Gear production grinding device

A technology of gears and gear bases, which is applied to grinding drive devices, grinding/polishing safety devices, grinding machines, etc., can solve the problems of secondary damage to the workpiece, unbalanced force control, affecting product quality, etc., to reduce labor costs, Convenient loading and unloading operation, saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

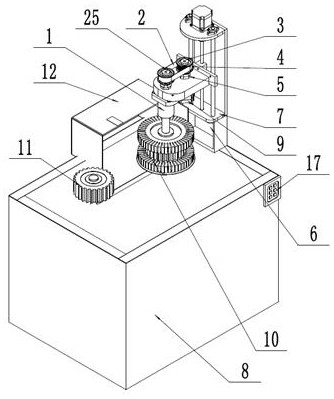

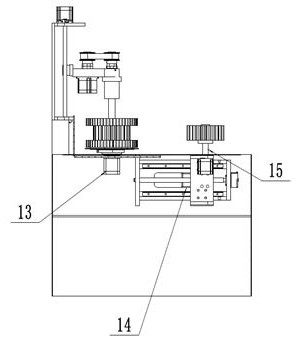

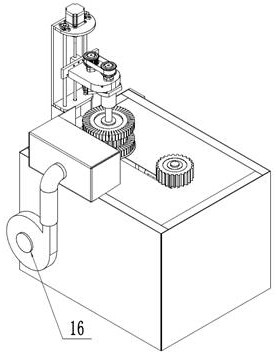

[0032] Example: such as Figure 1-Figure 7 The gear production and grinding device shown in the figure includes a polishing rotor assembly 1, a main shaft timing belt 2, an active gland 3, an active synchronous wheel 4, an active locking nut 5, a support 6, a lifting platform 7, a workbench 8, and a grinding wheel Motor 9, upper grinding wheel 10, workpiece gear 11, dust collection box 12, rotary positioning device 13, vertical screw group 14, gear seat 15, dust suction device 16, control panel 17, lower grinding wheel 18, polishing bushing 19 , positioning ring 20, driven lock nut 21, driven synchronous wheel 22, rotating shaft 23, main shaft lock nut 24, driven gland 25, upper seat plate 26, retaining ring 27, screw bearing 28, screw 29, Vertical plate 30, lead screw bearing seat 31, slide seat 32, slide rail bearing seat 33, slide rail shaft 34, lifting motor 35, lower seat plate 36, coupling 37, support plate 38, lift table slider 39, vertical Active synchronous wheel 40,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com