Multilayer ceramic capacitor and preparation method thereof

A technology of multilayer ceramics and capacitors, applied in the direction of capacitor manufacturing, multilayer capacitors, capacitors, etc., can solve the problems of increasing product loss value, increasing operation process, production cycle and cost impact, etc., to improve strength defects, improve bending resistance, etc. Strength and flexural strength, effect of improving flexural and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

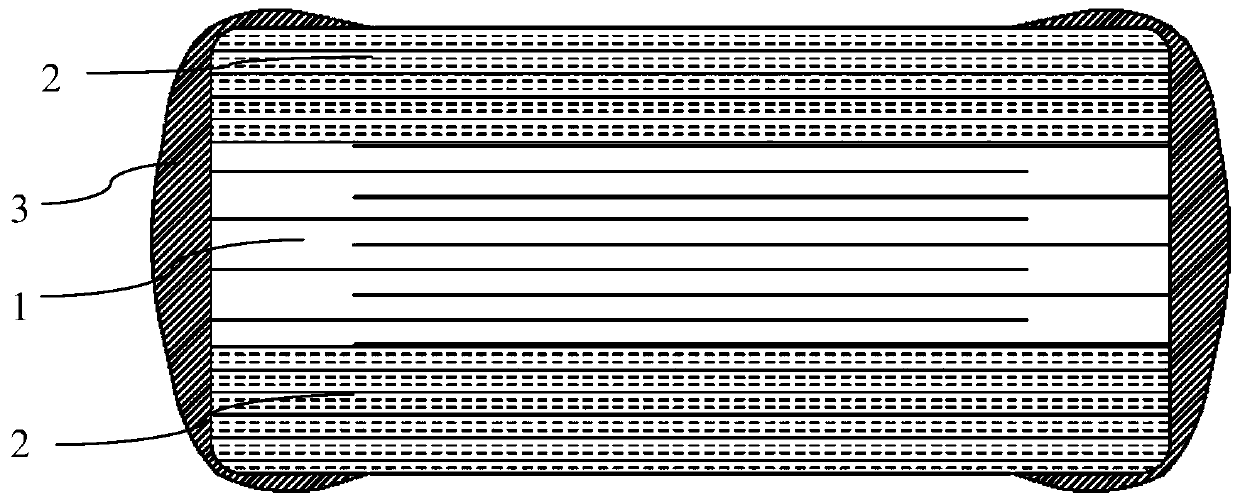

[0059] The structure diagram of the multilayer ceramic capacitor described in this embodiment is shown in figure 1 , the multilayer ceramic capacitor includes an effective electrode layer 1 and a reinforcement body 2, the reinforcement body 2 is arranged on the upper surface and the lower surface of the effective electrode layer 1, and the reinforcement body 2 is formed by stacking a plurality of reinforcement body units; The effective electrode layer 1 is formed by dislocation stacking of a plurality of effective electrode units, the effective electrode unit and the reinforcing body unit are stacked to form two end faces, and the two end faces are respectively in contact with the end electrodes 3 .

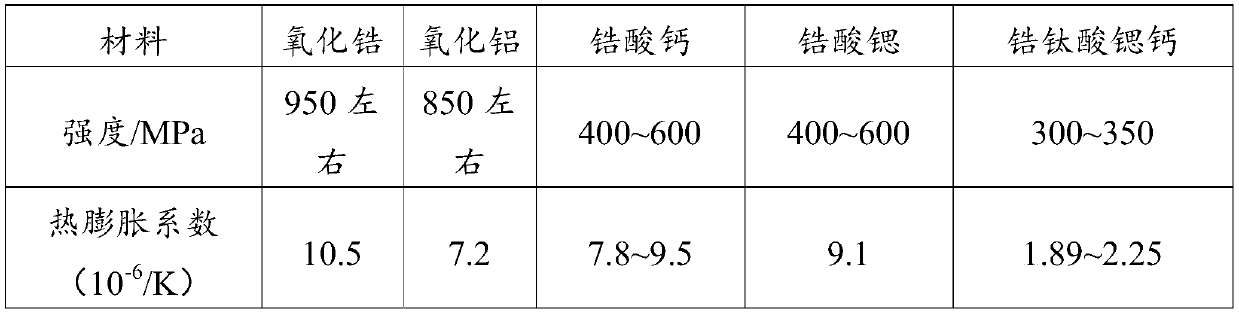

[0060] The reinforcement unit includes a high-strength material layer and a ceramic medium layer; the material of the high-strength material layer includes high-strength materials and auxiliary materials, and the high-strength materials include zirconia, alumina, calcium zirconate...

Embodiment 2

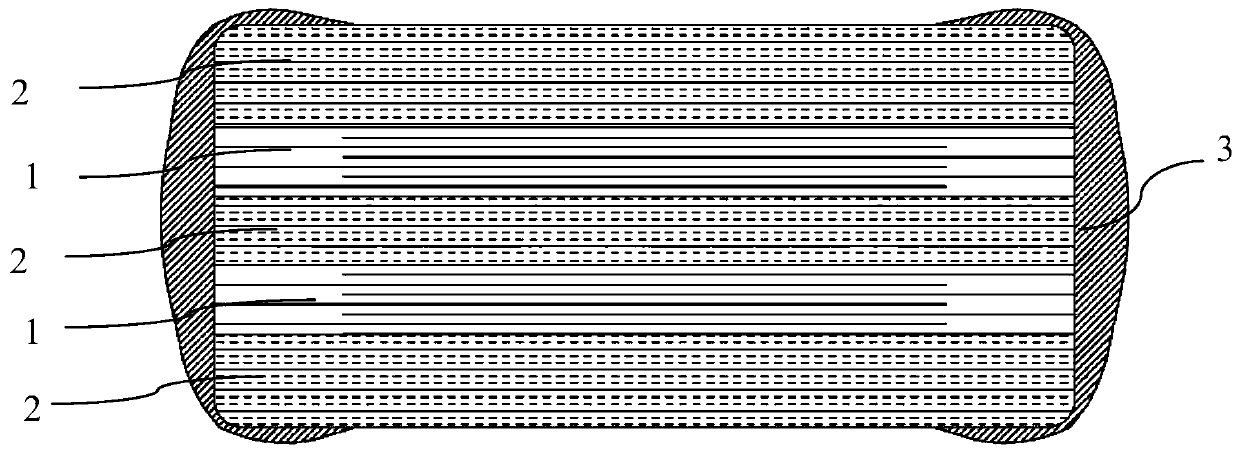

[0070] The structure diagram of the multilayer ceramic capacitor described in this embodiment is shown in figure 2, the multilayer ceramic capacitor includes an effective electrode layer 1 and a reinforcing body 2, the reinforcing body 2 is arranged on the upper surface, the lower surface of the effective electrode layer 1 and the inside of the effective electrode layer 1, and the reinforcing body 2 is composed of a plurality of reinforcing Body units are stacked; the effective electrode layer 1 is formed by dislocation stacking of a plurality of effective electrode units, the effective electrode unit and the reinforcing body unit are stacked to form two end faces, and the two end faces are respectively in contact with the end electrodes 3 .

[0071] The reinforcement unit includes a high-strength material layer and a ceramic medium layer; the material of the high-strength material layer includes high-strength materials and auxiliary materials, and the high-strength materials ...

Embodiment 3

[0081] In order to explore the impact of the thickness of the high-strength material layer and the ceramic dielectric layer on the performance of the multilayer ceramic capacitor, the multilayer ceramic capacitor structure according to embodiment 1 and embodiment 2 is changed. The thickness ratio setting table of the high-strength material layer and the ceramic dielectric layer Test groups 1 to 8 and control groups 1 to 3 in 3, change the thickness ratio of the high-strength material layer and the ceramic dielectric layer according to the multilayer ceramic capacitor structure described in embodiment 2, and set test groups 9 to 16 and the control group in table 3 4-6. Multilayer ceramic capacitors are manufactured according to the chip capacity of 0805 specifications, wherein the high-strength material layer contains the following components in parts by weight: 83 parts of calcium zirconate, 2 parts of zirconia, 2 parts of alumina, and 13 parts of auxiliary materials The auxili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com