Full-automatic big diamond saw blade double-surface edging machine

A double-sided cutting edge and diamond technology, which is applied in the direction of metal sawing equipment, metal processing equipment, grinding machine parts, etc., can solve the problems of low automation, high heat generation, and long cutting time, and achieve the goal of feeding Accurate quantity control, high degree of automation, and good cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

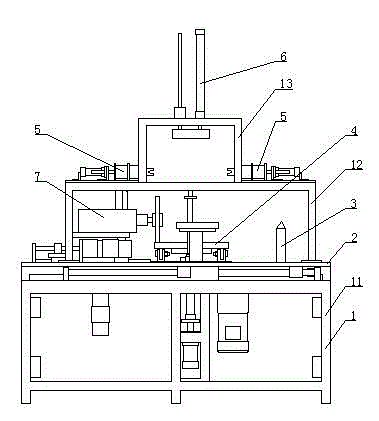

[0007] see figure 1 , the present invention includes a frame 1, a large panel 2, a loading and unloading device 3, a worktable rotation mechanism 4, a clamping and turning mechanism 5, a lifting mechanism 6 and a grinding head assembly 7, and the frame 1 includes a lower frame 11, a middle Frame 12 and upper frame 13, described middle frame 12 is installed on the lower frame 11, described upper frame 13 is installed on the middle frame 12, described large panel 2, loading and unloading device 3 and workbench The rotating mechanism 4 is installed on the lower frame 11, the material clamping and turning mechanism 5 is installed on the middle frame 12, the lifting mechanism 6 is installed on the upper frame 13, and the grinding head assembly 7 is installed on the large panel 2 superior.

[0008] When working, the workpiece is first sent to the workbench of the workbench rotating mechanism 4 by the loading and unloading device 3 from the material rack, and then the workbench driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com