Adjustable type plastic plate grinding equipment

A plastic plate and adjustable technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problem of inability to adjust the pre-tightening force of the grinding disc and the plastic plate, and reduce the quality, applicability and practicability of the finished product after grinding Limitation and other issues, to achieve the effect of good practicability, prevention of excessive grinding, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

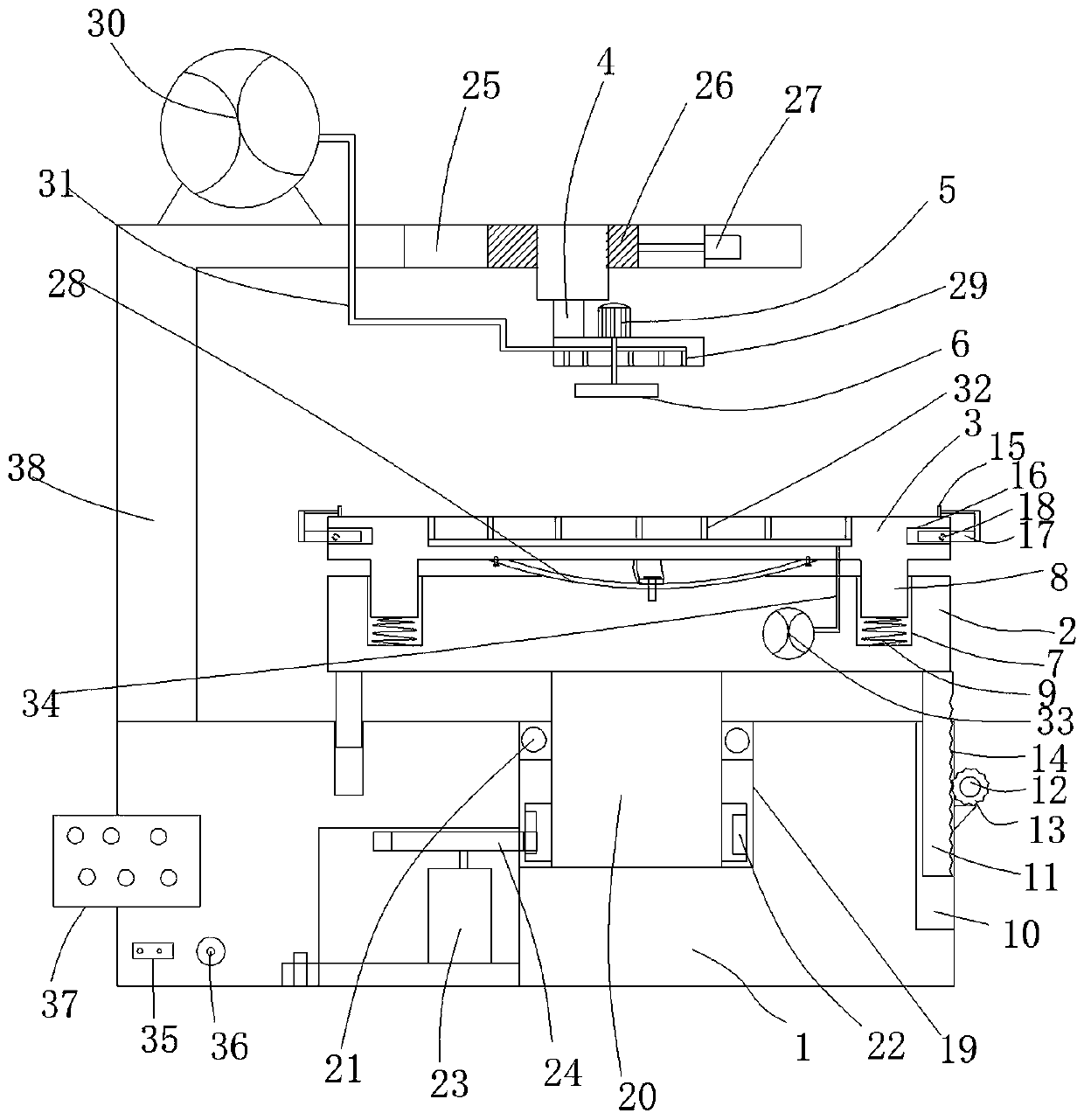

[0015] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0016] See figure 1 , an adjustable plastic plate grinding equipment, including a base 1, a support frame 2 disposed on the base 1 and a grinding panel 3 disposed on the support frame 2, a grinding frame 38 is fixed on the base 1 , a grinding seat 4 is arranged on the top of the grinding frame 38, a grinding motor 5 is fixed on the top of the grinding base 4, a grinding disc 6 is arranged on the main shaft of the grinding motor 5, and the grinding disc is in a grinding position. The bottom surface of the seat is provided with at least three buffer cavities 7 with openings on the top surface in the support frame 2, and a buffer post 8 with the same position as the buffer cavities is fixed on the bottom surface of the grinding panel. The buffer rod is inserted into the buffer cavity, and a buffer spring 9 is fixed between the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com