Dust collector for angle grinder

An angle grinder, dust cover technology, applied in grinding machines, portable grinding machines, grinding/polishing equipment, etc., can solve problems such as maintaining track fit accuracy deterioration, achieve low tolerances, reduce gaps, and optimize sealing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

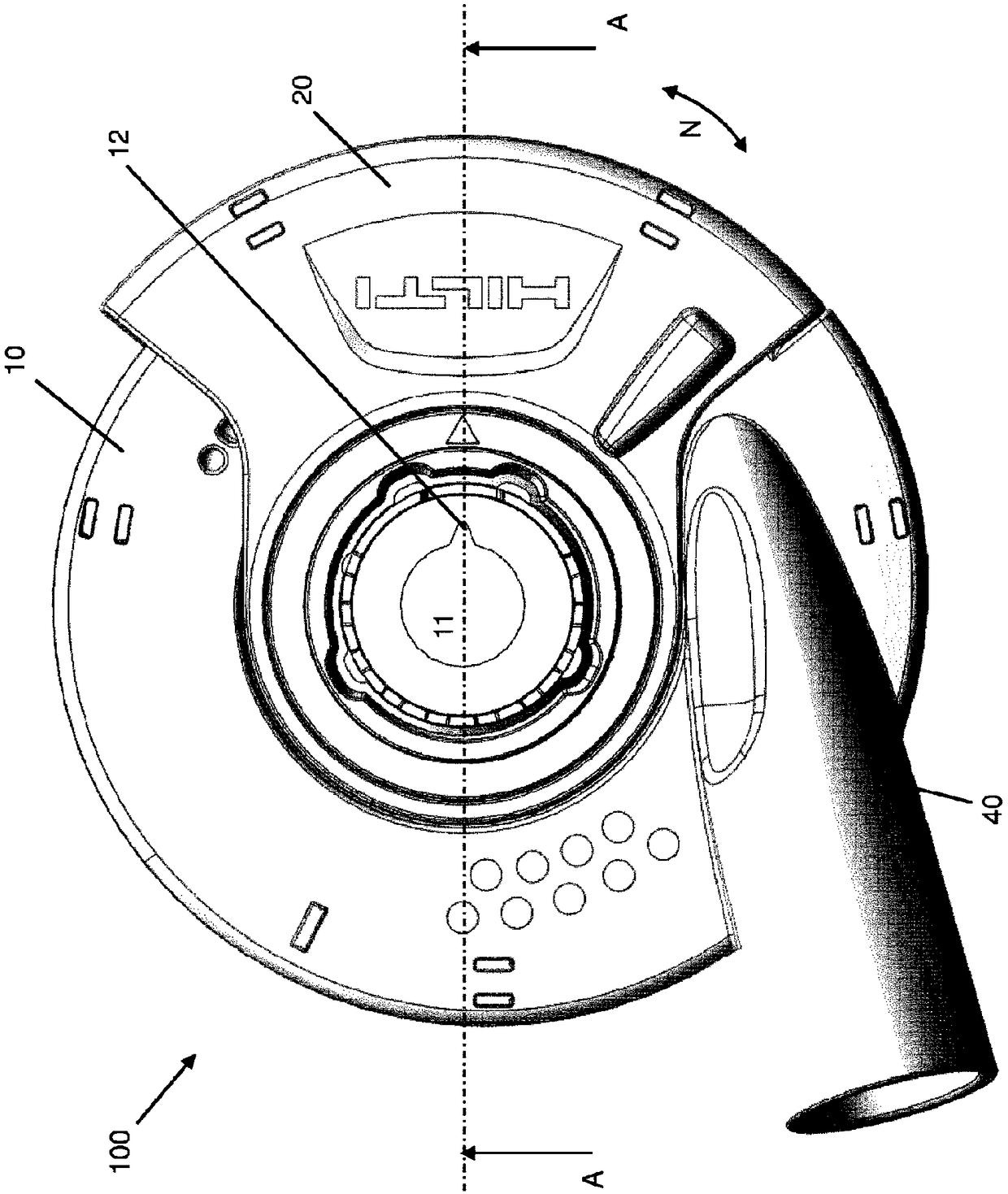

[0042] Angle grinder dust cover 100 according to the present invention is in figure 1 is shown in top view.

[0043] The angle grinder dust cover 100 has a cover body 10 for covering a round grinding wheel, not shown in the figures. The axis of rotation R of the grinding wheel is indicated by a dotted line. The angle grinder dust cover 100 likewise has a cover section 20 which is displaceable along the cover body 10 in the circumferential direction N of the cover body 10 .

[0044] The cover body 10 forms the main part for covering the grinding wheel, wherein a movable cover section 20 is provided for covering and releasing the remaining part of the grinding wheel.

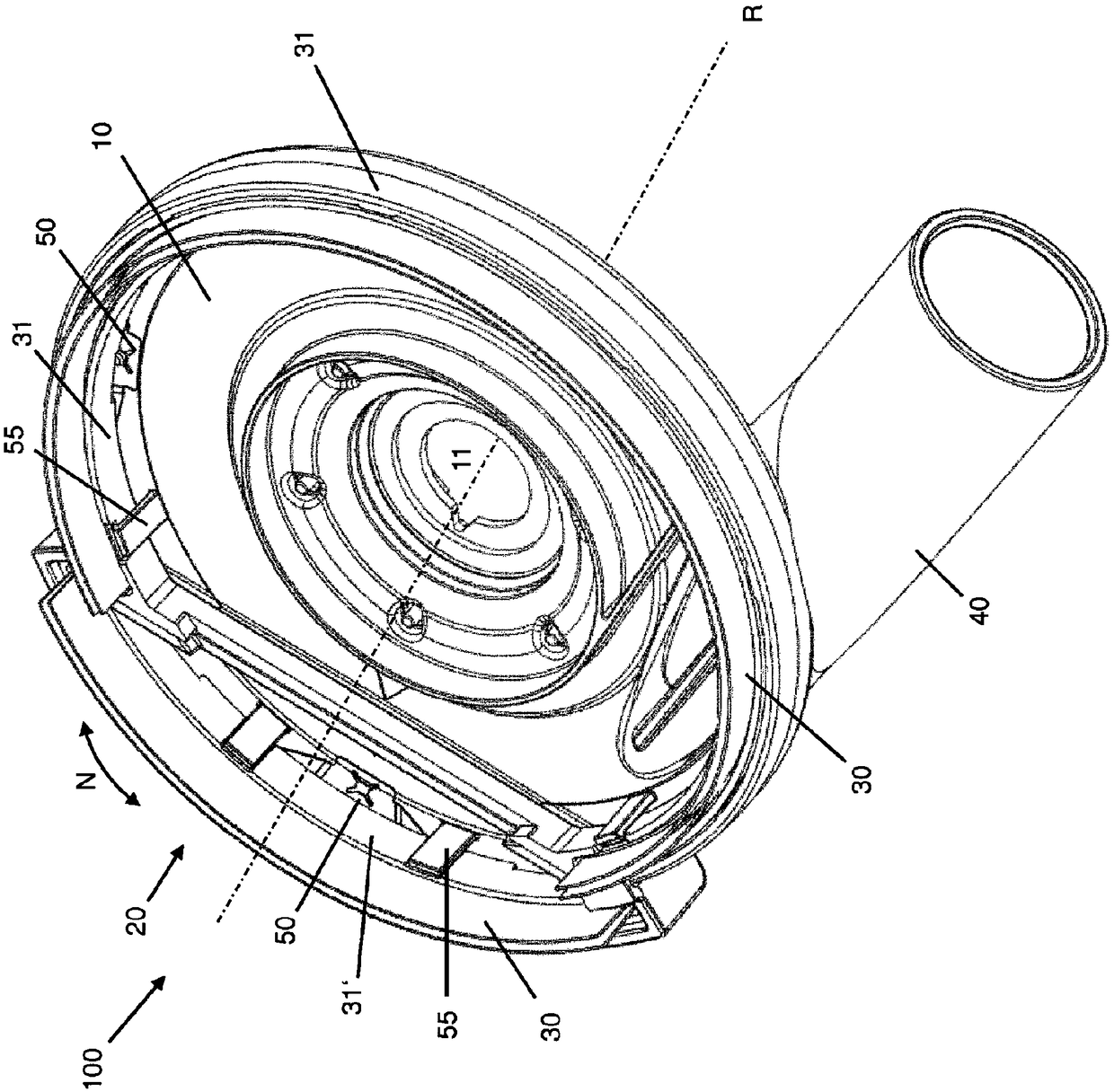

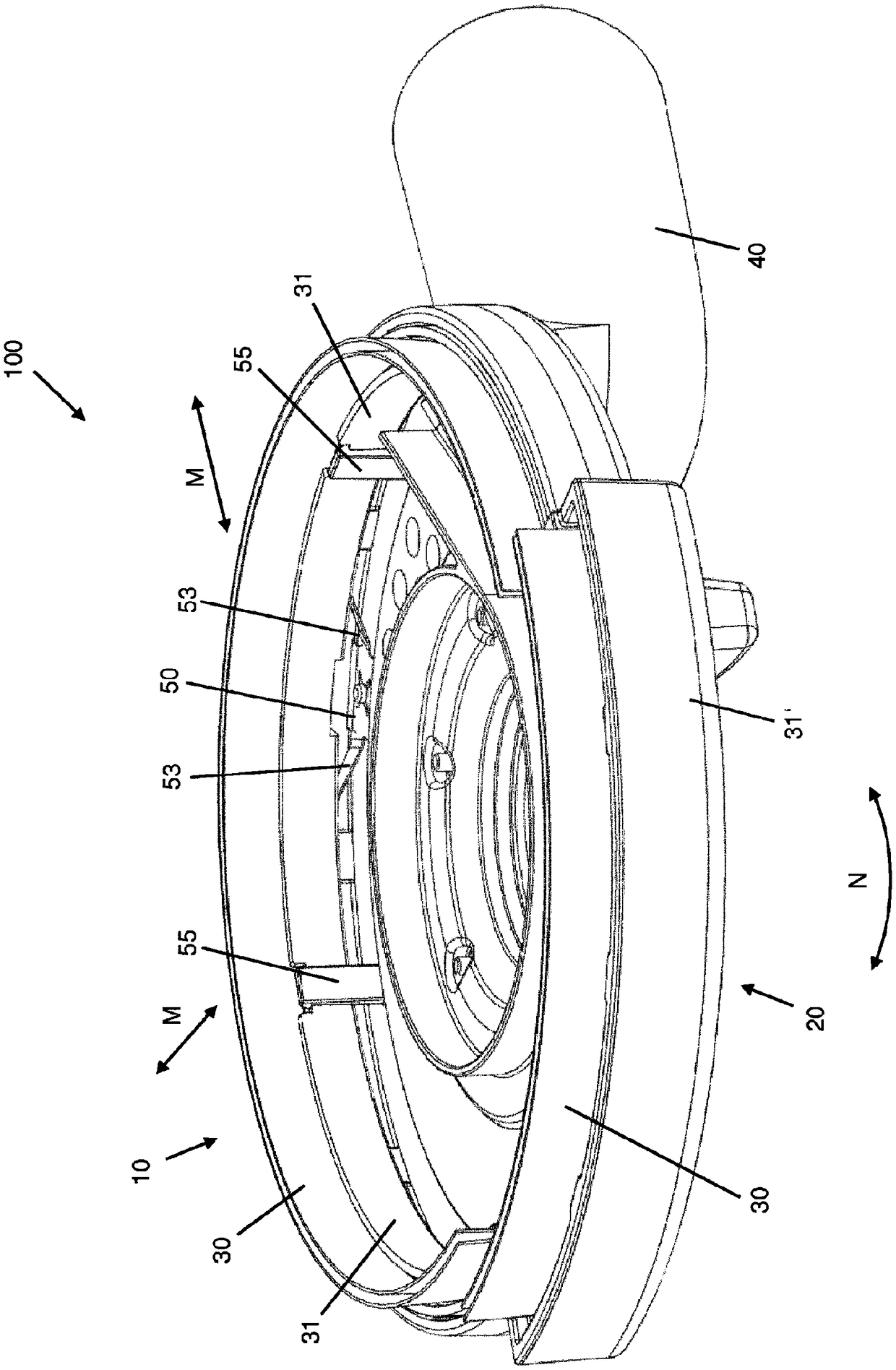

[0045] as in figure 2 , 3 , 4 and 5, both the hood body 10 and the movable hood segment 20 each have a sealing element 30 in the form of a wiper screen. As will be explained in more detail below, the sealing element 30 is positioned in the first holding rail 31 and in the second holding rail 31 ′.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com