Small polisher and polishing method thereof

A grinder, a small technology, applied in the field of cutting processing, can solve the problem of low processing quality, achieve the effect of improving processing quality, easy processing, and avoiding the effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

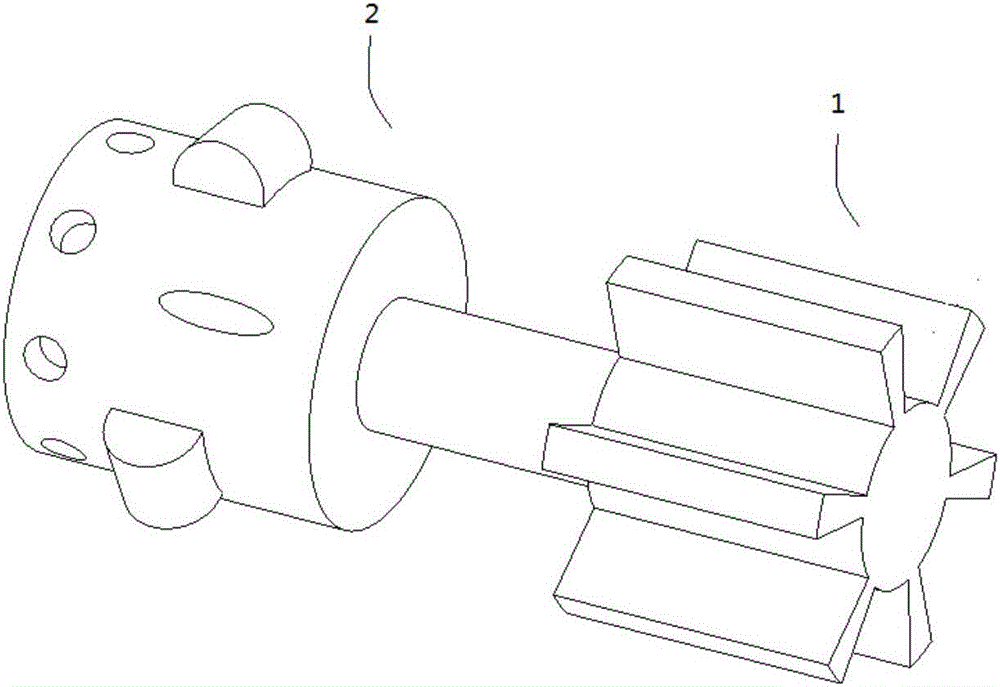

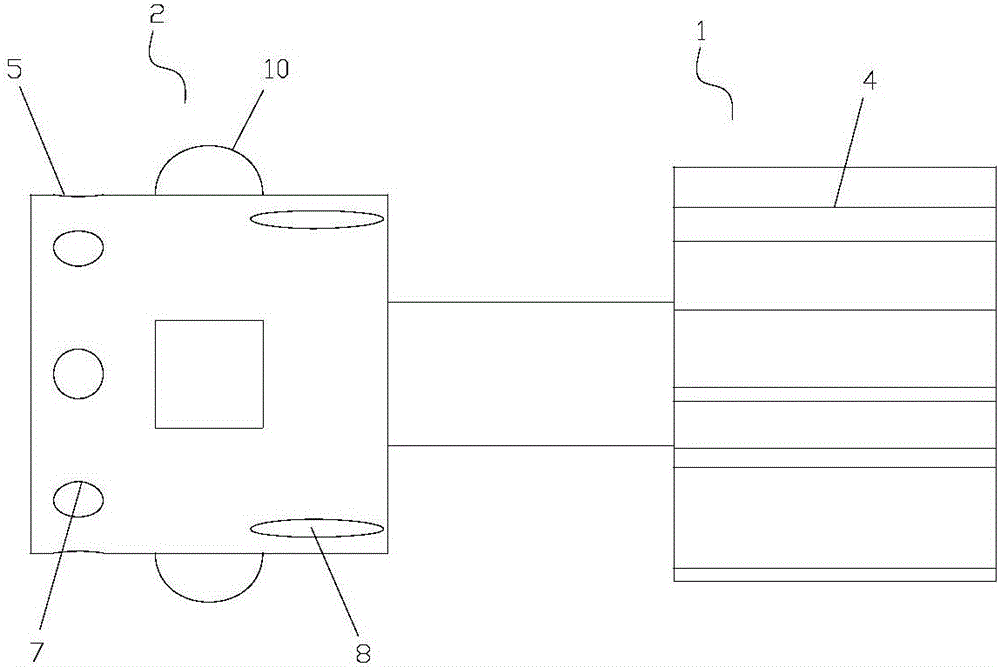

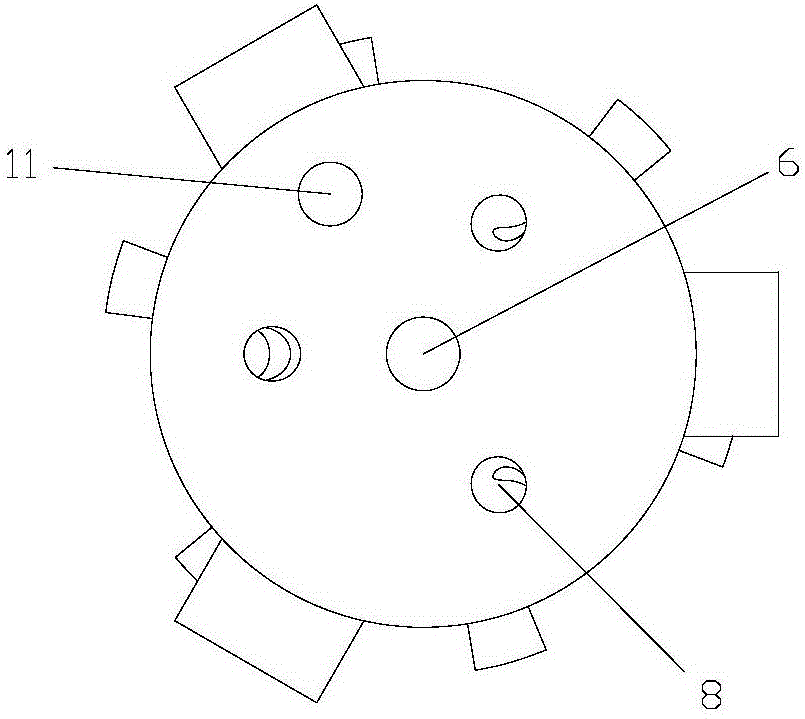

[0040] Such as Figure 1-4 As shown, a small grinder includes a grinding head assembly 1 and a grinding brake assembly 2. Specifically, the grinding head assembly includes an air motor 3 and a grinding head 4 detachably fixed to the motor shaft, and the grinding brake assembly includes a housing 5 And the independent driving air circuit, brake air circuit and travel air circuit arranged in the casing, the casing of this embodiment is a cylindrical tube with one end open and one end closed, and the air motor enters the cylindrical tube from the open end and fixes it, driving The air path is the axial air inlet 6, which is set at the closed end of the cylinder and communicates with the air motor air path. Compressed air enters from the axial air inlet to drive the air motor to rotate, and then drive the grinding head to work. The brake air pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com