Grinding and removing device for impurity scraps on surface of steel

A technology of steel and grinding discs, which is applied to grinding drives, grinding machines, portable grinding machines, etc., can solve the limitations of applicability and practicability, reduce grinding efficiency, and uneven grinding, save manpower and material resources, practical Good performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

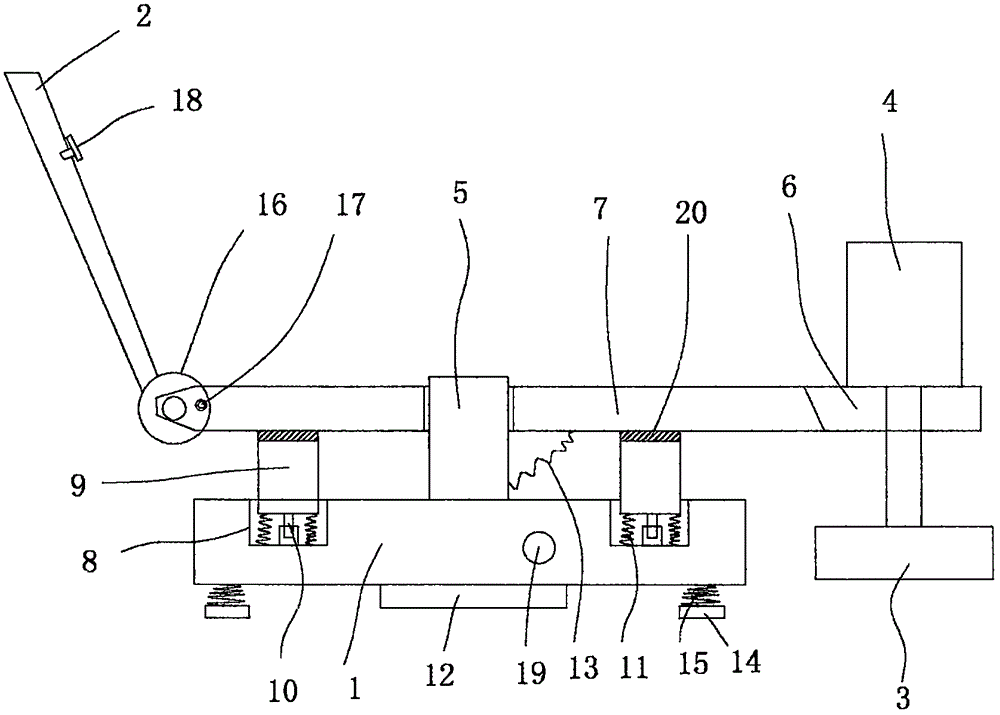

[0015] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0016] See figure 1 , a kind of scrap grinding device on the surface of steel, comprising a bracket 1, a handle 2 arranged on the bracket 1, a grinding disc 3 is provided under the end of the bracket 1, and a grinding disc 3 is arranged on the bracket 1 and The grinding motor 4 connected to the grinding disc 3 is provided with a rotating pole 5 in the middle of the support 1, and a grinding support plate 6 is provided on the support 1, and the grinding support plate 6 and the handle 2 There is a rotating connecting plate 7, the middle part of the rotating connecting plate 7 is set on the rotating pole 5, the grinding motor 4 and the grinding disc 3 are arranged at one end of the rotating connecting plate 7, and on the support 1 is also provided with an annular concave cavity 8 with an opening on the top surface. The circular conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com