Towing device for vehicle, method of manufacturing towing hook for vehicle, and method of manufacturing connection member for vehicle

A technology for traction devices and connecting components, which is applied in the direction of vehicle components, traction connectors, connecting components, etc., can solve problems such as unusable, easy to loose, and different installation positions, so as to eliminate the increase in size and weight, prevent looseness, and ensure safety Effects on Sex and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

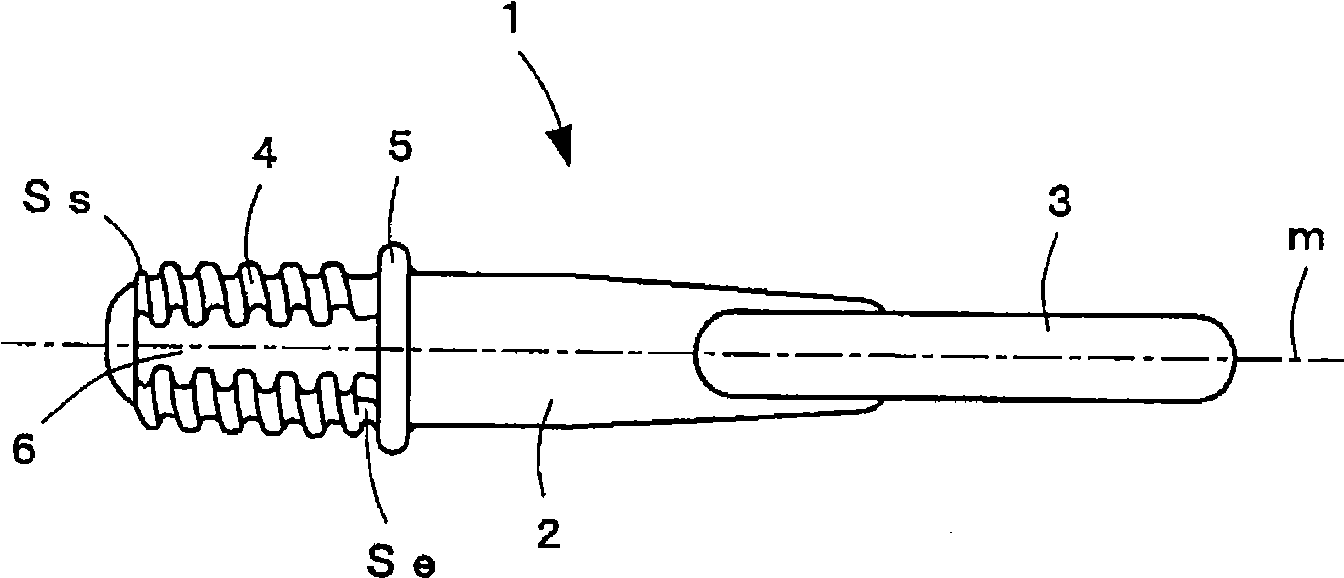

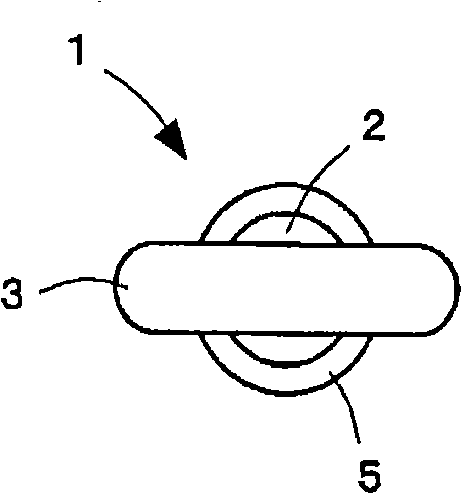

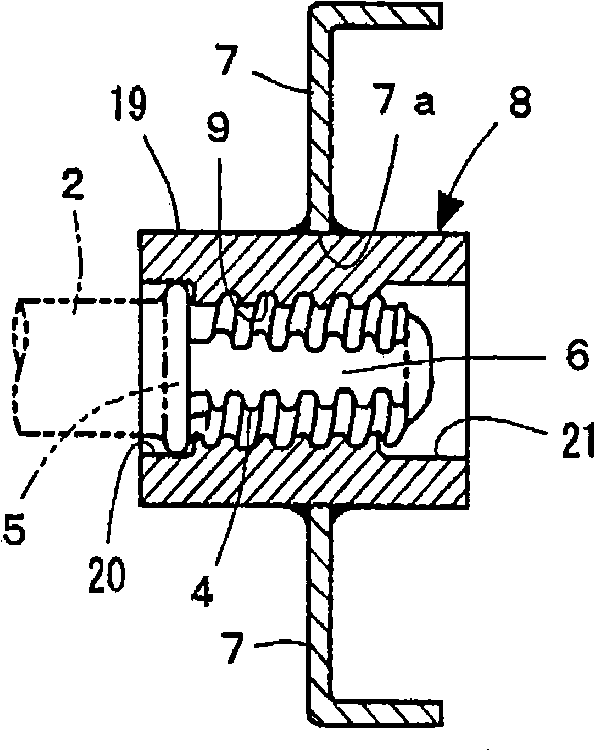

[0130] Hereinafter, when the illustrated embodiment of the present invention applied to a tow hook for automobiles is described, Figure 1 to Figure 15 The reference number 1 in is a towing hook manufactured by forging, which can be installed on the vehicle body frame described later around the shock absorber of the automobile (illustration omitted), and is provided with: a round bar-shaped shaft portion 2; One end portion of the shaft portion 2 can be hooked with an annular hook portion 3 such as a wire cable W as a traction member; A right-handed external thread portion 4 of the connection member; and a flange portion 5 protruding from the boundary between the shaft portion 2 and the external thread portion 4 .

[0131] In the figure, 6 is the side cutting part formed on both sides of the external thread part 4, which is formed along the direction perpendicular to the plane of the hook part 3, so this part 6 follows the draft angle when the external thread part 4 is not proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com