Moisture paper tissue holding container and bag binding mechanism for moisture paper tissue holding container

A technology for storage containers and wet wipes, which is applied in the field of wet tissue storage containers and their packaging structures, can solve the problems of deformation of the formed body, turbulent flow of resin, and reduced air tightness of the wet tissue storage container, so as to improve the air tightness. , Improve the effect of configuration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Next, specific embodiments of the present invention will be described with reference to the drawings. However, the scope of the present invention is not limited by the illustrated examples.

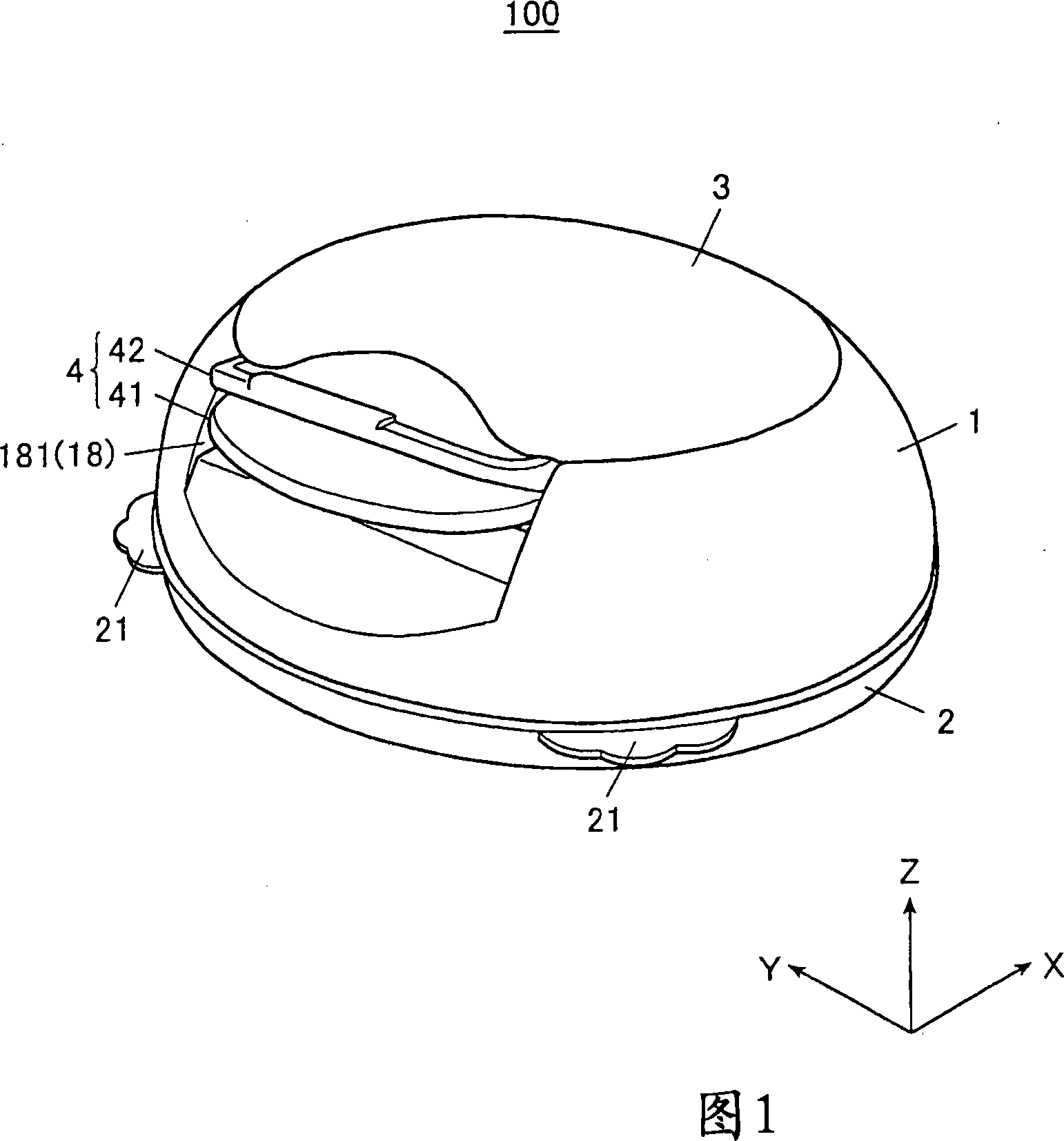

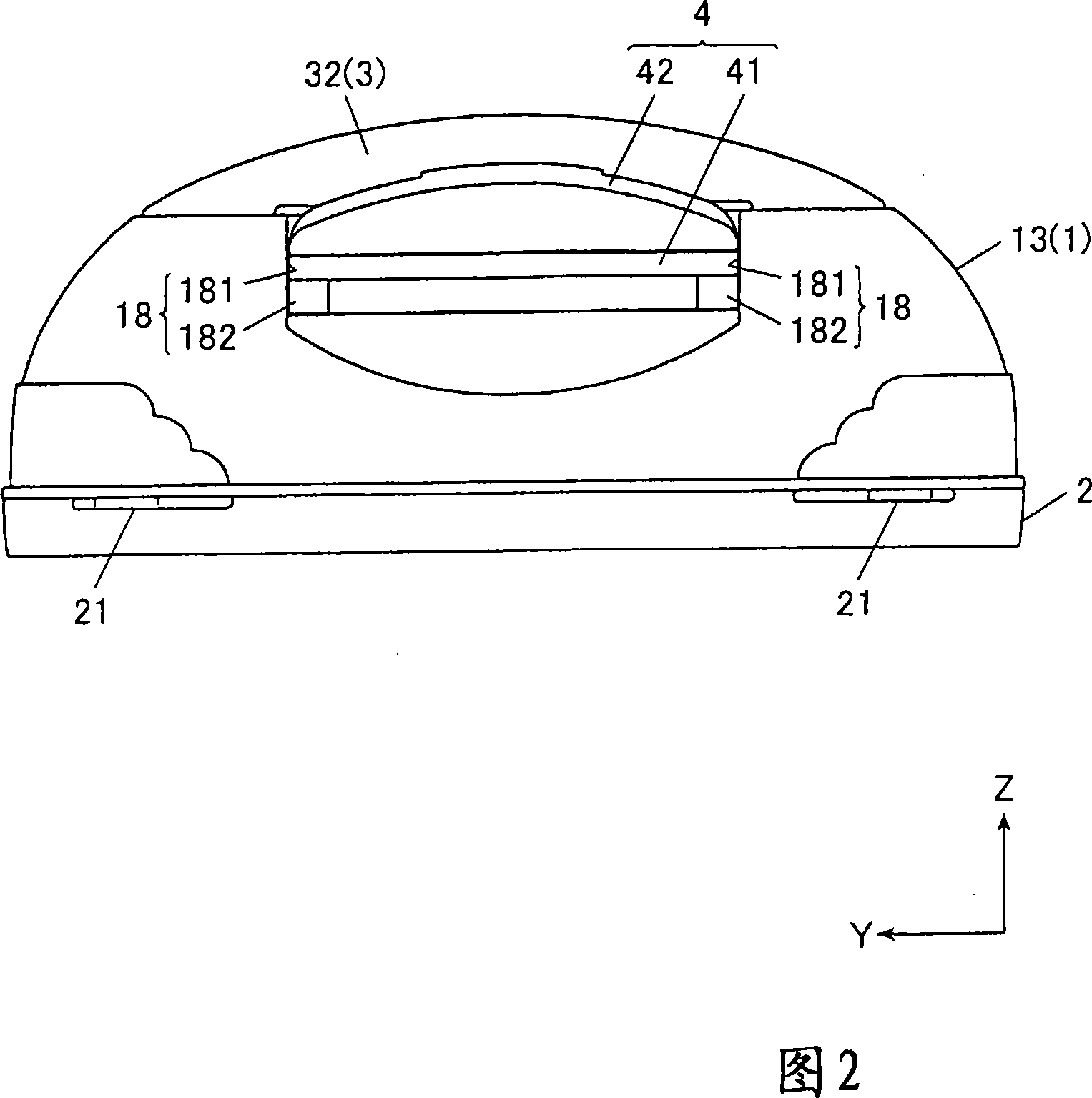

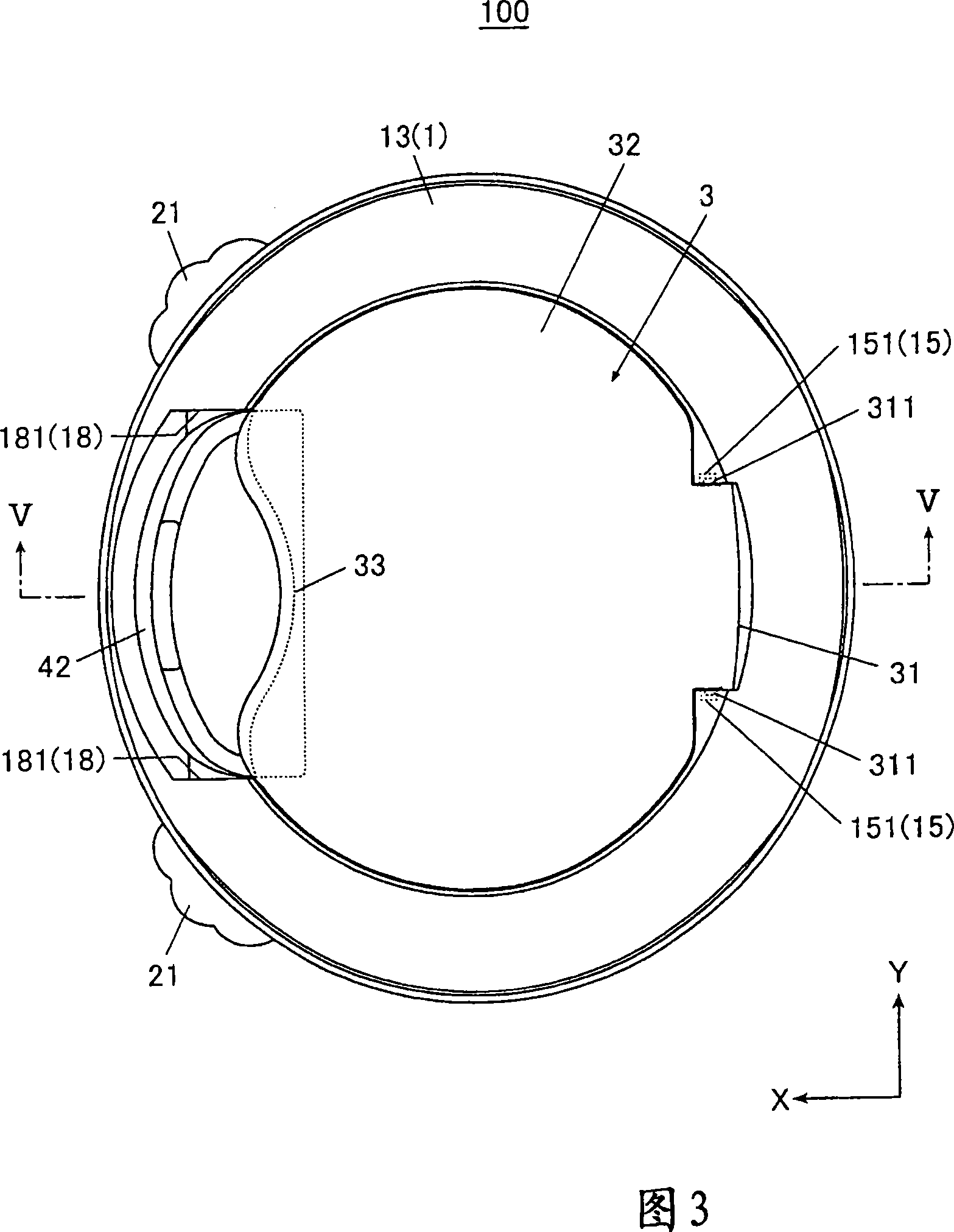

[0061] Fig. 1 is a perspective view of a wet tissue storage container 100 shown as an example of an embodiment to which the present invention is applied. FIG. 2 is a front view showing the wet tissue storage container 100 . 3 and 4 are plan views showing the wet tissue storage container 100. In FIG. 4, the upper cover 3 is indicated by a dotted line, and the upper cover 3 is shown through the figure. 5 is a cross-sectional view of the wet tissue storage container 100 taken along line V-V in FIG.

[0062] In the following description, the front-back direction of the wet tissue storage container 100 is referred to as the X-axis direction, the side on which the operation unit 4 is provided is referred to as the front side, and the side opposite to the operation unit 4 is referred to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com