Patents

Literature

46results about How to "Realize the grinding operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

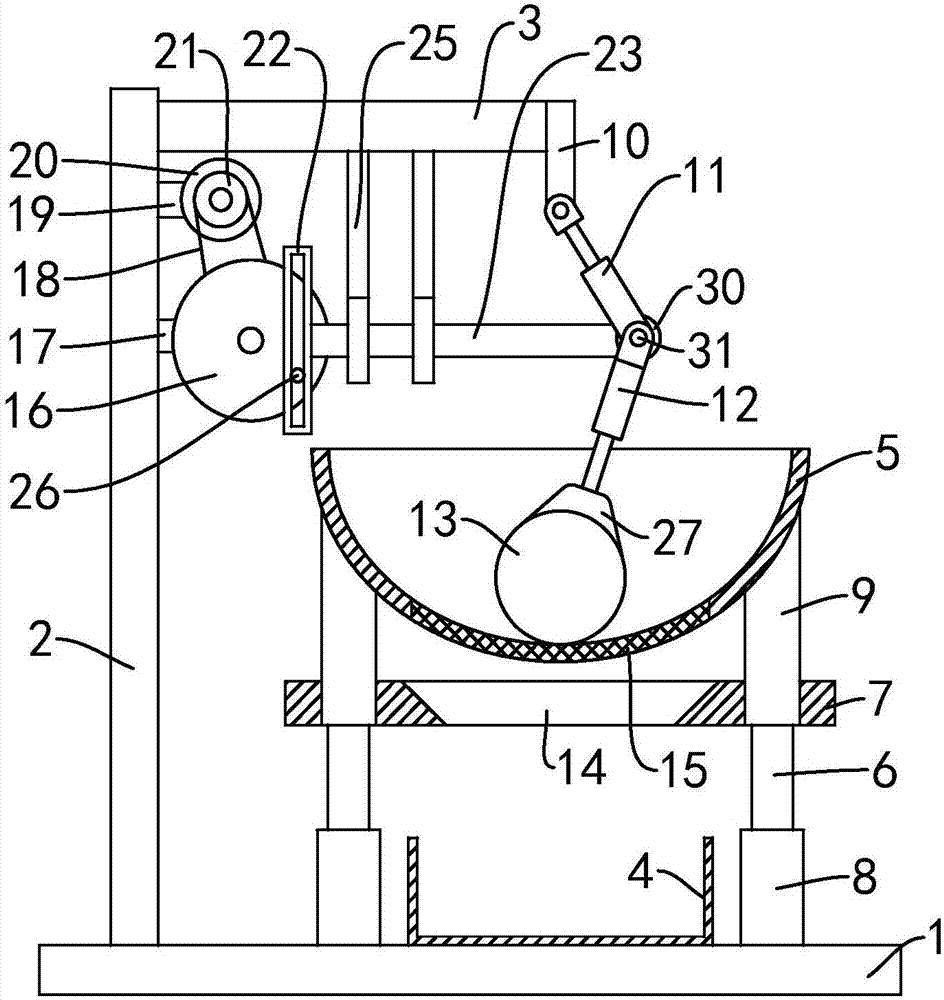

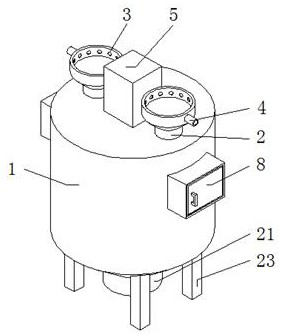

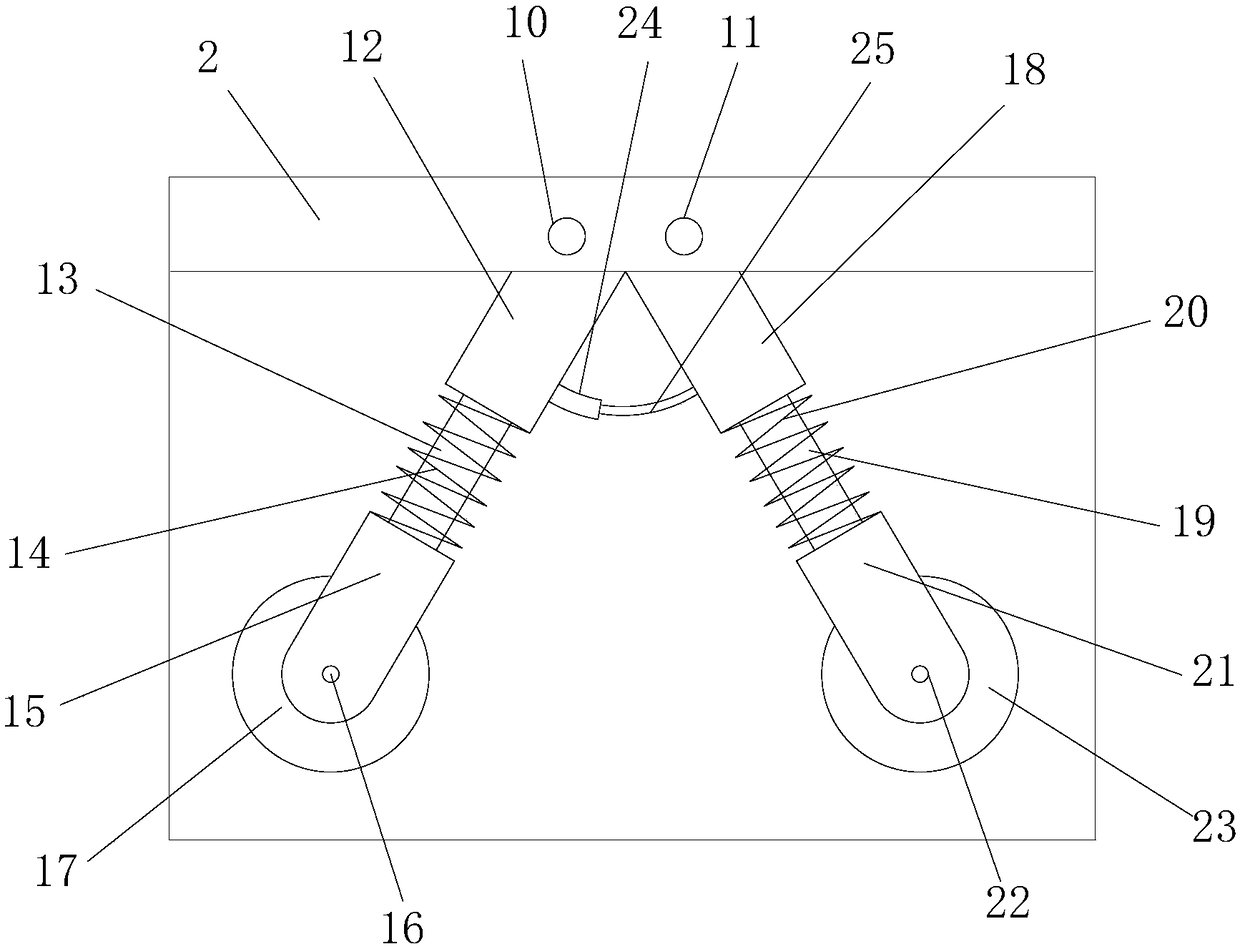

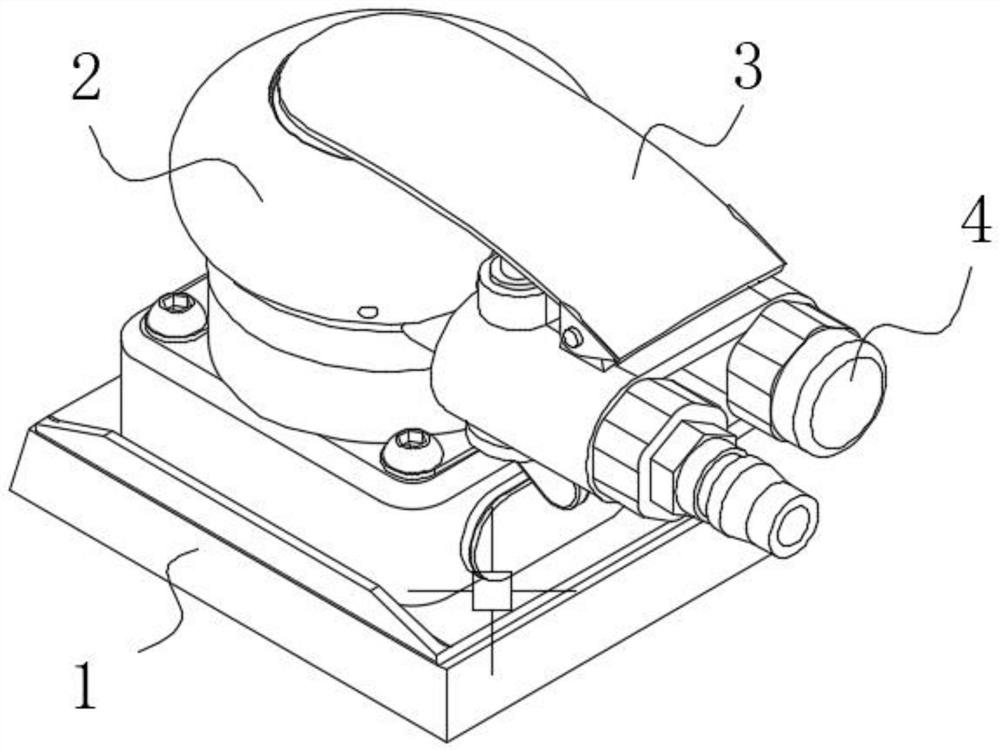

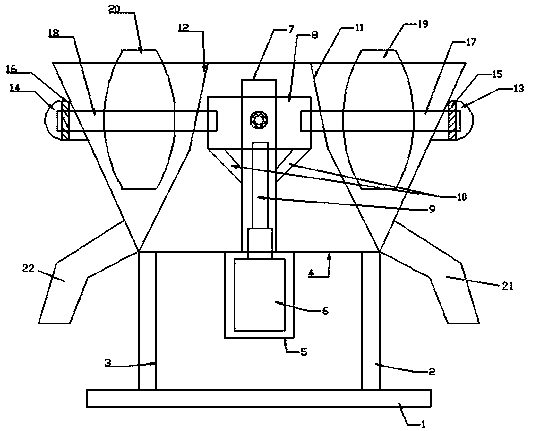

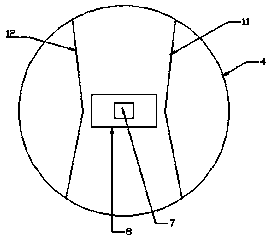

Refined grinding device for Chinese medicinal herbs

InactiveCN107282250AImprove grinding effectRealize the grinding operationGrain treatmentsCircular discMedicinal herbs

The invention discloses a refined grinding device for Chinese medicinal herbs. The refined grinding device comprises a base, a collecting box, a grinding groove, a support platform, a first telescopic sleeve rod, a second telescopic sleeve rod, grinding balls, a rotating disk, a movable sleeve plate and a push-pull rod. The bottom end of a coupling sleeve on the first telescopic sleeve rod is rotatably hinged with the top of the coupling sleeve on a second telescopic sleeve through an articulated shaft, and the end of the articulated shaft is fixedly provided with a connecting block; the upper part of the grinding balls is fixedly provided with a connecting plate, and the bottom end of a connection sliding rod on the second telescopic sleeve rod is connected to the connecting plate; the outer ring surface of the grinding balls is fixedly provided with a guide pillar, and the movable sleeve plate is sheathed on the guide pillar; and the movable sleeve plate is fixedly installed on one end of the push-pull rod of which the other end is fixedly connected to the connecting plate. The refined grinding device disclosed by the invention has the advantages of simple structure, easy operation, smart design, full and uniform grinding, and time and labor saving in the grinding process, and is suitable for popularization and application.

Owner:侯添有

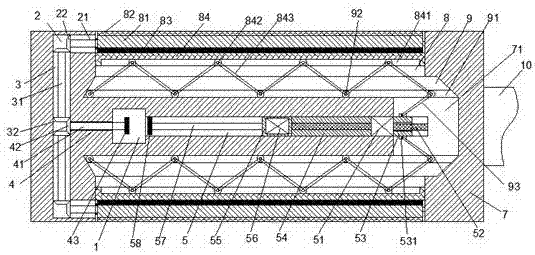

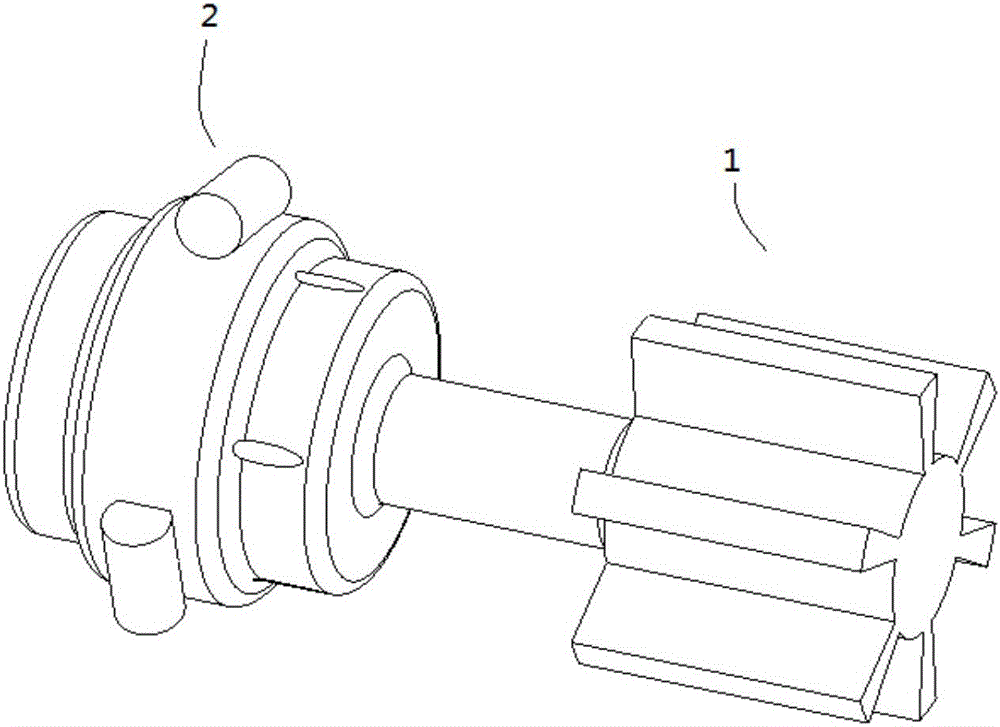

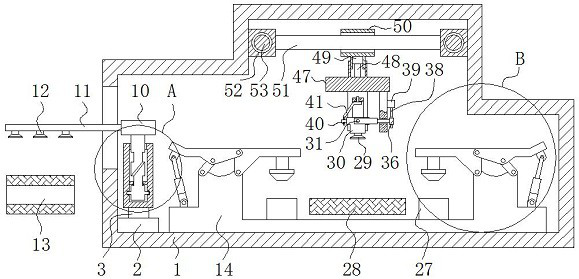

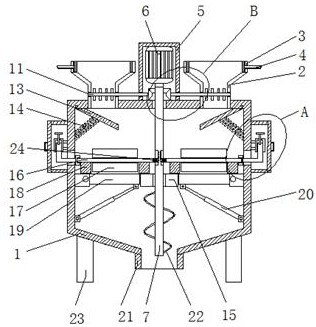

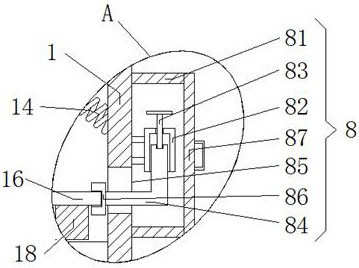

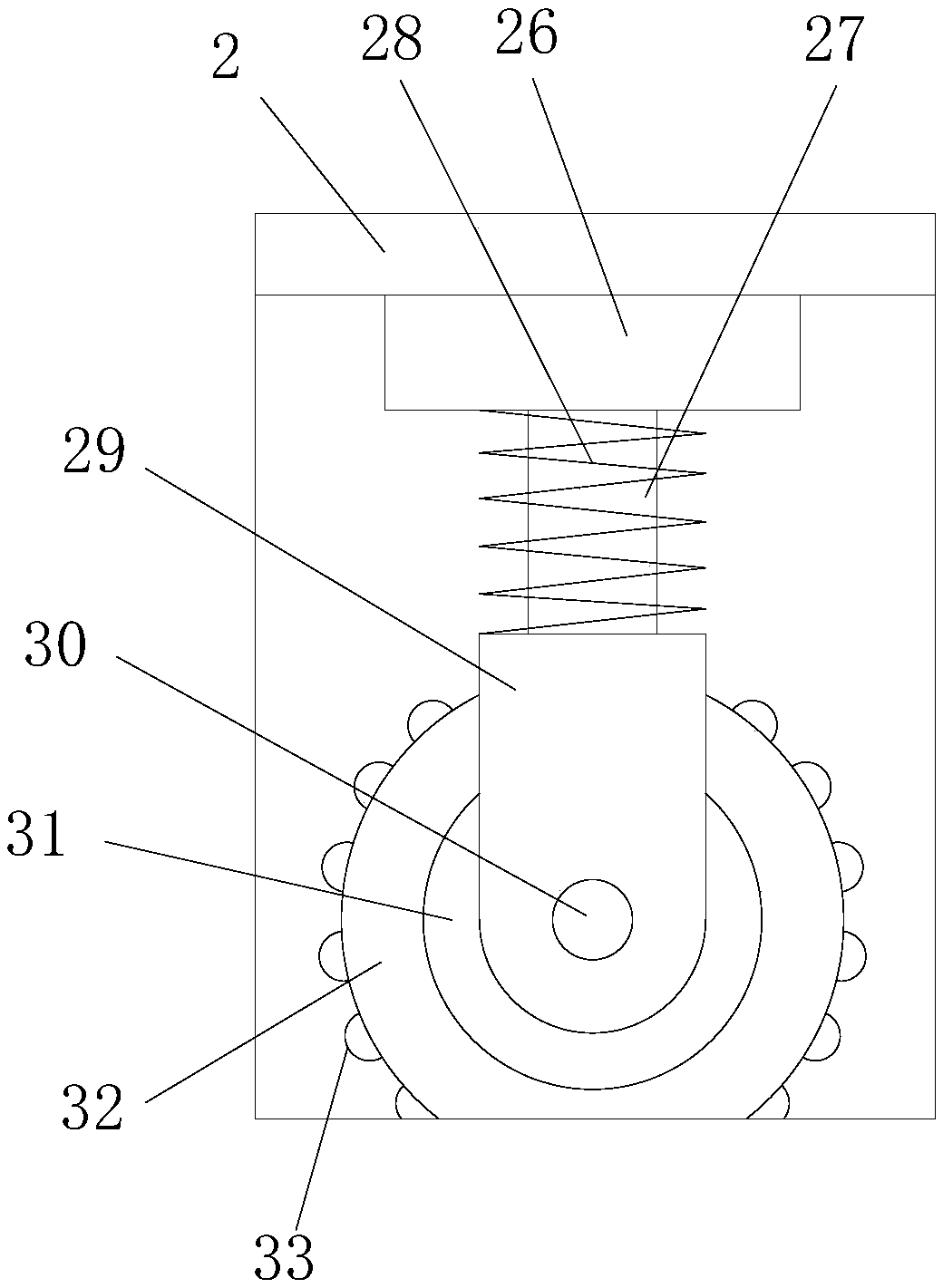

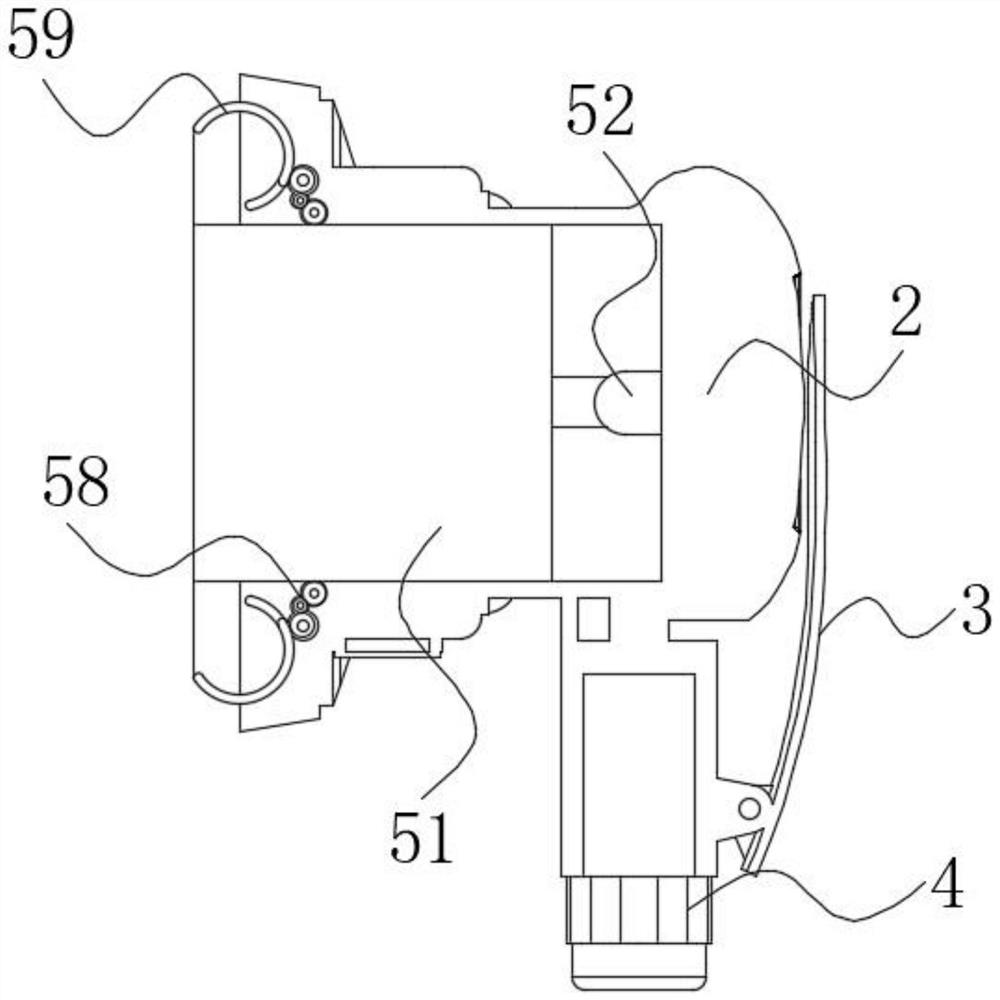

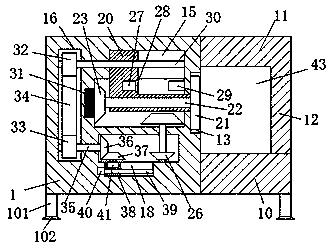

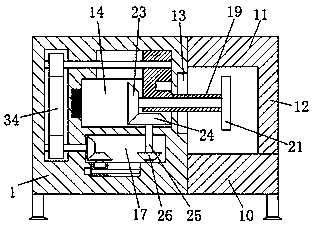

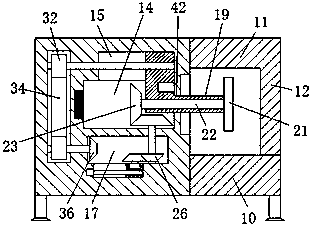

Novel pipe inner wall processing device

InactiveCN107971849AAvoid affecting the grinding effectRealize the grinding operationRevolution surface grinding machinesGrinding drivesEngineeringMechanical engineering

The invention discloses a novel pipe inner wall processing device. The novel pipe inner wall processing device comprises a rotary arm and a rotary cylinder connected with a drive device. Mounting grooves with outward openings are vertically and symmetrically formed in the rotary cylinder. A switching structure is arranged in each mounting groove. Movable grooves communicating with the mounting grooves are vertically and symmetrically formed in the rotary cylinder. A jacking press structure is arranged on each movable groove. A sliding groove is formed in the portion, located between the uppermovable groove and the lower movable groove, in the rotary cylinder. A drive structure is arranged in the sliding groove. A cavity communicating with the movable grooves is formed in the portion, on the right side of the sliding groove, of the rotary cylinder. The right side of the sliding groove extends into the cavity. The drive structure comprises a first motor fixedly arranged in the sliding groove, sliding sleeves and sliding blocks, wherein the sliding sleeves and the sliding blocks are slidably arranged in the sliding groove and located on the left side and the right side of the first motor. Threaded holes are correspondingly formed in the sliding sleeves and the sliding blocks. Threaded rods are mounted in the threaded holes in a threaded fit manner.

Owner:陈军

Pipe fitting inner wall machining device

InactiveCN107983733AImplement automatic conversionLow input costRevolution surface grinding machinesHollow article cleaningPipe fittingStructural engineering

The invention discloses a pipe fitting inner wall machining device. The pipe fitting inner wall machining device comprises a rotation barrel connected with a drive device through a rotation arm. Installing grooves with outward openings are formed in the rotation barrel in an up-down symmetry manner. A transformation structure is arranged in each installing groove. Movable grooves communicating with the installing grooves are formed in the rotation barrel in an up-down symmetry manner. Each movable groove is provided with a jacking structure. The part, located between the upper movable groove and the lower movable groove, in the rotation barrel is provided with a sliding groove. The sliding groove is internally provided with a drive structure. The part, on the right side of the sliding groove, in the rotation barrel is internally provided with a cavity communicating with the movable grooves. The right side end of the sliding groove extends into the cavity. The drive structure comprisesa first motor fixedly arranged in the sliding groove, a sliding sleeve and a sliding block, wherein the sliding sleeve and the sliding block are arranged in the sliding groove in a sliding manner andlocated on the left side and the right side of the first motor. Threaded holes are formed in the sliding sleeve and the sliding block, and threaded rods are arranged in the threaded holes in a threaded fit manner.

Owner:陈军

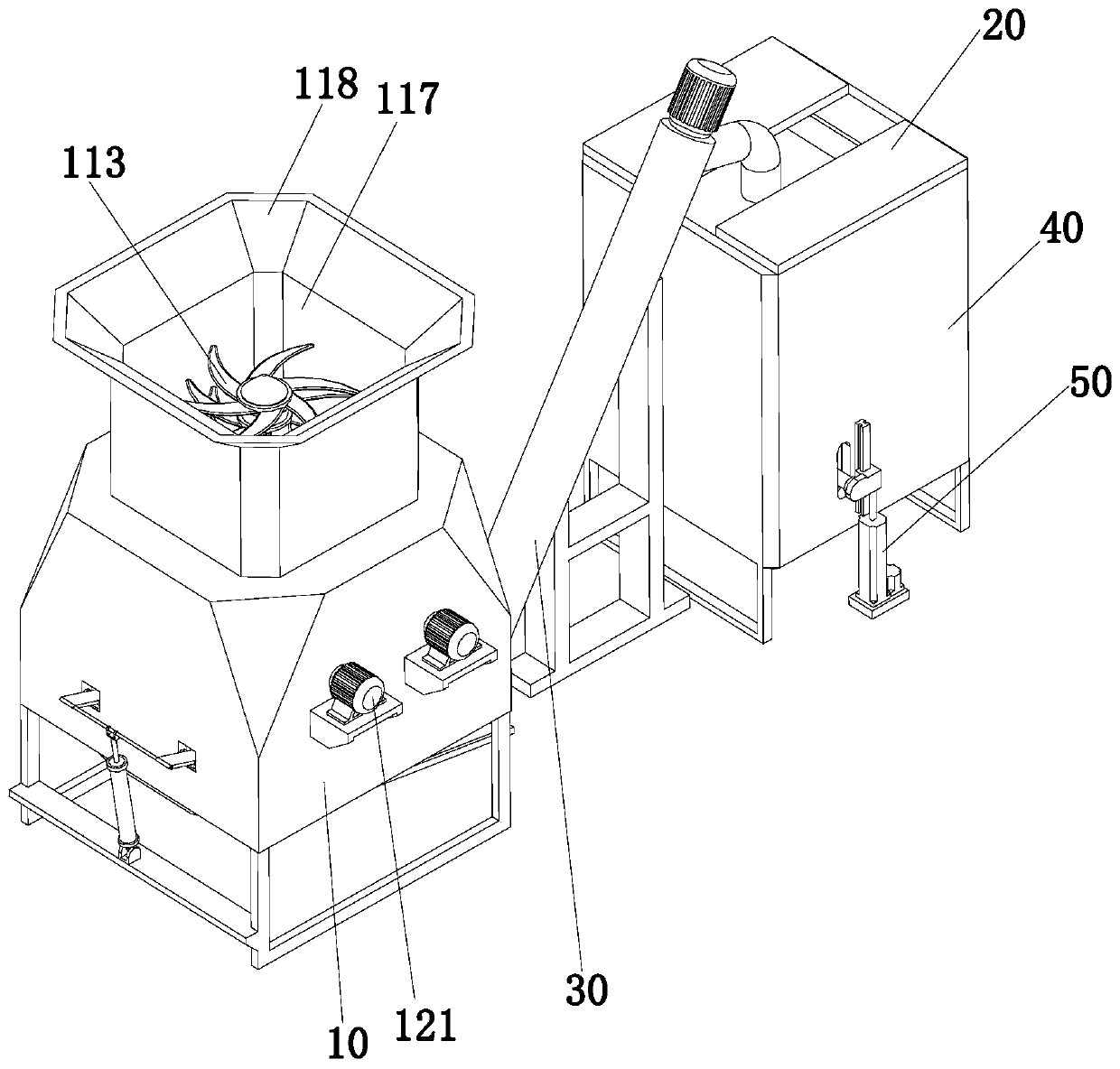

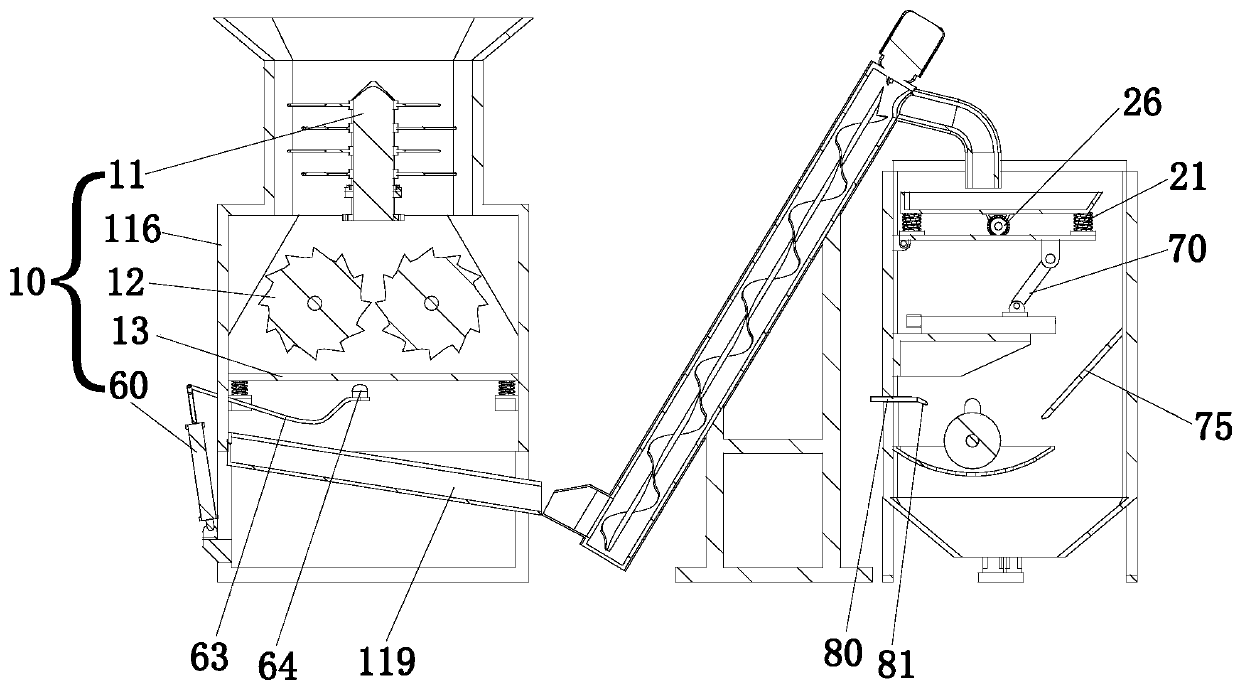

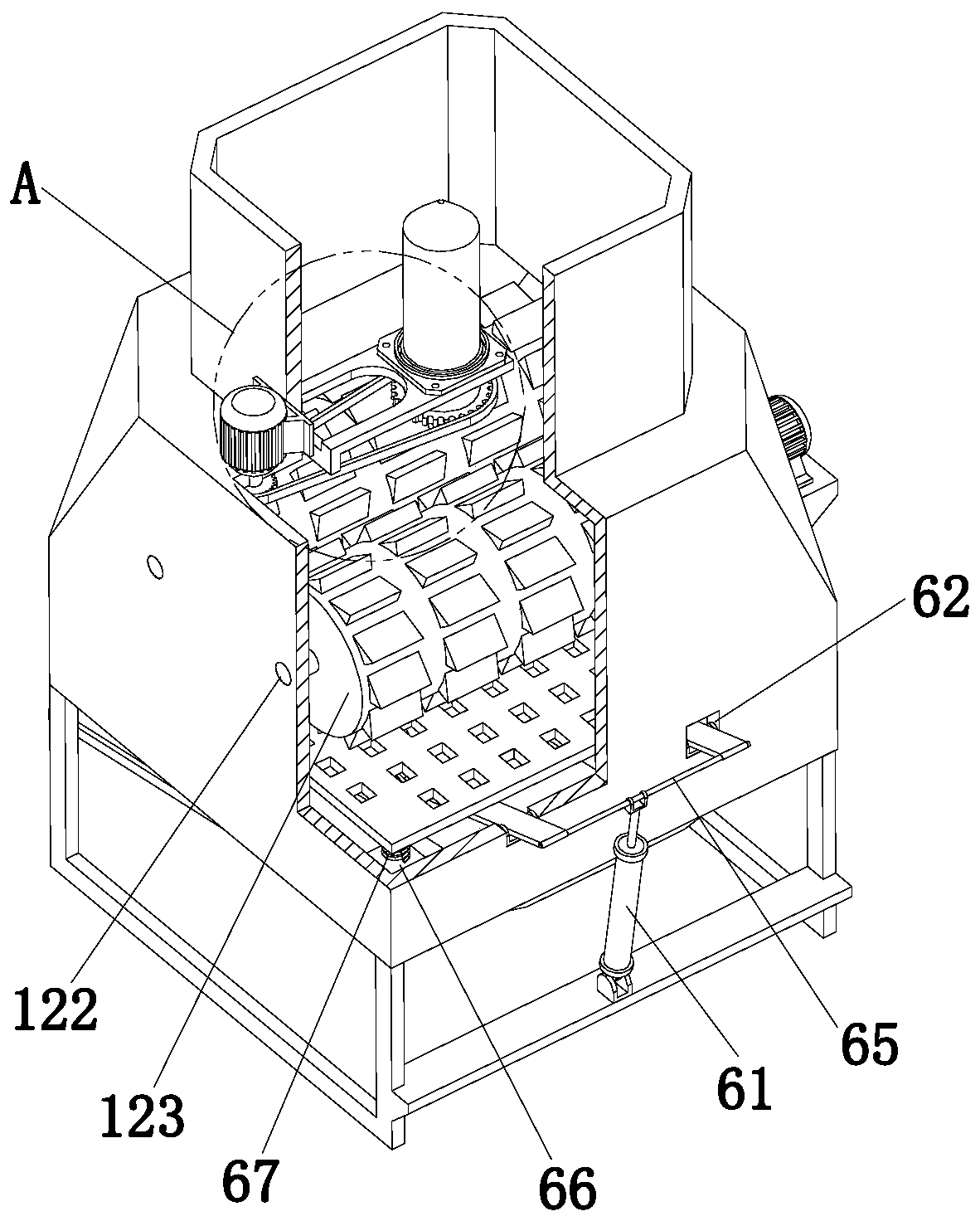

Fig fruit powder production device

The invention discloses a fig fruit powder production device, and belongs to the technical field of fig manufacturing. The fig fruit powder production device comprises a fruit crushing mechanism, a fruit particle drying mechanism, a feeding packing auger, a grinding cabinet and a fruit powdering and grinding mechanism, wherein the fruit crushing mechanism is provided with a cutting assembly, a crushing cabinet, a crushing assembly, a screening plate and a knocking vibration assembly; the top of the crushing cabinet is provided with a feeding hole and an anti-funnel; the bottom of the crushingcabinet is provided with a material conveying channel; the material conveying channel is provided with a water falling hole; the knocking vibration assembly comprises a driving air cylinder and two mounting grooves; a knocking rod is arranged in each mounting groove; a vibration hammer is arranged at the right end of each knocking rod; and a connecting rod is arranged between the left ends of thetwo knocking rods. According to the fig fruit powder production device, by knocking the vibration assembly, fig particles blocked in screening holes of a screening mesh can be vibrated out, the dryingoperation of figs can be realized through the fruit particle drying mechanism, and a drying box can be vibrated through a vibrating part, so that the figs positioned in the drying box are overturned.

Owner:义乌市昕闵日用品有限公司

Intelligent road construction device

InactiveCN105821745ARealize the grinding operationSimple structureRoads maintainenceEngineeringDrive motor

The invention discloses an intelligent road construction device which comprises a device shell. A cavity with an opening formed in the bottom face is formed in the device shell. A movable block is arranged in the cavity. An adjusting cavity is formed in the movable block. The movable block is provided with two vertical holes communicating with the adjusting cavity. A balance warping rod is arranged in the adjusting cavity. An abutting rod is arranged in one vertical hole. A rolling ball is arranged at the bottom end of the abutting rod. A grinding columnar rod is arranged in the other vertical hole and internally provided with a grinding drive motor. A grinding cutter head connected with the grinding drive motor is arranged on the bottom face of the grinding columnar rod. A stress buffer spring is arranged between the top of the abutting rod and the top wall of the adjusting cavity. A horizontally-moving lead screw and a forward and reverse rotation motor connected with the horizontally-moving lead screw are arranged in the cavity. A level detector is arranged on the device shell. The intelligent road construction device is simple in structure, convenient and quick to operate, good in use stability, high in intelligence, capable of effectively achieving roadbed grinding operation and greatly reducing the grinding cost and high in applicability and practicality.

Owner:李文艺 +22

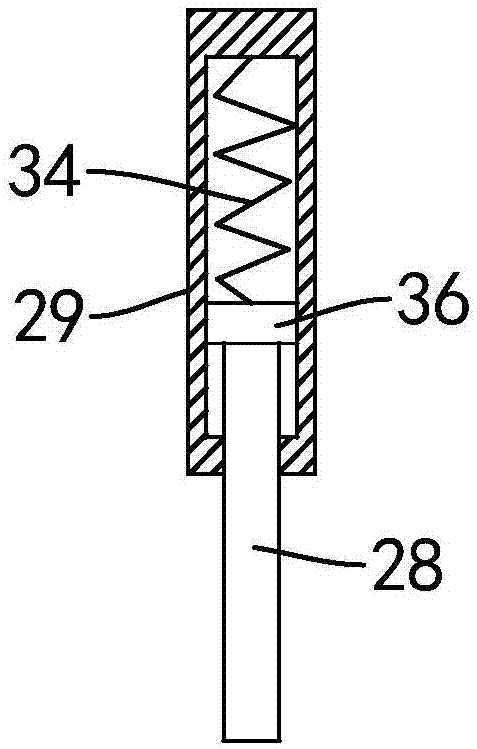

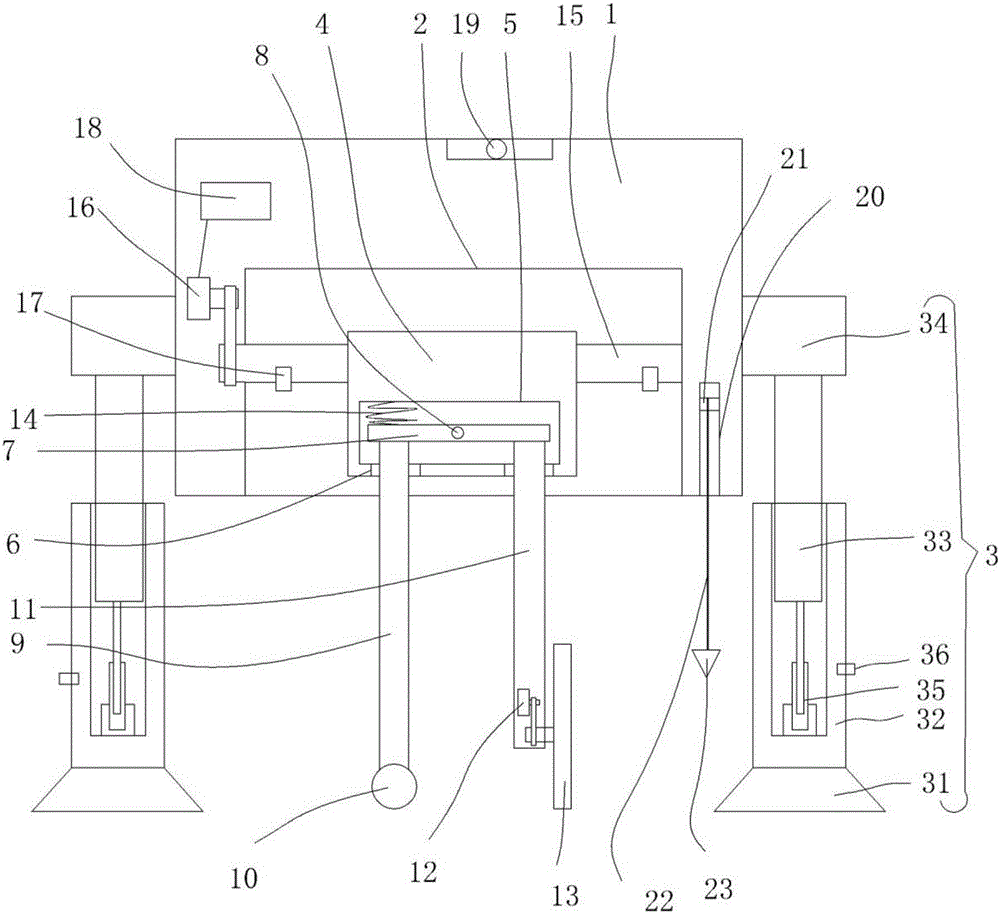

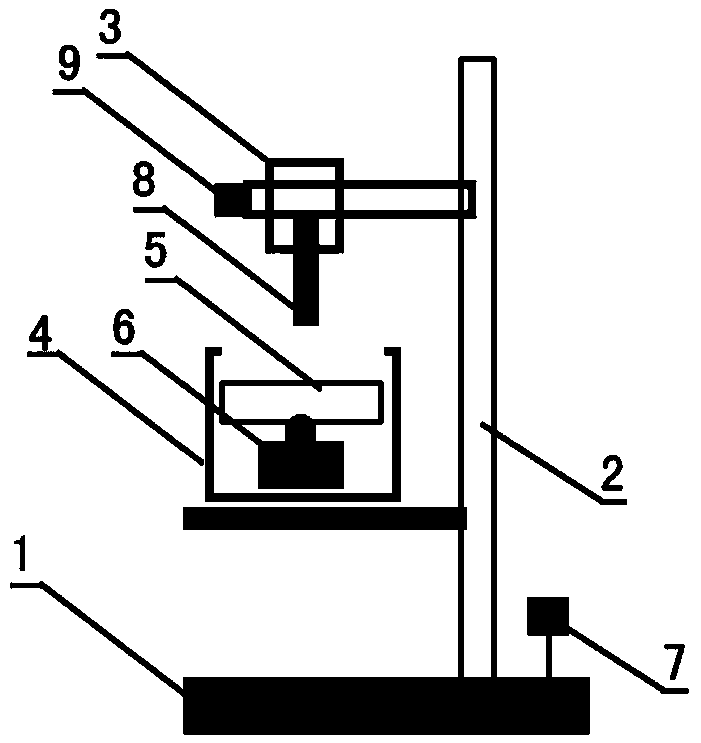

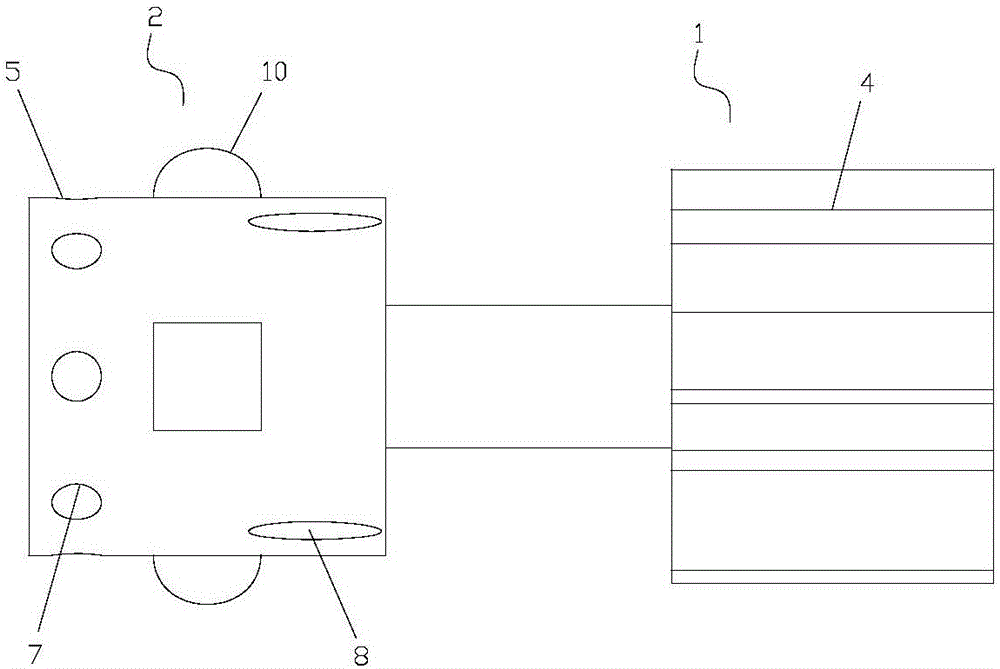

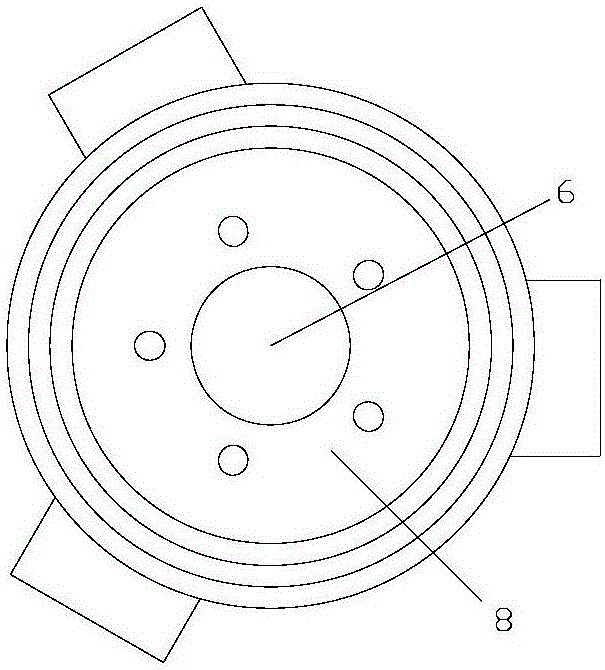

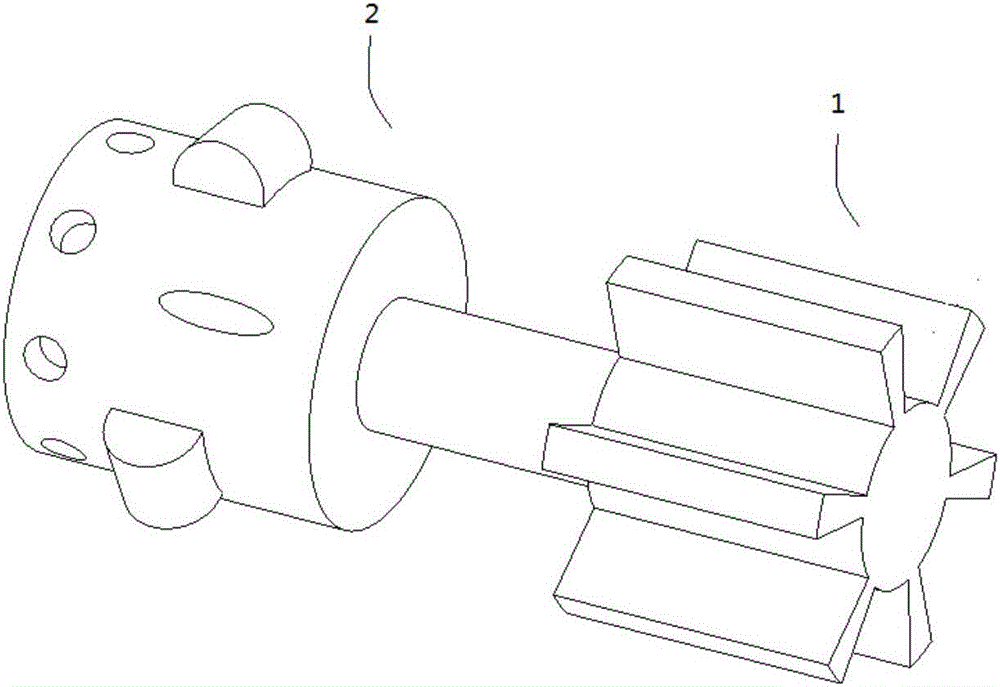

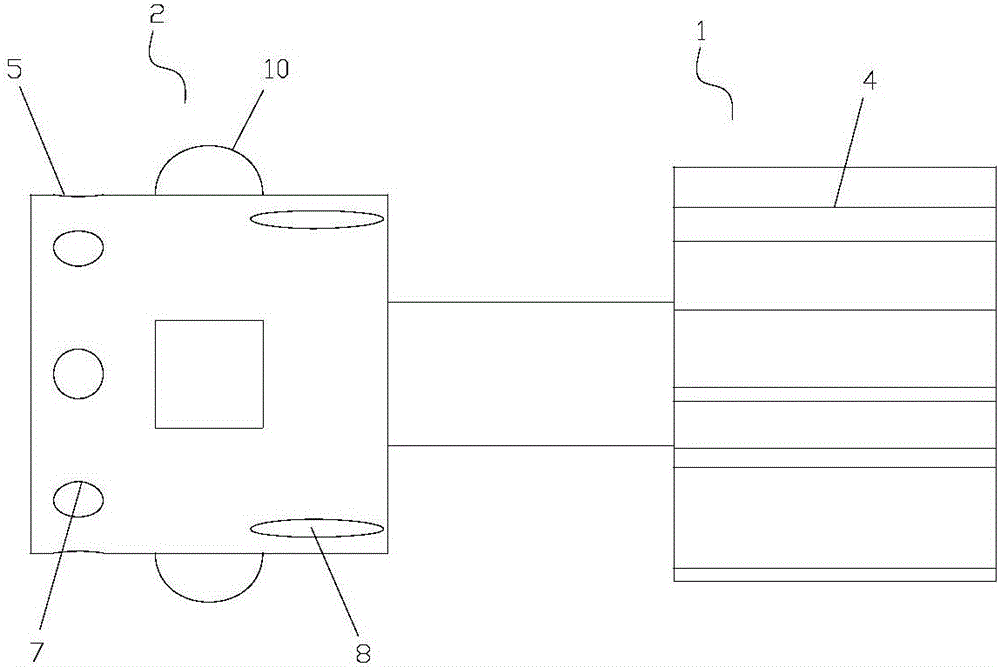

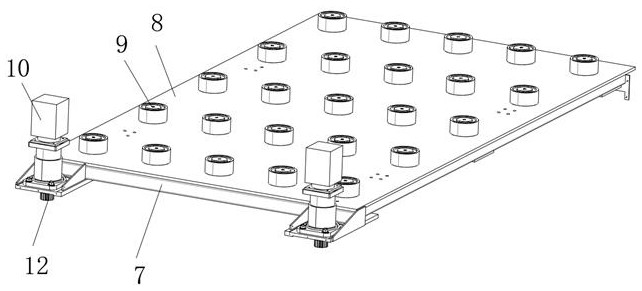

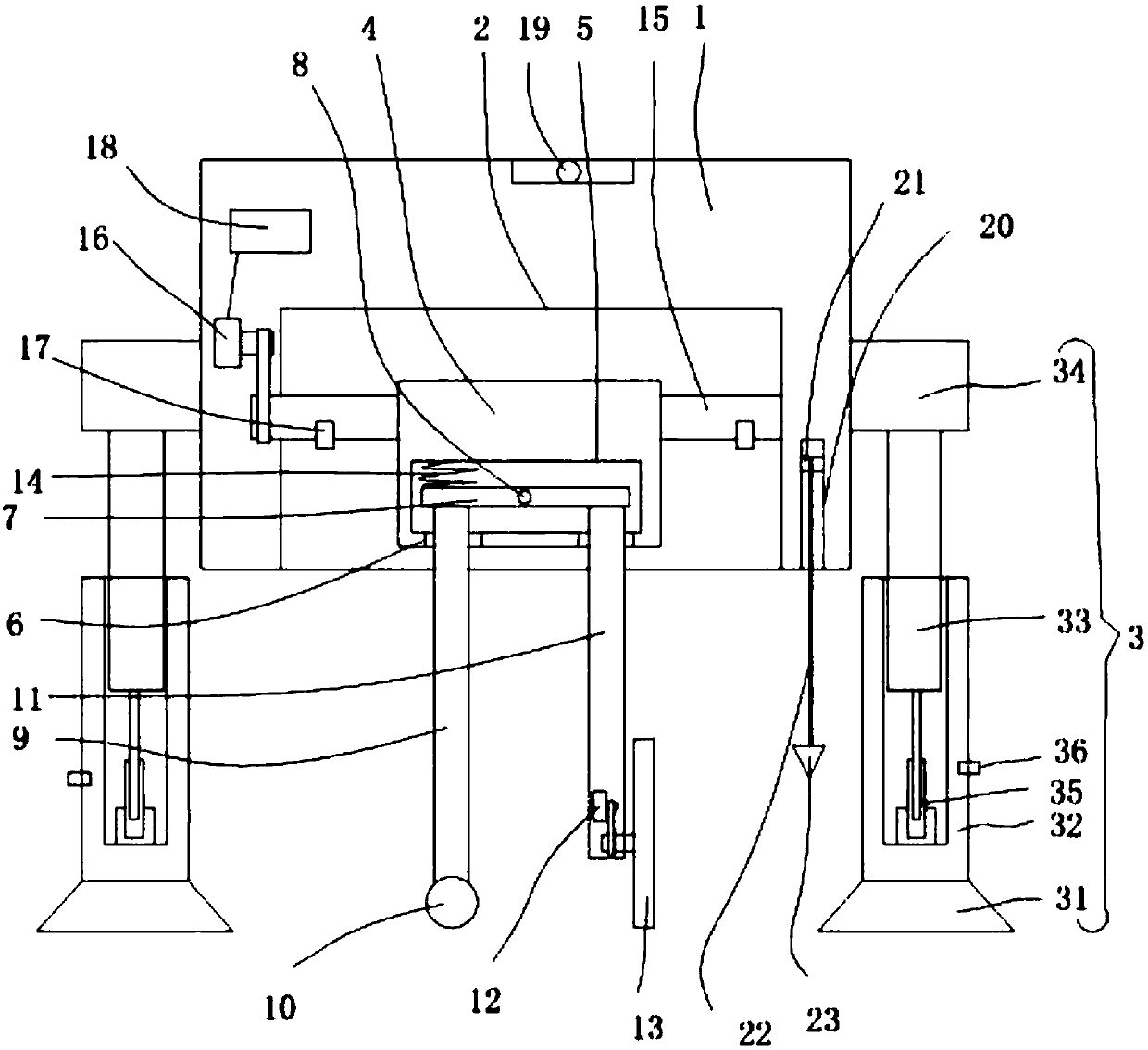

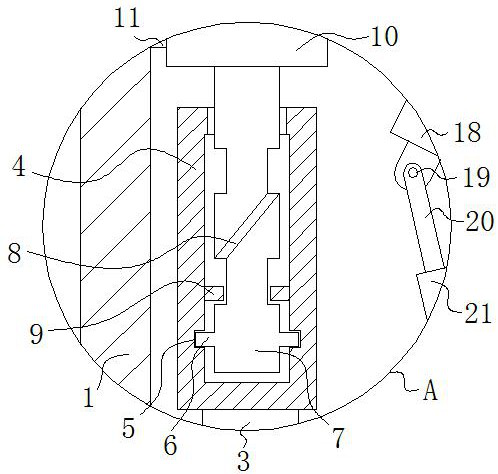

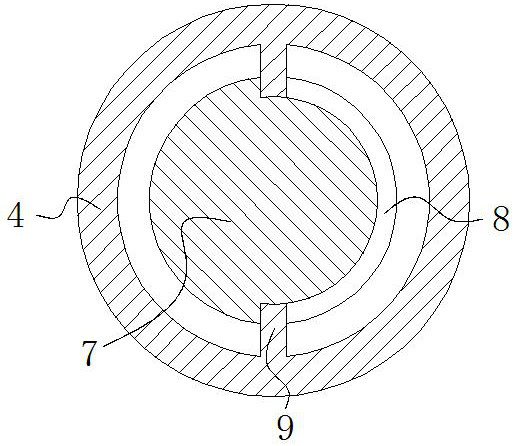

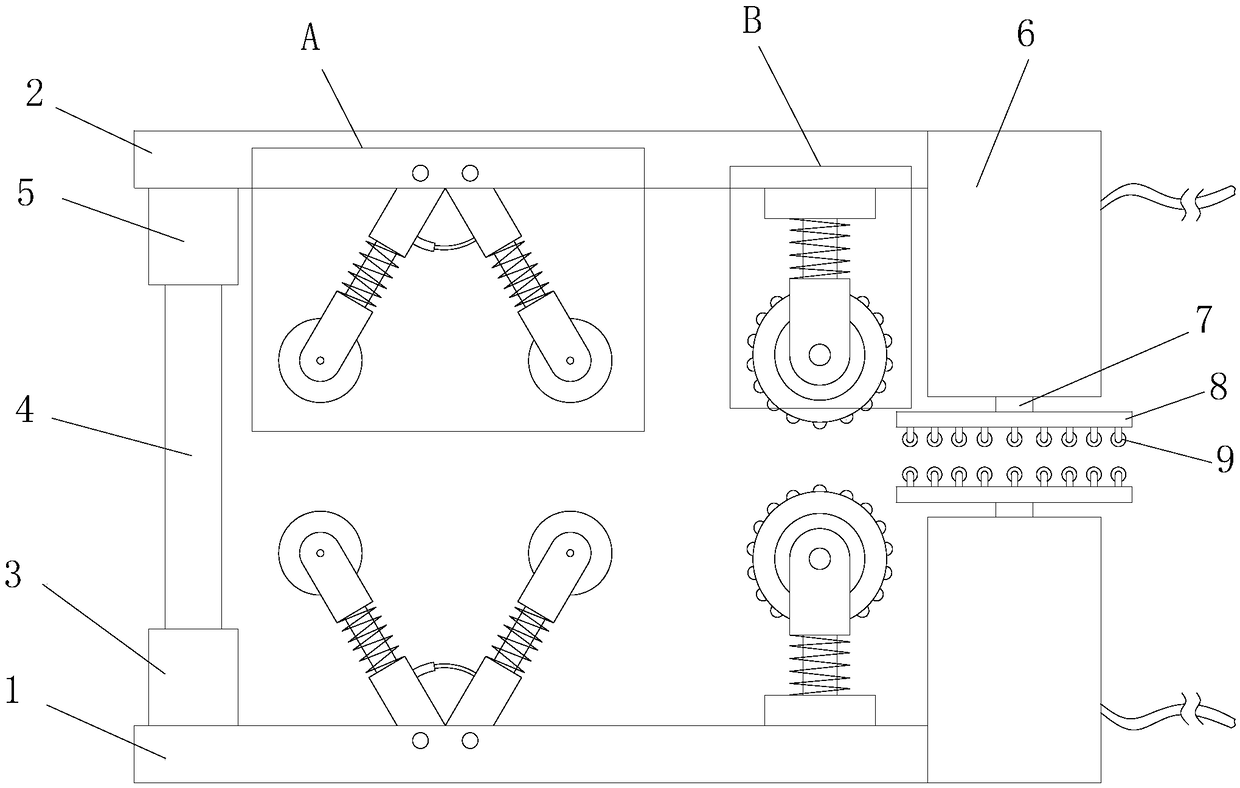

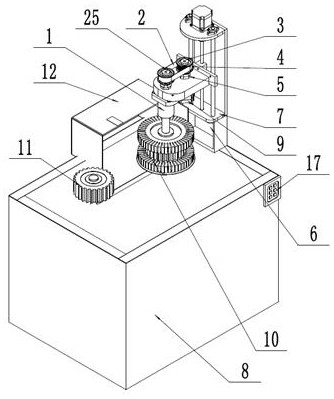

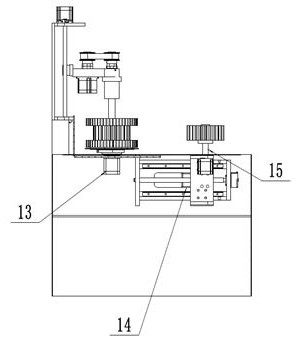

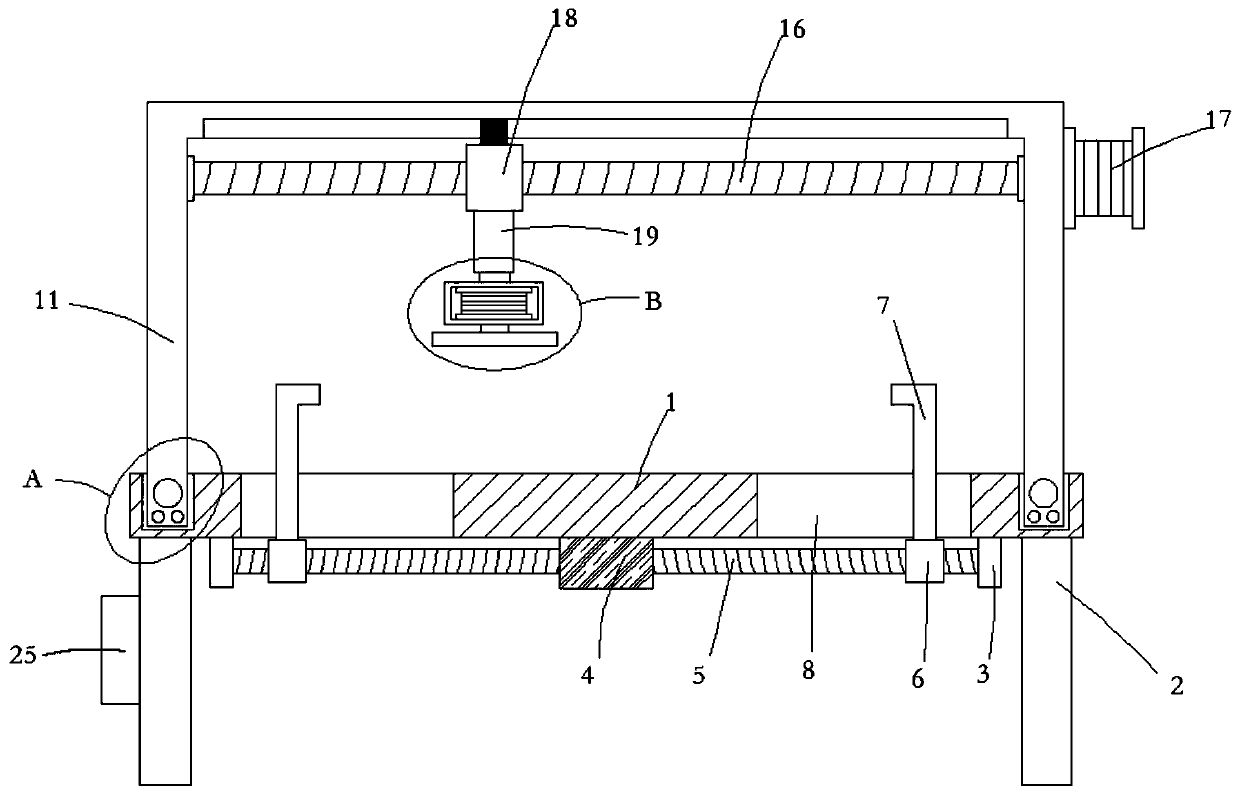

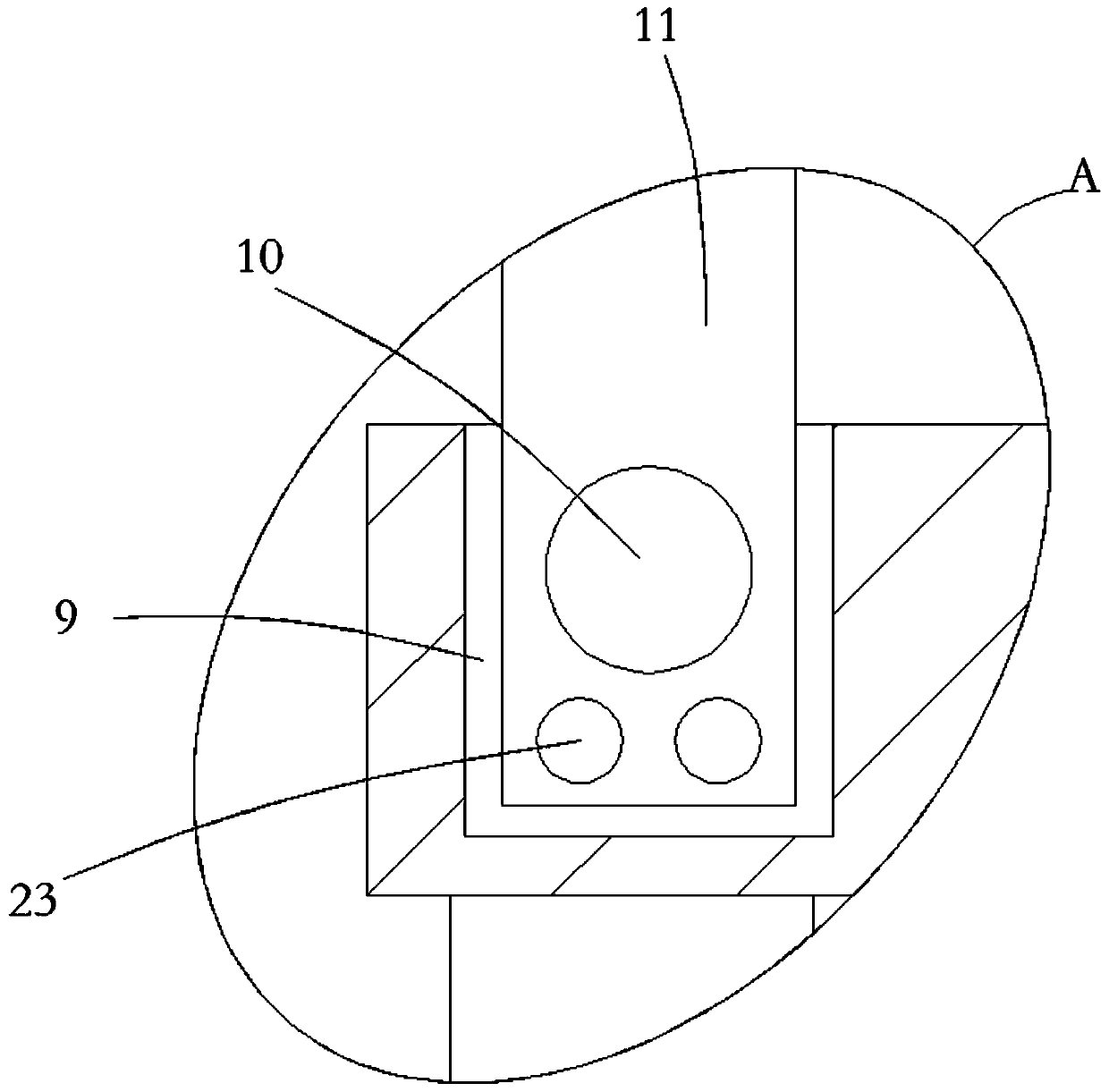

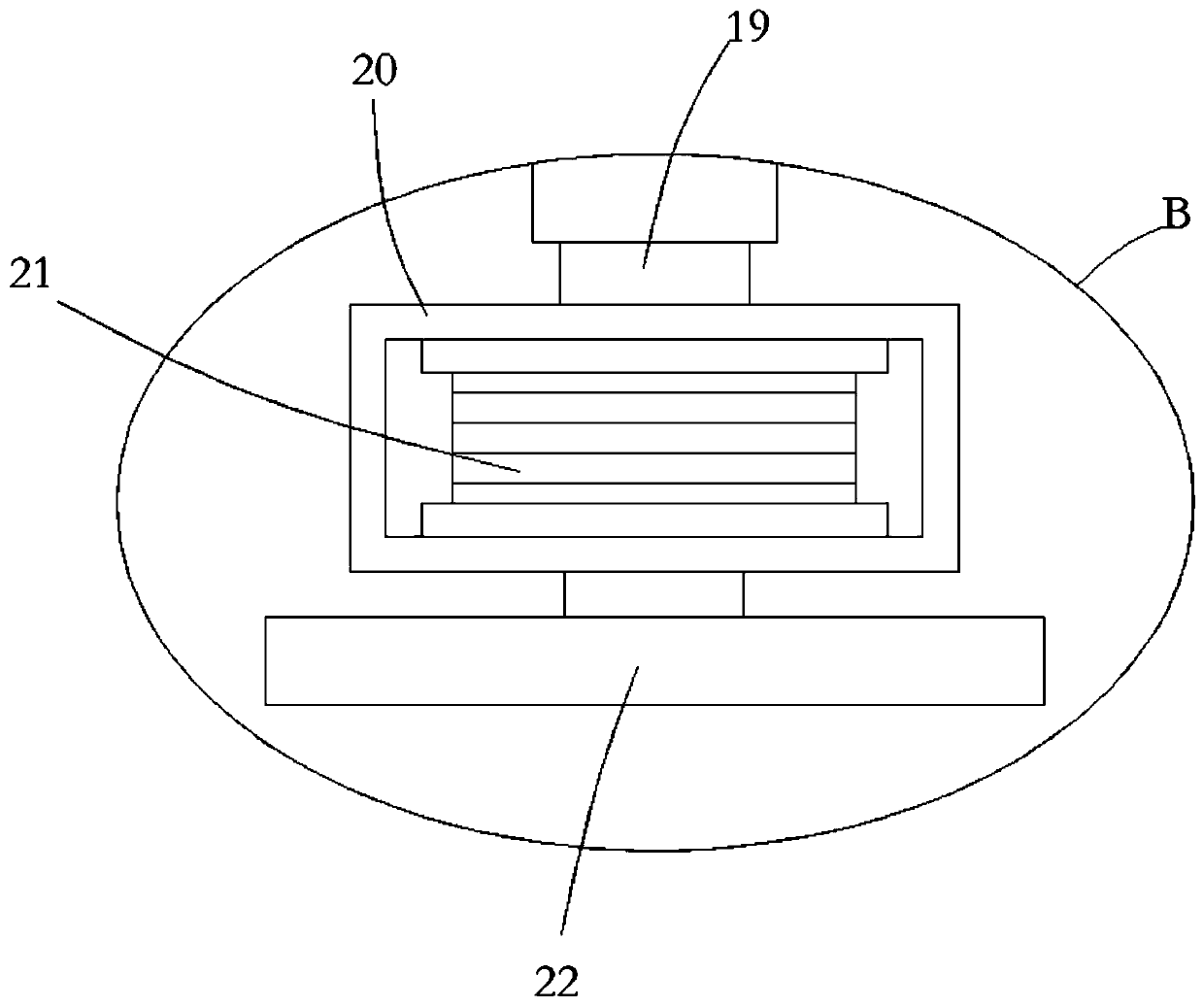

Bearing metallographic analysis grinding machine

InactiveCN103639883ARealize the grinding operationImprove work efficiencyLapping machinesGrinding wheelMechanical engineering

A bearing metallographic analysis grinding machine comprises a frame (1). A telescopic rail (2), a grinding table (4) and a prompter (9) are arranged on the frame, a metallographic piece fixing device (3) is arranged on the telescopic rail (2), the grinding table (4) comprises a grinding wheel (5), a motor (6) and a control device (7), a metallographic piece (8) is fixed on the metallographic piece fixing device (3) in grinding, grinding parameters are set on the control device (7), corresponding metallographic analysis grinding is performed, the metallographic piece fixing device (3) fixes the metallographic piece (8) by the aid of a fixture, the fixture fixes the metallographic piece in a screwing manner, the grinding progress is properly prompted by the prompter, the bearing metallographic piece can be conveniently, rapidly and efficiently grinded, and working efficiency and grinding accuracy are improved.

Owner:YINCHUAN BOJU IND PROD DESIGN

Intelligent road constructing device

InactiveCN105803910ARealize the grinding operationSimple structureRoads maintainenceEngineeringMechanical engineering

The invention discloses an intelligent road constructing device. The device comprises a device casing, wherein a cavity with a bottom opening is formed in the device casing, a moving block is arranged in the cavity, a regulating cavity is formed in the moving block, and two vertical holes communicated with the regulating cavity are formed in the moving block; a balancing raising rod is arranged in the regulating cavity; an abutting rod is arranged in one vertical hole, and a rolling ball is arranged at the bottom end of the abutting rod; a grinding post is arranged in the other vertical hole, a grinding driving motor is arranged in the grinding post, and a grinding cutter disc connected with the grinding driving motor is arranged on the bottom surface of the grinding post; a stress buffering spring is arranged between the top of the abutting rod and the top wall of the regulating cavity; a translation screw and a forward and reverse rotating motor connected with the translation screw are arranged in the cavity; a level detecting instrument is arranged on the device casing. The intelligent road constructing device is simple in structure and convenient to operate, has good application stability, high intelligence, high adaptability and good practicality, can effectively achieve roadbed grinding operation, and greatly reduces the grinding cost.

Owner:侯贤坤 +20

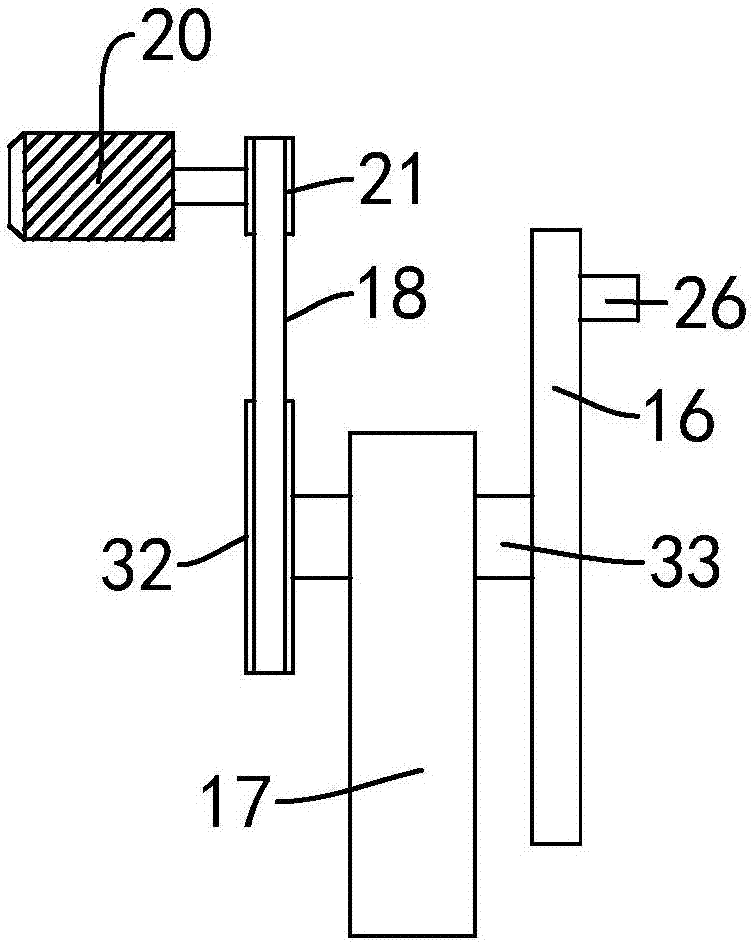

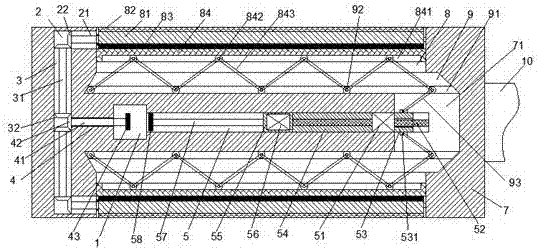

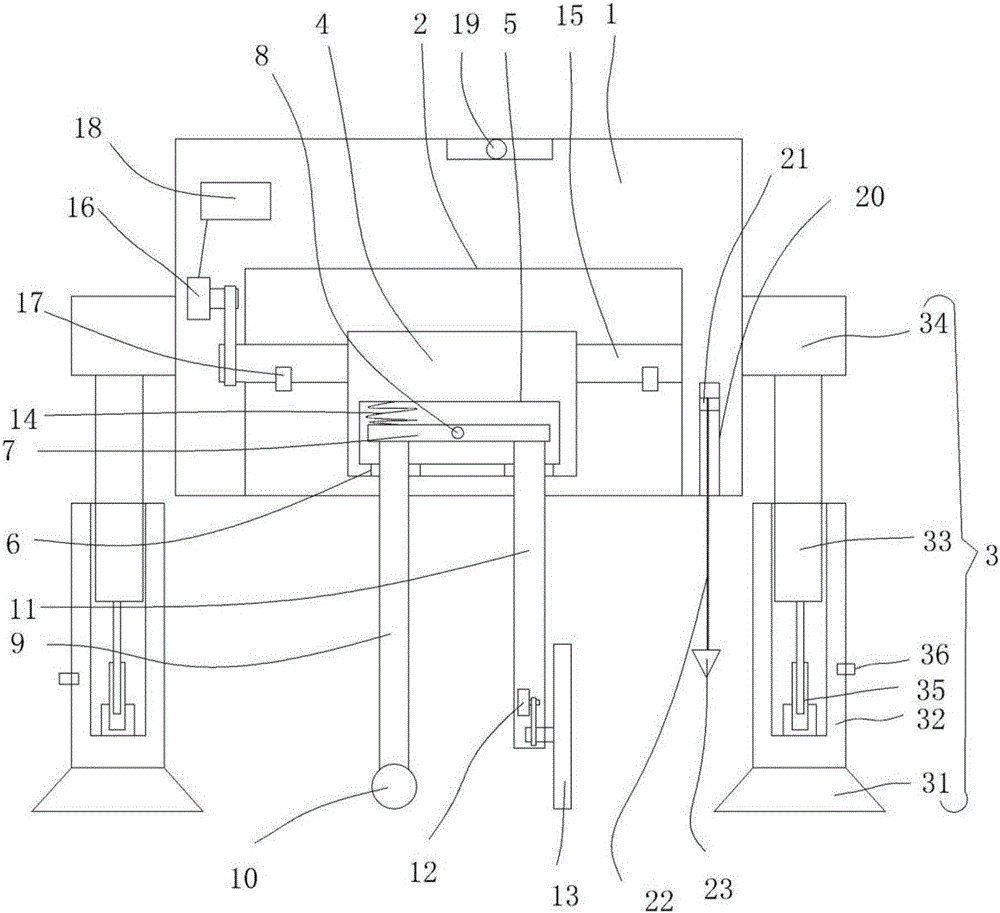

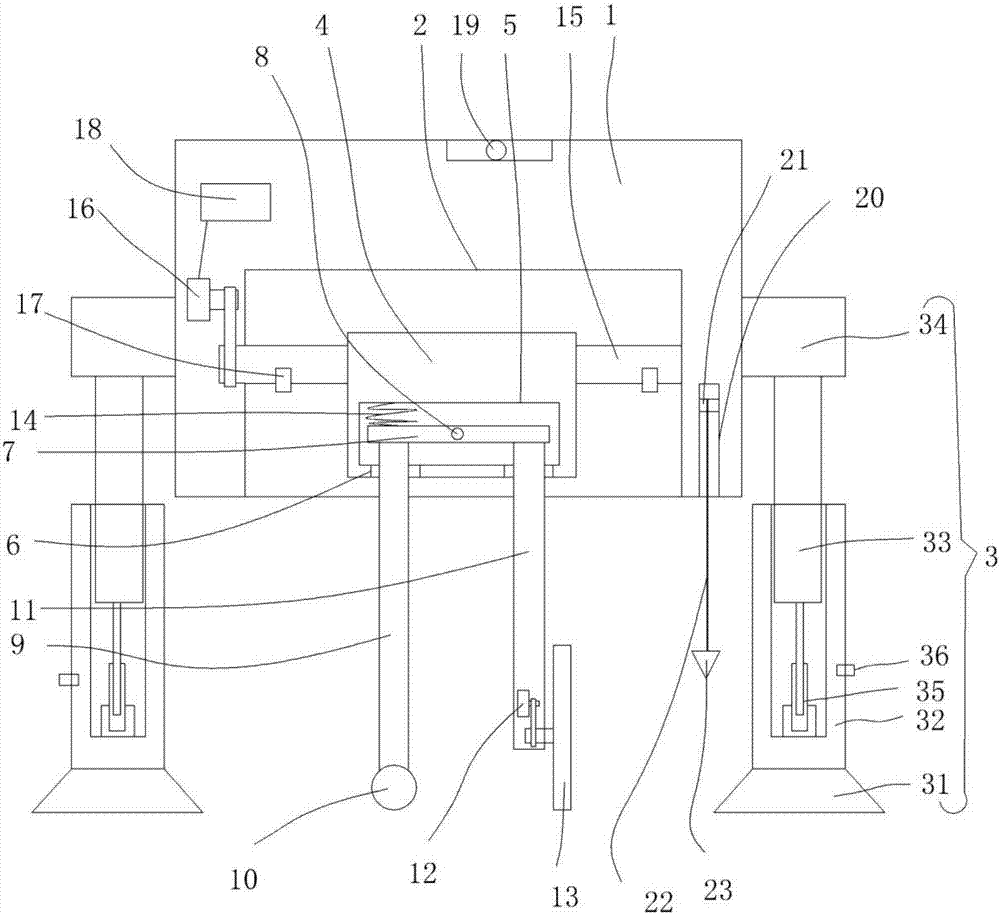

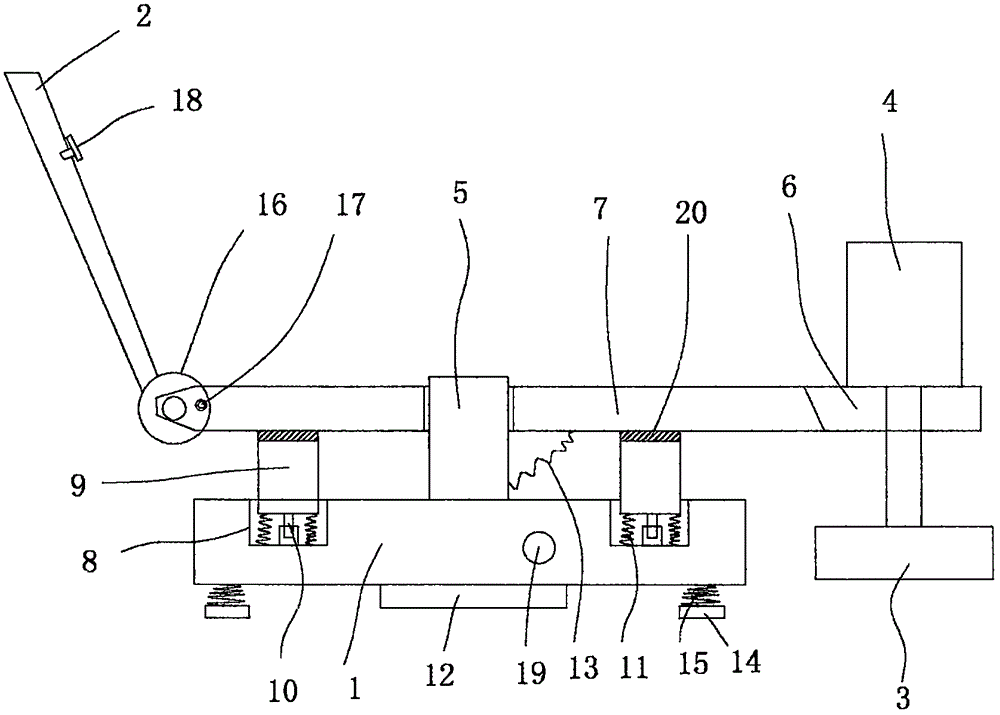

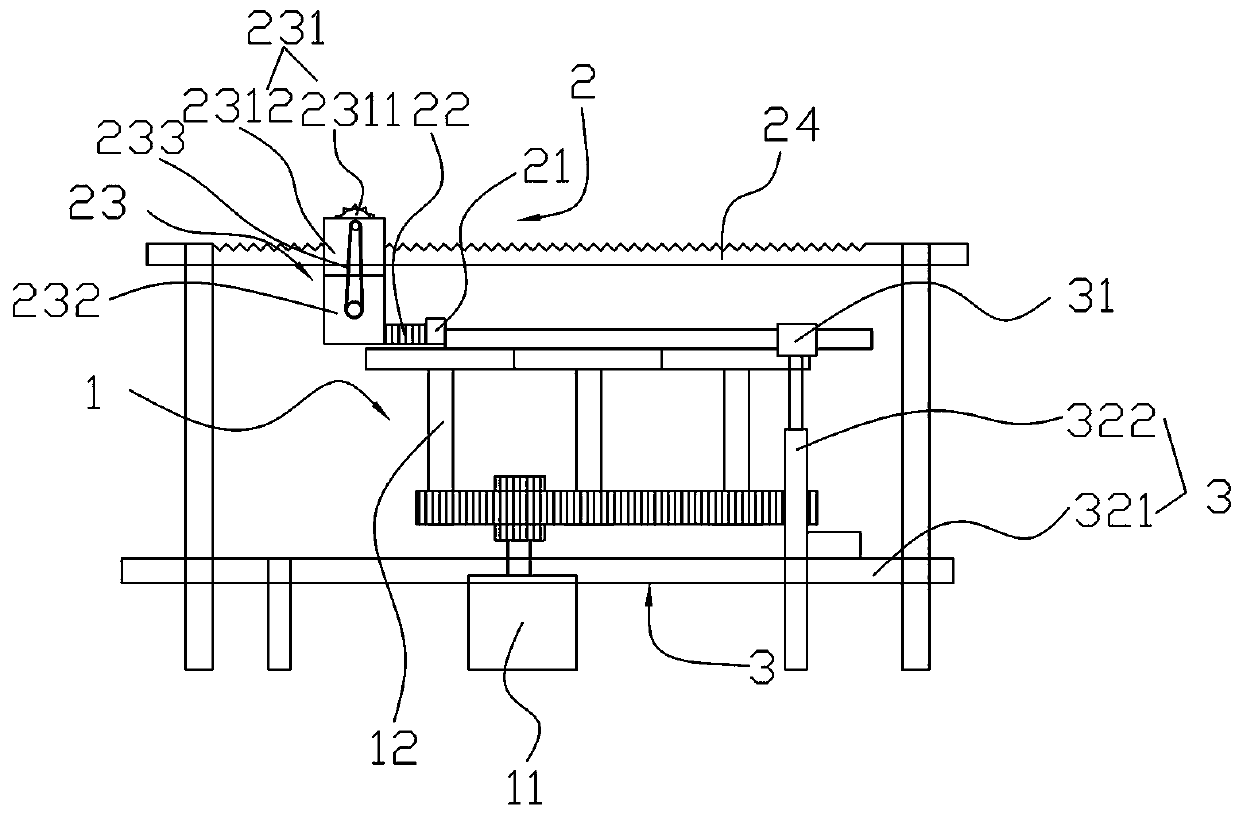

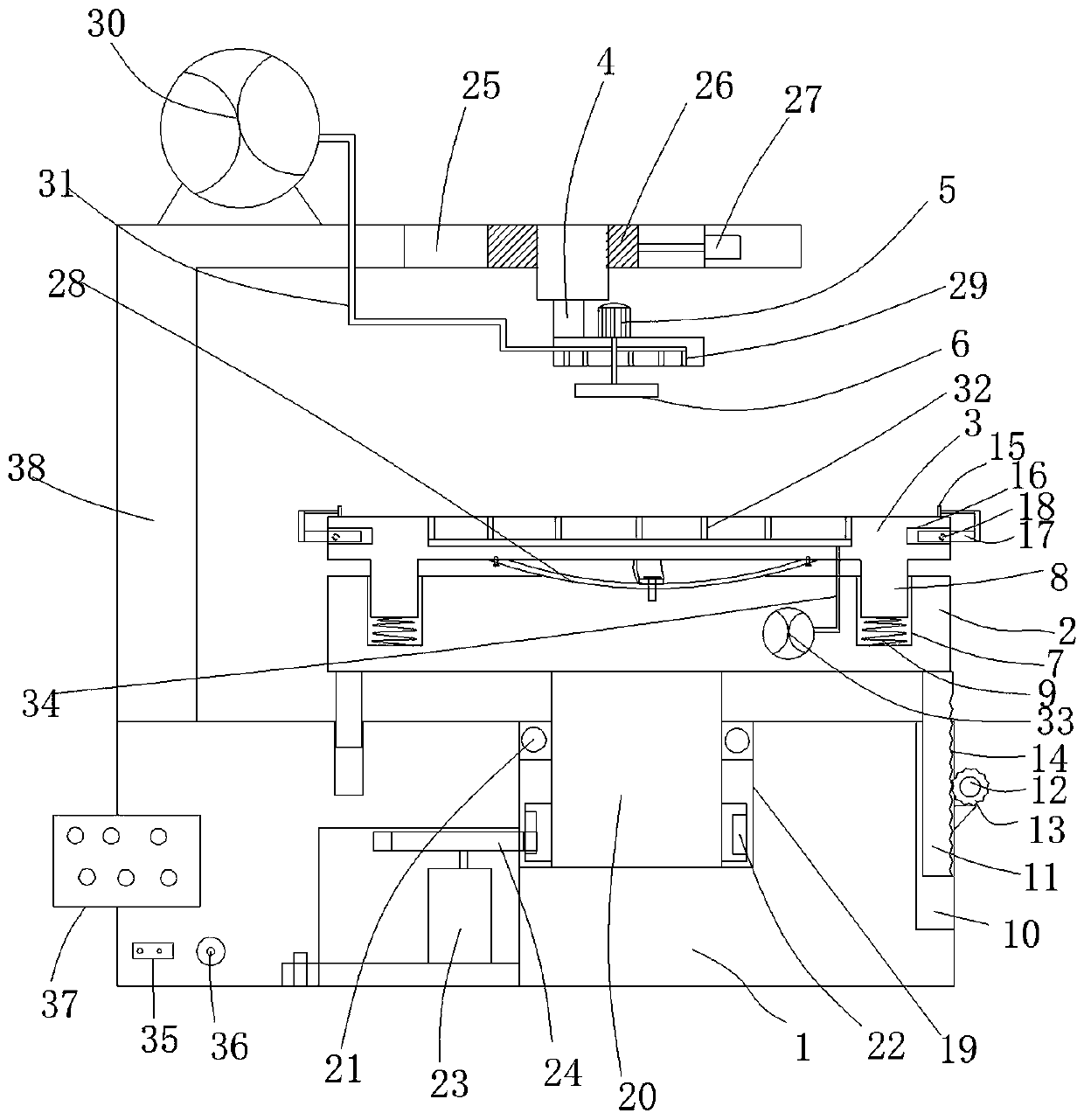

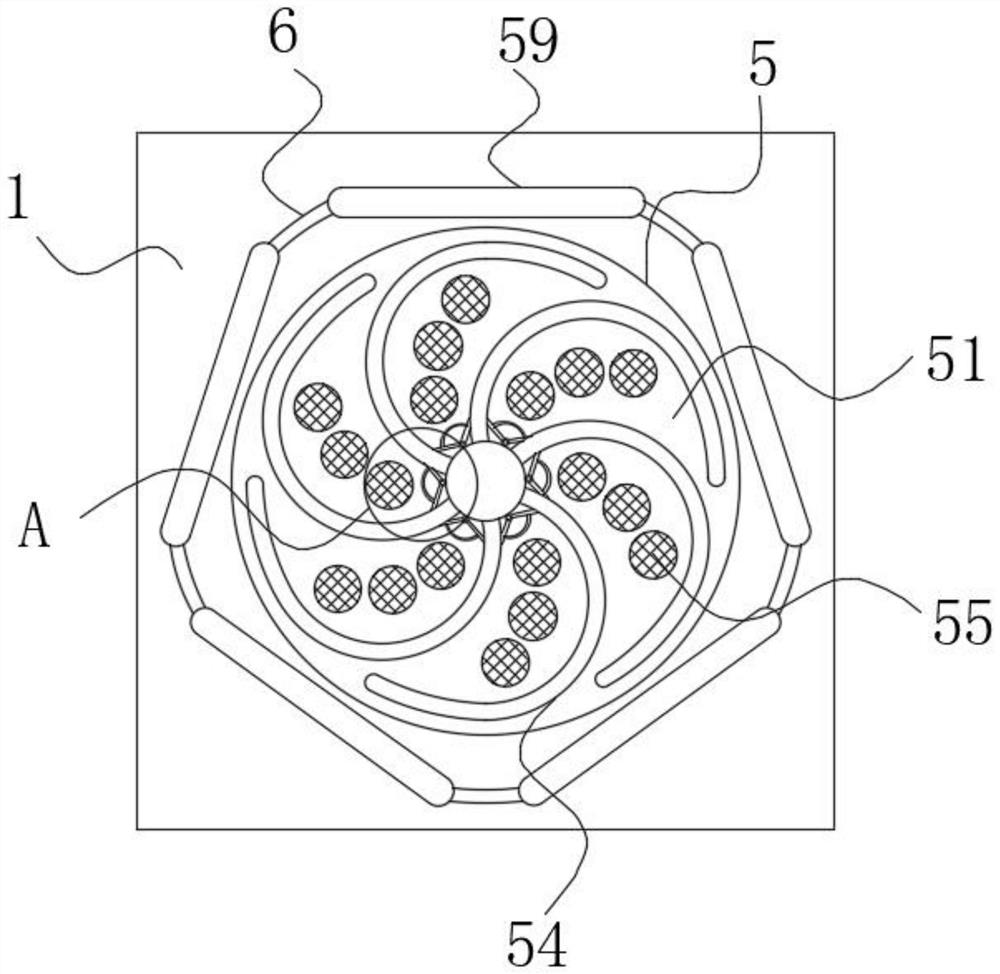

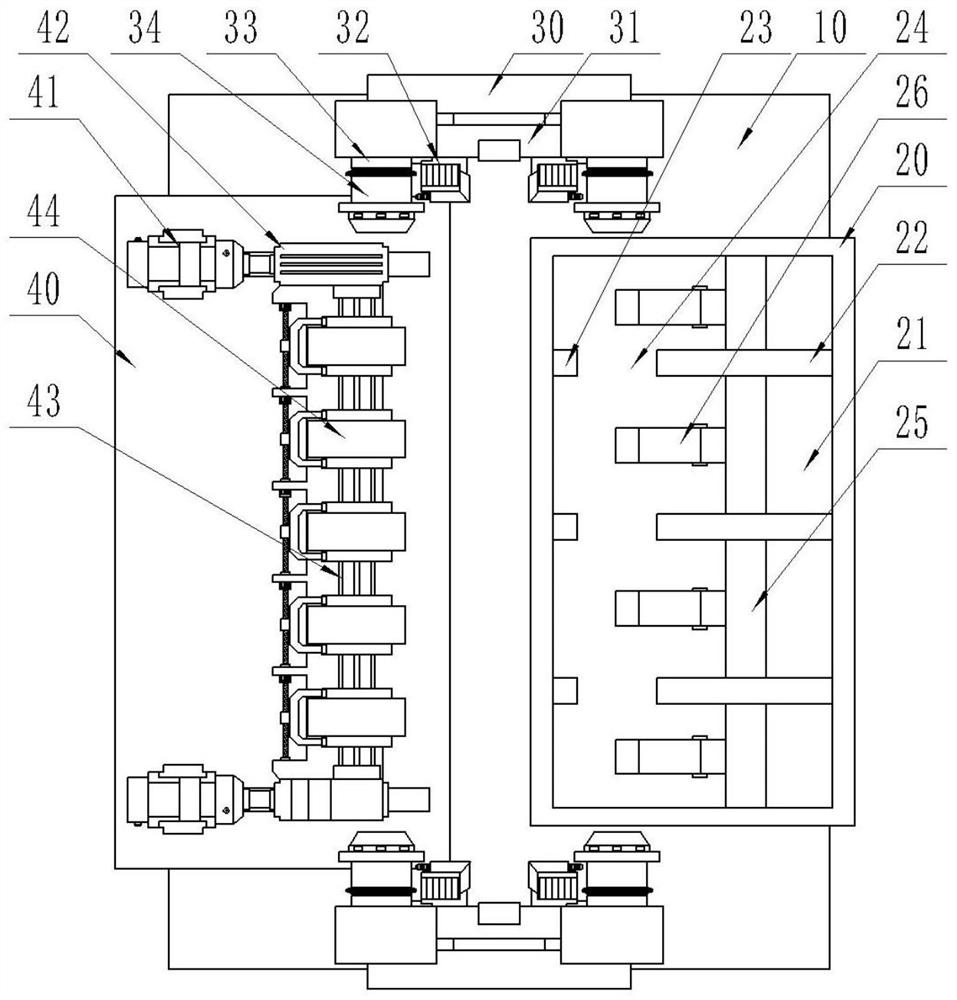

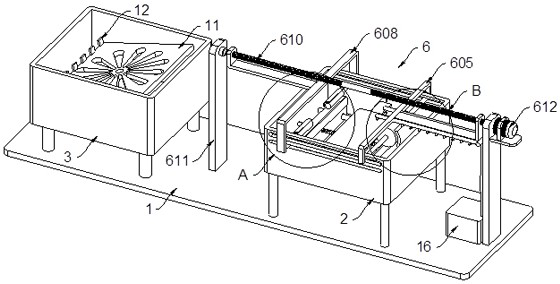

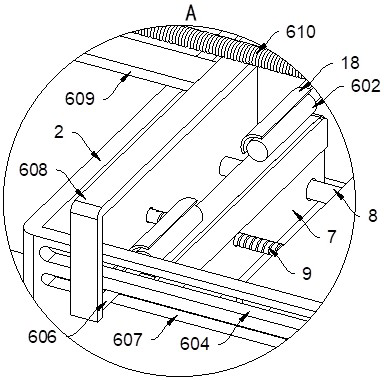

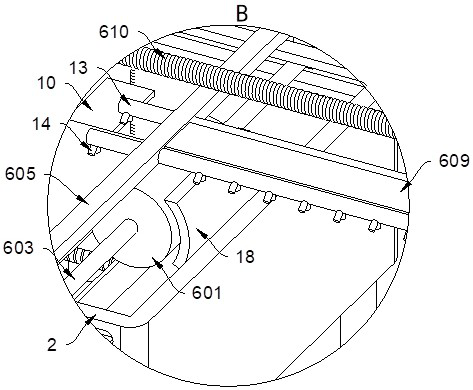

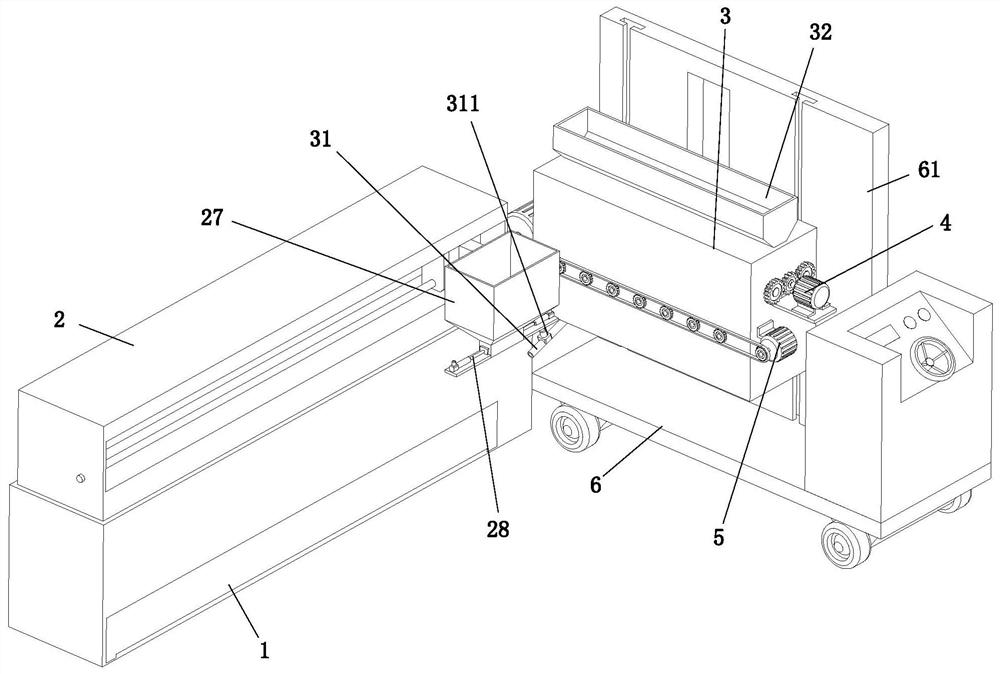

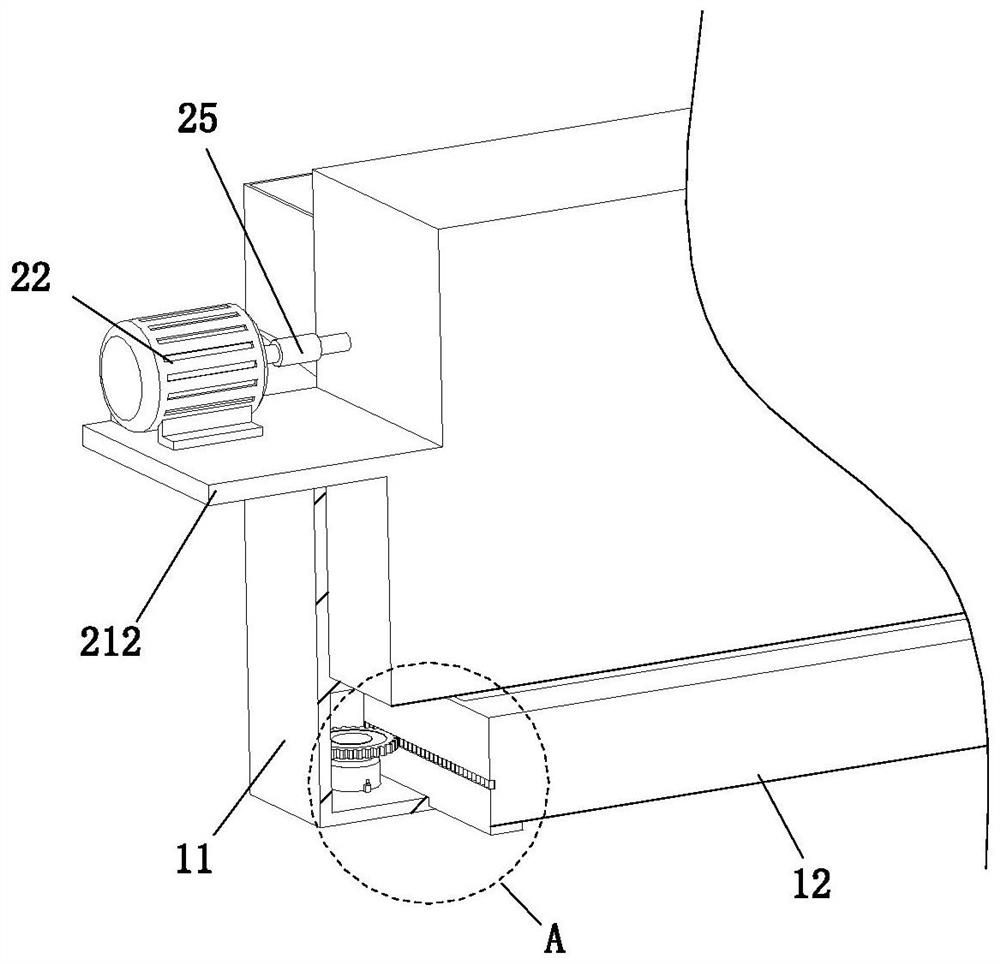

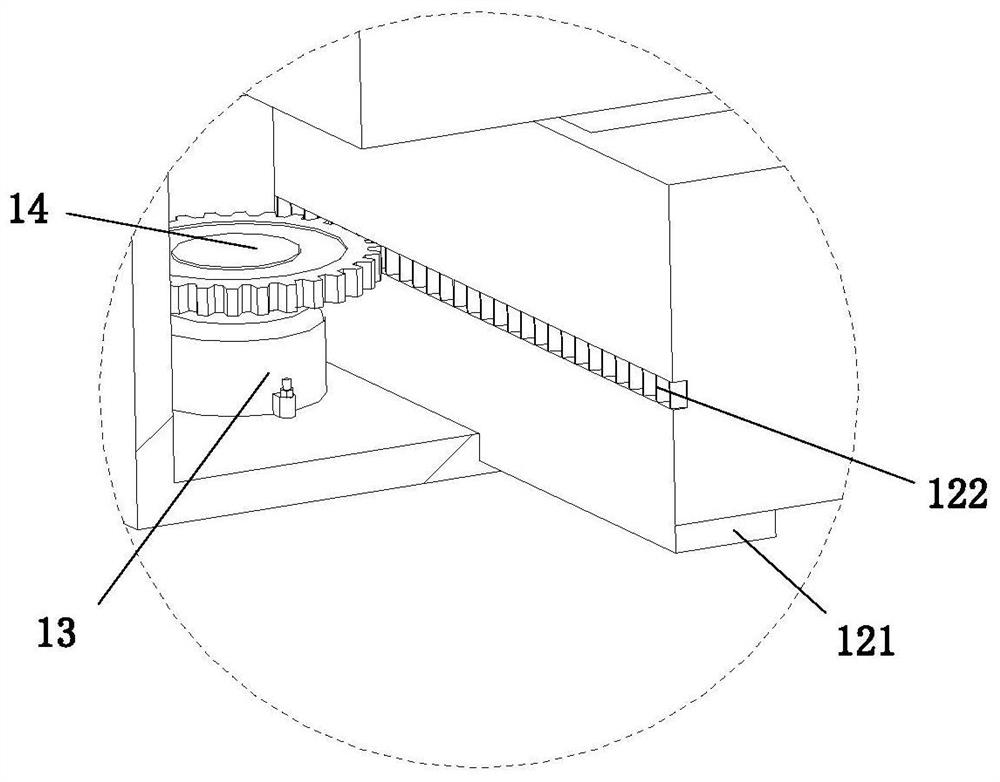

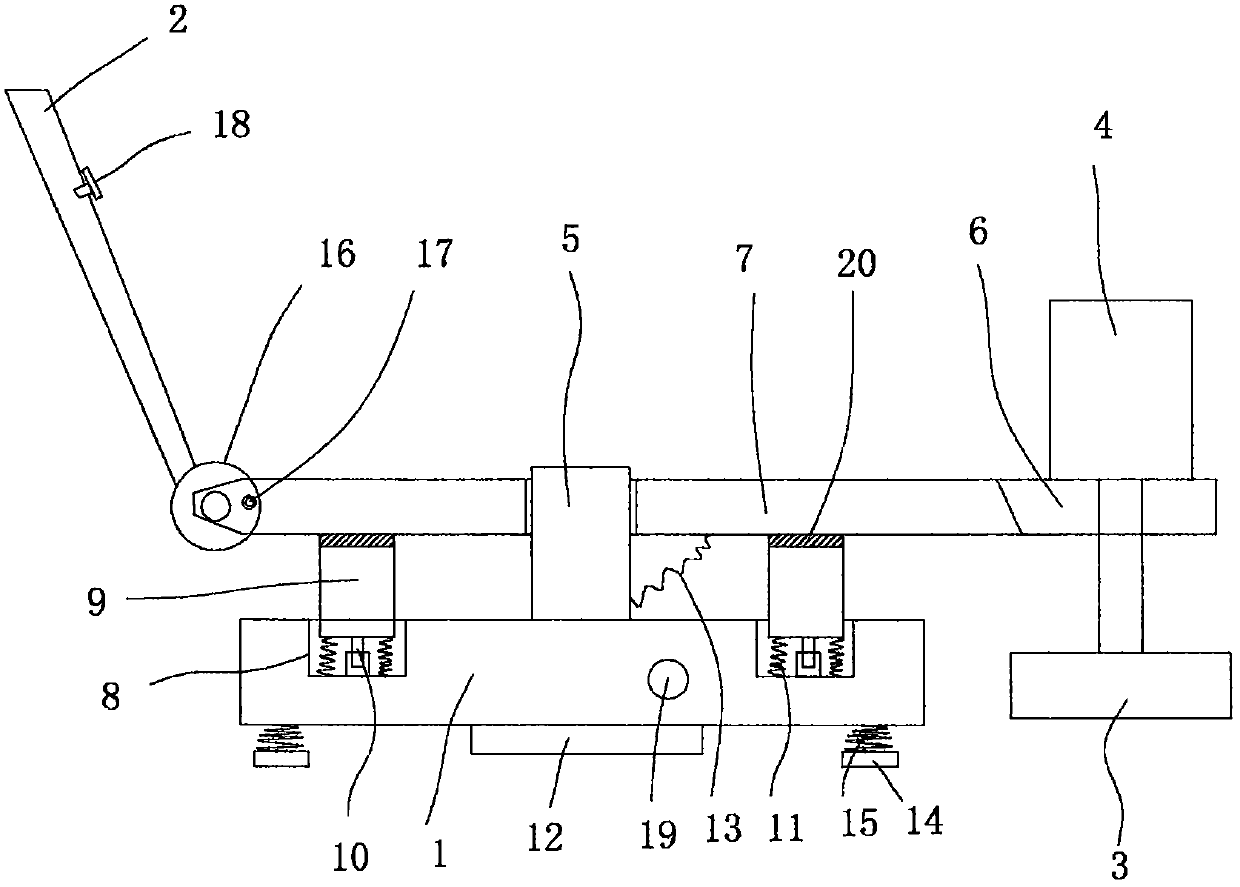

Full-automatic big diamond saw blade double-surface edging machine

InactiveCN104551239ARealize automatic flippingRealize the grinding operationGrinding machine componentsSawing tools dressing arrangementsEngineeringAutomation

The invention discloses a full-automatic big diamond saw blade double-surface edging machine. The full-automatic big diamond saw blade double-surface edging machine is characterized by comprising a rack (1), a big panel (2), a feeding and discharging device (3), a working platform rotating mechanism (4), material clamping and overturning mechanisms (5), a lifting mechanism (6) and a grinding head assembly (7), wherein the rack (1) comprises a lower rack (11), a middle rack (12) and an upper rack (13), the middle rack (12) is arranged on the lower rack (11), and the upper rack (13) is arranged on the middle rack (12); the big panel (2), the feeding and discharging device (3) and the working platform rotating mechanism (4) are arranged on the lower rack (11); the material clamping and overturning mechanisms (5) are arranged on the middle rack (12); the lifting mechanism (6) is arranged on the upper rack (13); the grinding head assembly (7) is arranged on the big panel (2). According to the full-automatic big diamond saw blade double-surface edging machine disclosed by the invention, automatic overturning on a big diamond saw blade can be realized, double-surface edging is realized, feeding and discharging are automatic, the feed amount can be accurately controlled, the automation degree is high, and the edging quality is good.

Owner:HUANGSHI QIBANG AUTOMATION EQUIP

Long pipe type part inner hole honing device and honing method thereof

InactiveCN106625194ARealize the grinding operationRealize mobile workHoning machinesEngineeringPneumatic motor

The invention discloses a long pipe type part inner hole honing device and a honing method thereof, and belongs to the technical field of cutting machining. The long pipe type part inner hole honing device comprises a honing head assembly and a honing brake assembly, the honing head assembly comprises a pneumatic motor and a honing head detachably fixed to a motor rotating shaft; the honing brake assembly comprises a shell, a brake arranged in the shell, a drive air way and an advancing air way, the drive air way and the walking air way are independent, the drive air way is an axial air inlet hole formed in the cylindrical barrel closed end and communicated with the pneumatic motor, and the advancing air way is formed by multiple inclined air holes; and the brake comprises an elastic wheel, a rotating shaft, a fixed support and a movement guide rod. According to the long pipe type part inner hole honing device, driving force of the honing head is provided through the advancing air way, the braking force of the elastic wheel is provided through a pre-tightening spring, the pushing force in the honing direction is provided through the advancing air way, movement of the honing device is driven, and therefore movable honing operation is achieved.

Owner:重庆市同浩同德创业咨询有限公司

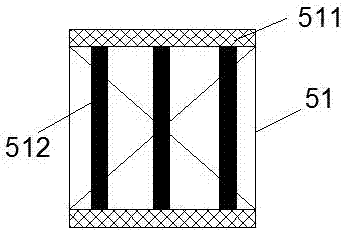

Small polisher and polishing method thereof

InactiveCN106625144AAvoid processing qualityRealize the grinding operationGrinding drivesPortable grinding machinesEngineeringPneumatic motor

The invention discloses a small polisher and a polishing method thereof, and belongs to the technical field of cutting machining. The small polisher comprises a polishing head assembly and a polishing braking assembly, wherein the polishing head assembly comprises a pneumatic motor and a polishing head detachably fixed to a rotary shaft of the motor; the polishing braking assembly comprises a housing as well as a drive air channel, braking air channels and running air channels which are arranged in the housing and mutually independent; the housing is a cylinder with an open end and a closed end; the pneumatic motor enters the cylinder from the open end and is fixed to the cylinder; the drive air channel is an axial air inlet hole; the braking air channels are a plurality of radial air holes; and the running air channels are a plurality of inclined air holes. According to the small polisher and the polishing method thereof which are disclosed by the invention, drive power, braking power and movement power are provided through the three mutually independent air channels respectively to realize polishing operation in an inner hole; a long tool bar in the prior art is cancelled, the rigidity of the cutting point of the small polisher is greatly improved, and the machining quality is remarkably improved.

Owner:重庆市同浩同德创业咨询有限公司

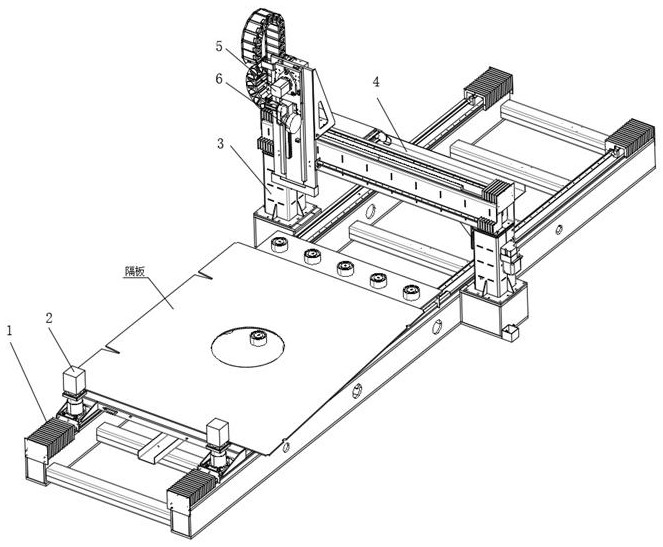

Grinding device for corrugated steel web steel box girder partition plate

PendingCN113664677AEffectively fixedFlexible choice of grinding positionGrinding machinesGrinding feedersGrinding wheelSteel box girder

The invention discloses a grinding device for a corrugated steel web steel box girder partition plate. The device comprises a fixed supporting base, a conveying mechanism, supporting frames, a transverse moving mechanism, a longitudinal moving mechanism and a grinding mechanism, wherein Wherein the whole fixed supporting base is in a lattice shape; the conveying mechanism comprises a conveying table and a conveying transmission mechanism arranged between the fixed supporting base and the conveying table; the supporting frames are arranged on the two sides of the fixed supporting base and clamp the fixed supporting base; the transverse moving mechanism comprises a cross beam arranged between the supporting frames, a transverse moving base located on one side of the cross beam and a transverse moving transmission assembly arranged between the cross beam and the transverse moving base; the longitudinal moving mechanism comprises a longitudinal moving base and a longitudinal moving transmission assembly arranged between the longitudinal moving base and the transverse moving base; the grinding mechanism comprises a connecting base arranged on the longitudinal moving base, a grinding transmission mechanism arranged on the connecting base and a grinding wheel arranged on the grinding transmission mechanism. According to the device, the large-size steel box partition plate can be mechanically and automatically ground, and the grinding operation is rapid and efficient.

Owner:甘肃博睿交通重型装备制造有限公司

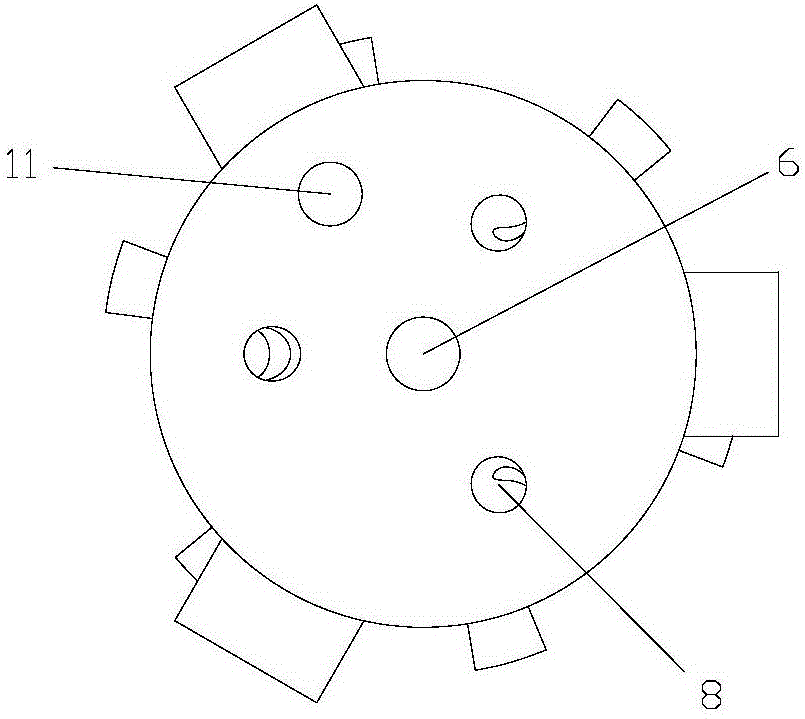

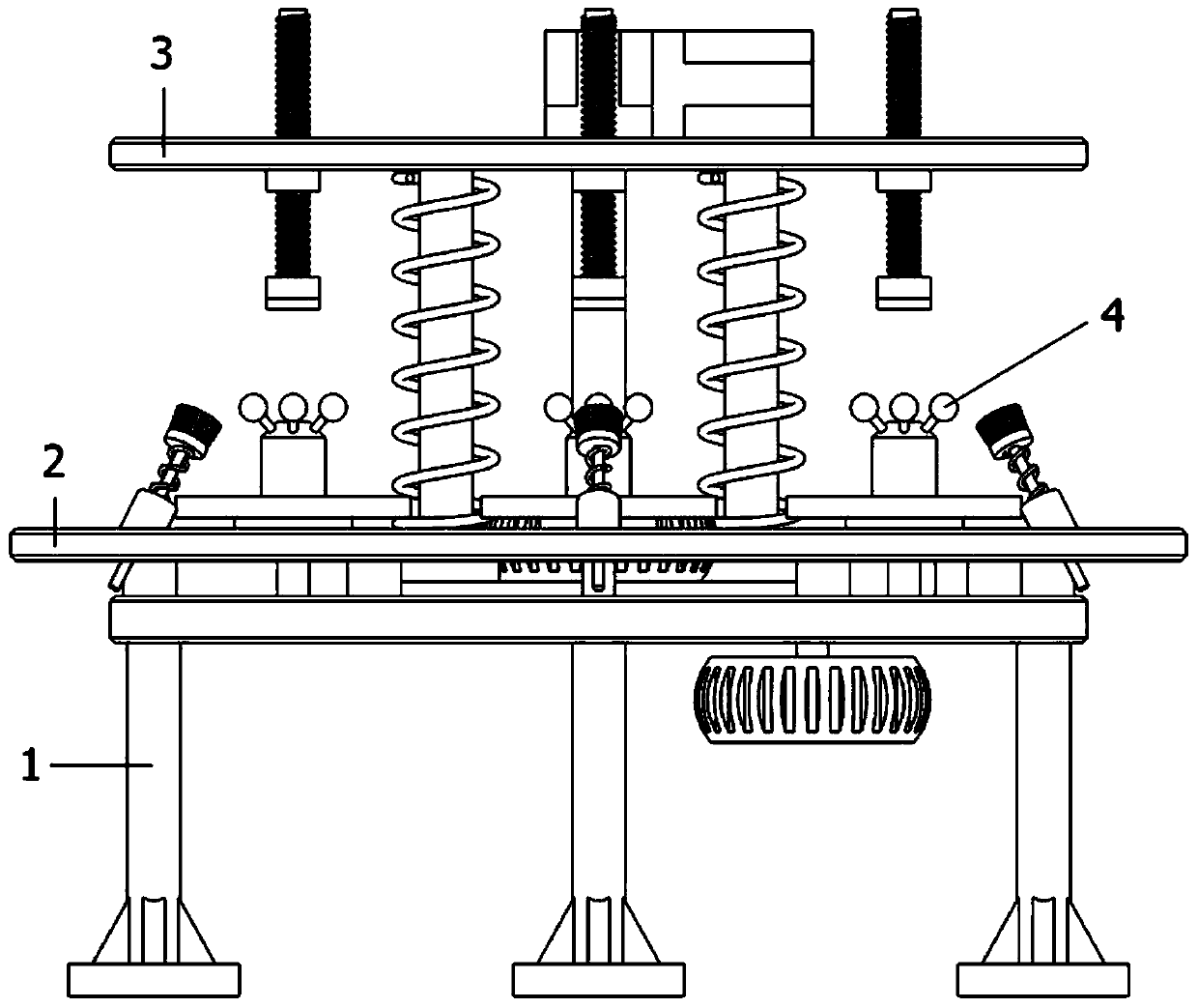

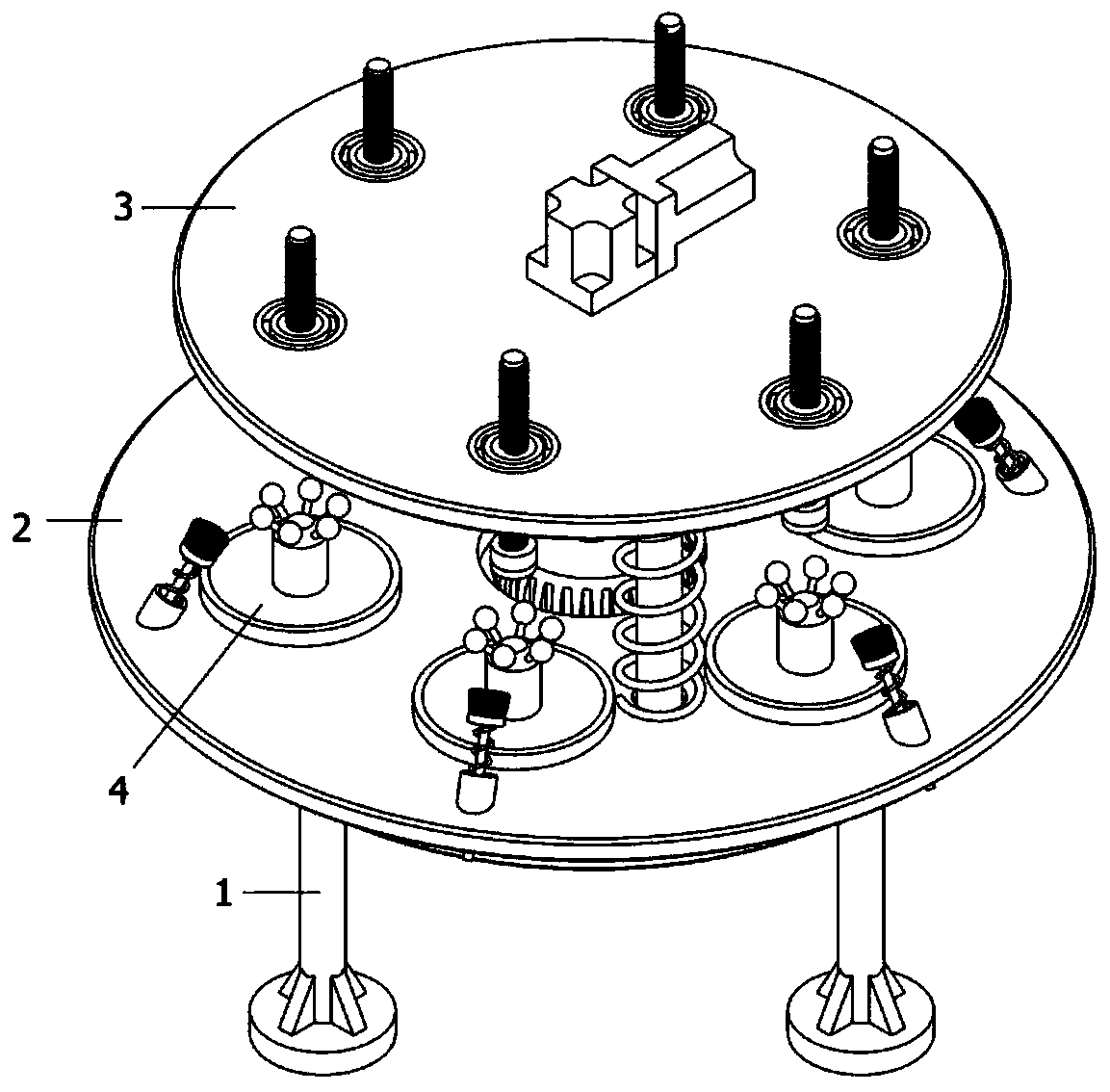

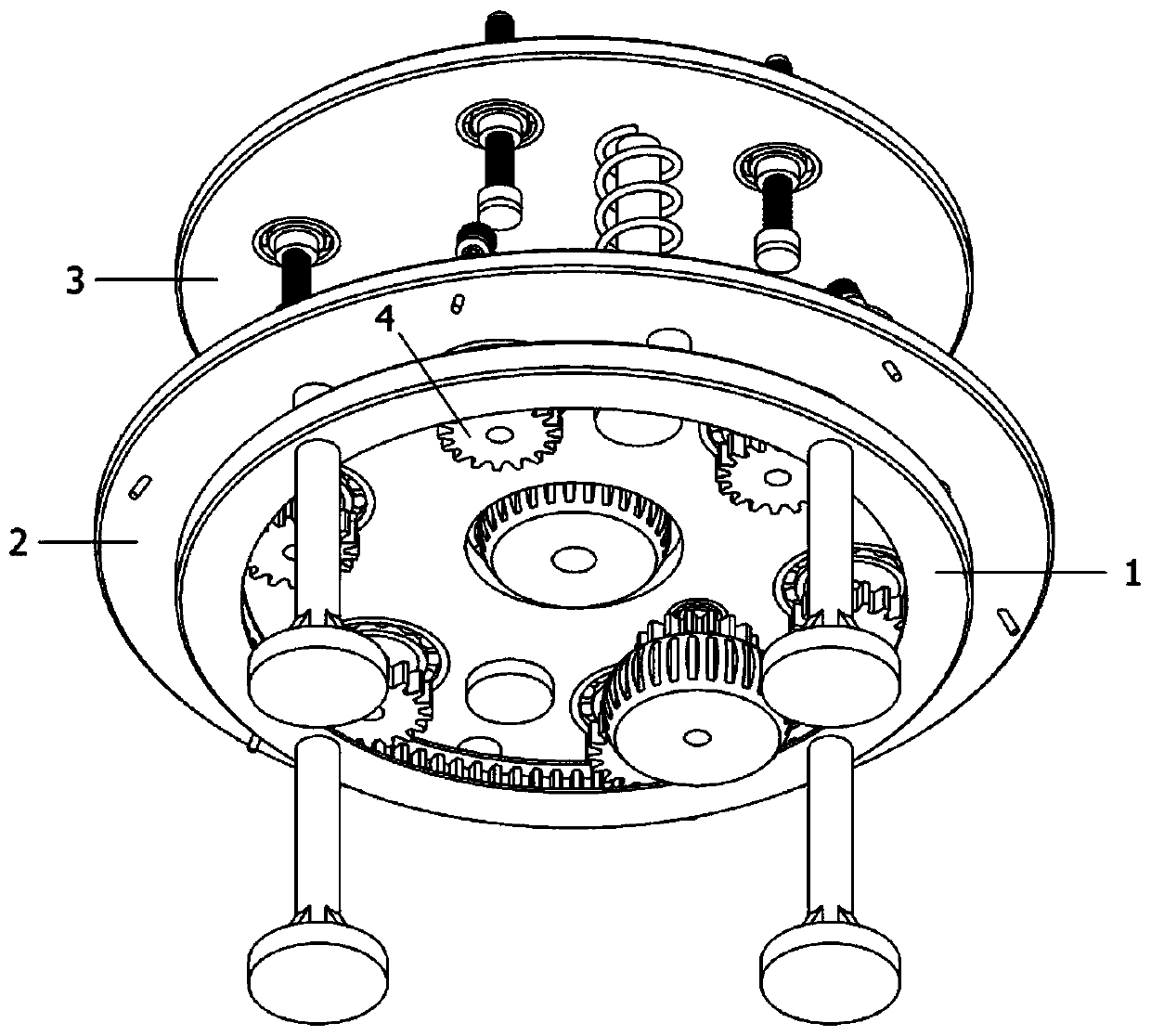

Bowl opening polishing mechanism based on ceramic production

InactiveCN111376146ARealize the grinding operationIncrease productivityEdge grinding machinesGrinding carriagesPolishing

The invention provides a bowl opening polishing mechanism based on ceramic production, and relates to the technical field of ceramic bowl production. The bowl opening polishing mechanism solves the problems that an existing polishing procedure before glaze sealing of a ceramic bowl opening is tedious in operation step and low in efficiency, gloves worn by workers are quickly worn in the polishingprocess, and the gloves worn by the workers need to be replaced frequently. The bowl opening polishing mechanism based on the ceramic production comprises a supporting mechanism, a polishing table isfixedly connected to the top end face of the supporting mechanism, and a pressing type transmission mechanism is slidably connected to the top of the polishing table. By means of the design of the bowl opening polishing mechanism, the workers can conduct bowl opening polishing operation on six ceramic bowls at the same time, the production efficiency of the ceramic bowls is greatly improved, the workers do not need to press the bottoms of the ceramic bowls all the time like the traditional bowl opening polishing procedure operation steps, the problem that the gloves worn by the workers are incontinuous frictional contact with the bottoms of the ceramic bowls is avoided, and the replacement frequency of the glove is greatly reduced.

Owner:郭建平

Intelligent road construction device and work method thereof

InactiveCN107815946ARealize the grinding operationSimple structureRoads maintainenceElectric machineEngineering

The invention discloses an intelligent road construction device and a work method thereof. The intelligent road construction device comprises a device shell, wherein a cavity is arranged in the deviceshell, an opening is formed in the bottom surface of the cavity, a movable block is arranged in the cavity, an adjusting cavity is arranged in the movable block, two vertical holes communicated withthe adjusting cavity are formed in the movable block, a balanced warped rod is arranged in the adjusting cavity, an abutting rod is arranged in one vertical hole, a rolling ball is arranged at the bottom end of the abutting rod, a polishing column rod is arranged in the other vertical hole, a polishing driving motor is arranged in the polishing column rod, a polishing cutter disk connected with the polishing driving motor is arranged on the bottom surface of the polishing column rod, a stress buffer spring is arranged between the top of the abutting rod and a top wall of the adjusting cavity,a translation lead screw and a forward-reversed-rotation motor connected with the translation lead screw are arranged in the cavity, and a horizontal detector is arranged on the device shell. The intelligent road construction device disclosed by the invention has the advantages of simple structure, convenience in operation, good use stability, high intelligence, ability in effectively achieving roadbed polishing operation, ability in greatly reducing polishing cost, strong applicability and good practicability.

Owner:蔡留凤

Intelligent road construction device

InactiveCN105821745BRealize the grinding operationSimple structureRoads maintainenceDrive motorEngineering

The invention discloses an intelligent road construction device which comprises a device shell. A cavity with an opening formed in the bottom face is formed in the device shell. A movable block is arranged in the cavity. An adjusting cavity is formed in the movable block. The movable block is provided with two vertical holes communicating with the adjusting cavity. A balance warping rod is arranged in the adjusting cavity. An abutting rod is arranged in one vertical hole. A rolling ball is arranged at the bottom end of the abutting rod. A grinding columnar rod is arranged in the other vertical hole and internally provided with a grinding drive motor. A grinding cutter head connected with the grinding drive motor is arranged on the bottom face of the grinding columnar rod. A stress buffer spring is arranged between the top of the abutting rod and the top wall of the adjusting cavity. A horizontally-moving lead screw and a forward and reverse rotation motor connected with the horizontally-moving lead screw are arranged in the cavity. A level detector is arranged on the device shell. The intelligent road construction device is simple in structure, convenient and quick to operate, good in use stability, high in intelligence, capable of effectively achieving roadbed grinding operation and greatly reducing the grinding cost and high in applicability and practicality.

Owner:李文艺 +22

Automobile roof production equipment having specially-shaped corner polishing function

InactiveCN112207657AChange the center positionRealize clamping workEdge grinding machinesGrinding drivesTransmission beltEngineering

The invention discloses automobile roof production equipment having a specially-shaped corner polishing function. The equipment comprises a main body frame; a first air cylinder is installed on the left side of the lower side of the inside of the main body frame; and a rotating cylinder barrel is welded to the upper side of a first air rod. Compared with existing common roof polishing production equipment, the automobile roof production equipment having the specially-shaped corner polishing function has the advantages that a guide column is arranged, a lifting block is arranged below the guidecolumn, the lifting block is matched with a lifting groove, the first air cylinder drives the rotating cylinder barrel to move through the first air rod, the rotating cylinder barrel drives the guidecolumn to rise and fall through the lifting block, a guide thread is arranged in the middle of the guide column, the guide thread is matched with a rotating block, the spiral angle of the guide thread is 180 degrees, the guide column can be driven to rotate by 180 degrees when a lifting cylinder barrel performs the lifting motion, and a roof is automatically transferred to a clamping base from afeeding conveying belt to be machined.

Owner:CHONGQING TECH & BUSINESS UNIV

Grinding device with cleaning mechanism for brown fused alumina abrasive material machining and grinding method

InactiveCN112264153AImplement cleanup operationsRealize the grinding operationDirt cleaningGrain treatmentsElectric machineryEngineering

The invention discloses a grinding device with a cleaning mechanism for brown fused alumina abrasive material machining and a grinding method. The grinding device comprises a round shell, two feedingpipes are fixedly connected to the top face of the round shell in a left-right symmetry mode, the feeding pipes penetrate through the round shell and communicate with the interior of the round shell,and the feeding pipes are arranged in a funnel shape. Dust collectors are fixedly connected to the top faces of the feeding pipes, a plurality of dust collection openings are formed in the inner wallsof the dust collectors, dust collection pipes are fixedly connected to the side walls of the sides, away from the center of the round shell, of the dust collectors, penetrate through the dust collectors and communicate with the dust collection openings, and a protection box is fixedly connected to the center of the top face of the round shell. A motor is installed in the protection box, a rotating shaft is fixedly connected to an output shaft of the motor, a first bevel gear is fixedly connected to the side wall of the rotating shaft, and the first bevel gear is located on the outer side of the round shell. Through a series of structures, the device has the characteristics of being high in grinding efficiency, high in use efficiency and the like.

Owner:HUZHOU HUA TONG GRINDER MFG CO LTD

Grinding and removing device for impurity scraps on surface of steel

InactiveCN105856035AEffective and fast sanding operationEfficient and fast implementation of grinding operationsGrinding drivesPortable grinding machinesPulp and paper industryVertical cylinder

The invention discloses a grinding and removing device for impurity scraps on the surface of steel. The device comprises a support, a handle and a grinding disk. The support is provided with a grinding motor used for being connected with the grinding disk. A rotating column rod is arranged on the middle portion of the support. The support is provided with a grinding supporting plate. A rotating connection plate is arranged between the grinding supporting plate and the handle. The middle portion of the rotating connection plate is arranged on the rotating column rod. The grinding motor and the grinding disk are arranged at one end of the rotating connection plate. The support is further provided with an annular concave cavity with an opening formed in the top face. In the annular concave cavity, arrangement is performed with the rotating column rod as the center; a height adjusting ring is arranged in the annular concave cavity; a vertical cylinder is arranged between the height adjusting ring and the annular concave cavity; a buffering pressing spring is arranged between the height adjusting ring and the bottom wall of the annular concave cavity; the bottom face of the rotating connection plate is pressed on the height adjusting ring in an abutting manner; and a grinding pressure disk is fixedly arranged on the bottom face of the rotating column rod. The grinding and removing device for the impurity scraps on the surface of steel is simple in structure, convenient and fast to operate, good in using stability, high in universality and good in practicability.

Owner:天津恒新伟业科技有限公司

Grinding device used for brush machining

ActiveCN108927714AImprove efficiency and qualityRealize the grinding operationGrinding machinesGrinding/polishing safety devicesPistonMachining

The invention discloses a grinding device used for brush machining. The device comprises a first mounting plate and a second mounting plate, a first piston is arranged on the first mounting plate, a first piston shaft is arranged on the first piston, a second piston is arranged on the first piston shaft, the second piston is arranged on the second mounting plate, an eighth piston is arranged on the opposite sides of the first mounting plate and the second mounting plate, an eighth piston shaft is arranged on the eighth piston, a ninth piston is arranged on the eighth piston shaft, a motor is arranged on the ninth piston, a third rotating shaft is arranged on the motor, a rotating disc is arranged on the third rotating shaft, and multiple grinding protrusions are arranged on the periphery of the rotating disc. The brush grinding efficiency and quality can be effectively improved.

Owner:望江县南山刷业有限公司

Alloy surface finish treatment equipment

InactiveCN111558860APrevent deviationAvoid deformationGrinding drivesGrinding work supportsPolishingElectric machinery

The invention discloses alloy surface finish treatment equipment and relates to the technical field of alloy surface treatment equipment. The alloy surface finish treatment equipment comprises a polishing mechanism and a transfer mechanism. The polishing mechanism comprises a polishing motor and a plurality of polishing wheel discs driven by the polishing motor to rotate, the polishing wheel discsare paved on a same horizontal plane, and the transfer mechanism comprises transfer pressure blocks fixing the front and back ends of an alloy plate and a transfer push rod connected to the transferpressure blocks. The transfer mechanism further comprises a propelling device arranged at the tail end of the transfer push rod and a transfer track arranged above the propelling device. The propelling device is mounted on the transfer track. The alloy surface finish treatment equipment is mainly used for polishing the surface of the alloy plate to improve the roughness of the surface of the alloy. The alloy surface finish treatment equipment can prevent the alloy plate from being extruded to deform while polishing the alloy plate, so that the polishing quality is improved. Meanwhile, the polishing precision can be further controlled by controlling the contact forces between the alloy plate and the polishing wheel discs and the operating power of the propelling motor.

Owner:嘉兴奥普劲达厨卫科技有限公司

Adjustable type plastic plate grinding equipment

PendingCN110103091AReasonable structureEasy to operateGrinding drivesGrinding work supportsEngineeringDrive motor

The invention discloses adjustable type plastic plate grinding equipment. The adjustable type plastic plate grinding equipment comprises a base, a supporting frame and a grinding panel, wherein a grinding base is arranged on the top of a grinding frame; a grinding motor is fixedly arranged on the top of the grinding base; a grinding disc is arranged on the main shaft of the grinding motor; at least three buffer concave cavities with openings in top surfaces are arranged in the supporting frame; the bottom surface of the grinding panel is fixedly equipped with buffer column rods which are the same with the buffer concave cavities in position; buffer springs are fixedly arranged between the bottom ends of the buffer column rods and the bottom walls of the buffer concave cavities; a verticaldovetail slide slot is formed in the side wall of the base; the bottom of the grinding frame is fixedly equipped with a dovetail-shaped slide block; a drive motor is fixedly arranged on the base; a drive gear is fixedly arranged on the main shaft of the drive motor; a positioning clamping block is arranged on the top surface of the grinding panel; and a positioning insertion slot is fixedly formedin the side surface of the grinding panel. The adjustable type plastic plate grinding equipment is reasonable in structure setting, facilitates preventing an excessive grinding condition, guaranteesgrinding quality, is strong in applicability and is high in practicability.

Owner:刘逸

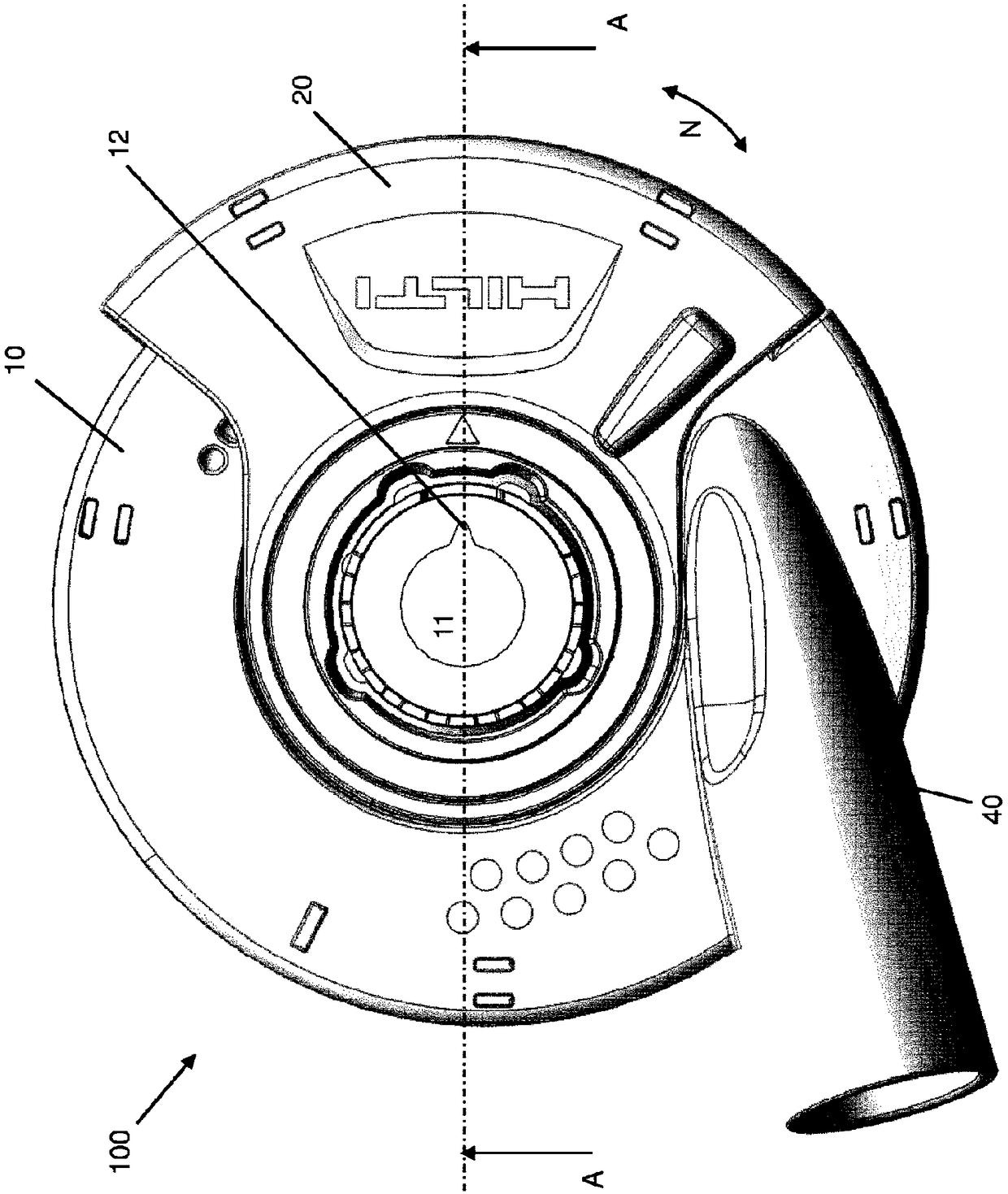

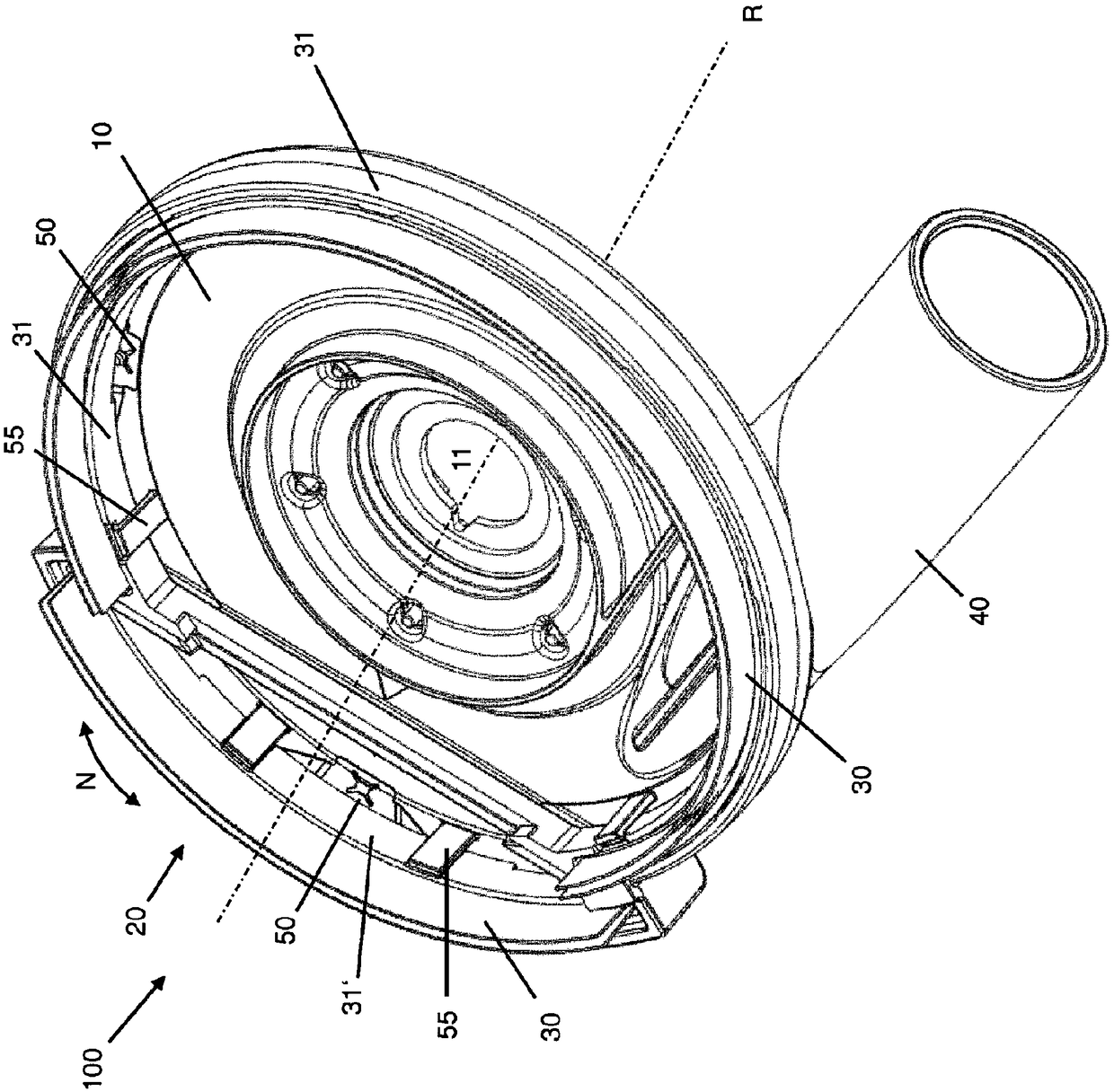

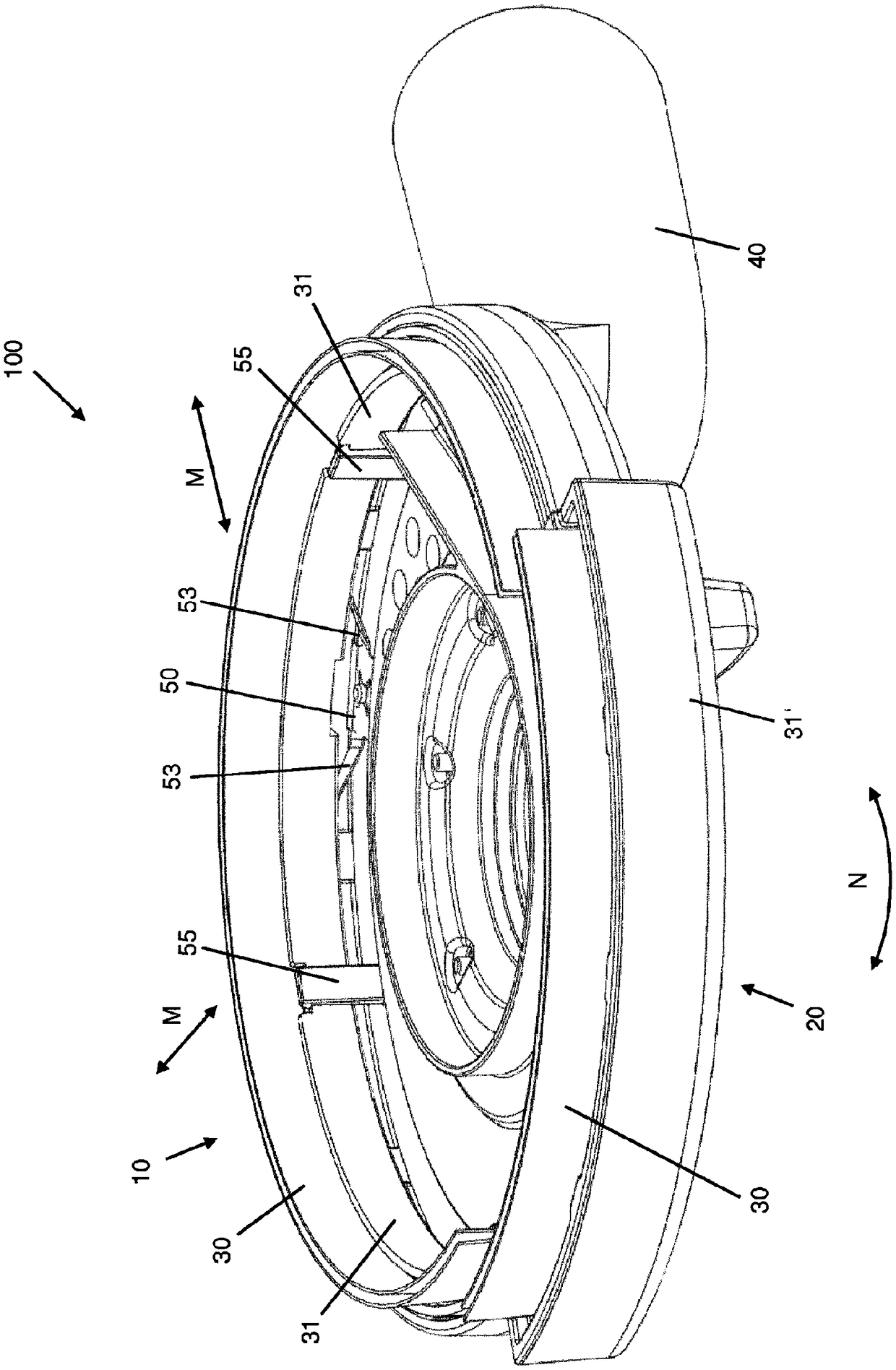

Dust collector for angle grinder

ActiveCN108698200ASmall toleranceImprove sealingPortable grinding machinesGrinding/polishing safety devicesAngle grinderEngineering

A dust collector for an angle grinder comprises a collector body for covering a circular grinding disk, a sealing element for sealing at least some sections of the collector body from a surface to bemachined by the grinding disk, at least some sections of the sealing element being placeable in a first and a second retaining rail, and a suction terminal via which the abraded surface particles canbe sucked off the collector body. The first retaining rail extends along a closed periphery of the collector body, and in the collector body, the sealing element is spring-mounted by at least one spring element in the axial direction relative to the axis of rotation of the grinding disk.

Owner:HILTI AG

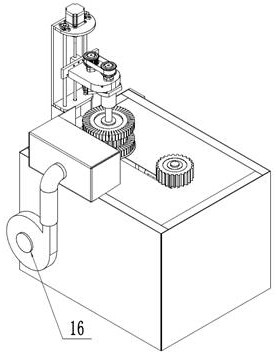

Environment-friendly grinding device

InactiveCN112809475AEasy to handleAchieve sanding effectGrinding drivesGrinding headsGear wheelElectric machinery

The invention belongs to the technical field of wall grinding, and particularly relates to an environment-friendly grinding device. The grinding device comprises a mounting block, a motor, a grip, a suction connector and a grinding mechanism, wherein the lower end of the mounting block is square, the motor is fixedly mounted in the upper end of the mounting block, the suction connector is fixedly mounted at the right end of the mounting block, and the grinding mechanism is arranged in the mounting block; the grip is fixedly connected to the outer end of the motor; the grinding mechanism comprises a rotating block, a telescopic rod, a mounting column, a scraping plate, a filter screen, a hinged plate, a gear set and an arc-shaped plate; and the inner end of the telescopic rod is fixedly connected to a rotating shaft at the front end of the motor in a sleeving mode, and the rotating block is fixedly connected to the outer end of the telescopic rod. In the rotating process of a rotating plate, the inner end of the rotating plate continuously extrudes a rubber ball in the wall of the scraping plate, so that cooling liquid in the rubber ball is continuously extruded against a cooling groove in the rotating plate through a hose for exchange, then high temperature generated in the grinding process is greatly lowered, the rotating plate is effectively protected, and a high grinding effect is ensured.

Owner:赵月凤

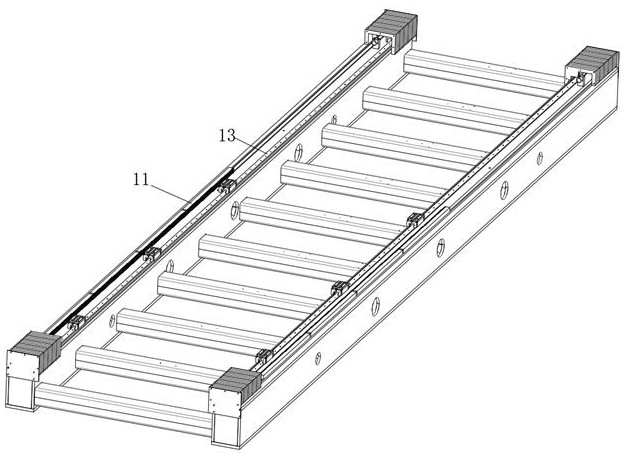

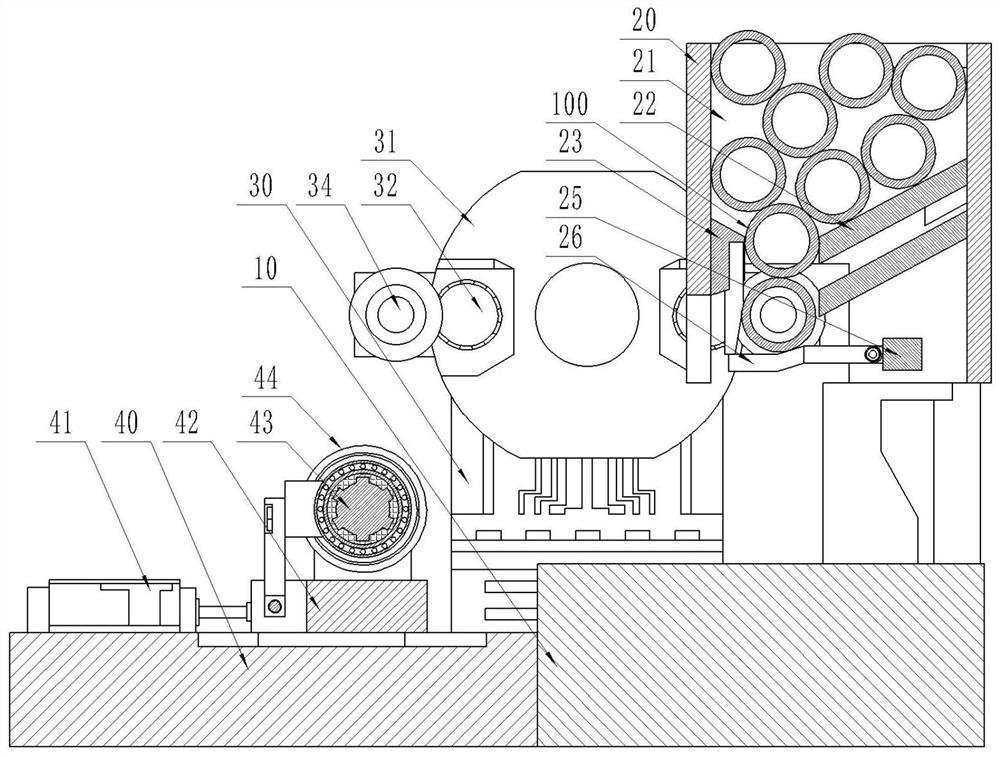

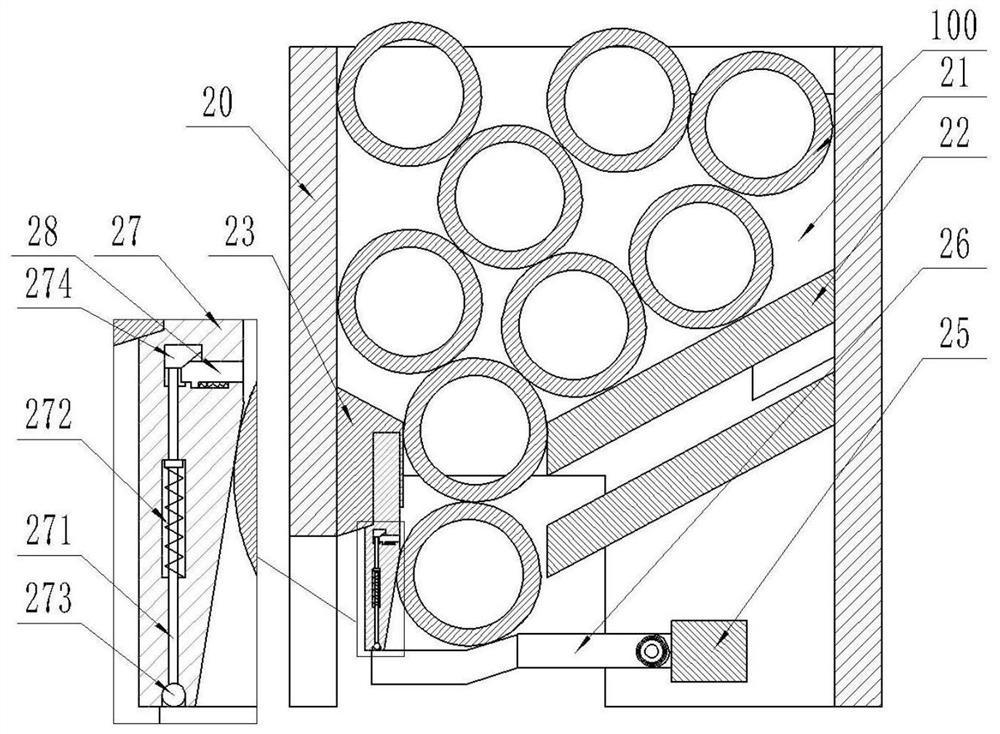

Automatic feeding and polishing device, production line with same and method

PendingCN113857946ARealize automatic feedingRealize the grinding operationEdge grinding machinesGrinding carriagesProduction linePolishing

The invention discloses an automatic feeding and polishing device and relates to the technical field of steel pipe polishing. The automatic feeding and polishing device comprises a feeding frame, a rotary fixing mechanism and a polishing seat. Steel pipes to be polished are placed in the feeding frame in a centralized mode, the single steel pipe is guided into a preset position of the bottom of a discharging opening through a right or left guide plate of the feeding frame, then the steel pipes at the bottom of the discharging opening are clamped in a telescopic mode through a clamping head of the rotary fixing mechanism, and the steel pipes are moved to the polishing seat to be rotationally polished. When the steel pipes at the bottom of the discharging opening move out of the discharging opening, a movable baffle on the side of the discharging opening is stressed to rotate, so that a gravity ball pulls a pressure head to extrude a barrier plate to extend out to limit the steel pipe on the discharging opening to fall into the bottom of the discharging opening, and the barrier plate can be reset only after the movable baffle is reset, and finally the steel pipe on the discharging opening falls into the bottom of the discharging opening. By means of the simple structure, the rotary fixing mechanism can move the steel pipes to be polished into the polishing seat one by one to be polishing, automatic feeding, clamping and polishing operation is achieved, and the polishing efficiency is greatly improved.

Owner:江苏宏宝优特管业制造有限公司

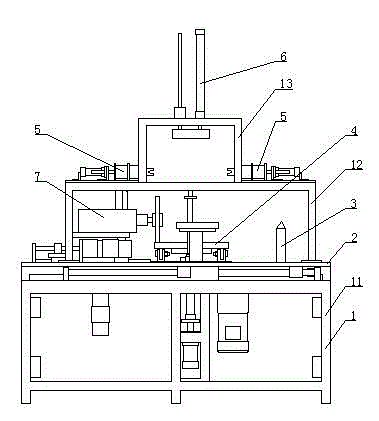

Gear production grinding device

ActiveCN112123073AImprove efficiencyEasy loading and unloadingEdge grinding machinesGrinding carriagesProcess engineeringWorkbench

The invention discloses a gear production grinding device. The device comprises a workbench fixed on the ground; a lifting table capable of driving a sliding base to move up and down is installed on the workbench; a polishing rotor assembly is fixed on the sliding base of the lifting table and used for installing an upper grinding wheel; the grinding wheel and a grinding wheel motor are driven bya synchronous belt to synchronously rotate to grind a workpiece, a dust removal device is installed on the side face of the workbench, the dust removal device is started to achieve dust-free operationwhile grinding operation is conducted, the control part of the whole device is installed on the side face of the workbench, and operation and maintenance are convenient. According to the gear production grinding device provided by the invention, the upper grinding wheel, a lower grinding wheel and a rotary motor for fixing the workpiece can be controlled through control buttons, the movements oflifting and traverse motors can be controlled separately, meanwhile, a linkage switch can be started, continuous action of the device is achieved through program control, grinding and dust removal areintegrated, the production process is efficient and rapid, the grinding precision is high, and the environmental protection performance is good; and meanwhile, the labor intensity of operators can beeffectively reduced.

Owner:上海鸿靓机械设备有限公司

External wall insulation plate production and processing equipment

InactiveCN111451861AQuick gripQuick fixGrinding carriagesGrinding drivesBall bearingElectric machinery

The invention relates to the technical field of external wall insulation plate production, and discloses external wall insulation plate production and processing equipment which comprises a workbench.Supporting legs are fixedly connected to the four corners at the bottom of the workbench, two vertical plates are fixedly connected to the lower end of the workbench in a left-right symmetrical mode,a first double-shaft motor is fixedly connected to the lower end of the workbench, output shafts at the two ends of the first double-shaft motor are fixedly connected with clamping screw rods correspondingly, the ends, away from the first double-shaft motor, of the clamping screw rods are rotationally connected to the side wall of the vertical plate through ball bearings, the rod walls of the twoclamping screw rods are in threaded connection with moving rods, two L-shaped clamping rods are fixedly connected to the upper ends of the moving rods in a front-back symmetrical mode, and the surface of the workbench is provided with strip-shaped openings from which the L-shaped clamping rods penetrate out in a penetrating mode. The external wall insulation plate production and processing equipment has the advantages of being capable of carrying out all-direction automatic polishing operation, greatly improving the insulation plate production and processing efficiency and being convenient touse.

Owner:马鞍山市金韩防水保温工程股份有限公司

A high-efficiency wet mill used in mining production

ActiveCN107837894BEfficient grinding operationsPrecise and stable grinding operationGrain treatmentsProcess engineeringWet grinding

Owner:泰州市振亚机械设备有限公司

A non-ferrous metal processing device

ActiveCN108436669BGrinding is safe and stablePrevent rotationGrinding drivesGrinding machinesMaterial resourcesEngineering

The invention discloses a non-ferrous metal treatment device. The non-ferrous metal treatment device comprises a pedestal and a conveying table; the conveying table is removably arranged at the bottomof the right end surface of the pedestal; standing bars are fixedly arranged at the four corners of the bottom of the pedestal and the bottom of the conveying table; sucking disks used for sucking the whole device on the ground are fixedly arranged at the bottoms of the standing bars; an accommodating cavity is formed in the right end surface of the pedestal; a cavity body is formed in the part,located at the left end of the accommodating cavity, in the pedestal; an upper driving and moving groove is formed in the top end wall of the cavity body; a first conversion cavity elongating up and down is formed in the part, located at the left end of the cavity body, in the pedestal; a second conversion cavity is formed in the part, located below the cavity body, in the pedestal; and a lower driving and moving groove is formed in the bottom end wall of the second conversion cavity. The non-ferrous metal treatment device is simple in structure and convenient and rapid to operate, the use ofmanpower and material resources is reduced, and the safety of equipment is improved.

Owner:烟台吉森新材料科技有限公司

Unsealing device and unsealing method for flip chip device

ActiveCN114603455ANo slidingRealize the grinding operationGrinding drivesCleaning using liquidsFriction forceSemiconductor technology

The invention belongs to the technical field of semiconductors, and particularly relates to an unsealing device and unsealing method for a flip chip device.The unsealing device comprises a base, a polishing box and a cleaning box are arranged at the top of the base, a plurality of supporting legs are fixedly connected to the bottom of the polishing box and the bottom of the cleaning box, a supporting plate is arranged in the polishing box, and the supporting legs are fixedly connected to the bottom of the cleaning box. An adjusting device is arranged at the bottom of the supporting plate, a grinding device is arranged at the top of the supporting plate, and clamping plates are arranged on the two sides of the supporting plate. The polishing device is arranged, in the process of polishing the base plate, a first electric polishing roller and a second electric polishing roller are driven by a third screw to polish the base plate from two opposite directions at the same time, and due to the fact that the rotating directions of the first electric polishing roller and the second electric polishing roller are opposite, the polishing effect is good; therefore, friction force generated by the first electric grinding roller and the second electric grinding roller on the base plate can be counteracted, and it is guaranteed that the base plate cannot slide in the grinding process.

Owner:合肥鑫丰科技有限公司

A kind of poultry breeding device and its operation method convenient for feed feeding

ActiveCN110269000BAvoid condensationRealize the grinding operationAvicultureGrain treatmentsAnimal scienceSolenoid valve

Owner:湖南欣牧达畜牧设备有限公司

Steel Surface Debris Grinding Device

InactiveCN105856035BEffective and fast sanding operationEfficient and fast implementation of grinding operationsGrinding drivesPortable grinding machinesEngineeringVertical cylinder

The invention discloses a grinding and removing device for impurity scraps on the surface of steel. The device comprises a support, a handle and a grinding disk. The support is provided with a grinding motor used for being connected with the grinding disk. A rotating column rod is arranged on the middle portion of the support. The support is provided with a grinding supporting plate. A rotating connection plate is arranged between the grinding supporting plate and the handle. The middle portion of the rotating connection plate is arranged on the rotating column rod. The grinding motor and the grinding disk are arranged at one end of the rotating connection plate. The support is further provided with an annular concave cavity with an opening formed in the top face. In the annular concave cavity, arrangement is performed with the rotating column rod as the center; a height adjusting ring is arranged in the annular concave cavity; a vertical cylinder is arranged between the height adjusting ring and the annular concave cavity; a buffering pressing spring is arranged between the height adjusting ring and the bottom wall of the annular concave cavity; the bottom face of the rotating connection plate is pressed on the height adjusting ring in an abutting manner; and a grinding pressure disk is fixedly arranged on the bottom face of the rotating column rod. The grinding and removing device for the impurity scraps on the surface of steel is simple in structure, convenient and fast to operate, good in using stability, high in universality and good in practicability.

Owner:天津恒新伟业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com