Milling method for small automatic feeding experiment with automatic stone mill

A self-feeding, fully automatic technology, applied in cocoa, grain processing, food science, etc., can solve the problems of material waste, low work efficiency, and unsuitable for experimental use, so as to reduce the cost of use, improve work efficiency, and be environmentally friendly taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

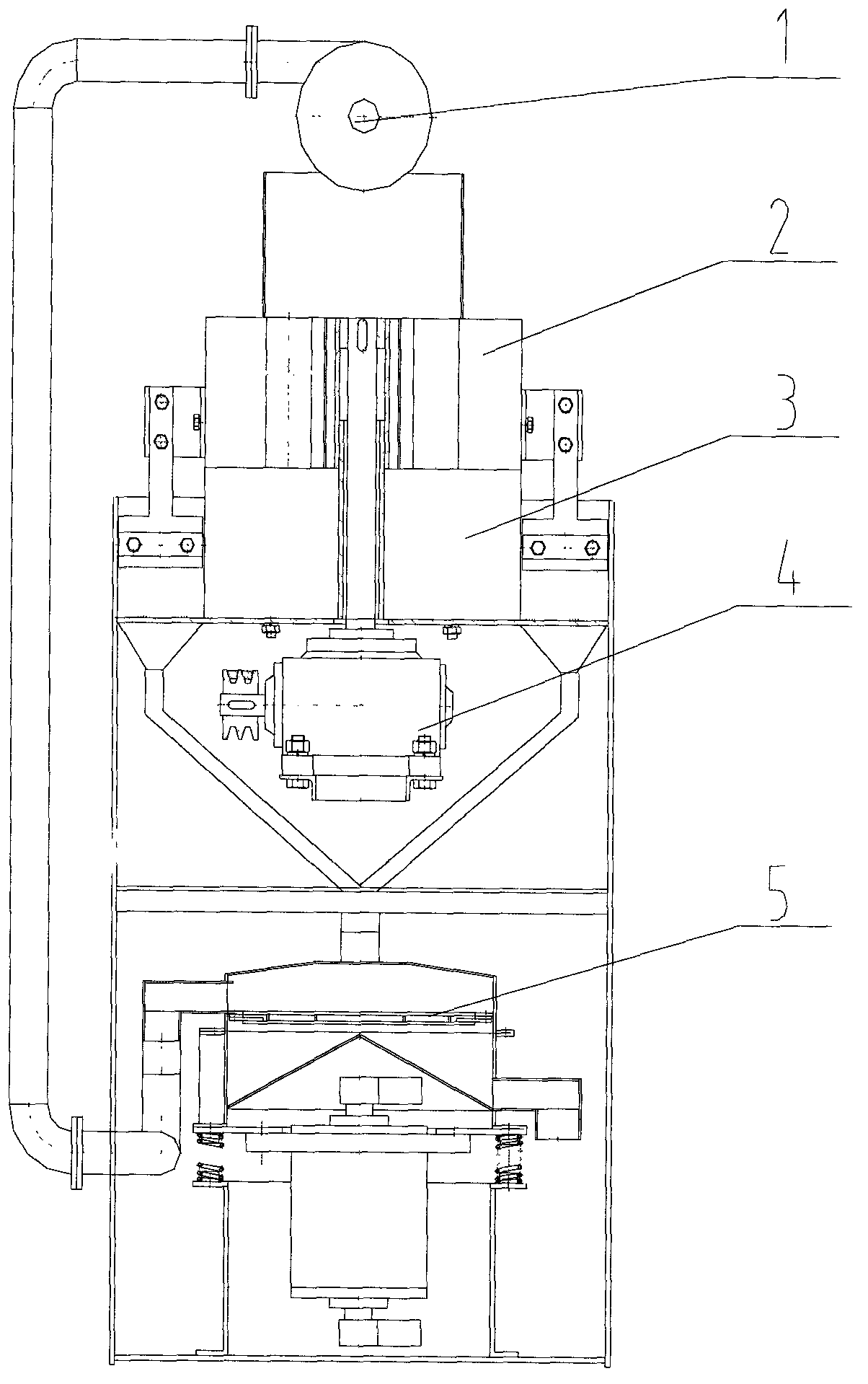

[0017] Hereinafter, the present invention is further explained through the accompanying drawings of the specification;

[0018] Such as figure 1 As shown, a full-automatic stone mill small-scale self-feeding experimental grinding method, the specific steps are as follows:

[0019] 1) Unloading: select high-quality materials, use the horizontal unloader 1 to enter the unloading hopper, which is made of plexiglass, so that the production process can be clear at a glance;

[0020] 2) Grinding: Grind the material with the help of the pattern between the upper stone grinding disc 2 and the lower stone grinding static disc 3. The upper stone grinding disc 2 and the lower stone grinding static disc 3 are forged with natural red sandstone. Manufactured, which is more green and environmentally friendly, tastes delicious and tastes good;

[0021] 3) Stone mill transmission device: the combined transmission device 4 is used to drive the upper stone grinding disk 2 to rotate, and the combined tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com