Machining device for shaft sleeve oil groove

A processing device and oil tank technology, which is applied in the field of processing devices, can solve problems such as difficulty in meeting high-efficiency and large-volume production requirements, difficulty in ensuring the depth and width of oil tanks, and high requirements for workers' manipulation skills, so as to reduce repeated confirmation time and solve processing positions. Inaccurate, reduce the effect of processing cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now, the present invention will be described in further detail in conjunction with the accompanying drawings and preferred embodiments.

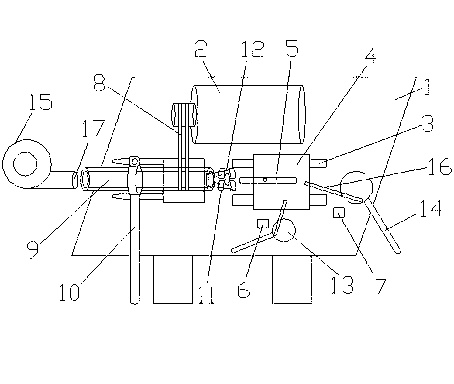

[0014] like figure 1 As shown, a shaft sleeve oil groove processing device includes a bed 1, a motor 2 arranged at the front end of the bed 1, a guide rail 3 is fixed on the bed 1, and a boss 4 is arranged on the guide rail 3. A tool 5 is fixed on the boss 4, and a first limiting plate 6 and a second limiting plate 7 are fixed on the left end of the bed 1 to determine the width and depth of the processing oil tank. The right end of the bed 1 is provided with There is a clamping part for clamping the bushing, wherein the clamping part includes a hollow main shaft 9, a ring rod 10 fixed to the main shaft 9 and four sector blocks 11, and the motor 2 is connected to the Clamp part connection.

[0015] The right side end surface of the main shaft 9 is obliquely fixed on the end surface of the sector block 11 by an iron bar 12, so as to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com