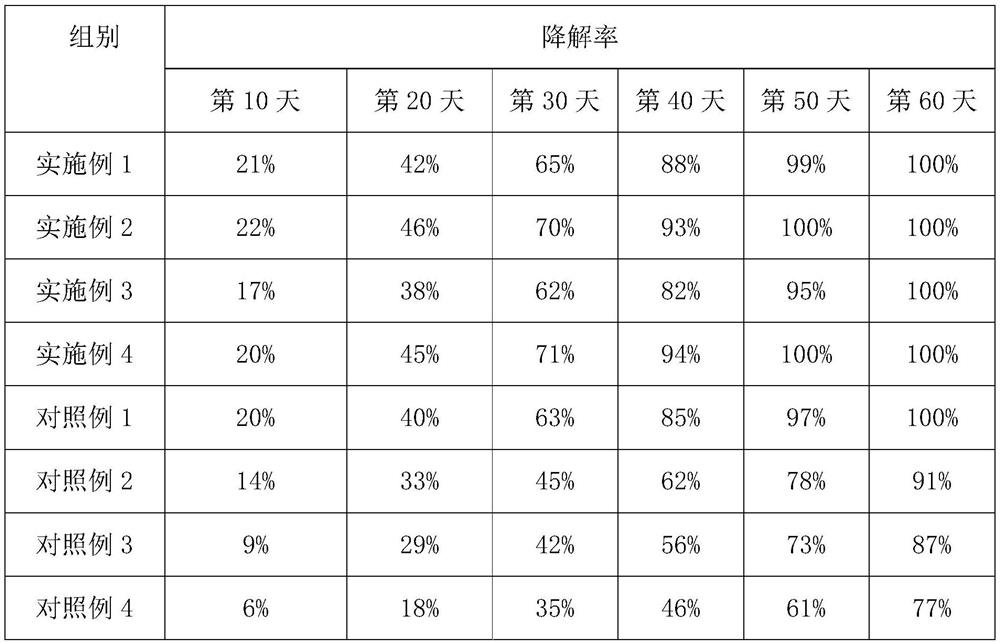

A production method and filter material technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of inability to effectively replenish fine particles, unstable antibacterial effect, low air permeability, etc., and achieve good organic high polymer Biocompatibility, good for environmental protection, and good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation steps of ferulic acid-chitosan graft copolymer comprise:

[0030] Step A: Dissolve chitosan powder in citric acid-sodium citrate buffer solution with a pH value of 5.5, add 80mL of 30% hydrogen peroxide solution, and react at 65°C for 90min to obtain chitosan with a chitosan concentration of 100mmol solution; when the chitosan solution is cooled to room temperature, add 10mL of ferulic acid-dissolved methanol solution and laccase in sequence, stir evenly to obtain a mixed solution, the concentration of ferulic acid in the mixed solution is 10mmol, and the density of laccase is 3.0U / mL;

[0031] Step B: Introduce oxygen into the mixed solution, and the oxygen flow rate is 35L / min. After the mixed solution is reacted for 2.5 hours, dialyze with a molecular weight 14000 dialysis membrane for 72 hours to remove unreacted ferulic acid, and use methanol, The chitosan-ferulic acid graft copolymer was obtained after thorough rinsing with ethanol and water, and ...

Embodiment 1

[0040] A method for making a novel filter material, specifically comprising the following steps:

[0041] Step 1: Melt and blend ferulic acid-chitosan graft copolymer, polycaprolactone and polypropylene at a mass ratio of 5:10:85, and use melt-blown technology to obtain a non-woven fabric layer, a non-woven fabric The fiber diameter of the layer is 135-142nm, the air permeability is 0.6m / s, and the thickness is 1mm;

[0042] Step 2: Add silver-loaded nano-titanium dioxide powder with a particle size of 10 to 15 nm into 500 parts by weight of deionized water to prepare silver-loaded nano-TiO with a concentration of 0.5 mg / mL 2 Dispersion liquid, then add 50 parts of polyvinylpyrrolidone and 1 part of ammonium persulfate, use ultrasonic dispersion method to fully mix, and spray evenly on both sides of the surface of the non-woven fabric layer by XKD-AS600 spraying machine, the spraying pressure is 0.05 Mpa, spray volume 0.05ml / cm2;

[0043] Step 3: Prepare and prepare polytetr...

Embodiment 2

[0047] A method for making a novel filter material, specifically comprising the following steps:

[0048] Step 1: Melt and blend ferulic acid-chitosan graft copolymer, menthol essential oil, polycaprolactone and polypropylene at a mass ratio of 5:1:9:85, and use melt-blowing technology to obtain a nonwoven For the cloth layer, the fiber diameter of the non-woven fabric layer is 137-151nm, the air permeability is 0.6m / s, and the thickness is 1mm;

[0049] Step 2: Add silver-loaded nano-titanium dioxide powder with a particle size of 10 to 15 nm into 500 parts by weight of deionized water to prepare silver-loaded nano-TiO with a concentration of 0.5 mg / mL 2 Dispersion liquid, then add 50 parts of polyvinylpyrrolidone and 1 part of ammonium persulfate, use ultrasonic dispersion method to fully mix, and spray evenly on both sides of the surface of the non-woven fabric layer by XKD-AS600 spraying machine, the spraying pressure is 0.05 Mpa, spray volume 0.05ml / cm2;

[0050] Step 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com