Patents

Literature

246results about How to "Avoid affecting the grinding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ore fine crushing and grinding device

InactiveCN107983488AEasy to grind and crushAvoid affecting the grinding effectGrain treatmentsEngineeringAeroshell

The invention discloses an ore fine crushing and grinding device which comprises a machine shell, a hot oil cavity, a cylinder block, a grinding roller and a collecting groove. The hot oil cavity is formed in the upper end of the outer side of the machine shell in a sleeved manner, a sleeve is rotationally connected to the upper end of the inner side of the machine shell, and a first rotating rodis arranged in the sleeve; the first rotating rod penetrates and is hinged to a base plate of the inner side of the shell to be fixedly connected with the grinding roller, and a taper bottom is correspondingly arranged at the lower end of the grinding roller; and the collecting groove is arranged in the bottom of the inner side of the machine shell in a sliding manner, and the right end of the collecting groove penetrates the machine shell and is fixedly connected with a pull handle. By means of the ore fine crushing and grinding device, the hot oil cavity is arranged so that ore can be heated, ore crushing and grinding are facilitated, and the working efficiency is improved; when the arranged first rotating rod downwards moves, four fan-shaped plates are driven by a pull rod to downwardsrotate, cur ore intermittently falls downwards, the intermittent discharging effect is achieved, falling and stacking of too much ore are prevented, the follow-up grinding effect is influenced, and the practicability is high.

Owner:XIAN UNIV OF SCI & TECH

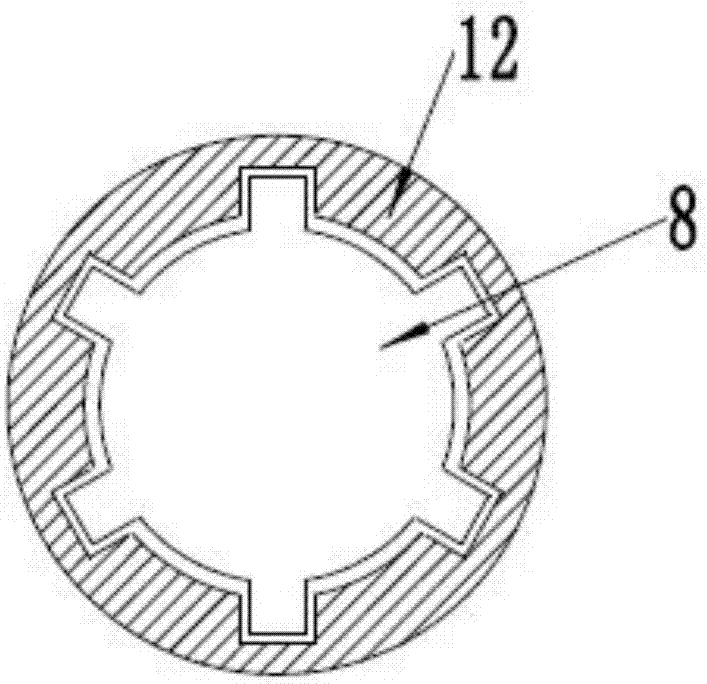

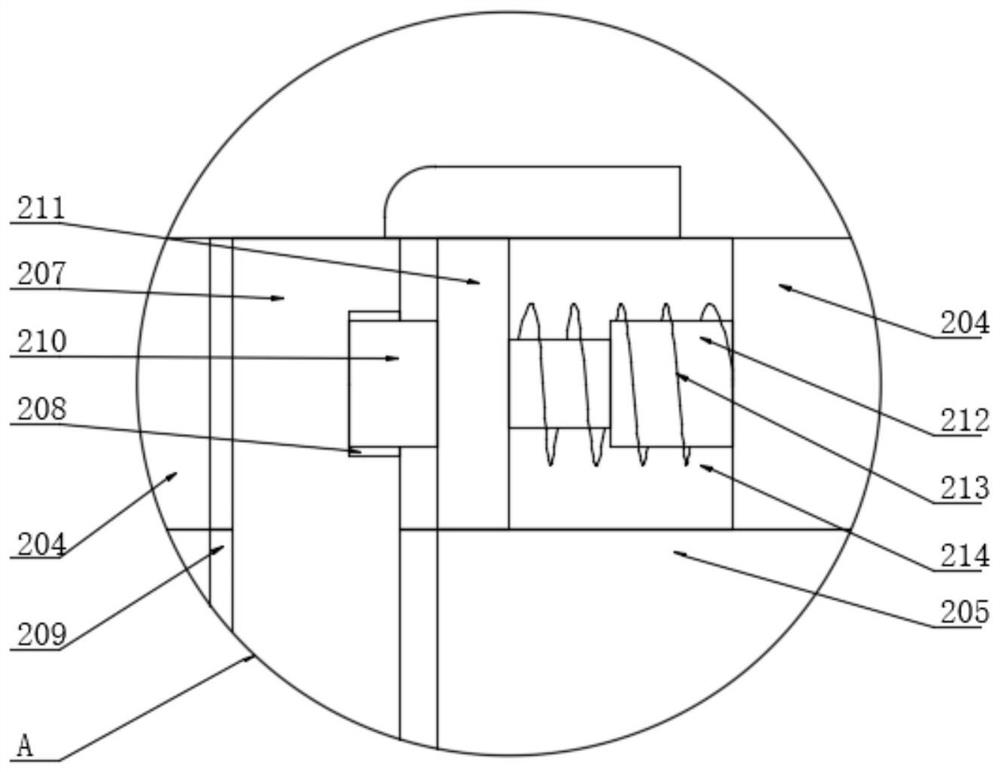

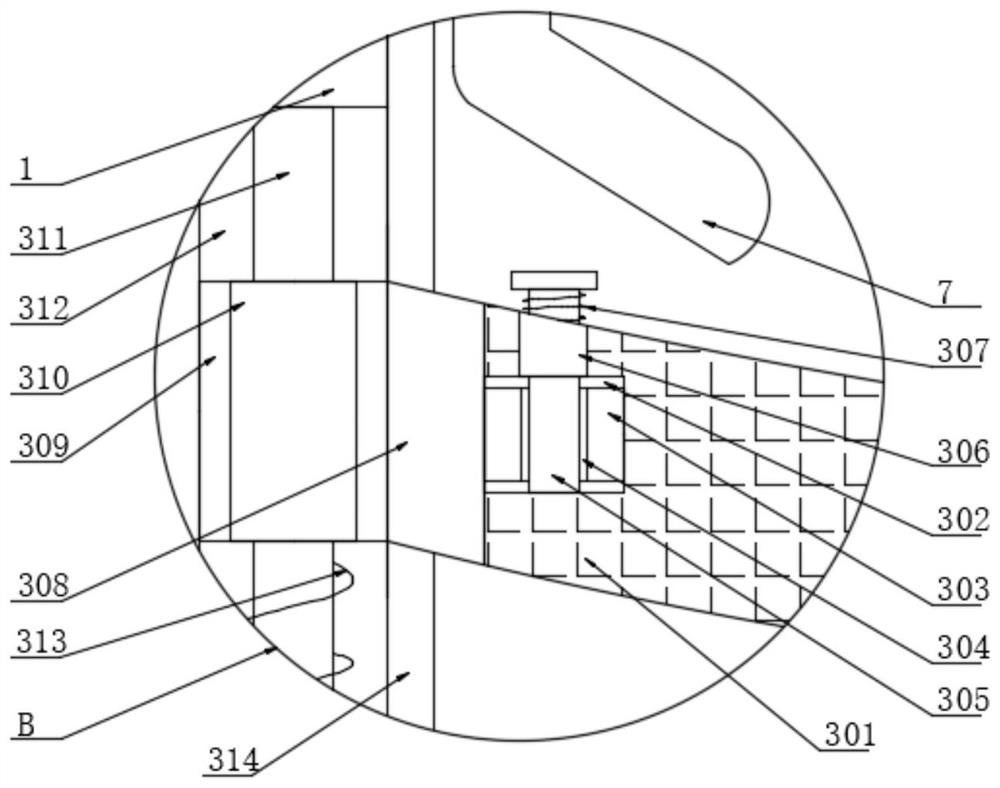

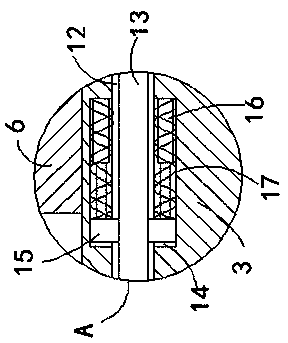

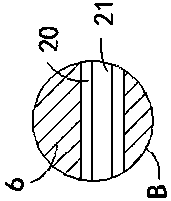

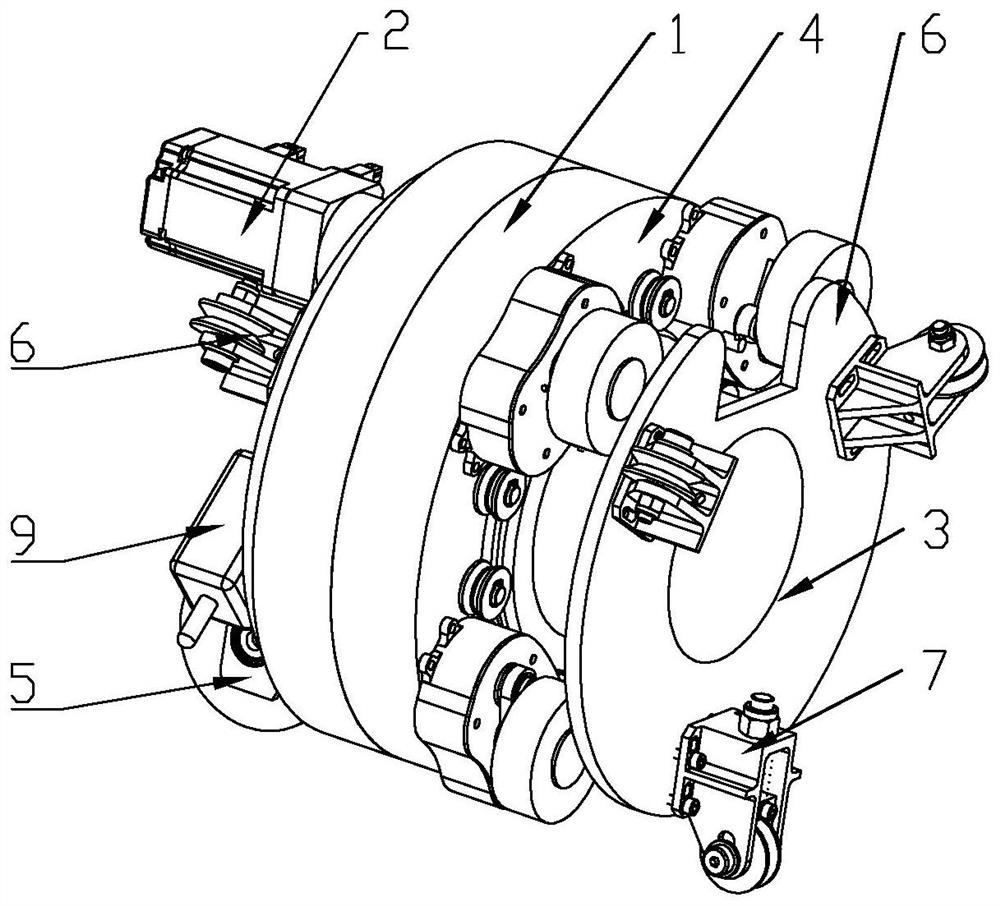

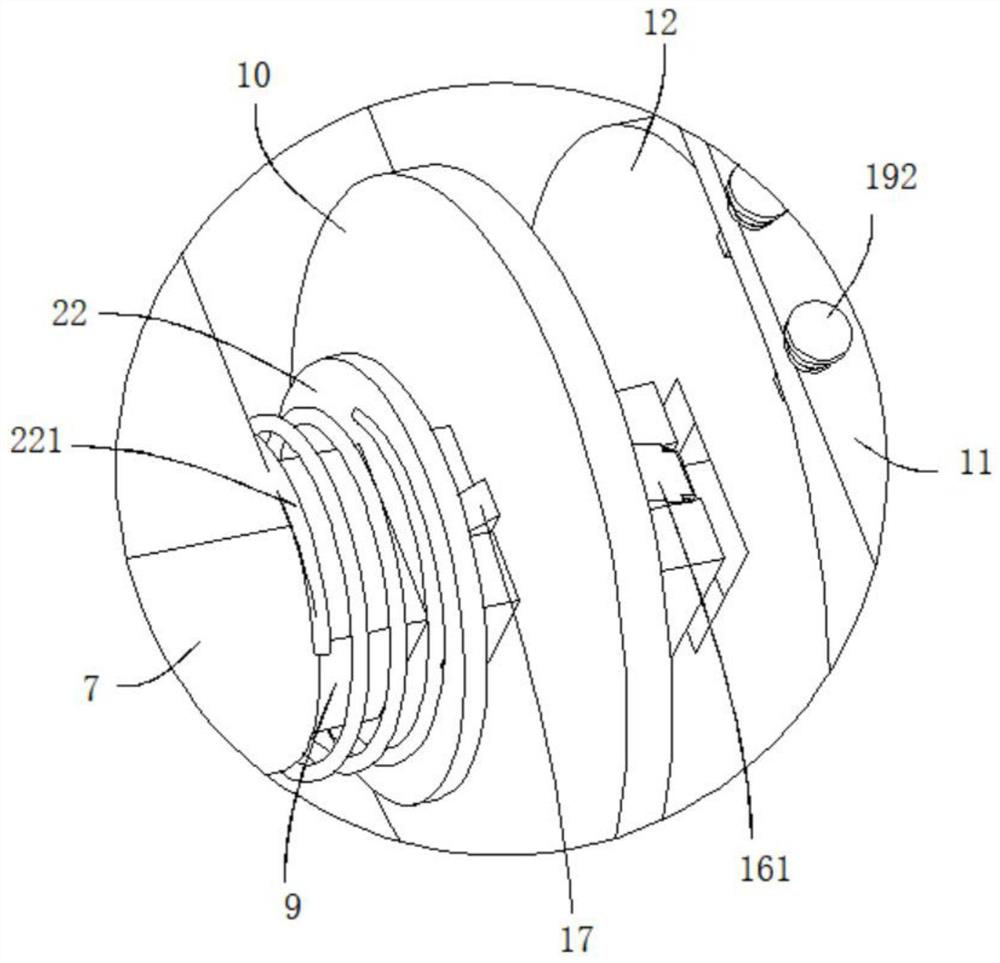

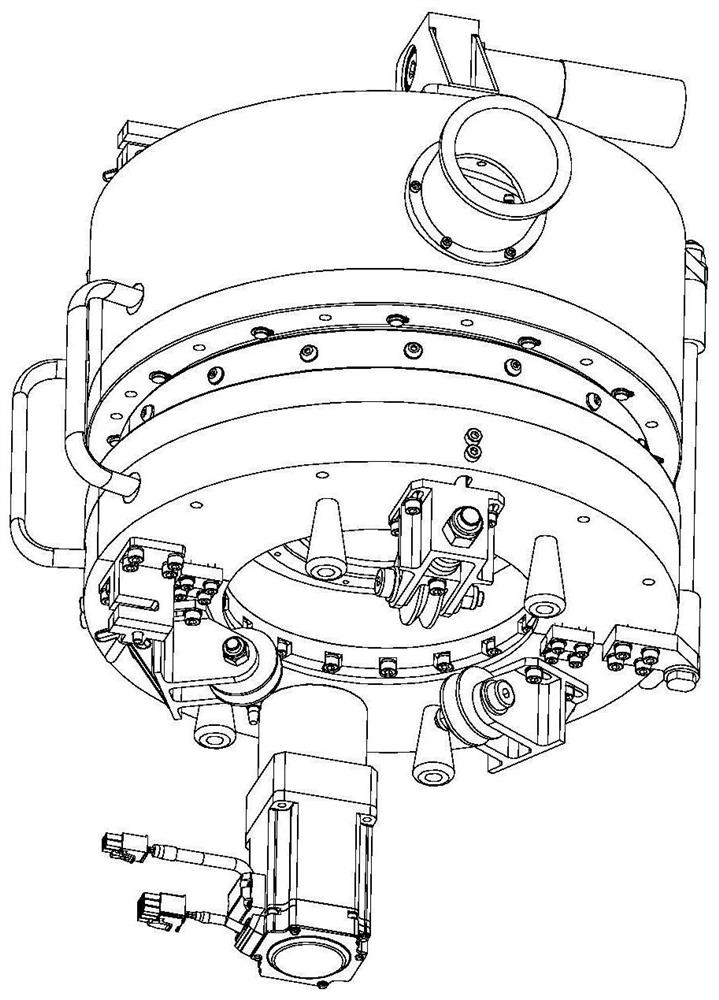

Novel pipe inner wall processing device

InactiveCN107971849AAvoid affecting the grinding effectRealize the grinding operationRevolution surface grinding machinesGrinding drivesEngineeringMechanical engineering

The invention discloses a novel pipe inner wall processing device. The novel pipe inner wall processing device comprises a rotary arm and a rotary cylinder connected with a drive device. Mounting grooves with outward openings are vertically and symmetrically formed in the rotary cylinder. A switching structure is arranged in each mounting groove. Movable grooves communicating with the mounting grooves are vertically and symmetrically formed in the rotary cylinder. A jacking press structure is arranged on each movable groove. A sliding groove is formed in the portion, located between the uppermovable groove and the lower movable groove, in the rotary cylinder. A drive structure is arranged in the sliding groove. A cavity communicating with the movable grooves is formed in the portion, on the right side of the sliding groove, of the rotary cylinder. The right side of the sliding groove extends into the cavity. The drive structure comprises a first motor fixedly arranged in the sliding groove, sliding sleeves and sliding blocks, wherein the sliding sleeves and the sliding blocks are slidably arranged in the sliding groove and located on the left side and the right side of the first motor. Threaded holes are correspondingly formed in the sliding sleeves and the sliding blocks. Threaded rods are mounted in the threaded holes in a threaded fit manner.

Owner:陈军

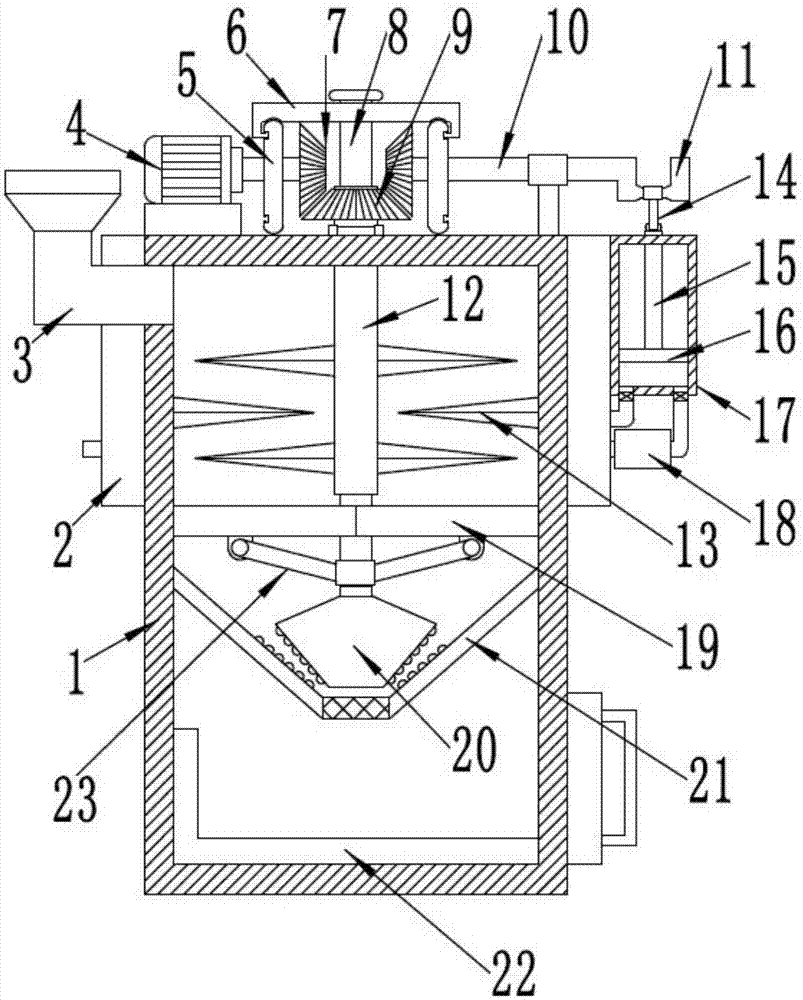

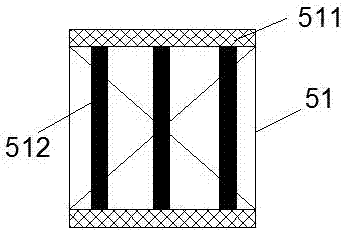

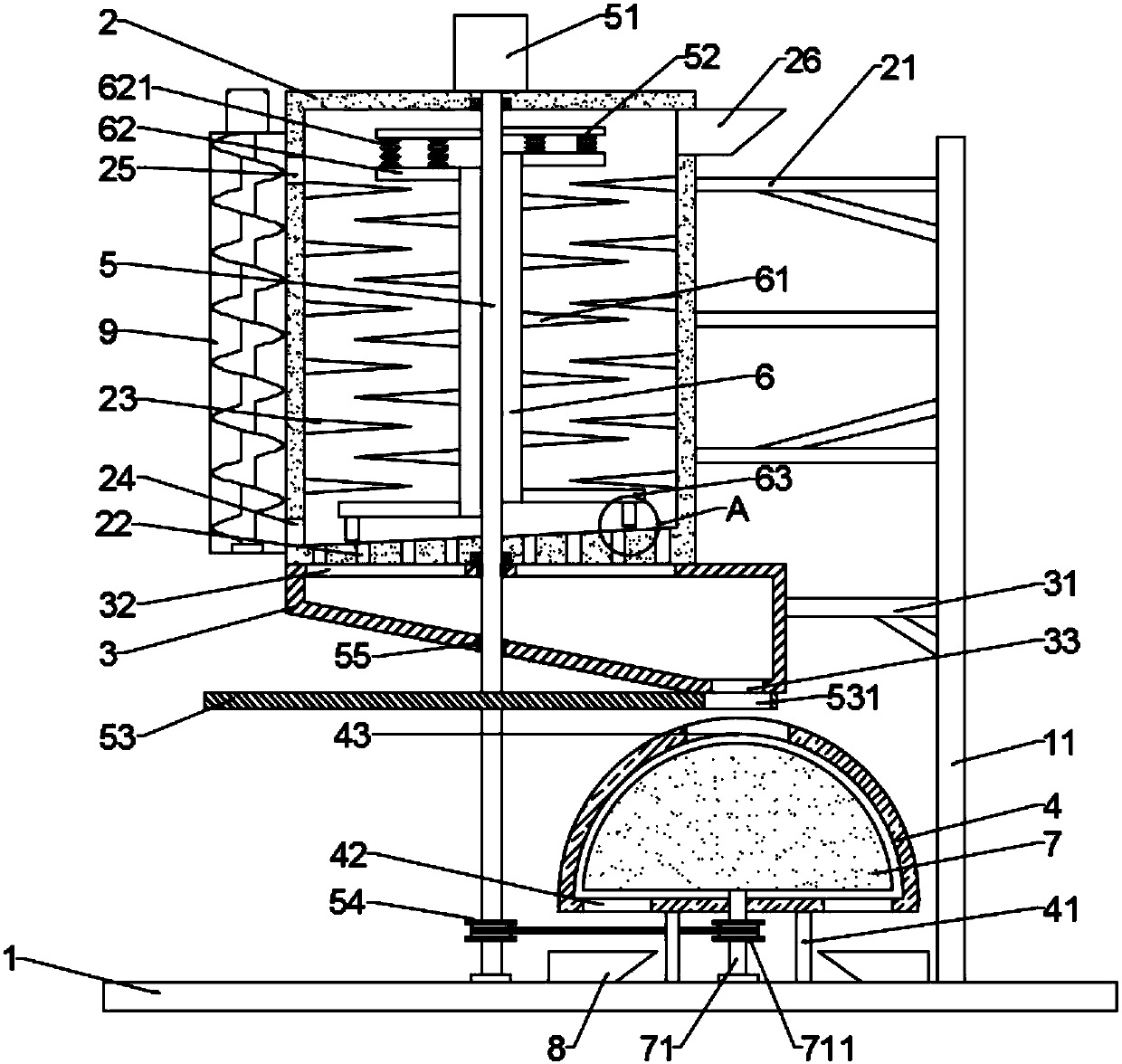

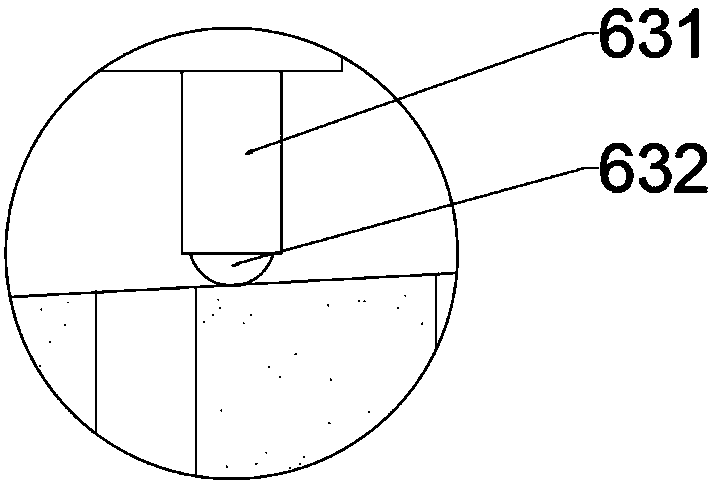

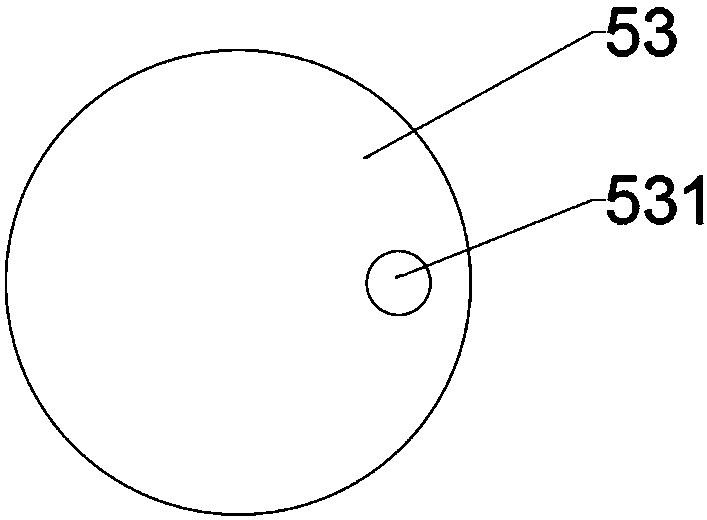

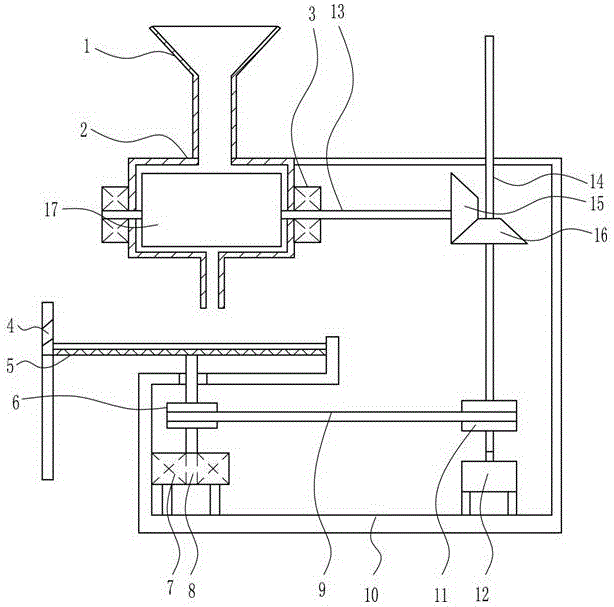

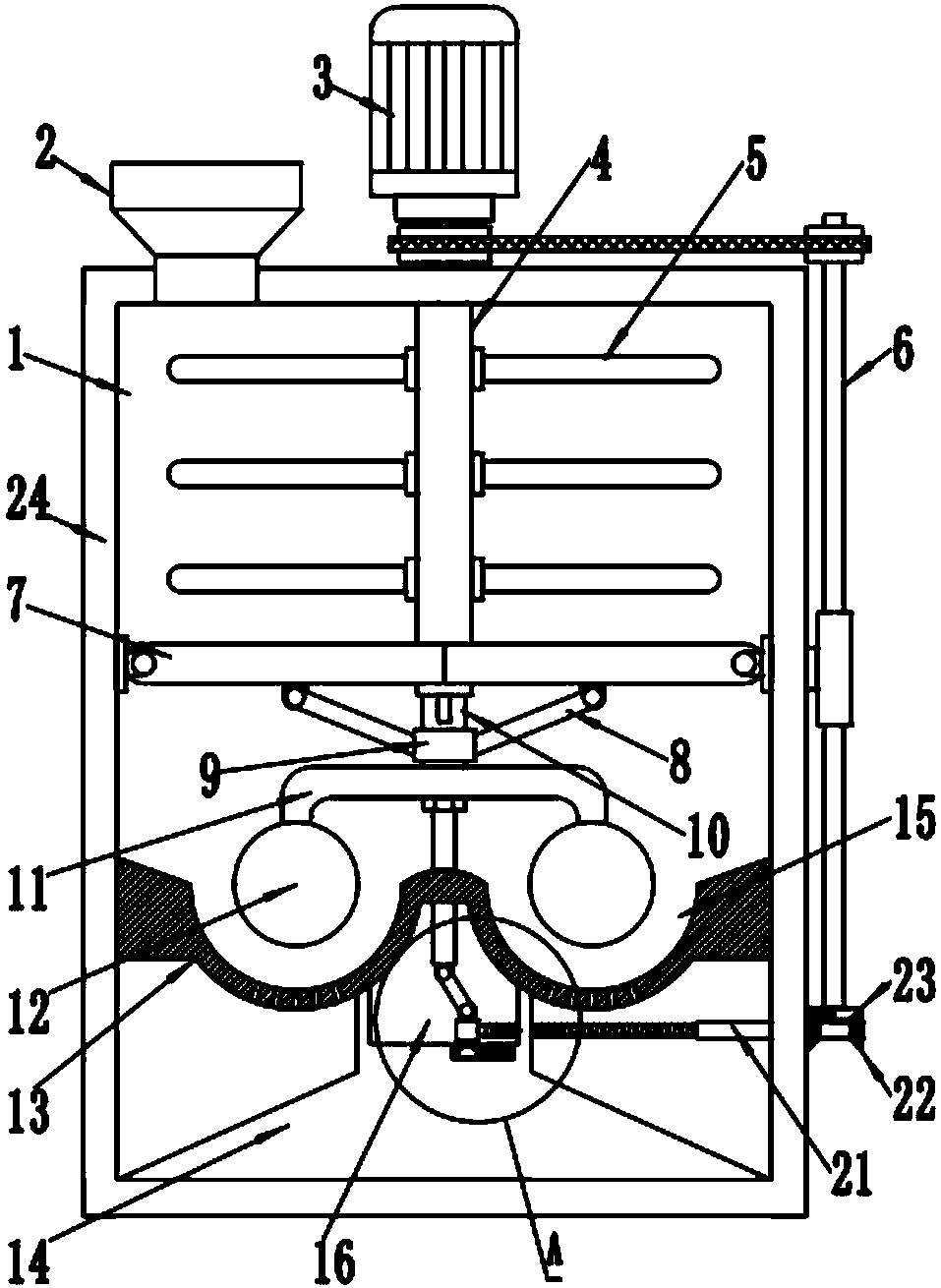

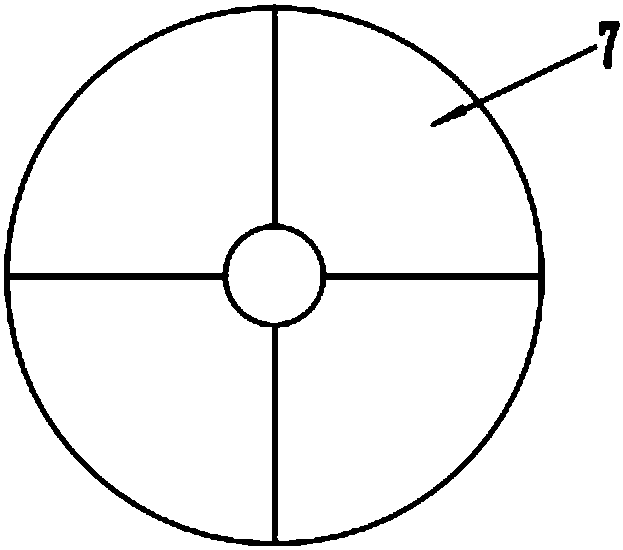

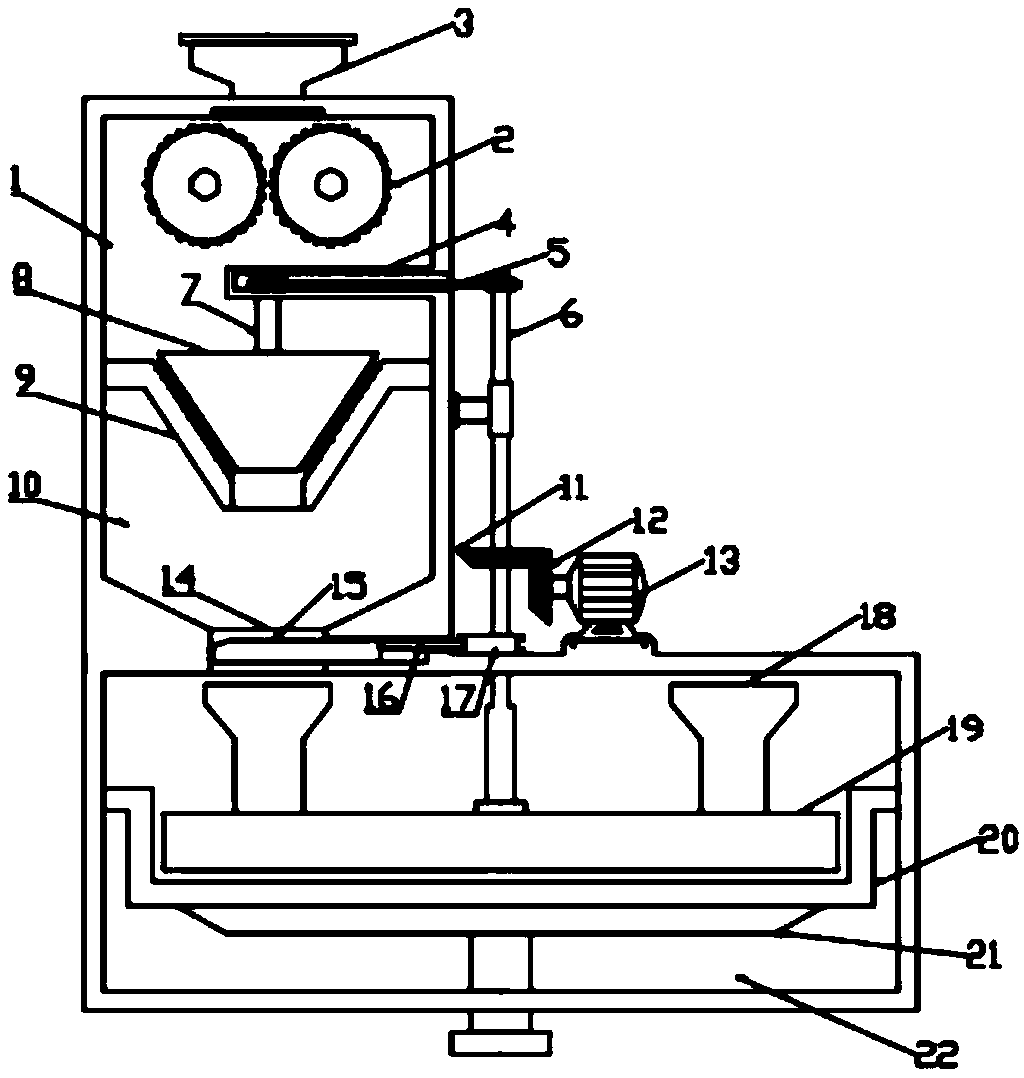

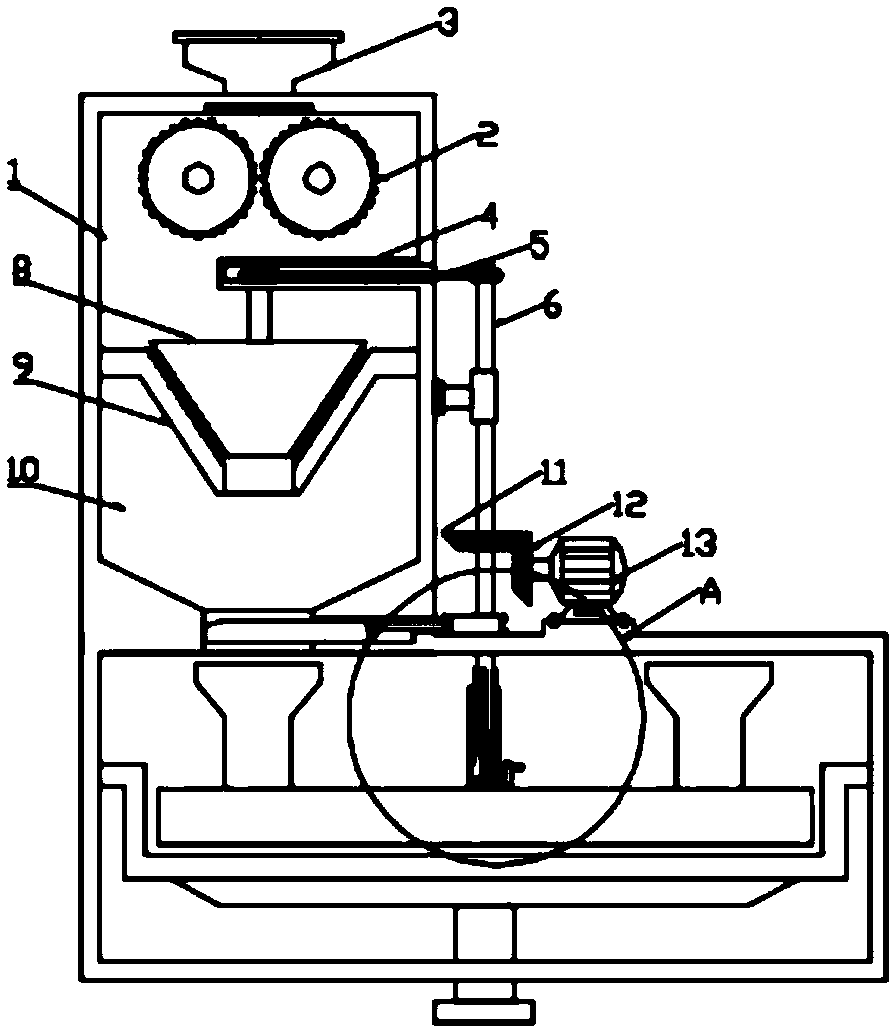

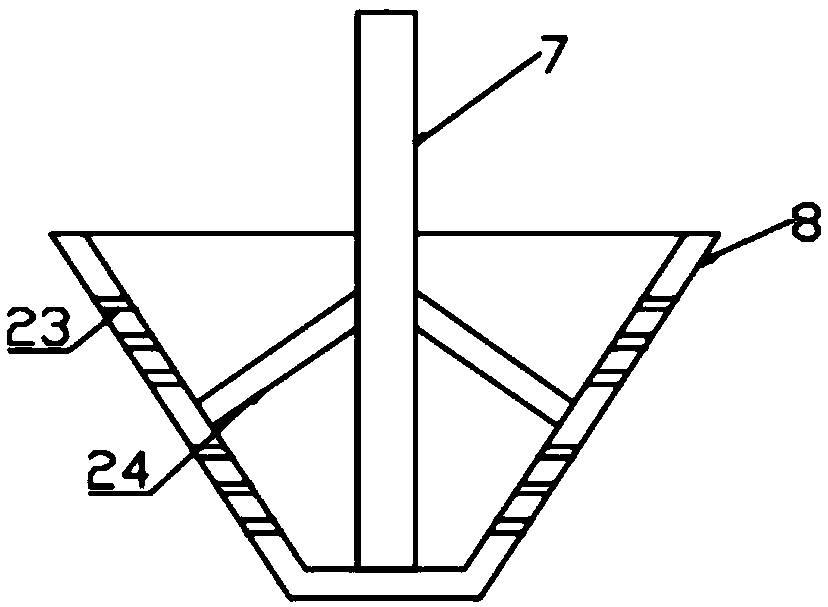

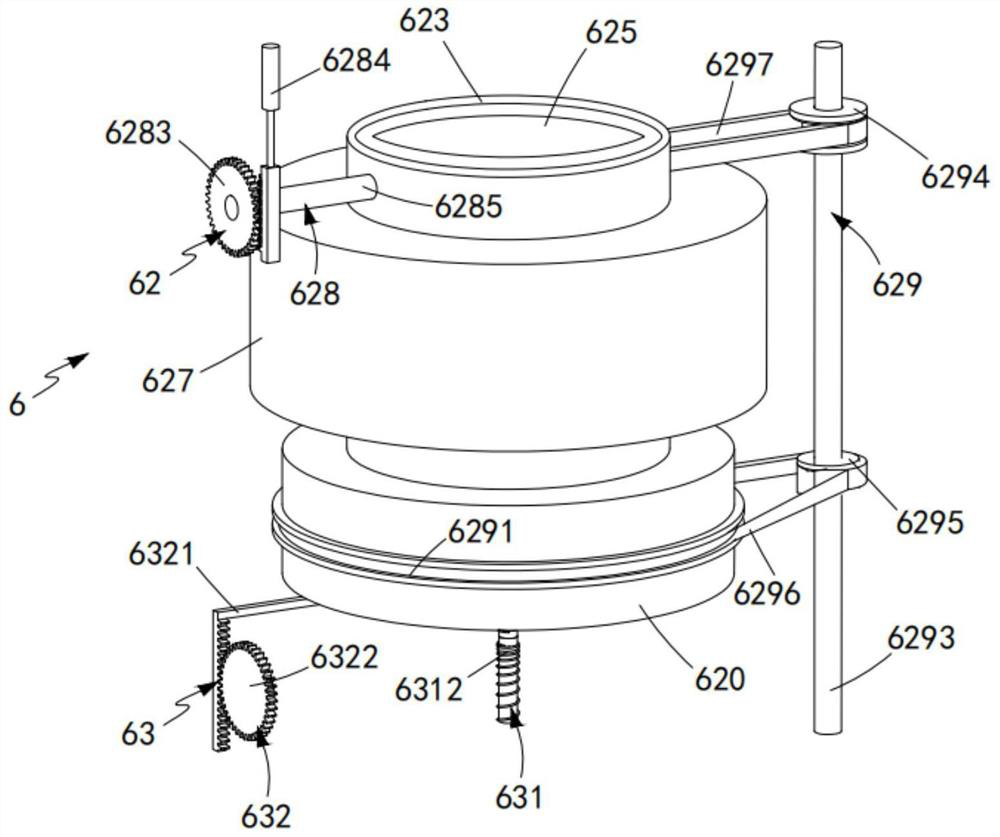

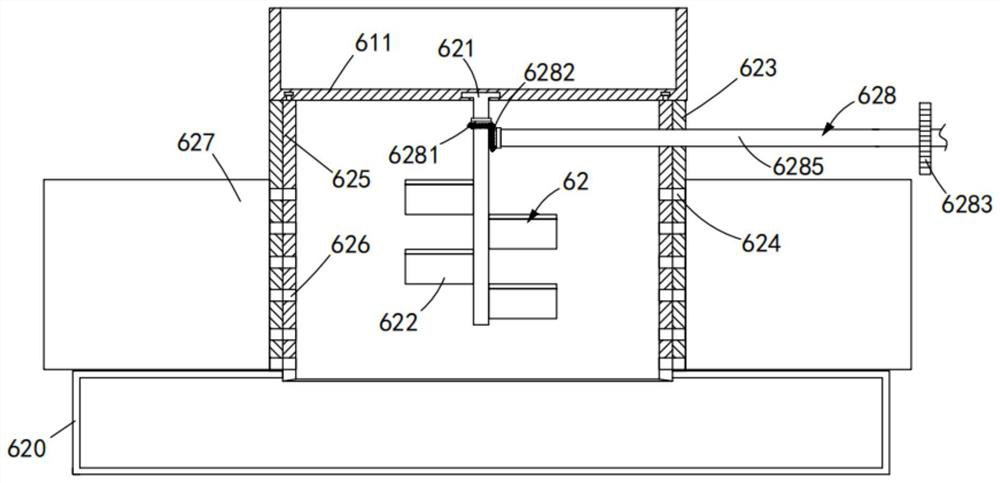

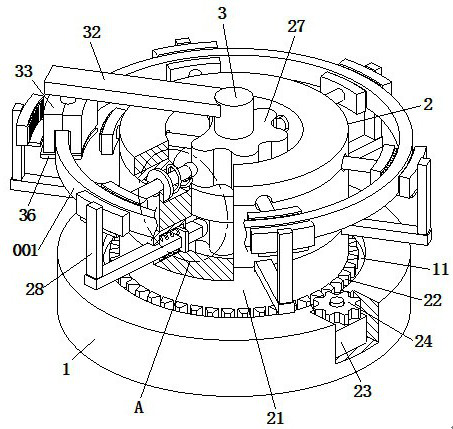

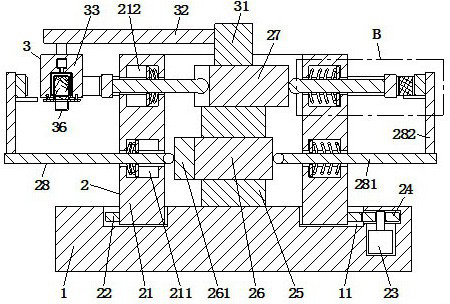

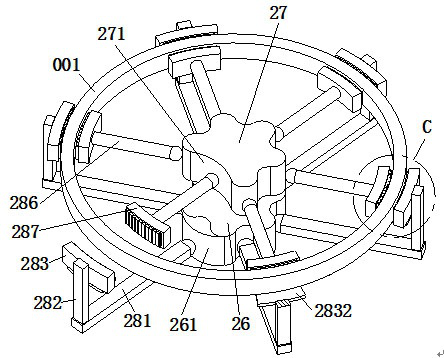

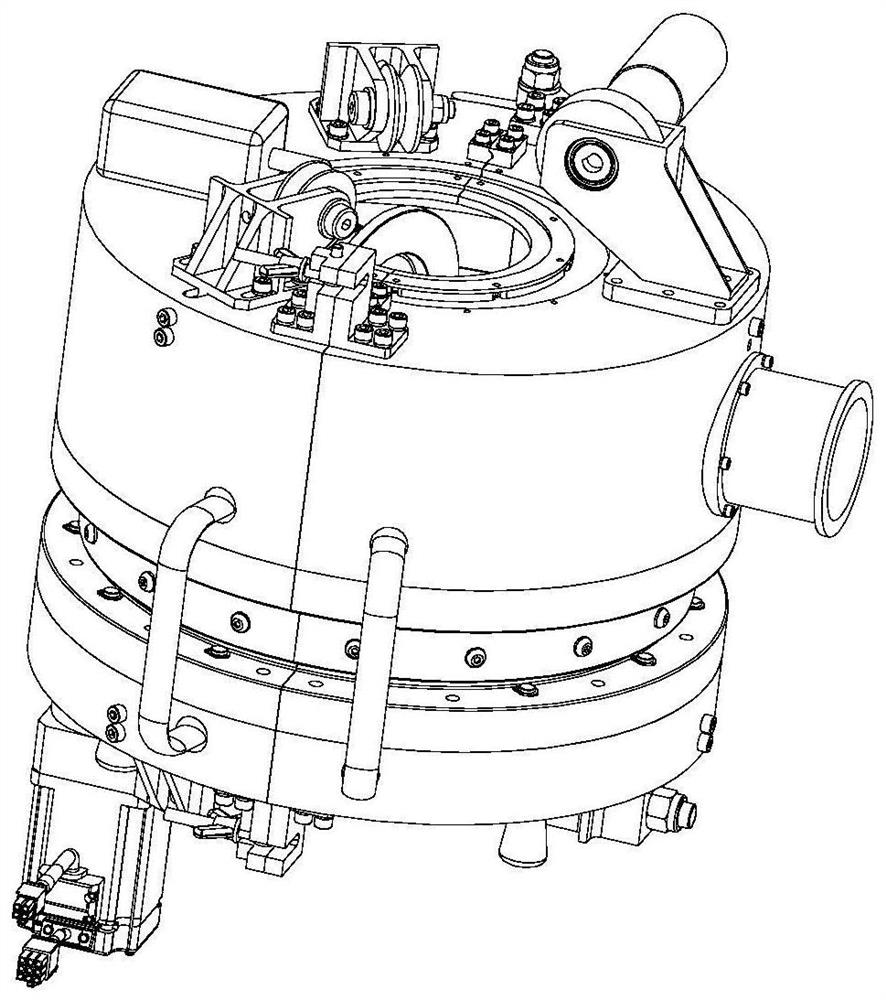

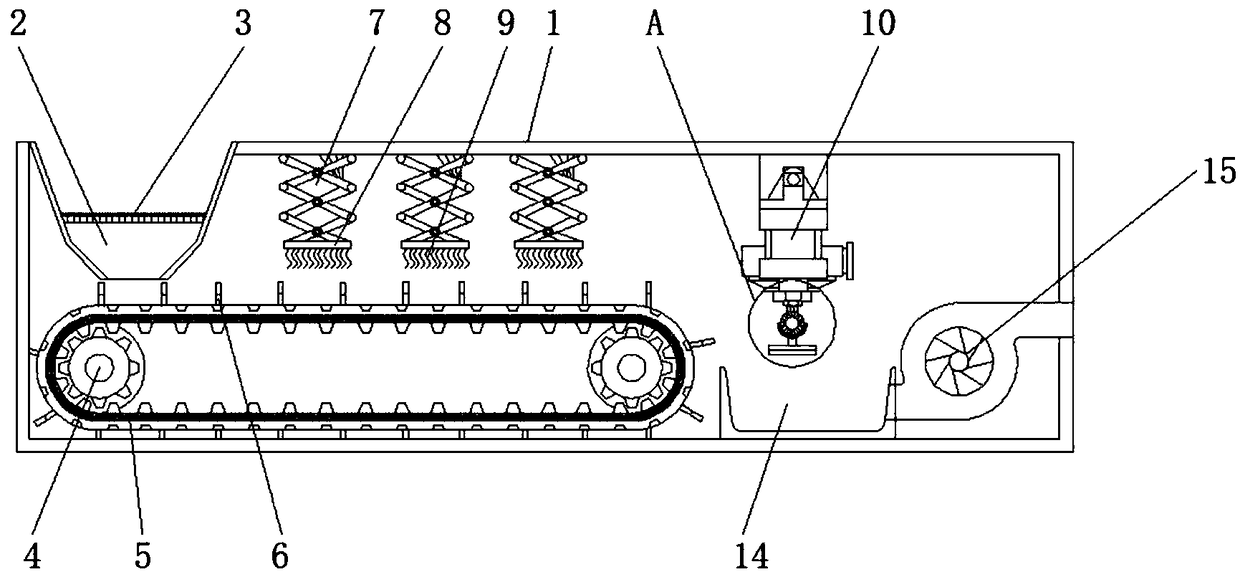

Pulverizing and grinding all-in-one machine for preparing Chinese herbs

ActiveCN107755050ARealize circular crushingGuaranteed uniformityGrain treatmentsDrive shaftMaterial transfer

The invention discloses a pulverizing and grinding all-in-one machine for preparing Chinese herbs. The pulverizing and grinding all-in-one machine comprises a pulverizing box, a material transfer boxand a grinding shell which are arranged on a base from top to bottom as well as a transmission shaft connected with the base in a rotating manner; the transmission shaft is disposed on the center of the pulverizing box, the transmission shaft is connected with a plurality of tool posts in a sliding manner, and the tool posts are provided with movable cutter blades; the material transfer box is fixed on the bottom of the pulverizing box, and the periphery of a shaft body, disposed below the material transfer box, of the transmission shaft is fixedly provided with a rotating baffle plate; the grinding shell is disposed below the right of the material transfer box; a grinding block is arranged in the grinding shell. By integrating a pulverizing step and a grinding step of the Chinese herbs, the working efficiency is increased; moreover, the Chinese herbs can be efficiently and thoroughly pulverized; the ground Chinese herb particles are high in uniformity.

Owner:武汉钧安制药有限公司

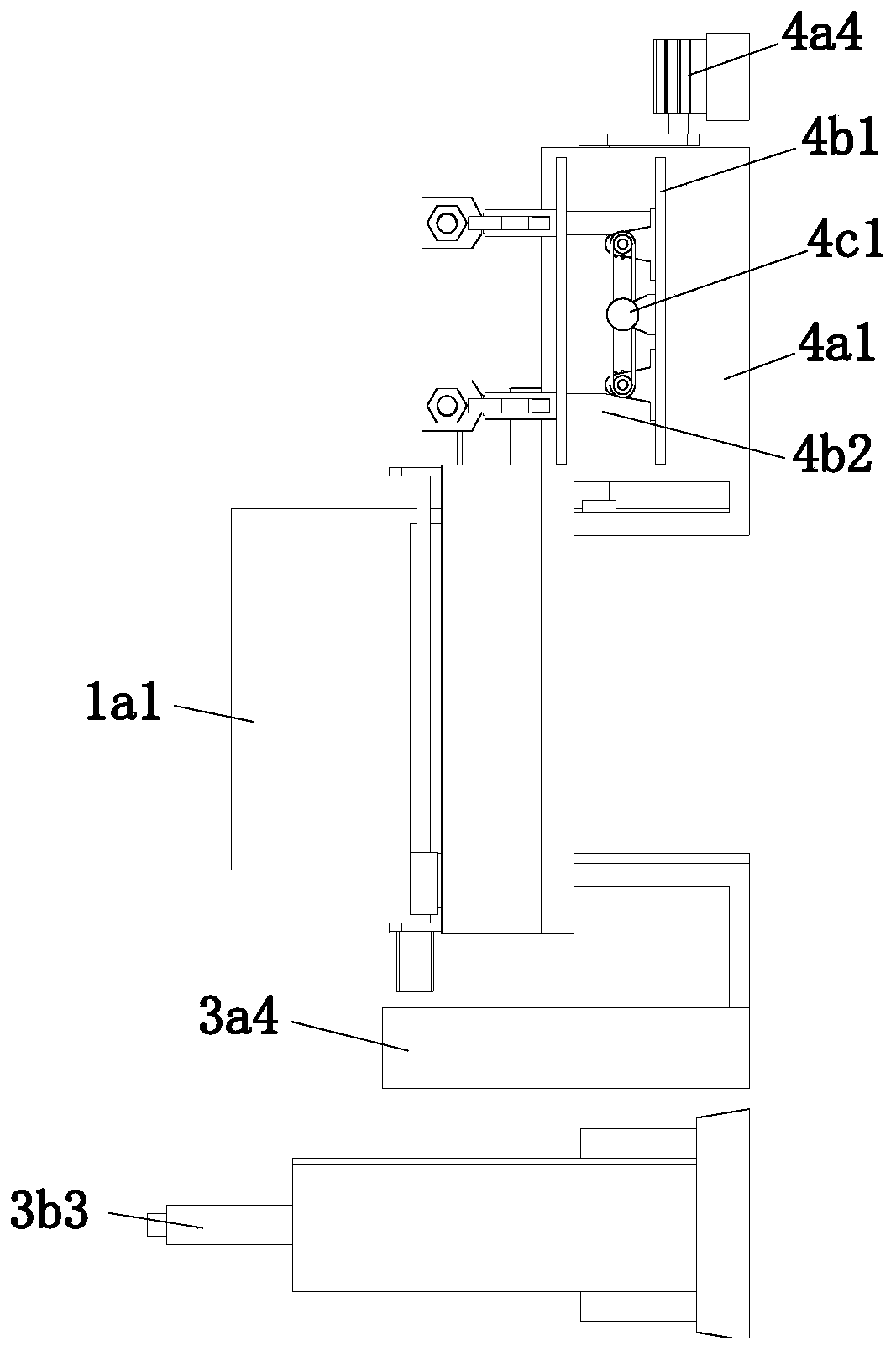

Pipe fitting inner wall machining device

InactiveCN107983733AImplement automatic conversionLow input costRevolution surface grinding machinesHollow article cleaningPipe fittingStructural engineering

The invention discloses a pipe fitting inner wall machining device. The pipe fitting inner wall machining device comprises a rotation barrel connected with a drive device through a rotation arm. Installing grooves with outward openings are formed in the rotation barrel in an up-down symmetry manner. A transformation structure is arranged in each installing groove. Movable grooves communicating with the installing grooves are formed in the rotation barrel in an up-down symmetry manner. Each movable groove is provided with a jacking structure. The part, located between the upper movable groove and the lower movable groove, in the rotation barrel is provided with a sliding groove. The sliding groove is internally provided with a drive structure. The part, on the right side of the sliding groove, in the rotation barrel is internally provided with a cavity communicating with the movable grooves. The right side end of the sliding groove extends into the cavity. The drive structure comprisesa first motor fixedly arranged in the sliding groove, a sliding sleeve and a sliding block, wherein the sliding sleeve and the sliding block are arranged in the sliding groove in a sliding manner andlocated on the left side and the right side of the first motor. Threaded holes are formed in the sliding sleeve and the sliding block, and threaded rods are arranged in the threaded holes in a threaded fit manner.

Owner:陈军

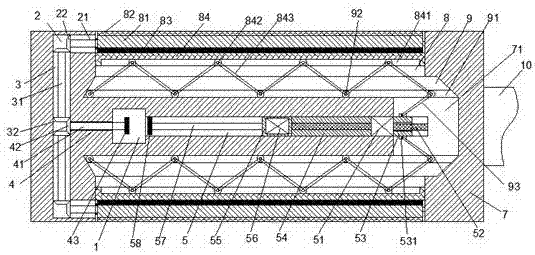

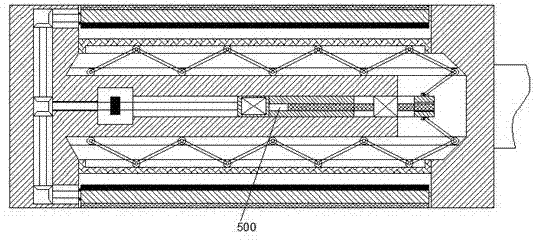

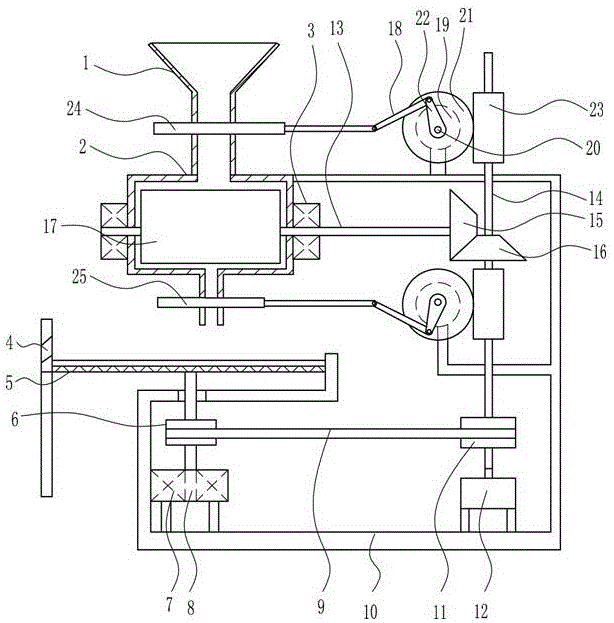

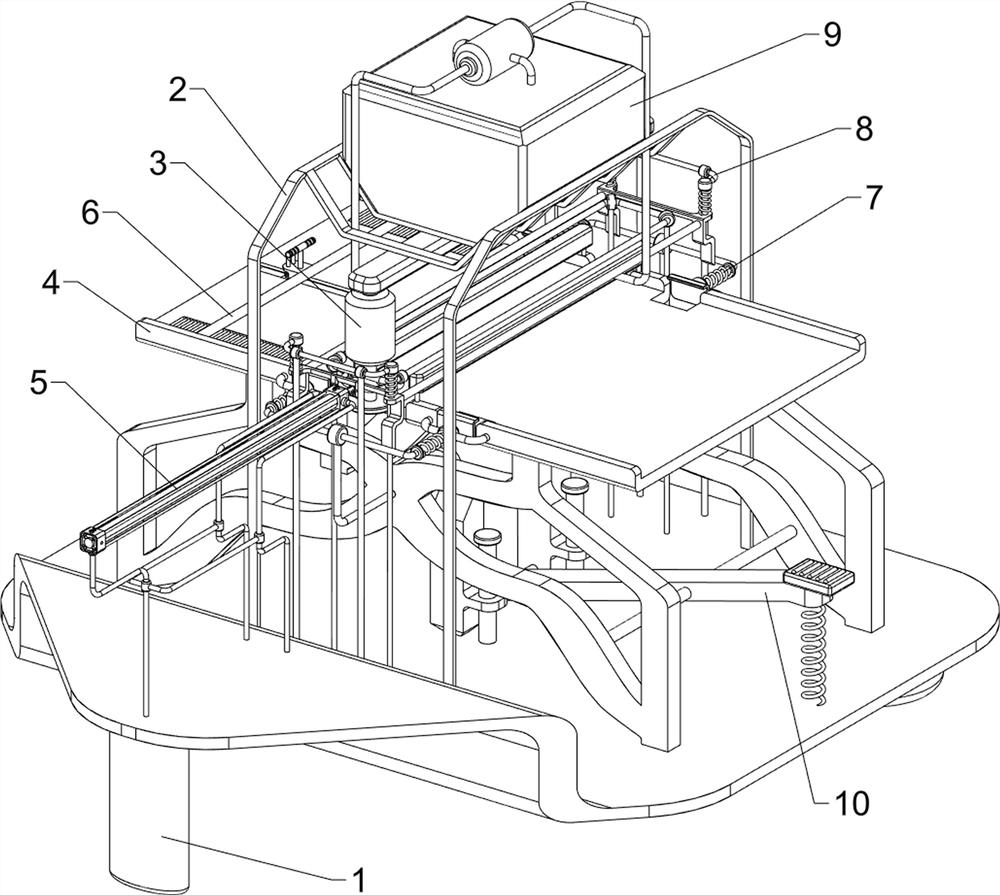

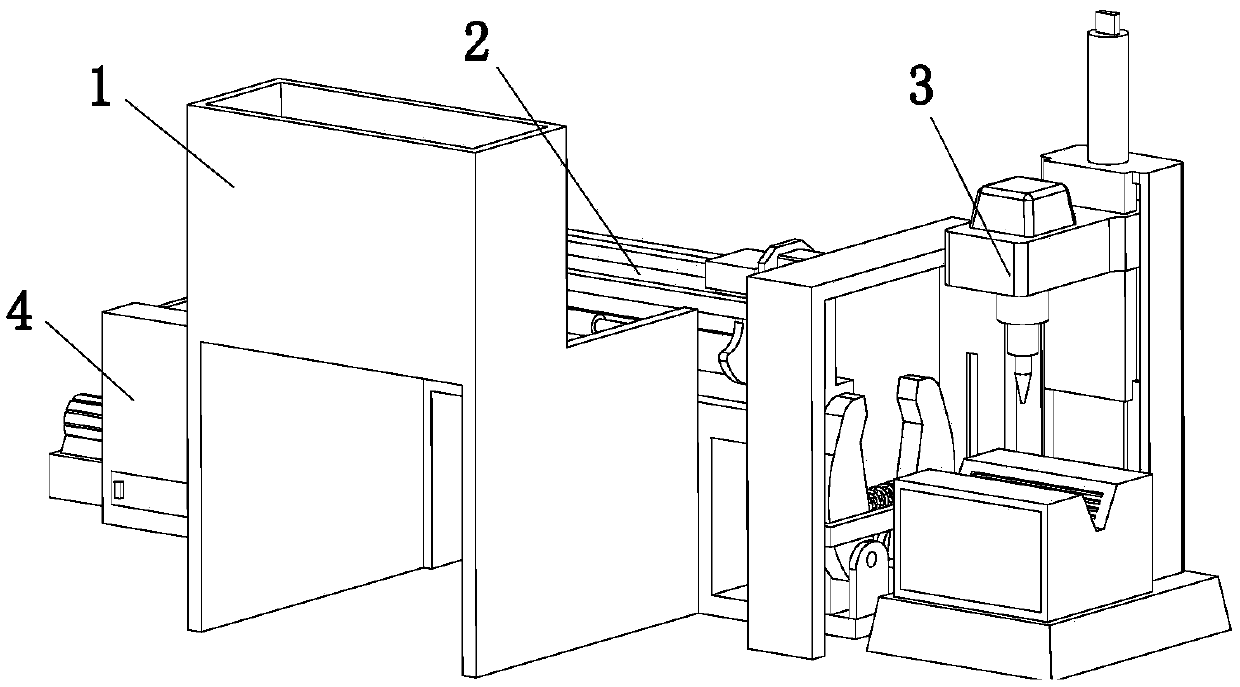

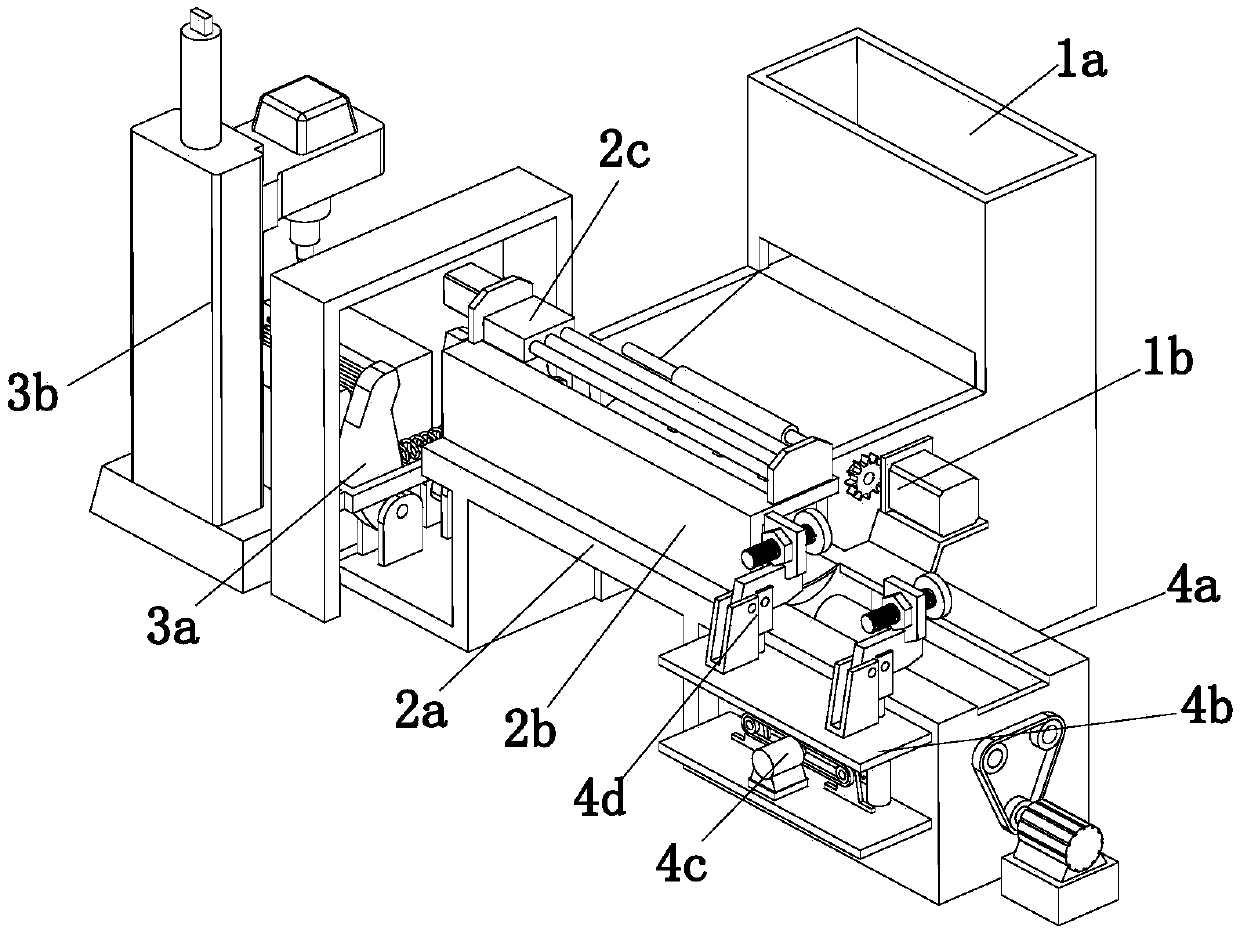

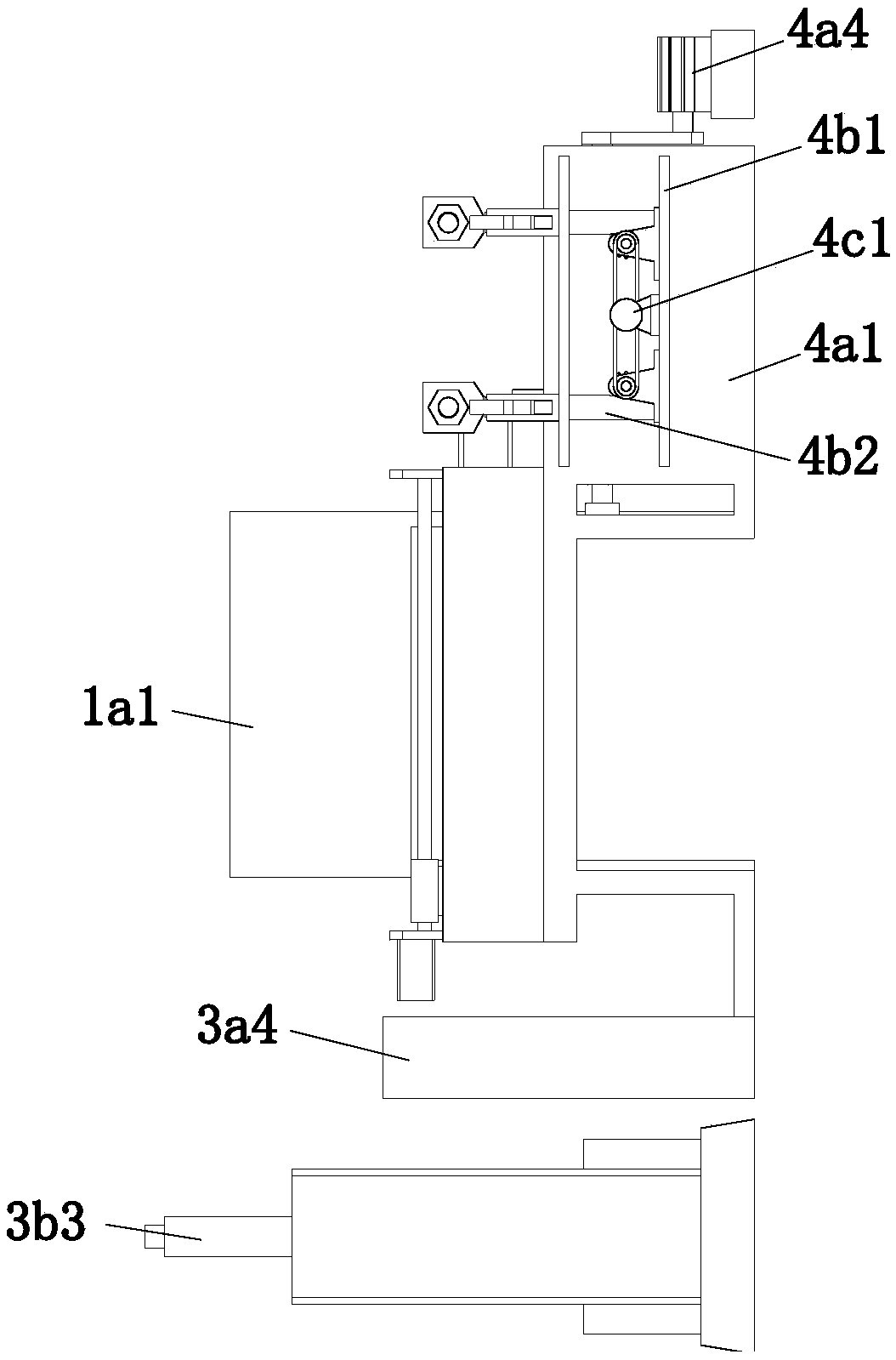

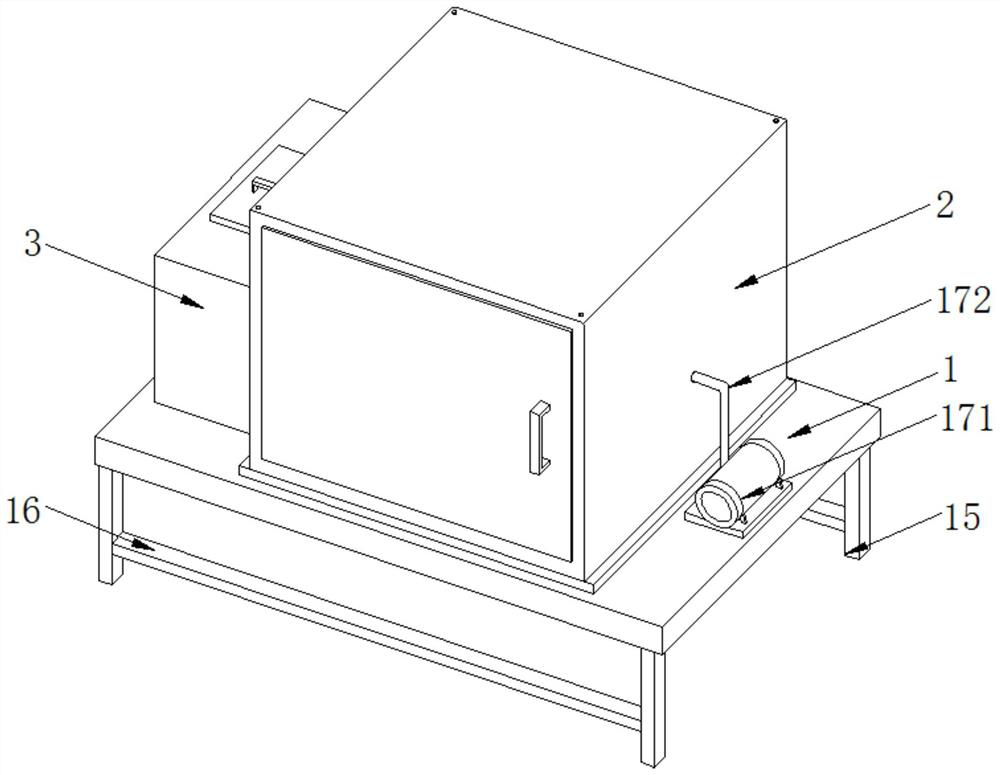

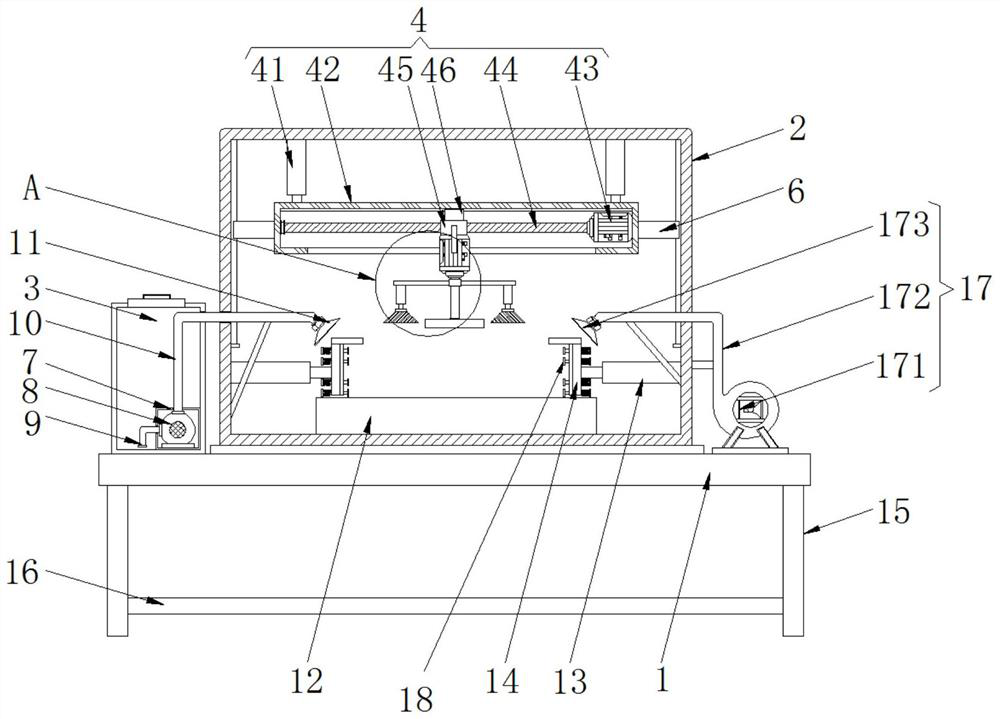

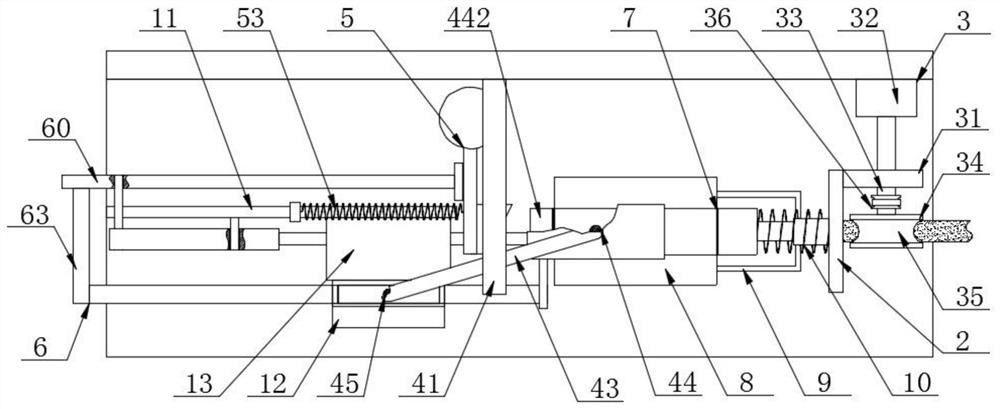

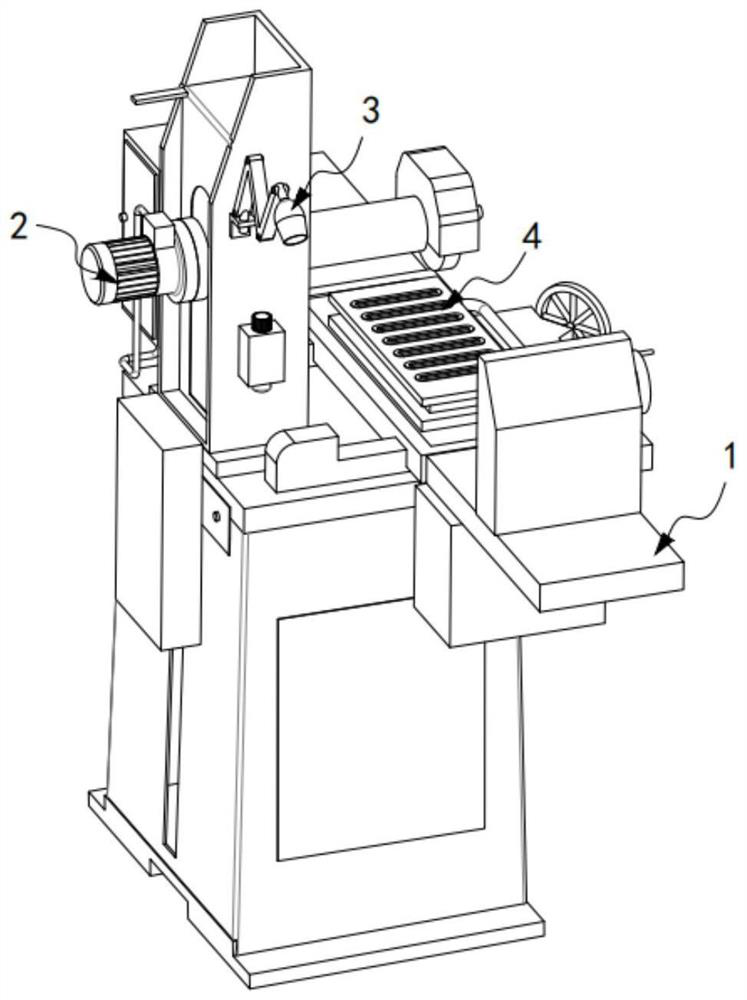

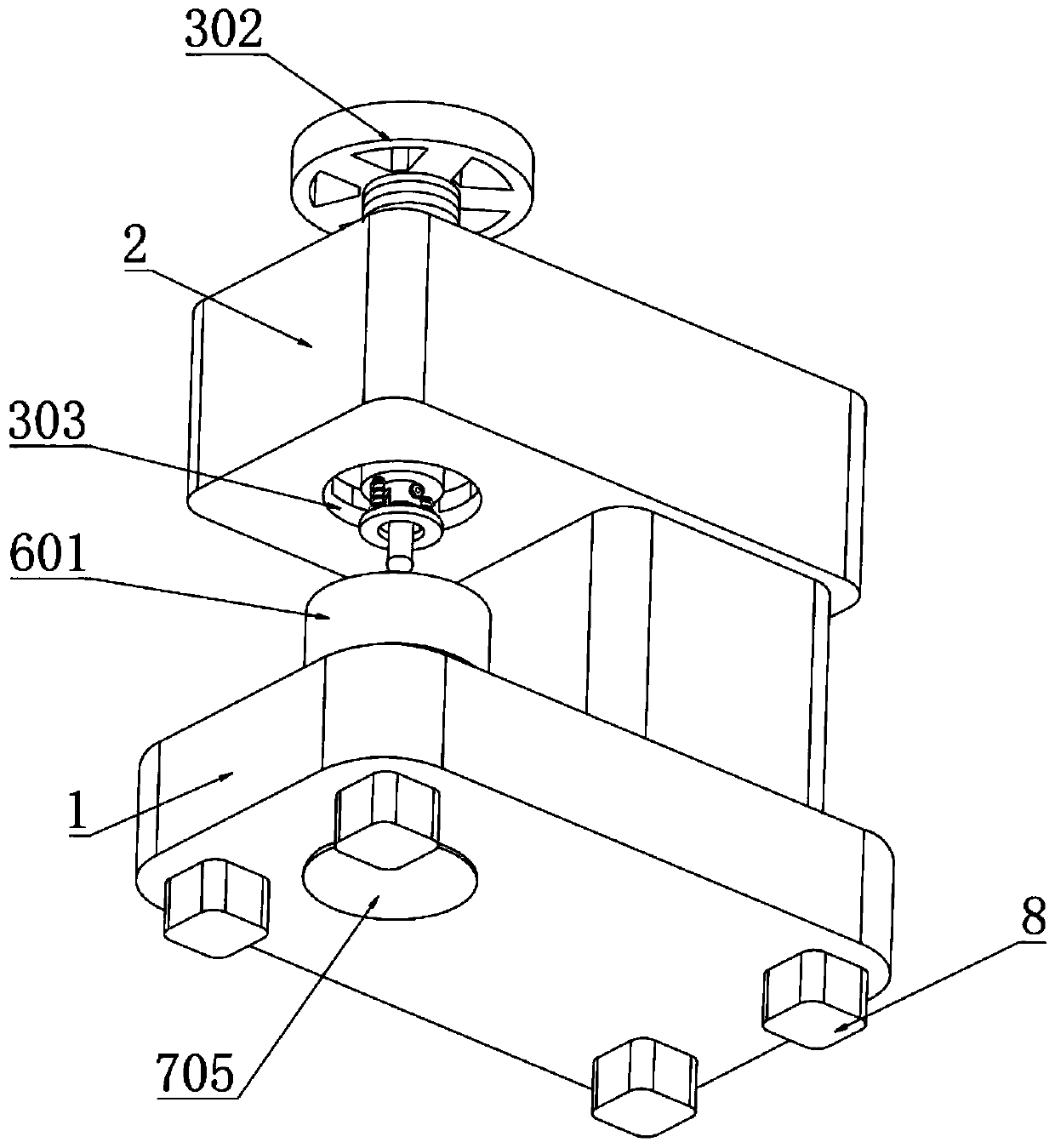

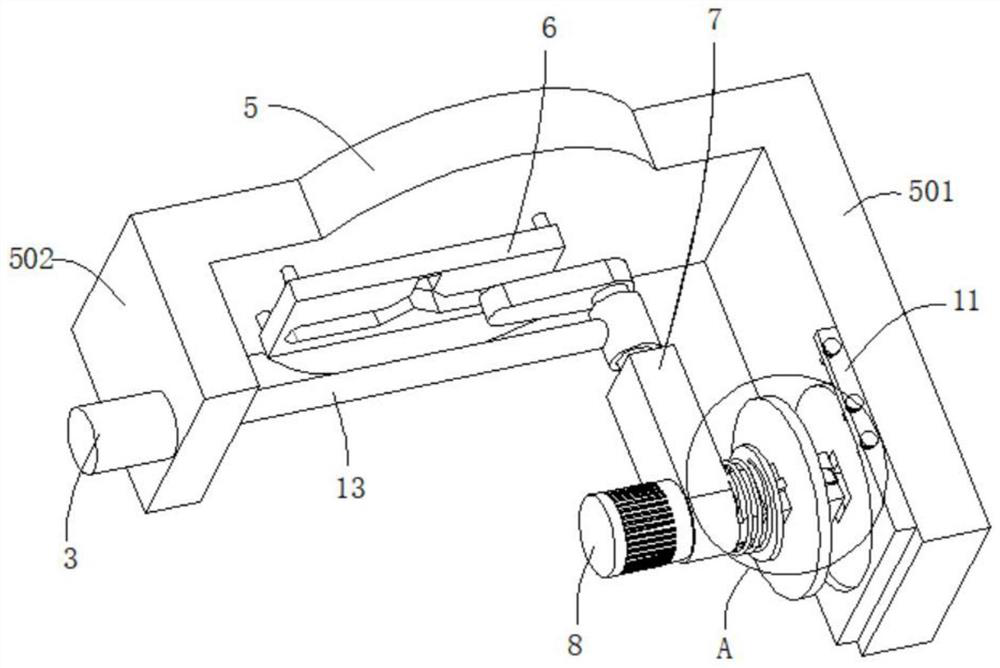

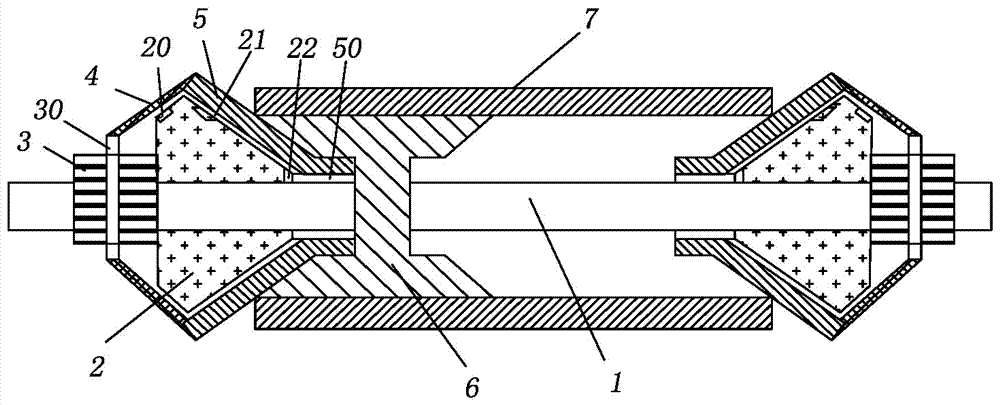

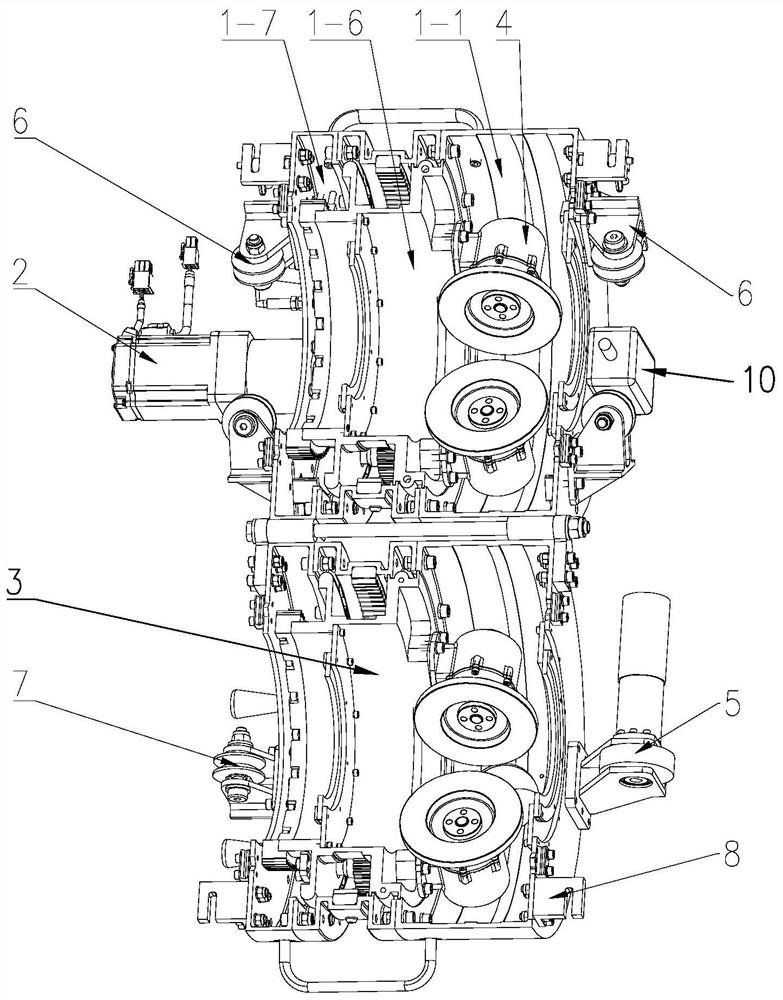

Working method of aluminum alloy bar processing equipment

ActiveCN109702495ASolve grinding problemsSolve processabilityOther manufacturing equipments/toolsPositioning apparatusAluminium alloyScrap

The invention discloses a working method of aluminum alloy bar processing equipment, and belongs to the field of aluminum alloy processing equipment. The processing equipment includes a feeding device, a transfer device, a drilling and milling device and a grinding device, the feeding device includes a feeding assembly and a material control assembly, the grinding device includes a bearing grinding assembly, a supporting assembly, a driving assembly and two pressing assemblies, the bearing grinding assembly is arranged at one end of the transfer device and is connected with the transfer device, the supporting assembly is installed on the side wall of the bearing grinding assembly, the driving assembly is installed on the supporting assembly and is connected with the two pressing assembliesin a transmission mode, the drilling and milling device includes a positioning assembly and a tapping and milling assembly, and the positioning assembly is arranged between the other end of the transfer device and the tapping and milling assembly. According to the working method of the aluminum alloy bar processing equipment, grinding and drilling and milling alternately processing for aluminum alloy bars can be realized, and waste can be centrally recycled while the aluminum alloy bars can be processed, so that overall practicability is improved.

Owner:帅翼驰新材料集团有限公司

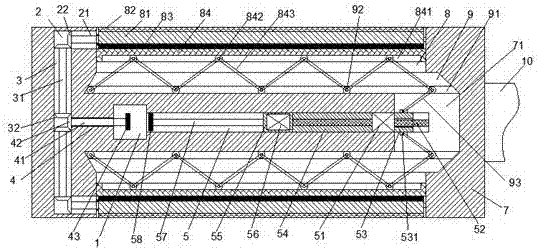

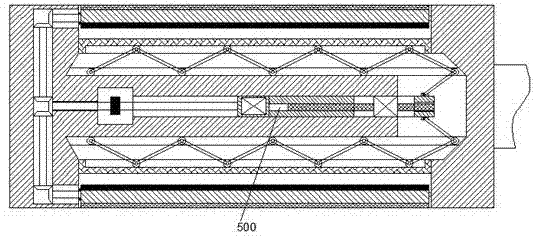

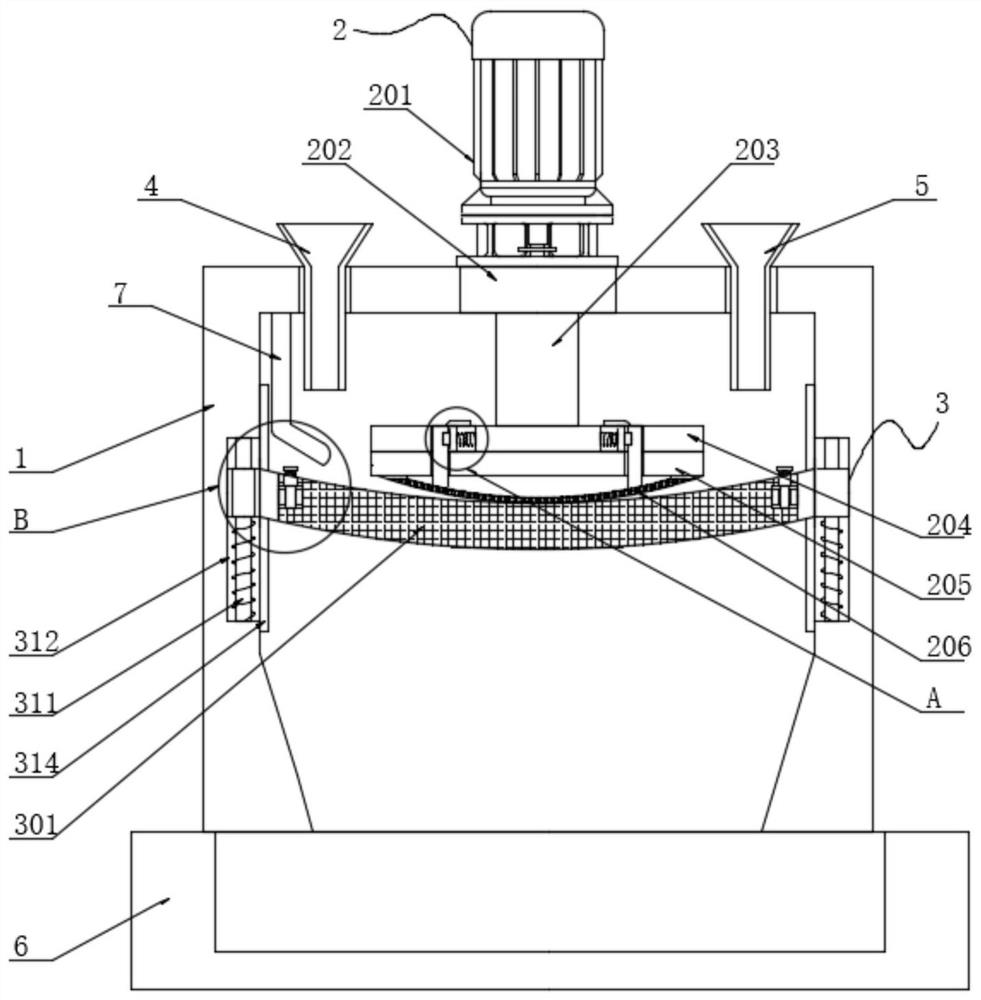

Ball milling and screening integrated equipment for water coal slurry preparing and forming

InactiveCN106732981AAvoid affecting the grinding effectEasy to filterSievingScreeningCoal slurryBall mill

The invention relates to ball milling and screening integrated equipment, in particular to ball milling and screening integrated equipment for water coal slurry preparing and forming. The ball milling and screening integrated equipment for water coal preparing and forming comprises a feeding hopper, a grinding cylinder body, a second bearing seat, a round mesh screen, a first belt wheel, a first bearing seat, a first rotating shaft, a connecting belt, a fixing frame, a second belt wheel and the like. A bearing in the first bearing seat is in interference fit connection with the first rotating shaft. The first rotating shaft is connected with the first belt wheel through a flat key. The round mesh screen is welded to the upper end of the first rotating shaft. The ball milling and screening integrated equipment achieves the effects of working efficiency improving and operation step simplifying; and ball milling and screening are integrated, so that working time is shortened, production benefits are improved, grinding is full, and the production quality is improved.

Owner:上海翁大电气科技有限公司

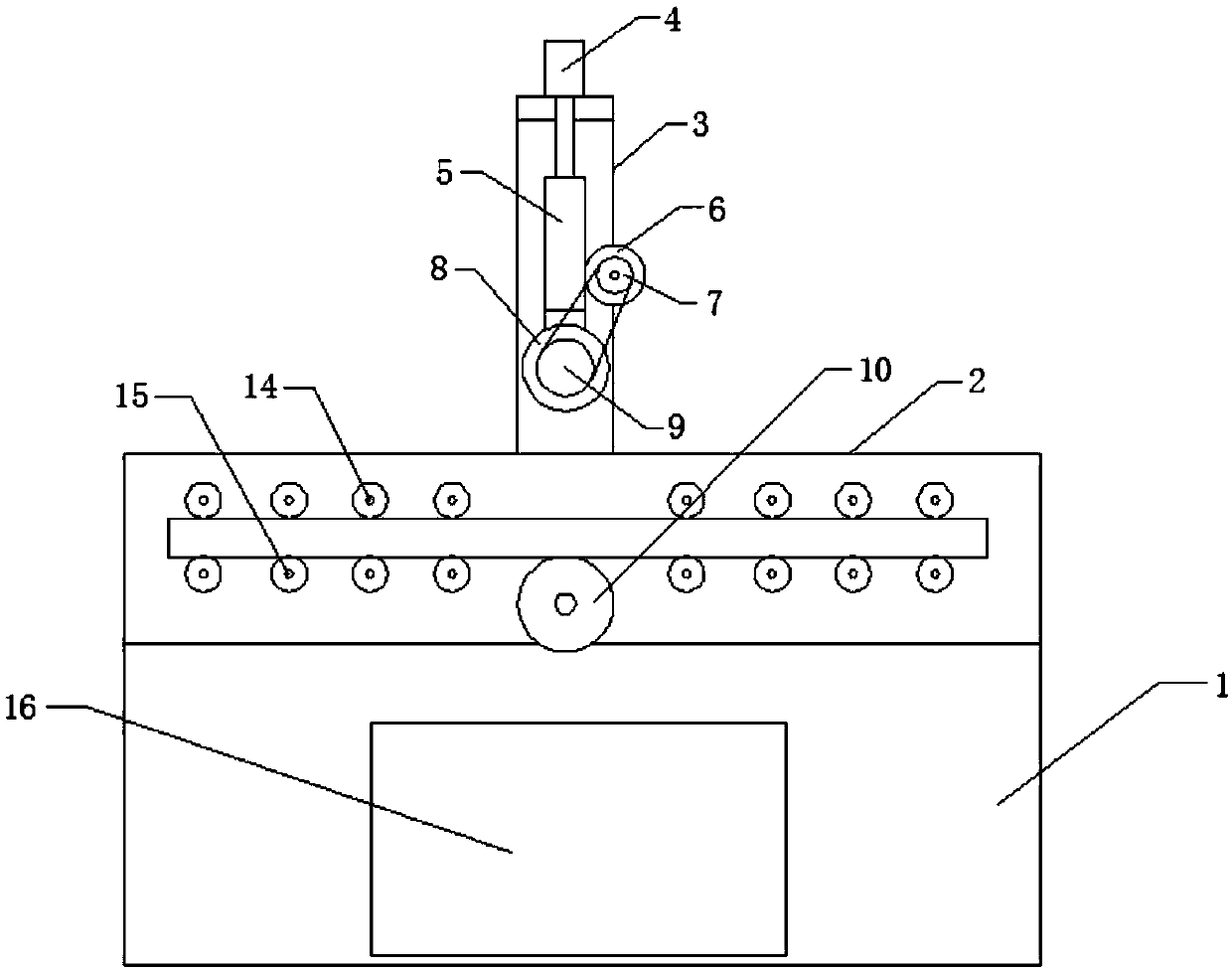

Automatic polishing device

InactiveCN109590867ASave human effortImprove work efficiencyEdge grinding machinesGrinding carriagesMechanical engineering

The invention provides an automatic polishing device. The automatic polishing device comprises a workbench, a first support, a second support, an air cylinder, a lifting frame, a second motor, an upper polishing roller, a lower polishing roller and a first motor. The first support is arranged on the workbench, the lower polishing roller and a plurality of transmission rollers are arranged on the first support in parallel, the first motor is arranged in the workbench, and the lower polishing roller is connected with the first motor. The second support is further arranged on the workbench, the air cylinder stretching out and drawing back in the vertical direction is arranged above the second support, the lifting frame is connected to the lower portion of the air cylinder through a telescopicrod, the upper polishing roller is arranged below the lifting frame, and the upper polishing roller and the lower polishing roller are parallel to each other and located over the lower polishing roller; and the second motor is arranged on the lifting frame, and the upper polishing roller is connected with the second motor. According to the automatic polishing device, double-face polishing can beconducted on plates, and adjustment can be conducted according to the thicknesses of the plates.

Owner:XINCHANG DINGSHI TECH CONSULTING SERVICE CO LTD

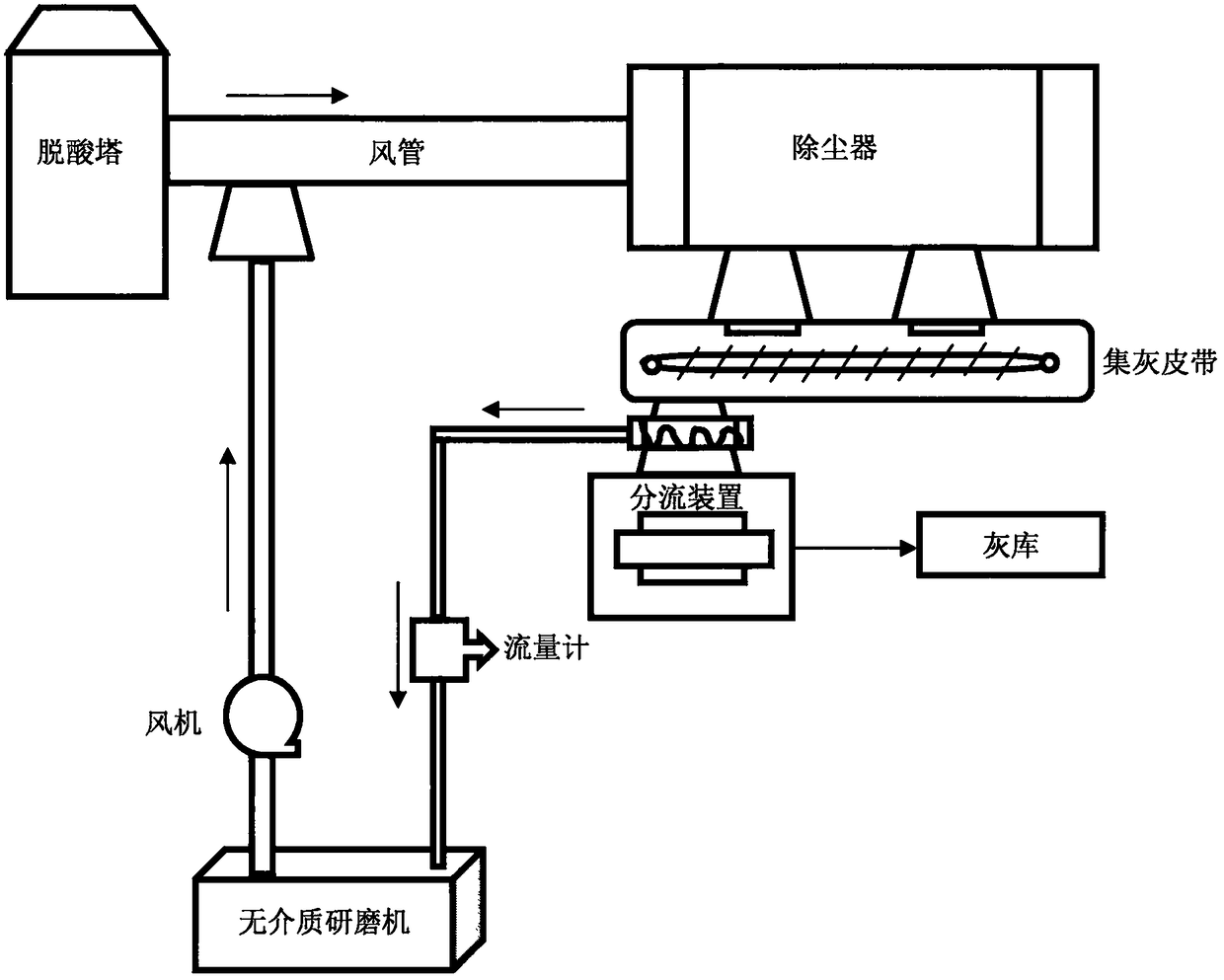

Household waste incineration fly ash cyclic utilization method

ActiveCN108273825AFlexible control of the amount of fly ashContinuous industrial productionSolid waste disposalTransportation and packagingPrillPhosphate

The invention relates to a household waste incineration fly ash cyclic utilization method. A flow distributing device is installed at the lower end of a dust remover of a waste incineration smoke treatment system and controls the amount of fly ash circularly entering a non-medium grinding machine, and therefore the phenomenon that since the fly ash agglomerates at a grinding medium or adheres to the inner wall of the grinding machine, the grinding effect is influenced is avoided. After the fly ash is smashed in a grinding bin, a high-pressure centrifugal fan brings the grinded powder materialsinto a powder selecting machine, fine powder meeting the fineness requirement enters a circulatory system along with airflow, and coarse particle materials incapable of meeting the fineness requirement return to the grinding bin to continue to be grinded. It is guaranteed that the particle sizes of the grinded fine powder are uniform and kept within a certain range, unreacted calcium hydroxide isfully exposed, the specific surface area of the fly ash is increased, the utilization rate of the calcium hydroxide in the fly ash can be improved to be 80% or over, and continuous industrial production can be achieved. Meanwhile, phosphate is fed into the non-medium grinding machine so as to pre-stabilize heavy metal and reduce the application amount of follow-up deacidification agents, and thephosphate also has the grinding assistance function. A strong oxidant is added and achieves the desulfurization and denitration function and the function of promoting dioxin to decompose.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

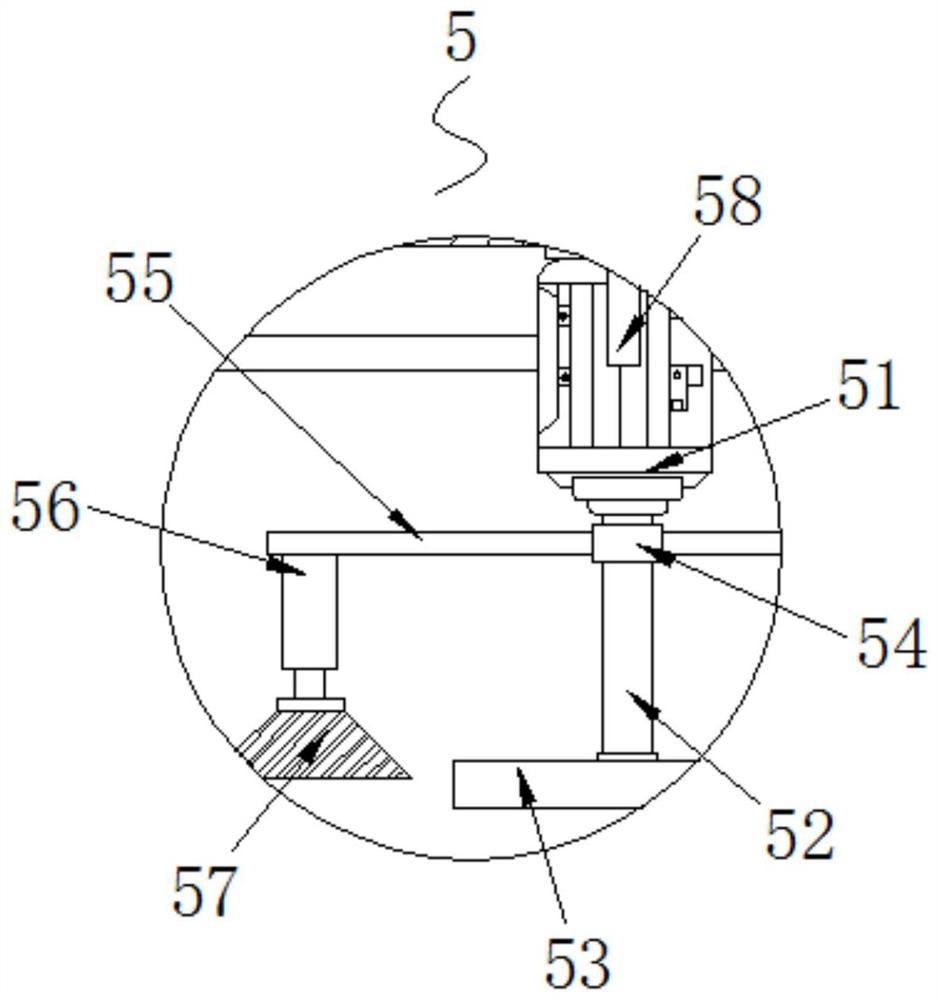

Efficient grinding device for ore machining

InactiveCN108126797AImprove work efficiencyImprove grinding efficiencyCocoaGrain treatmentsPistonPiston cylinder

The invention discloses an efficient grinding device for ore machining. The efficient grinding device comprises a shell, a heating cavity, a piston cylinder and a grinding disc, wherein the heating cavity is arranged at the upper end of the outer side of the shell in a sleeving mode; the lower end of a cylinder is connected with a fixing plate in a rotating mode, the fixing plate is fixedly arranged on the inner side of the shell, and a rotating plate is arranged below the fixing plate; a movable rod is arranged in the cylinder, the lower end of the movable rod is hinged to a sliding block, and the sliding block is slidably connected to a movable plate, and the left end of the movable plate is hinged to the inner side of the outer shell; and a second motor is fixedly arranged at the left end of the movable plate, and an output shaft of the second motor penetrates through the movable plate and is fixedly connected with the grinding disc. According to the efficient grinding device for ore machining, the design is novel, operation is simple, the automation degree is high, and the effect of intermittent discharging can be realized, so that excessive ores can be prevented from falling out of a stack, and the follow-up grinding effect is prevent from being influenced; and meanwhile, the distance between the grinding disc and a sieve plate is changed intermittently, and ore moves on the sieve plate, so that the grinding efficiency is improved, the grinding effect is improved, and practicability is high.

Owner:西钢集团灯塔矿业有限公司

Surface polishing device for integrated circuit copper clad laminate

InactiveCN109465695ALabor savingReduce labor costsGrinding work supportsPlane surface grinding machinesEngineeringCopper

The invention discloses a surface polishing device for an integrated circuit copper clad laminate, and the device includes a base, two brackets, two conveying devices and a support plate, the two brackets are fixedly connected with the upper end of the base, the two conveying devices are fixedly connected with the brackets, and the support plate is fixedly connected with the middle part of the upper end of the base. The copper clad laminate does not need to be manually placed on the polishing device one by one in the polishing process through the conveying devices, so that the labor can be saved, the labor cost can be reduced, and the working efficiency can be improved. Through the cooperation of a reciprocating screw rod and a polishing sleeve, the surface of the copper clad laminate canbe completely polished, so as to avoid polishing dead corners and improve the polishing effect. The copper clad laminate is firmly sucked by a suction cup to achieve a fixing function, and at the sametime, the copper clad laminate is fixed before polishing through the cooperation of a clamping device, so that sliding during polishing is avoided and the polishing effect is guaranteed.

Owner:合肥酷睿网络科技有限公司

Rotary grinding equipment for iron plate weld mark of hardware

InactiveCN112476115AImprove work efficiencyImprove securityEdge grinding machinesGrinding carriagesElectric machineryManual handling

The invention relates to grinding equipment, in particular to rotary grinding equipment for iron plate welding mark of hardware. The rotary grinding equipment for the iron plate welding mark of the hardware has the advantages of automatic collection of scraps and high working efficiency. The rotary grinding equipment for the iron plate welding mark of the hardware comprises a base, a first supportframe arranged in the top middle of the base, a motor arranged at the upper part of the first support frame slidably, a placing assembly arranged on one side of the top of the base, and a grinding assembly arranged between one side of the top of the base and an output shaft of the motor. Through cooperation of the placing assembly and the grinding assembly, the weld mark on an iron plate can be automatically ground, and the working efficiency of people is improved; injuries caused by manual operation can be avoided, and the safety of people is improved; the grinding effect is good, and through a locating assembly, the welding mark can be aligned to the position under diamond; and the grinding precision is improved.

Owner:廖子宁

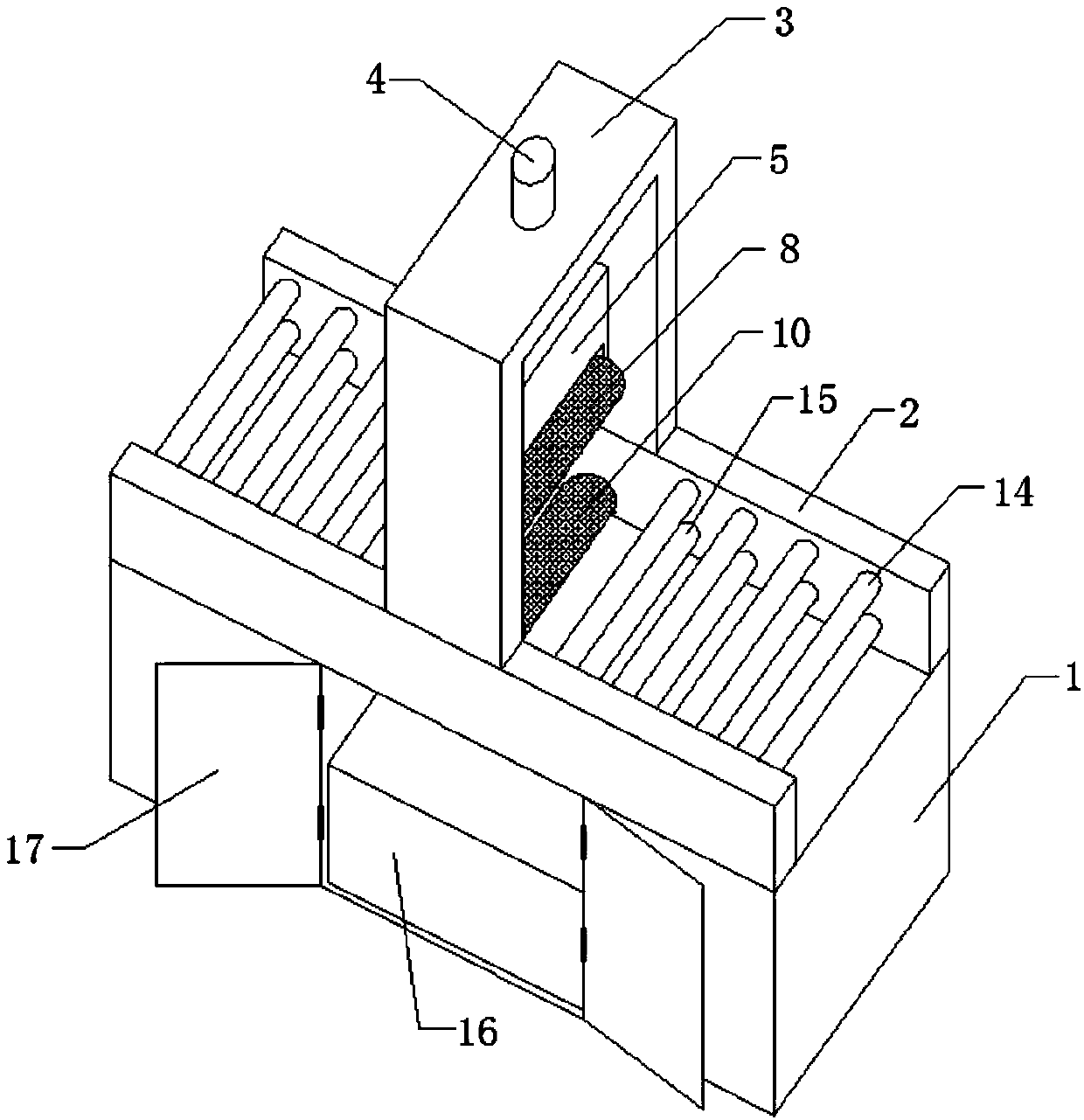

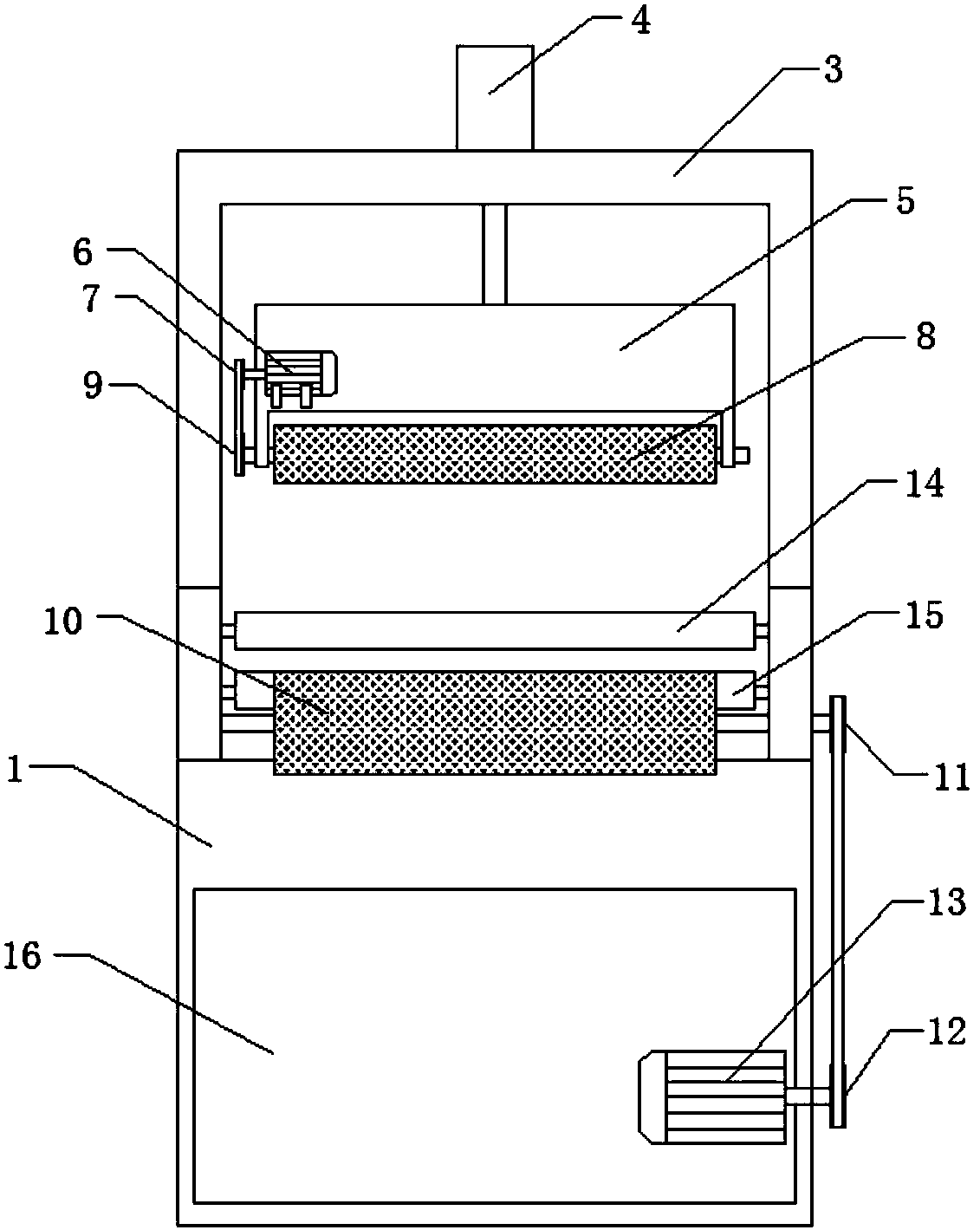

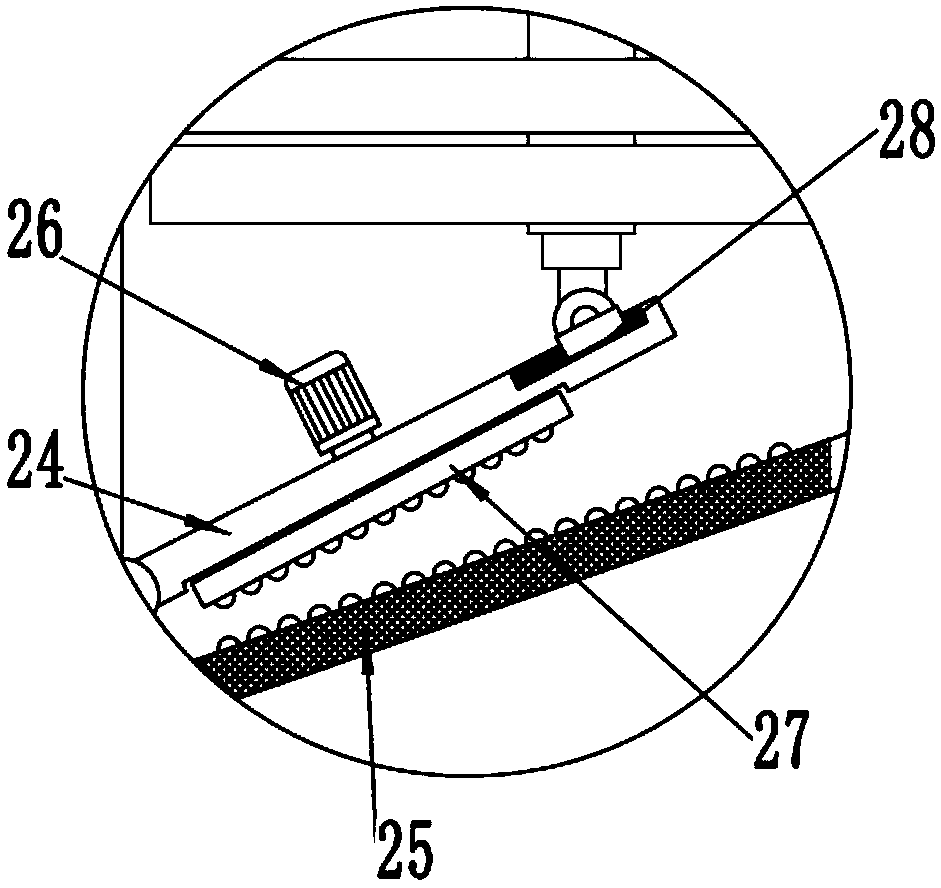

Fine sueding and grinding machine

The invention discloses a fine sueding and grinding machine, comprising a cloth intake and discharge mechanism, a frame, a grinding mechanism, a brushing mechanism and a cloth traction mechanism, wherein the grinding mechanism, the brushing mechanism and the cloth traction mechanism are respectively arranged on the frame. The fine sueding and grinding machine is characterized in that the grinding mechanism comprises a grinding roller, an embossing roller, a first drive mechanism, a second drive mechanism, a third drive mechanism and a fourth drive mechanism, wherein the grinding roller can be arranged on the frame in the form of moving along the axial direction of the frame; the embossing roller is arranged on the frame and can move relative to the grinding roller between a working position and a stand-by station; the first drive mechanism drives the embossing roller to move between the working position and the stand-by station; the second drive mechanism drives the grinding roller to move in a reciprocating manner along the axial direction of the grinding roller; the third drive mechanism drives the embossing roller to rotate; the fourth drive mechanism drives the grinding flower to rotate; the embossing roller is tangent to the grinding roller in parallel to clamp cloth when being in the working position. The fine sueding and grinding machine is high in machining accuracy, and can be used for sueding and grinding thinner fabrics.

Owner:晋江创鑫机械有限公司

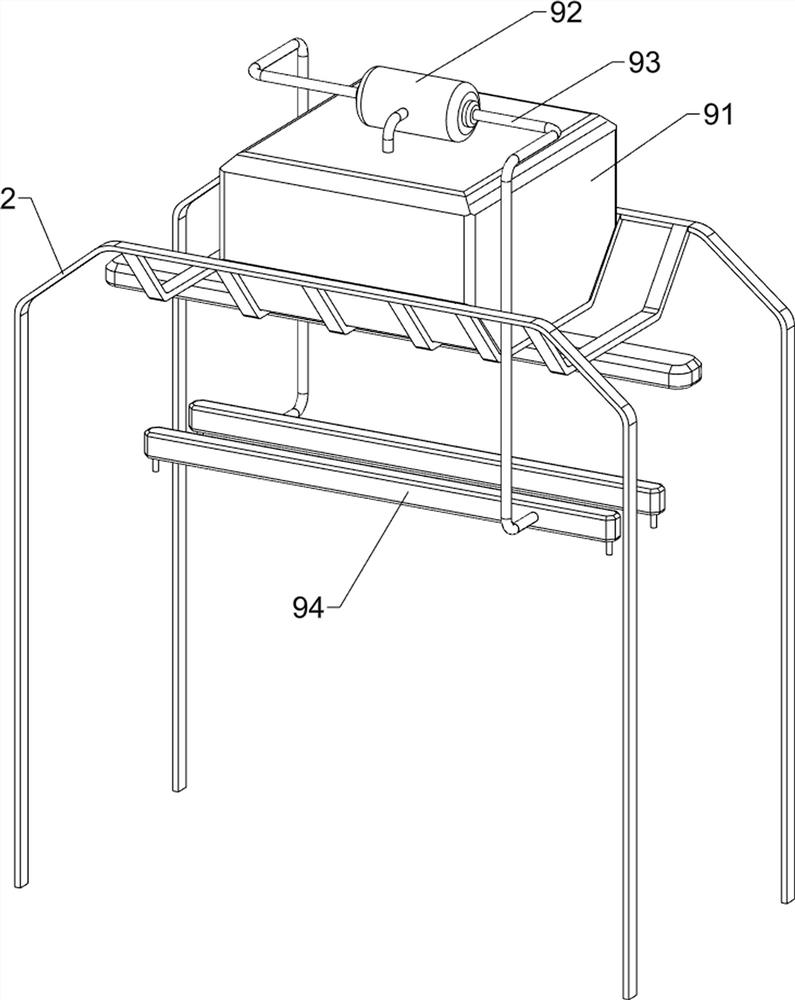

Automatic water supply and feed adding system for sheep farm

ActiveCN112219740AAvoid the effects of eating and drinkingImprove the efficiency of eating and drinkingSievingScreeningSheep farmingAnimal science

The invention discloses an automatic water supply and feed adding system for a sheep farm, and relates to the technical field of sheep farming. The automatic water supply and feed adding system comprises a box body, a grinding mechanism is arranged at the top of an inner cavity of the box body, a screening mechanism is attached to the bottom of the grinding mechanism, and a feeding trough is arranged at one side of the box body. According to the automatic water supply and feed adding system, feed is fed into the box body through a feeding pipe, the feed falls to the top of a sieve plate through the feeding pipe and a material blocking plate in a blocking connection manner, an output shaft of a motor rotates to drive a grinding net plate to be attached to the top of the sieve plate to rotate, the feed can be attached to the top grinding net plate to be ground and crushed when the sieve plate rotates, and the filtered and screened feed can fall into the bottom feeding trough; and throughcooperation of the sieve plate and the grinding net plate, large particles are collected while cakes in the feed are crushed, and therefore the influence of the feed cakes on sheep flock feeding andwater drinking can be effectively avoided, the feed and a water source can be fully mixed and then fed, the feeding and water inlet efficiency is effectively improved, and the overall use requirementis met.

Owner:ANHUI PROVINCE TIANCHANG CITY ZHOUSHI SHEEP CO LTD

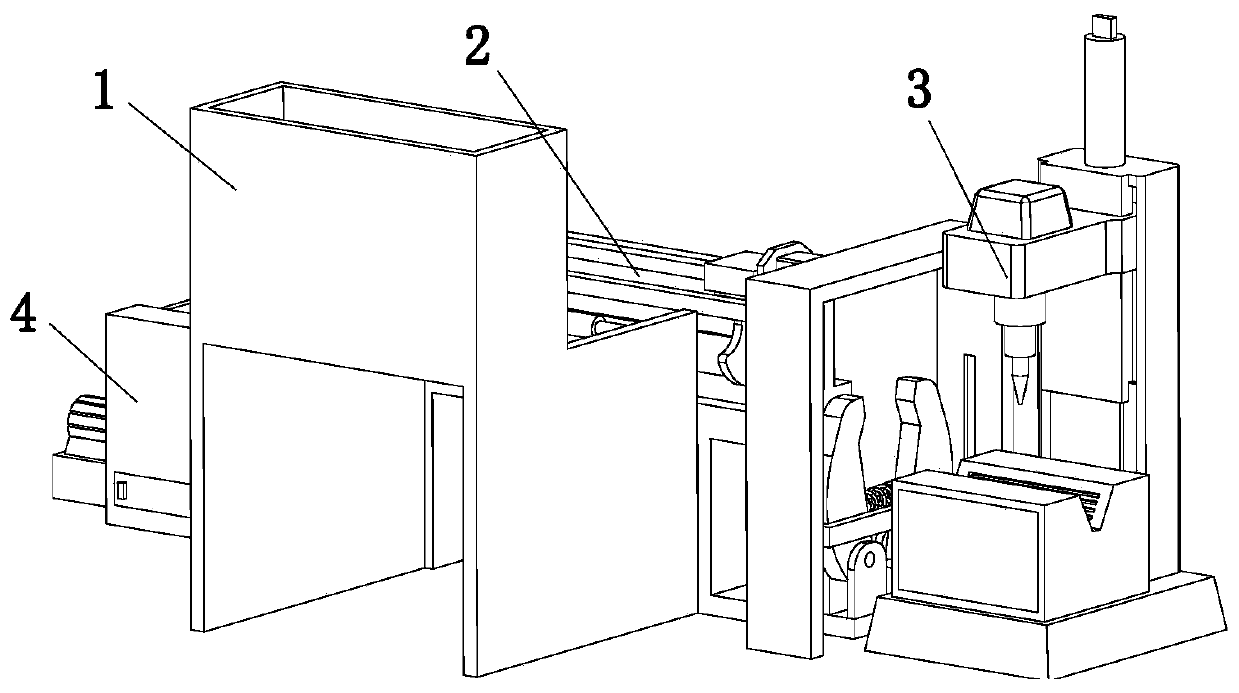

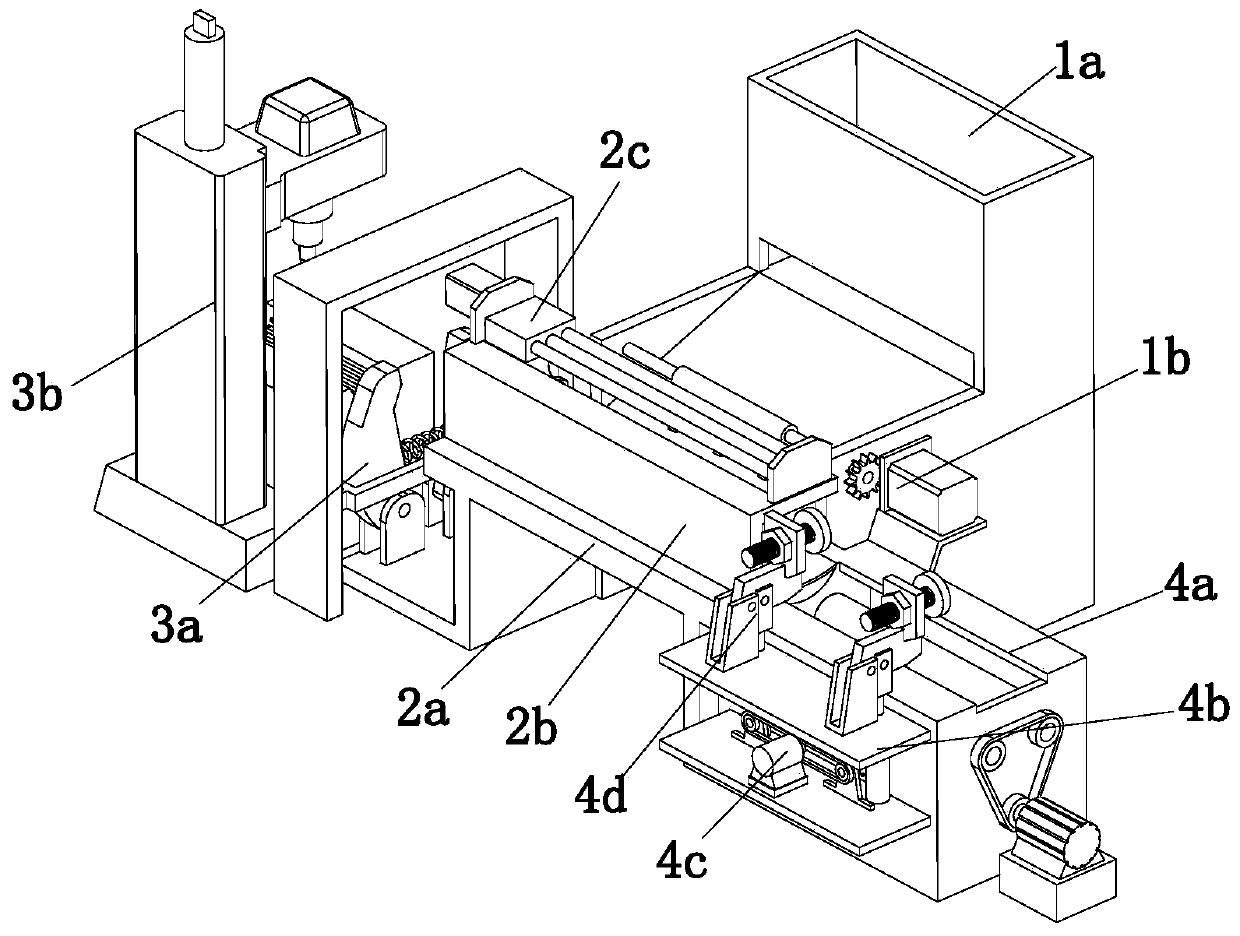

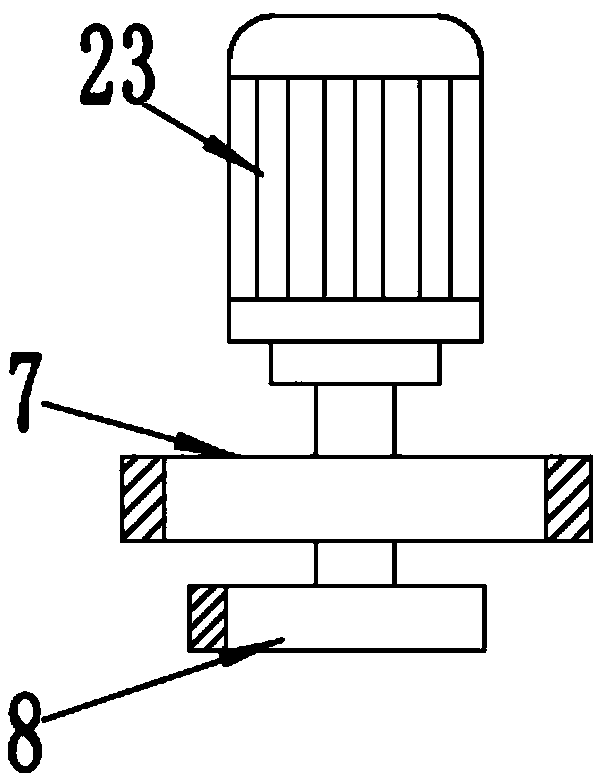

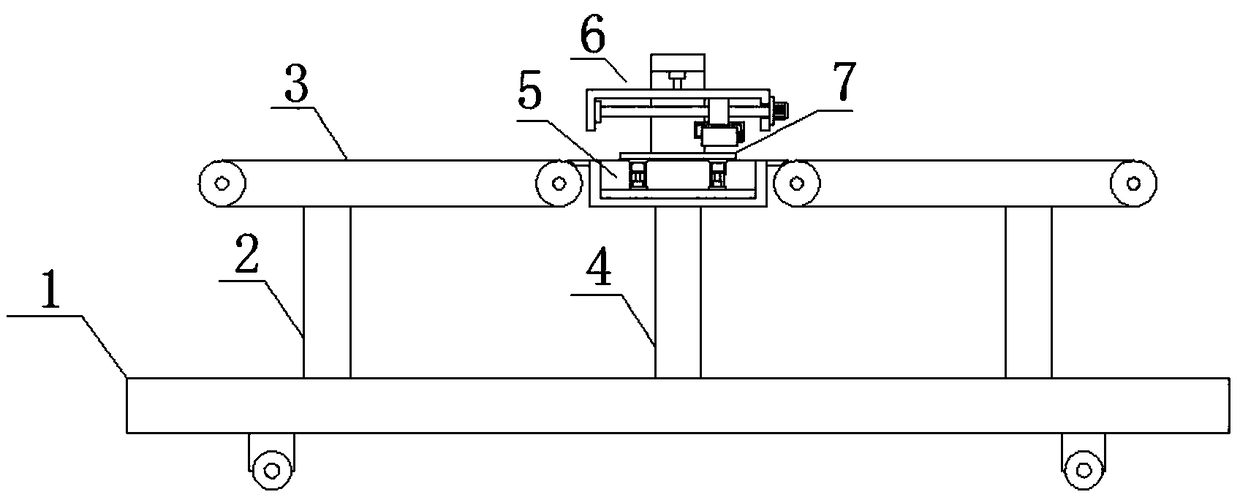

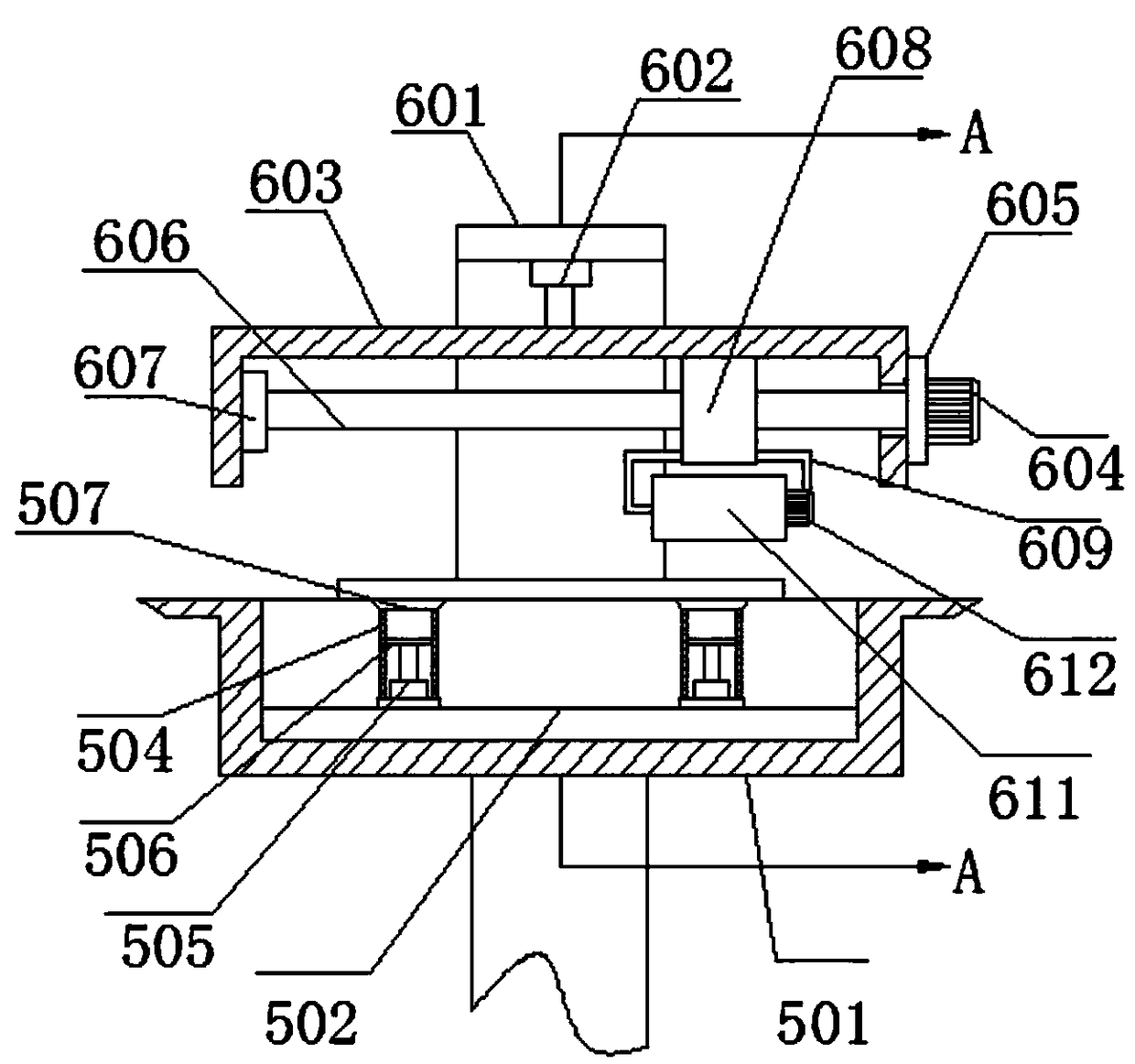

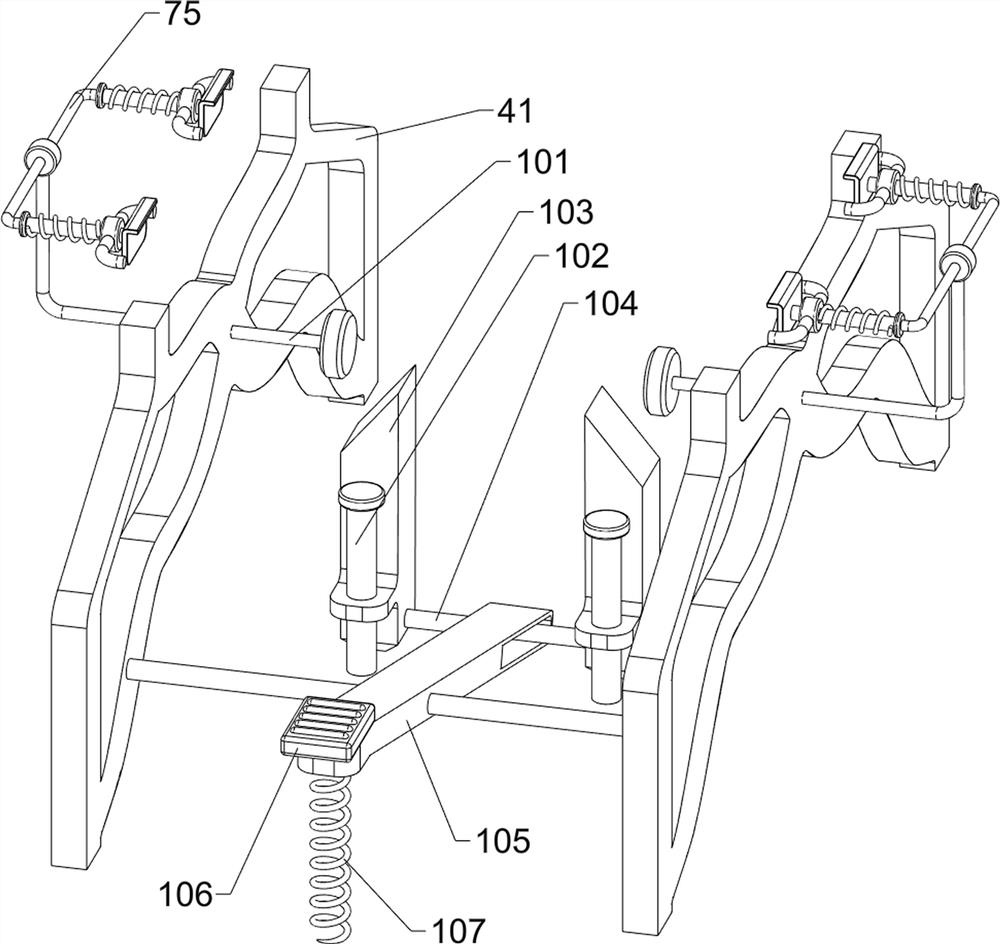

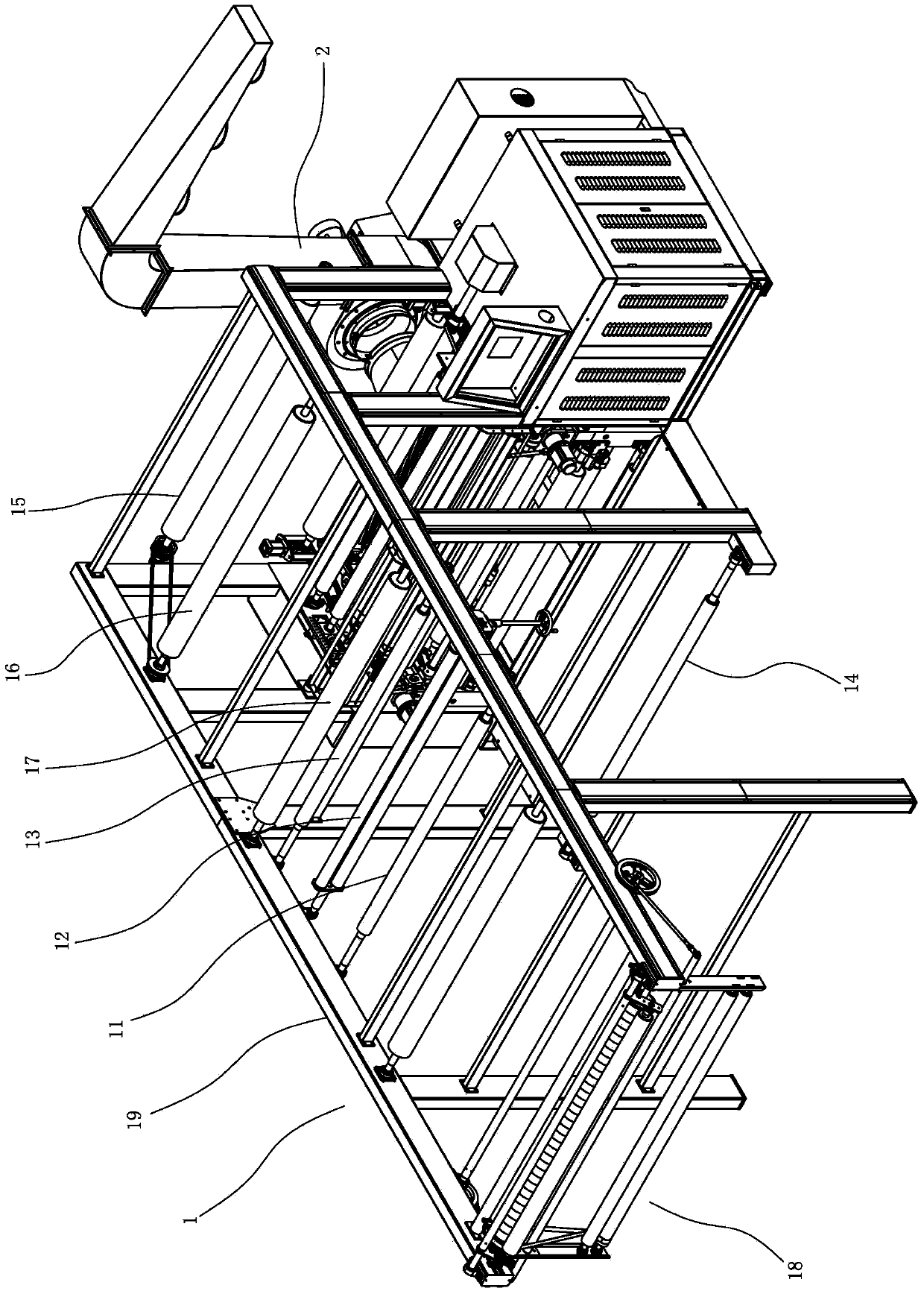

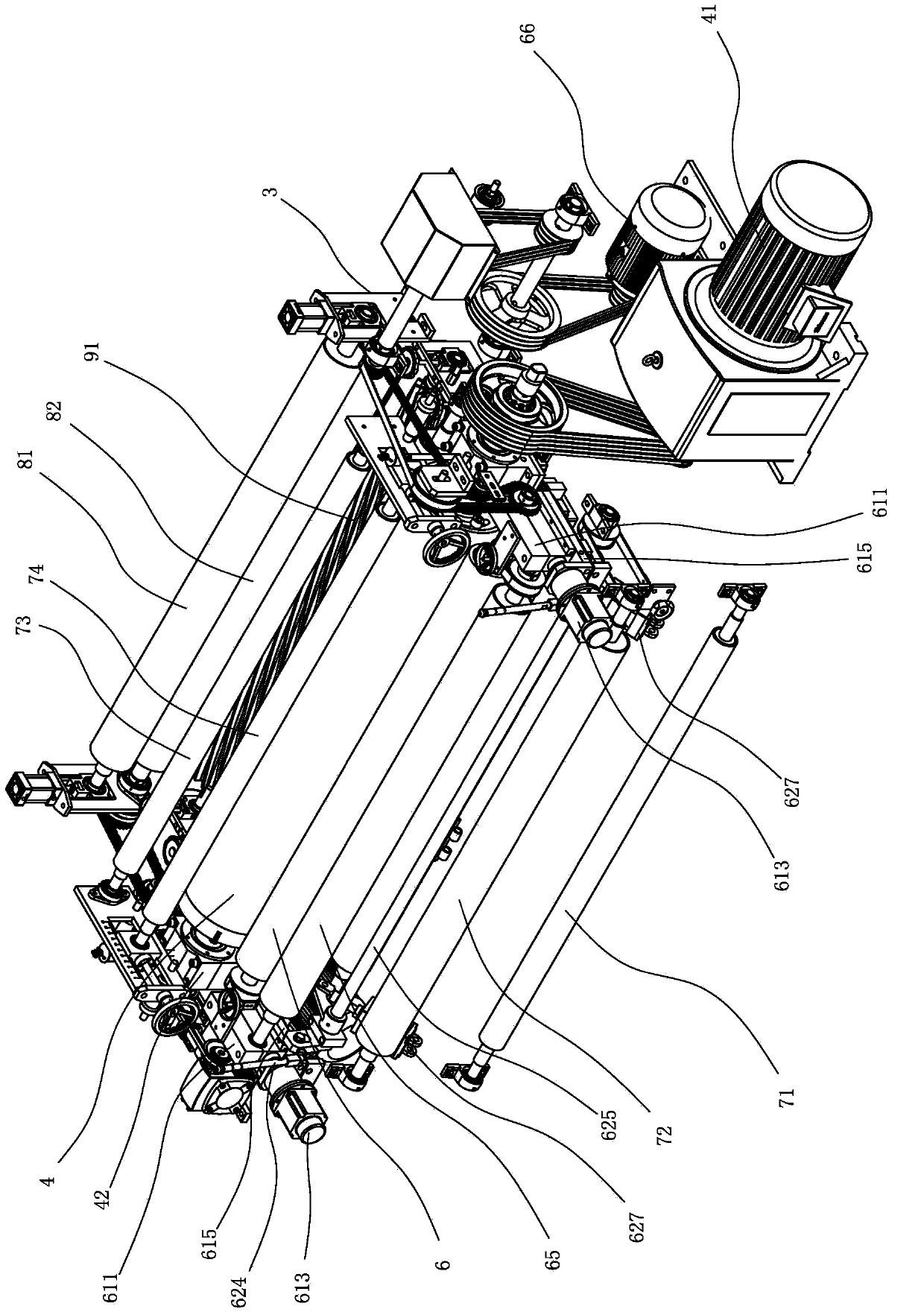

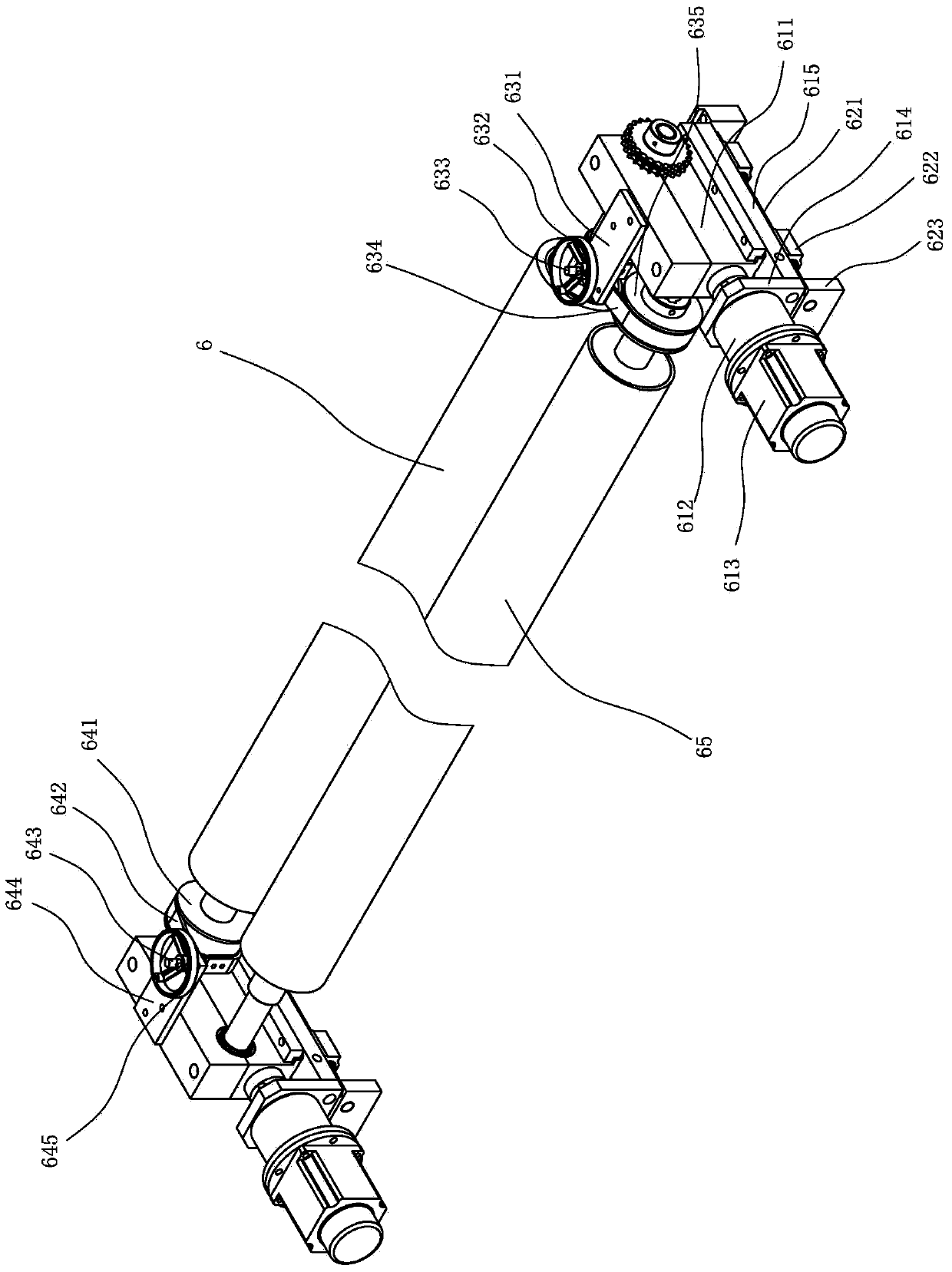

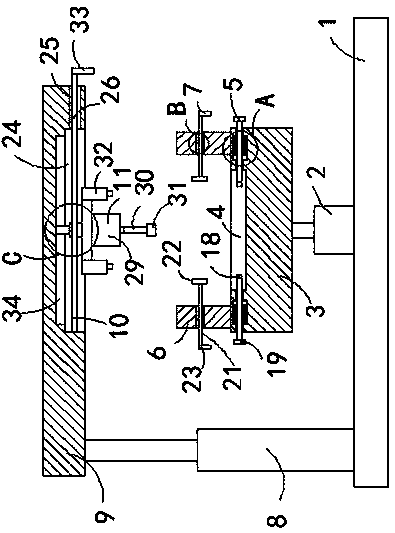

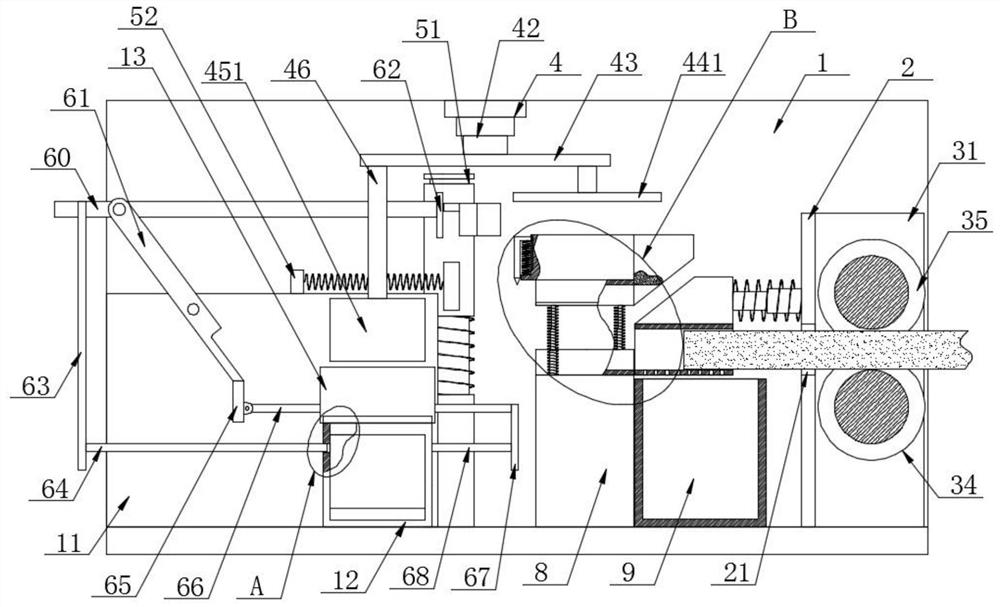

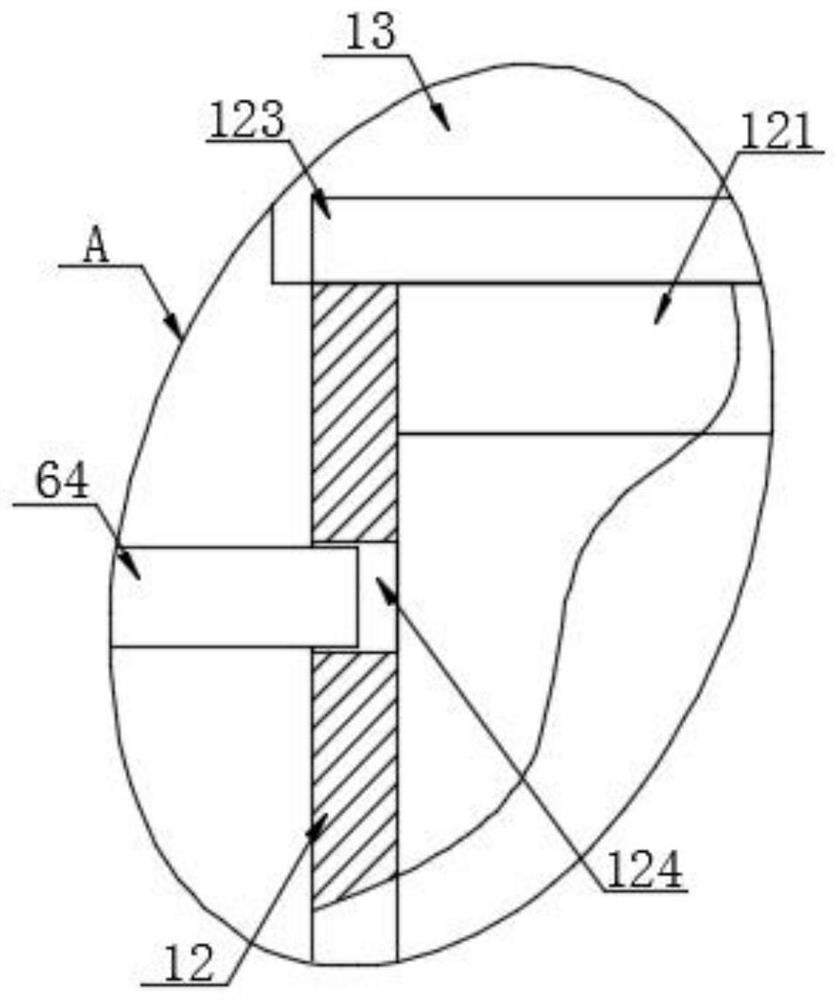

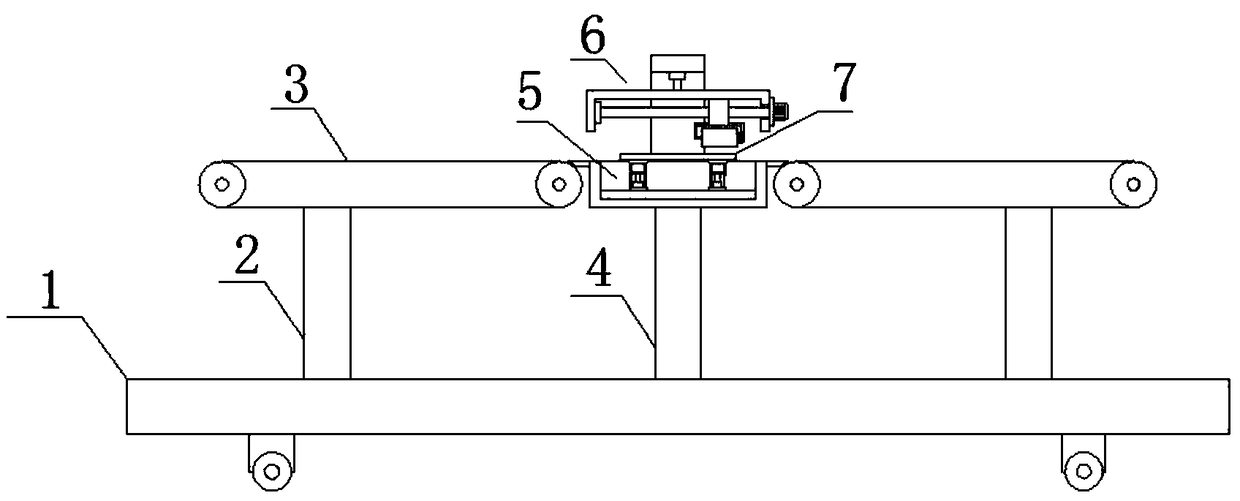

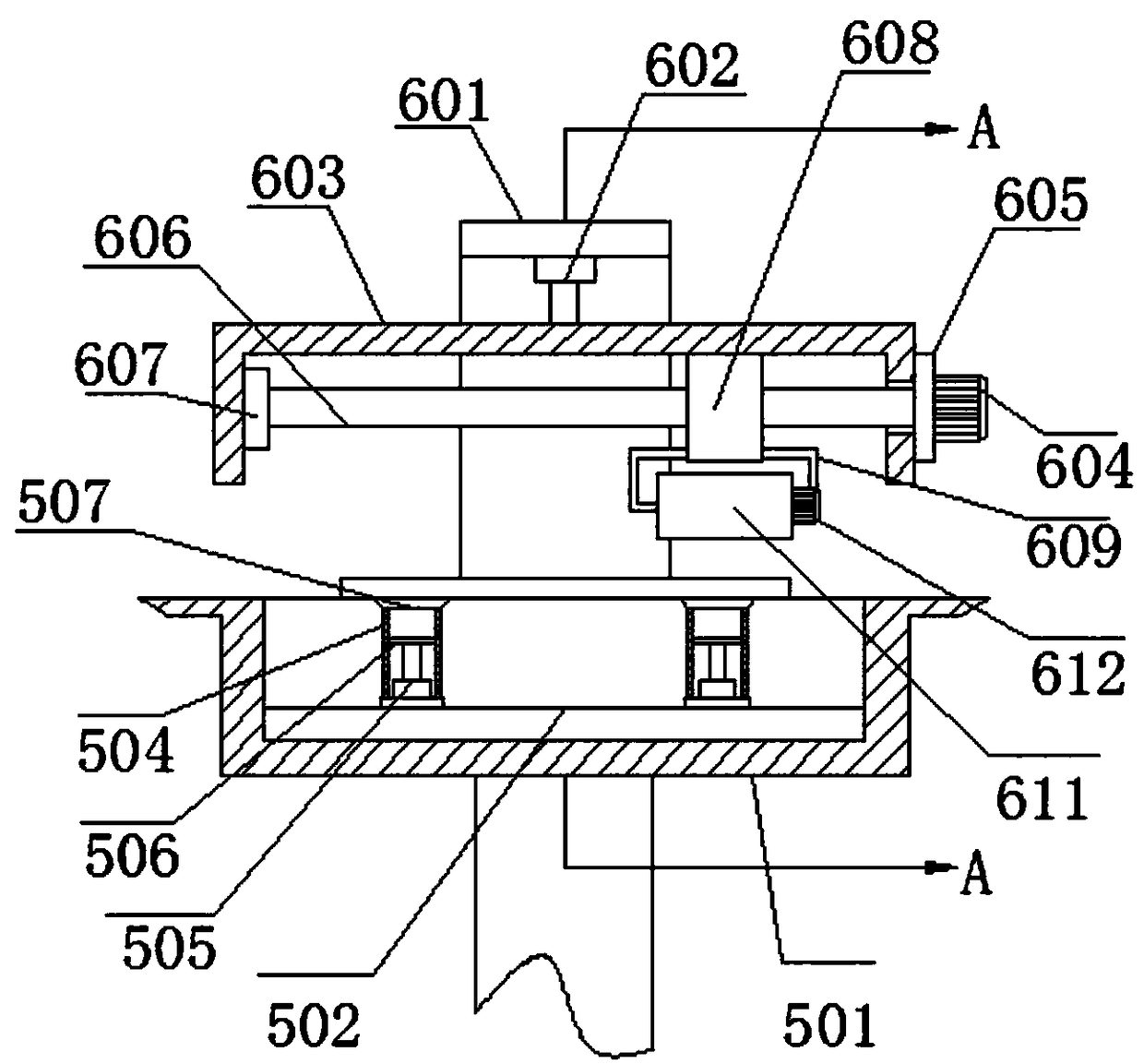

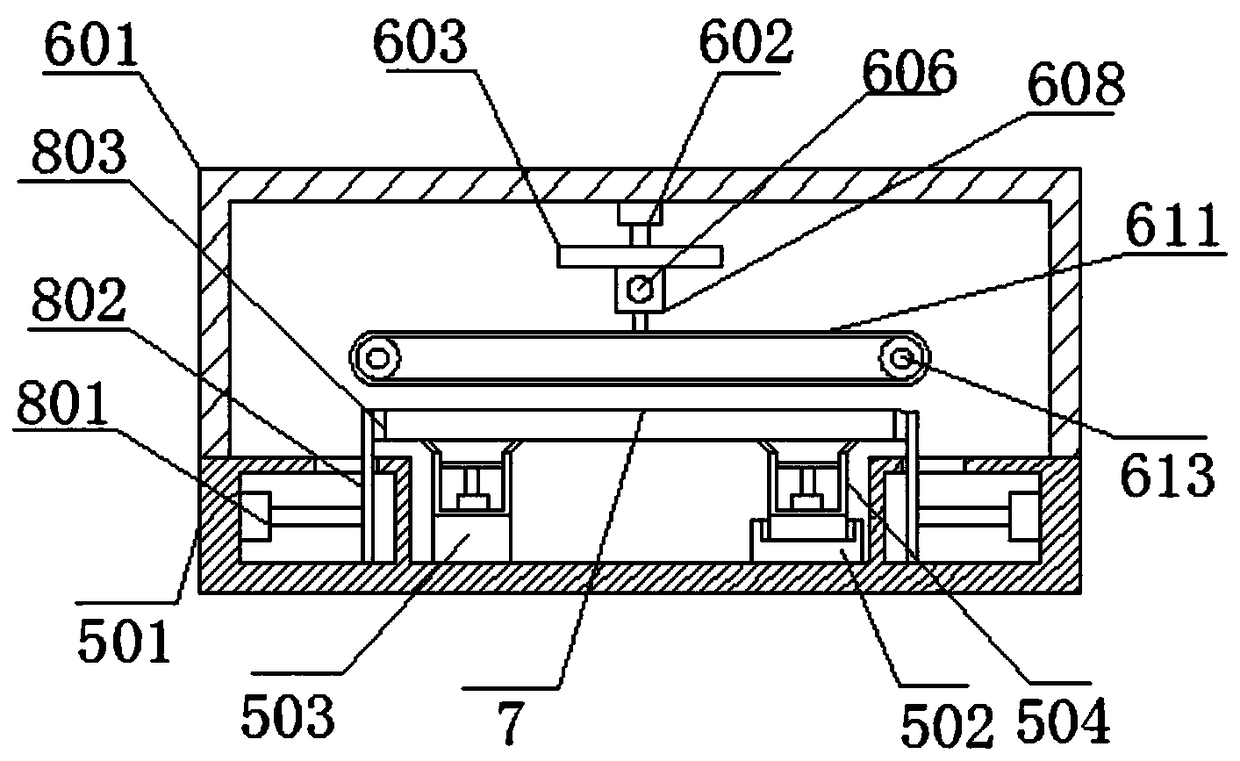

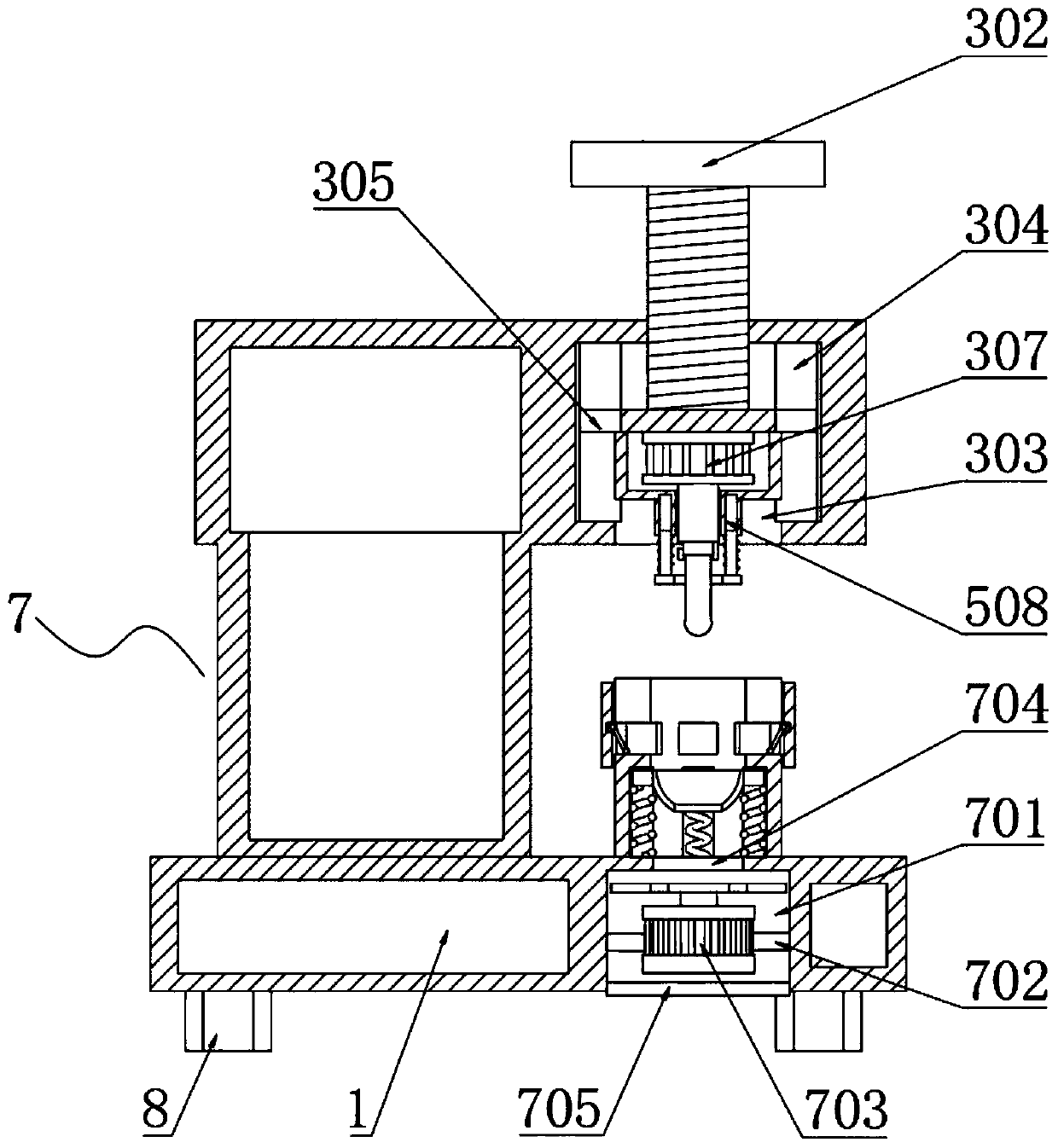

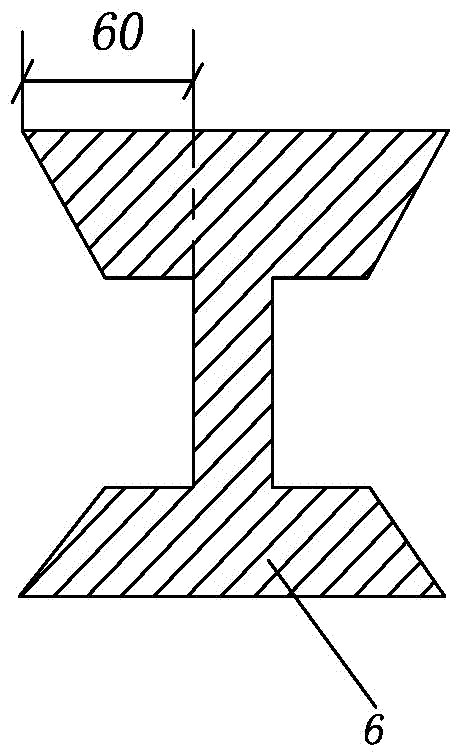

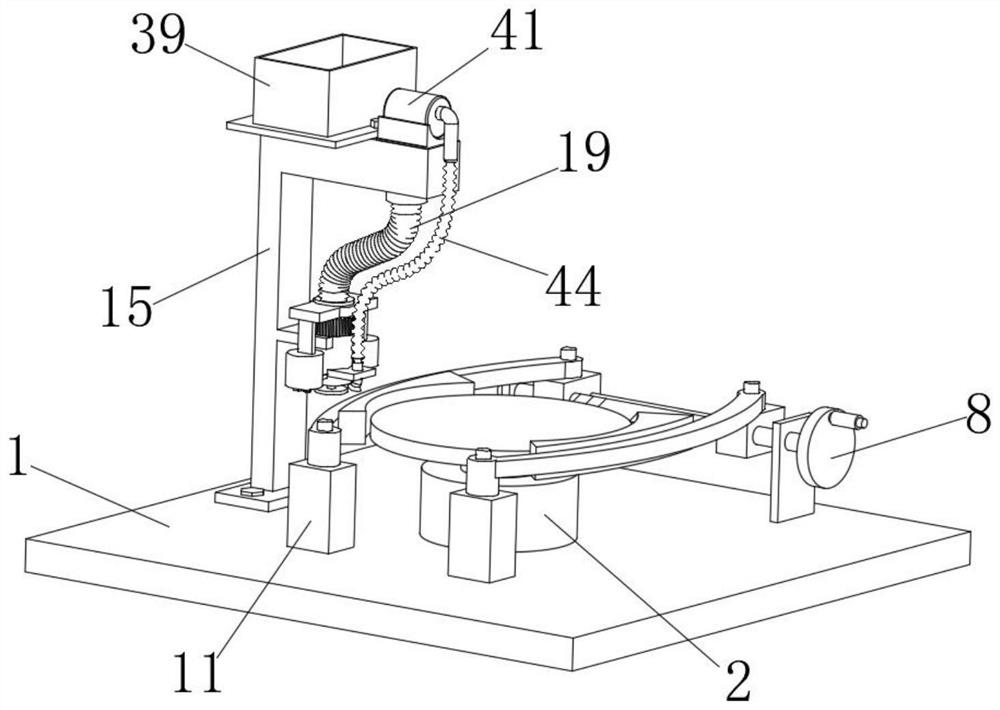

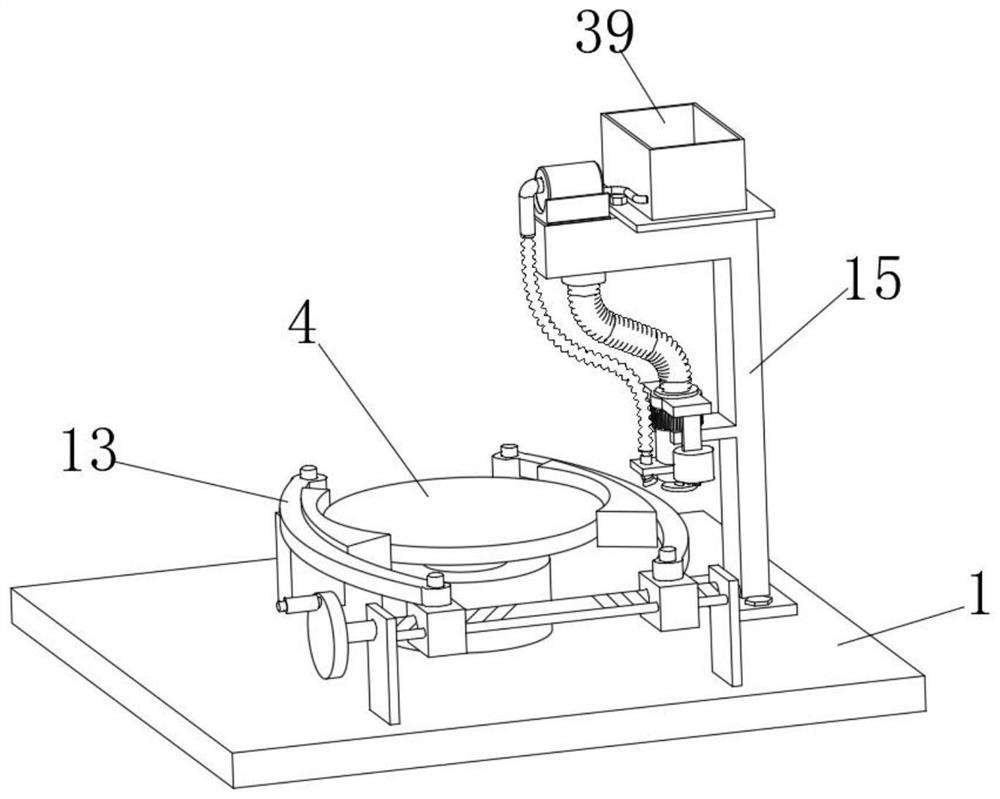

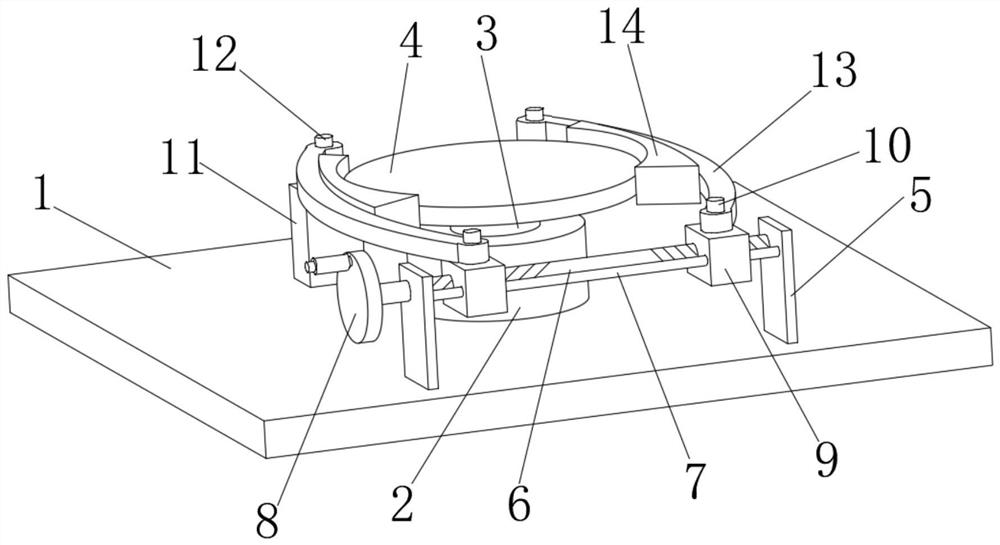

Machining equipment of aluminum alloy rods

ActiveCN109676450ASolve grinding problemsSolve processabilityRevolution surface grinding machinesGrinding drivesMaterial supplyAluminium alloy

The invention discloses machining equipment of aluminum alloy rods, and belongs to the field of aluminum alloy machining equipment. The machining equipment comprises a material supply device, a transfer device, a drilling and milling device and a grinding device. The material supply device comprises a material supply assembly and a material control assembly. The grinding device comprises a bearinggrinding assembly, a supporting assembly, a driving assembly and two pressing assemblies. The bearing grinding assembly is arranged at the position of one end of the transfer device and is in linkedcooperation with the transfer device, the supporting assembly is mounted on the side wall of the bearing grinding assembly, the driving assembly is mounted on the supporting assembly and is in transmission connection with the two pressing assemblies, the drilling and milling assembly comprises a positioning assembly and a tapping and milling assembly, and the positioning assembly is arranged between the other end of the transfer device and the tapping and milling assembly. The aluminum alloy rods can be ground and drilled and milled alternately, waste can be recycled and treated in a centralized manner while the aluminum alloy rods are machined, and therefore the overall practicality of the machining equipment is improved.

Owner:百色市彩虹铝业有限公司

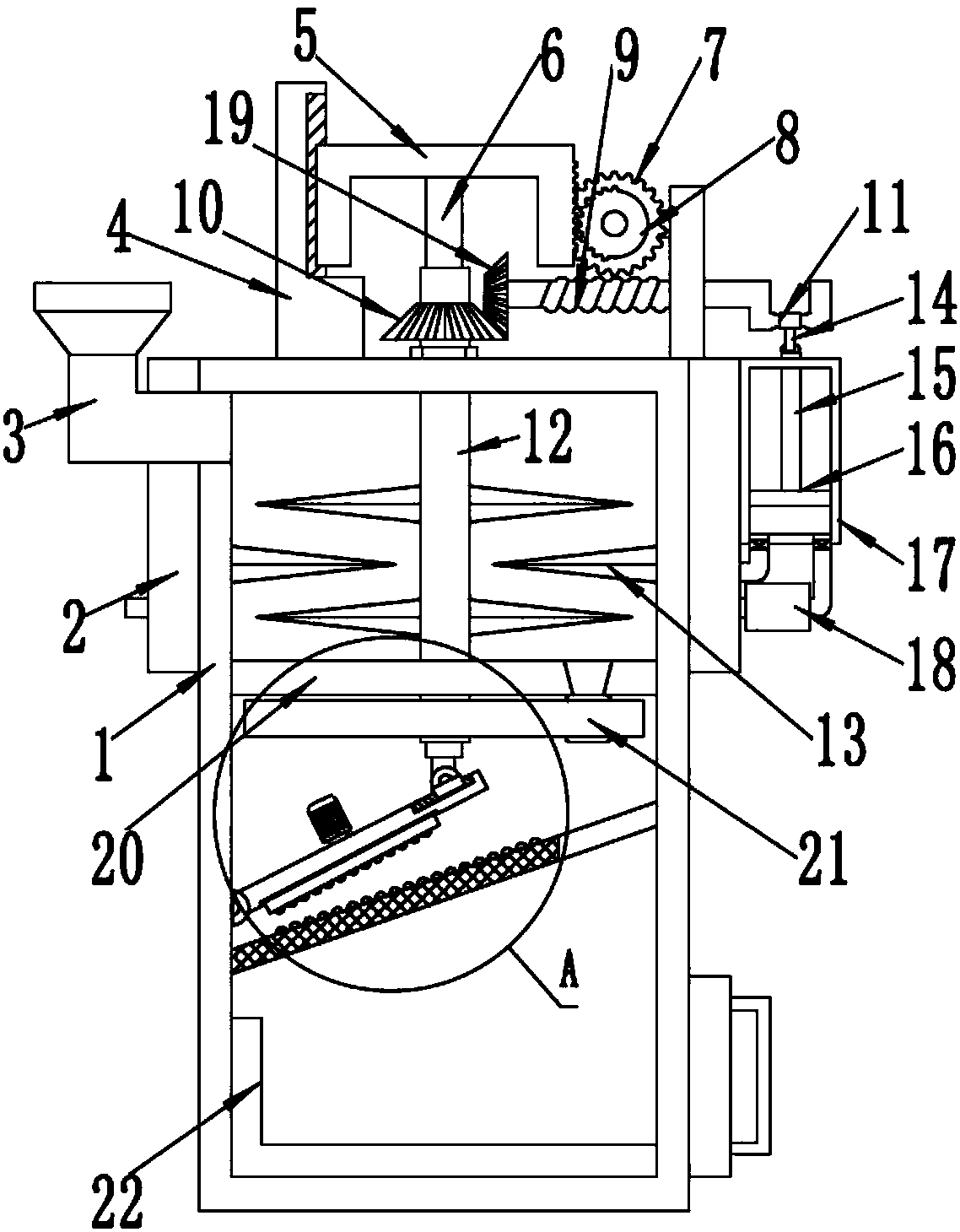

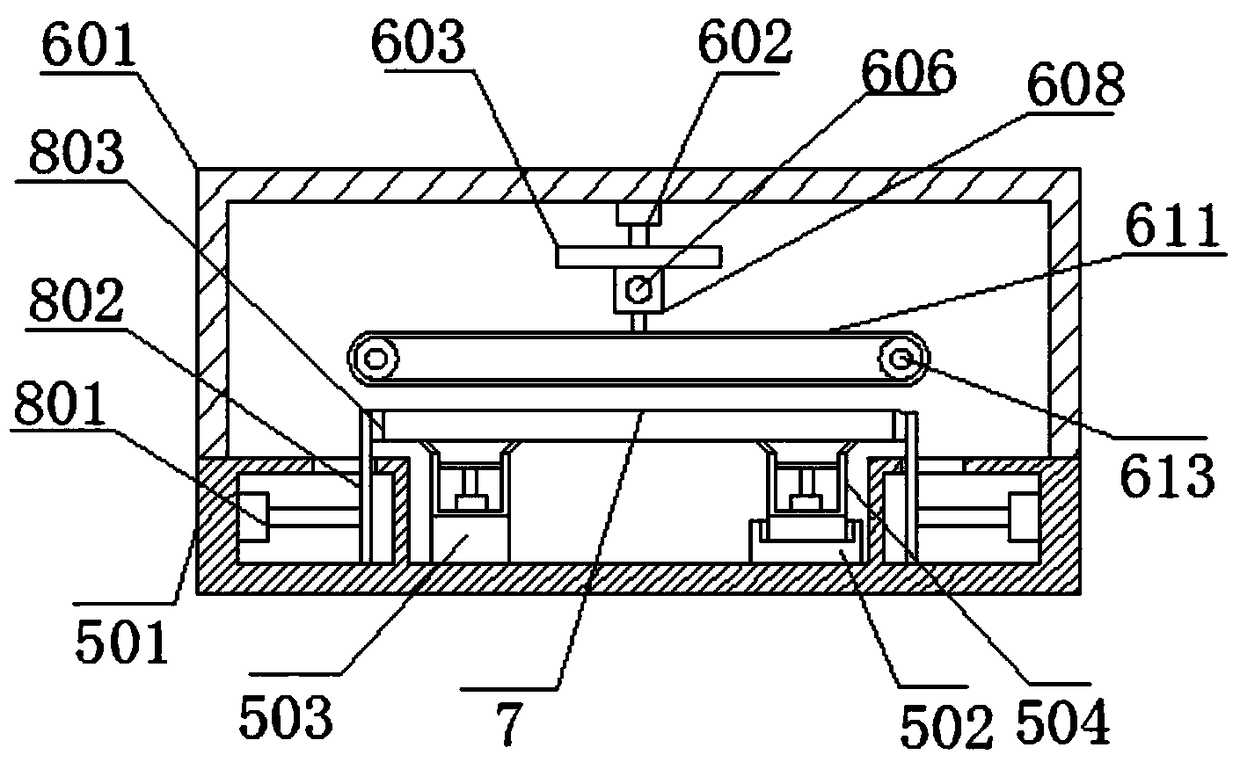

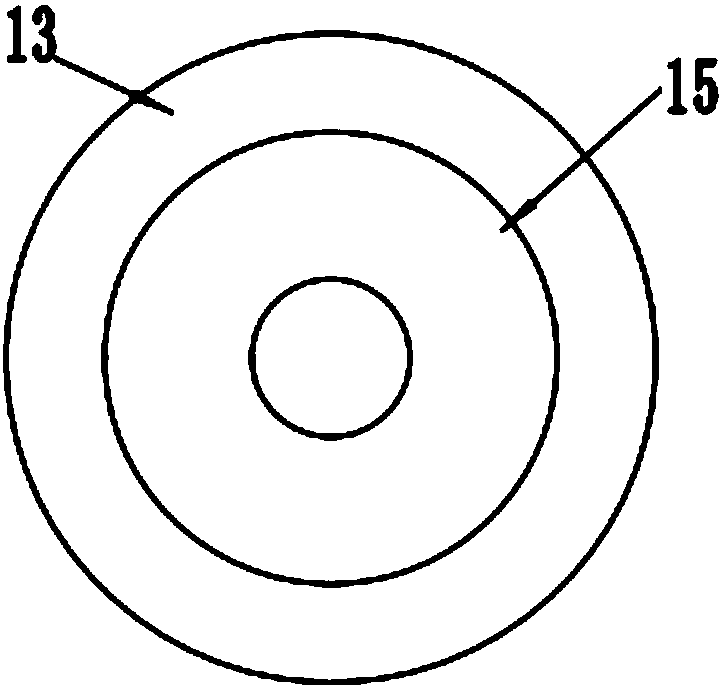

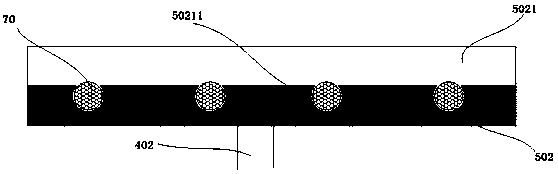

Disc type grinding device for machining heavy calcium carbonate

ActiveCN110152803AAvoid affecting the grinding effectRealize the function of intermittent feedingGrain treatmentsEngineeringCalcium carbonate

The invention discloses a disc type grinding device for machining heavy calcium carbonate. The disc type grinding device comprises a stirring cavity, a motor, a bottom plate, grinding balls, grindingdiscs, a transmission cavity and a shell, wherein the stirring cavity is formed in the upper end of the inner side of the shell, a motor is arranged at the middle position of the upper end of the shell, the output end of the motor is fixedly connected with a rotating shaft, the rotating shaft penetrates through the upper end of the shell and extends into the stirring cavity, and the bottom plate is arranged at the lower end of the stirring cavity; and the grinding discs are fixedly installed at the lower end of the inner side of the shell, annular grinding grooves are formed in the upper endsof the grinding discs, the grinding balls are symmetrically arranged above the annular grinding grooves, and the grinding balls are fixedly installed on a U-shaped supporting rod. According to the disc type grinding device, the design is novel, an ejector rod is driven to reciprocate up and down through a push rod when a movable block moves left and right, the ejector rod drives the grinding ballsto move up and down through the U-shaped supporting rod, so that the heavy calcium carbonate on the side edge of the grinding balls slides to the bottoms of the grinding balls, and then the grindingefficiency is improved.

Owner:山东汇泰环保科技有限公司

Medical nose department medicine powder grinding device

InactiveCN109433318ARealize the degree of grindingRealize automatic fillingGrain treatmentsCylindrical grindingMaterial storage

The invention discloses a medical nose department medicine powder grinding device. The device comprises a primary grinding cavity, a material storage cavity and a secondary grinding cavity; the primary grinding cavity is separated from the material storage cavity through a cylindrical grinding disc, a conical grinding roller is arranged on the inner side of a conical grinding disc, the conical grinding roller is of a hollow structure, an opening is formed in the upper end of the conical grinding roller, the conical grinding roller is fixedly connected with a rotating rod through a fixing rod fixed on the inner wall of the conical grinding roller, and the upper end of the rotating rod penetrates through the lower wall of a transmission cavity fixed on the inner wall of the primary grindingcavity and is connected with the transmission cavity in a rotating mode. According to the device, the design is novel, when the conical grinding roller arranged rotates, medicine powder on the inner side of the conical grinding roller enters the position between the conical grinding roller and the conical grinding disc through a centrifugal hole to realize grinding, the medicine powder is ground in a centrifugal manner, and automatic packing is realized; when a rotating shaft rotates, a baffle plate is driven by an eccentric wheel and a connecting rod to move in a reciprocating mode, thereforeintermittent discharging of the medicine powder in the material storage cavity is realized, so that the phenomenon that a large amount of medicine powder falls into the secondary grinding cavity at the same time so as to influence the grinding effect is avoided.

Owner:翟明伟

Grinding device for mould manufacturing

InactiveCN111266966AStrong fixed effectEasy to useGrinding drivesGrinding machinesEngineeringMechanical engineering

The invention discloses a grinding device for mould manufacturing. The grinding device for mould manufacturing comprises a base; the upper end of the base is fixedly connected with a hydraulic cylinder; the upper end of a piston rod of the hydraulic cylinder is fixedly connected with a worktable; a placement groove is formed in the upper end of the worktable; a first limiting mechanism is arrangedon the worktable; the upper end of the worktable is fixedly connected with two vertical plates; a second limiting mechanism is arranged on each vertical plate; the upper end of the base is fixedly connected with a plurality of electric pushing rods; the upper ends of the plurality of the electric pushing rods are fixedly connected with a mounting plate; an adjustment mechanism is arranged on themounting plate; the lower end of the adjustment mechanism is fixedly connected with a grinding mechanism; and the first limiting mechanism comprises two first mounting holes formed in the left end andthe right end of the worktable. The grinding device for mould manufacturing has a strong clamping effect on a mould and can prevent the mould from moving to affect a grinding effect; the height of agrinding head and the worktable can be adjusted, so that the mould with different thicknesses can be ground; and the use of an operator is facilitated.

Owner:新沂经济开发区建设发展有限公司

Metal material surface rust removal device convenient to clamp

InactiveCN112139953AEasy to adjustEasy to operateGrinding carriagesGrinding drivesMetallic materialsElectric machinery

The invention discloses a metal material surface rust removal device convenient to clamp and relates to the technical field of metal material machining. The metal material surface rust removal deviceconvenient to clamp comprises a workbench, a box body and a water tank. The right side of the top of the workbench is fixedly connected with the bottom of the box body, the left side of the top of theworkbench is fixedly connected with the bottom of the water tank, and an adjusting mechanism is fixedly connected to the top of the inner wall of the box body. A rust removal mechanism is arranged atthe bottom of the adjusting mechanism and comprises a first motor. According to the metal material surface treatment device capable of achieving rapid rust removal, the adjusting mechanism is fixedlyconnected to the top of the inner wall of the box body, the rust removal mechanism is arranged at the bottom of the adjusting mechanism, the rust removal mechanism comprises a first motor, rust removal can be automatically conducted on the surface of a metal material, and the labor intensity of workers is relieved; and through arrangement of a brush disc, gaps in the surface of a metal material can be conveniently treated, the rust removal effect is improved, the quality of the metal material is higher, and the working efficiency is higher.

Owner:蚌埠知博自动化技术开发有限公司

Building steel bar bending and cutting device

ActiveCN113579107AEasy to processNo human intervention requiredGrinding machinesConstruction engineeringRebar

The invention discloses a building steel bar bending and cutting device, and particularly relates to the technical field of steel bar machining. The building steel bar bending and cutting device comprises an L-shaped base; a first vertical plate is fixedly arranged at one end of the bottom end face of the inner side of the L-shaped base, and a third vertical plate is fixedly arranged at the other end of the bottom end face of the inner side of the L-shaped base; a steel bar conveying mechanism is arranged on one side of the first vertical plate away from the third vertical plate; the first vertical plate and the third vertical plate are provided with a fixing table; a pretreatment mechanism is arranged at the top of the fixing table; a downward pressing mechanism is arranged in the middle of the top of the inner side of the L-shaped base; a closing mechanism is arranged on the front side of the third vertical plate; a deflection reset assembly is arranged between the third vertical plate and the fixing table; the downward pressing mechanism comprises a beam plate fixedly connected with the L-shaped base; and an air cylinder is fixedly installed at the bottom of one end of the beam plate away from the L-shaped base. According to the invention, the surface treatment, cutting and bending forming procedures in the steel bar frame machining process can be integrally carried out; and therefore, convenience and rapidness are achieved, manual intervention is little, and the machining efficiency is greatly improved.

Owner:中工建总建筑集团有限公司

Integrated circuit copper-clad plate surface polishing device

InactiveCN109382738ALabor savingReduce labor costsPrinted circuit manufactureGrinding work supportsEngineeringCopper

The invention discloses an integrated circuit copper-clad plate surface polishing device. The polishing device comprises a base, two brackets, two conveying devices and a support plate; the two brackets are fixedly connected to the upper end of the base, the two conveying devices are fixedly connected to the brackets, and the support plate is fixedly connected to the middle of the upper end of thebase. Through the conveying devices, copper-clad plates are not required to be manually placed on a polishing device body one by one during polishing so that manual work can be reduced, the labor cost is reduced, and the work efficiency is improved; through the cooperation between a reciprocating screw and a polishing sleeve, the surfaces of the copper-clad plates can be completely polished to avoid polishing of dead corners, so that the polishing effect is improved; the copper-clad plates are firmly sucked by suckers to achieve a fixing effect; meanwhile, by cooperating with a clamping device, the copper-clad plates are fixed before polishing to avoiding the situation that the polishing effect is affected by slippage during polishing.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

Numerical control grinding machine capable of quickly removing cooling liquid for machining

InactiveCN112536682AGood effect of removing impuritiesImprove the quality of useGrinding carriagesGrinding machinesCooling effectCnc grinding

The invention relates to a numerical control grinding machine capable of quickly removing cooling liquid for machining. The numerical control grinding machine comprises a grinding machine, a grindingmechanism, a cooling mechanism, a bearing mechanism, an adsorption mechanism and a screening mechanism; the screening mechanism comprises a scrap iron collecting assembly, a clear water output assembly arranged below the scrap iron collecting assembly, a grinding stone particle collecting assembly arranged below the clear water output assembly and cooperates with the clear water output assembly tocomplete clear water throwing-out work, and a circulating assembly of which one end of communicates with the grinding stone particle collecting assembly and the other end communicates with the cooling mechanism; and the adsorption mechanism and the grinding mechanism work in a synchronous transmission mode through a first transmission mechanism. The technical problems that when water cools the grinding mechanism, the temperature of the water rises, the water cannot be quickly cooled in the recycling process, and then the cooling effect on the grinding mechanism is affected when circulating water conducts cooling work again are solved.

Owner:张达宇

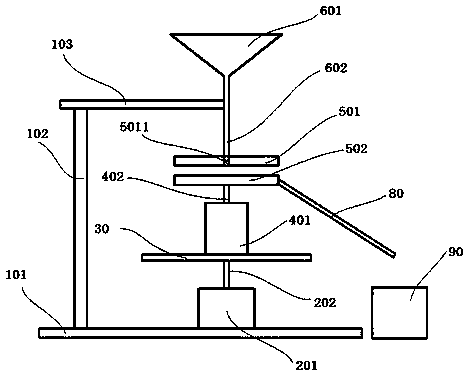

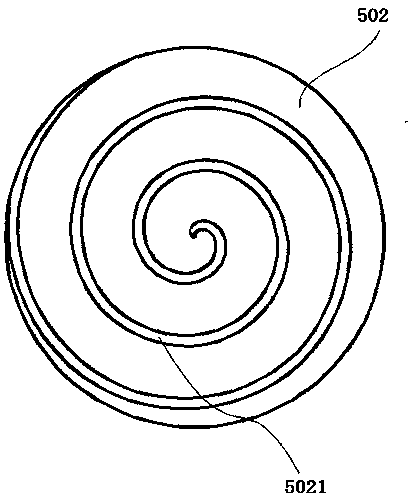

Beans crushing and collecting device

PendingCN107824282AGrind fullyAvoid frictionless rotationGrain treatmentsElectric machineryEngineering

The invention provides a beans crushing and collecting device, which comprises a substrate, a connecting rod and a mounting rod. The lower end of the connecting rod is fixedly connected with the substrate, and the connecting rod is positioned on the substrate and parallel to the substrate. A pneumatic cylinder comprises a cylinder body and a piston rod. The cylinder body is fixedly installed on the upper surface of the substrate. A support plate is connected to the cylinder body through the piston rod, and the support plate is parallel to the substrate. A motor comprises a motor body and a rotating shaft. A grinding disc comprises an upper disc-shaped grinding disc and a lower disc-shaped grinding disc. The upper surface of the lower grinding disc is provided with a planar spiral groove. The upper grinding disc and the lower grinding disc are coaxially arranged. The center of the upper grinding disc is provided with a through hole. A hopper comprises a hopper body and a hopper mouth. The hopper body is connected to the hopper mouth through a through hole. The lateral side of the hopper mouth is connected to the connecting rod through the mounting rod. The device also comprises a chute, one end of which is fixedly installed at the lateral side of the lower grinding disc at a discharge opening. A storage tank is arranged below the other end of the chute. Vertical height of one end of the chute is greater than vertical height of the other end of the chute. By integrating grinding and collection, the device of the invention has high grinding efficiency.

Owner:惠州市肆方农业发展有限公司

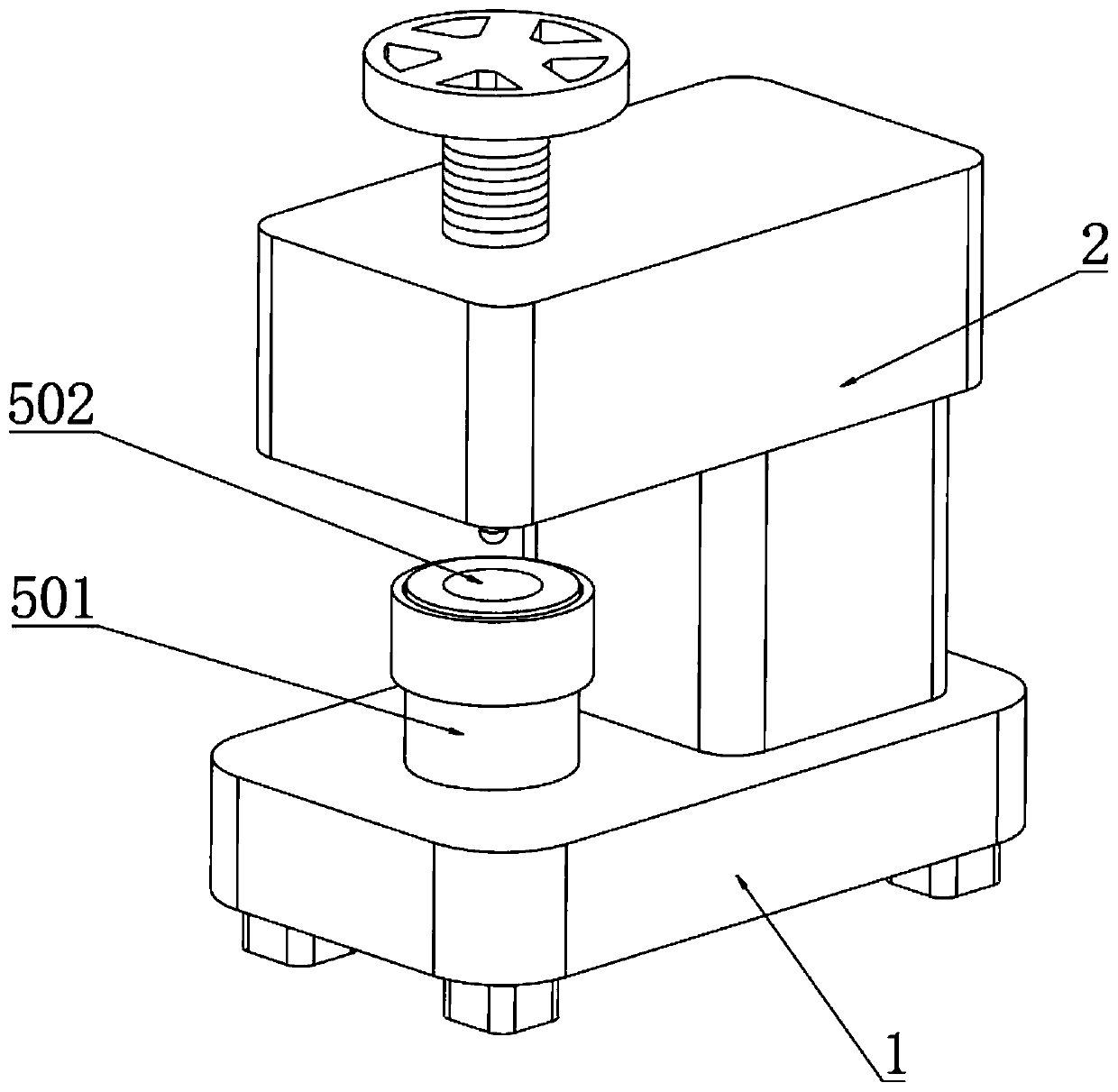

Anti-loss molecular biology experimental sample grinder

ActiveCN111530536AScientific and reasonable structureEasy to useGrain treatmentsRotational axisElectric machine

The invention discloses an anti-loss molecular biology experimental sample grinder. The anti-loss molecular biology experimental sample grinder comprises a base. A supporting frame is fixedly connected with the lateral side of the top end of the base. A lifting mechanism is movably connected with the lateral side of the top end of the supporting frame. The lifting mechanism comprises a rotating rod, a rotary disc, a round groove, a slide groove, a slider, a fixed base, rotating motor and a rotating shaft base. The rotating rod is screwed in and rotationally connected with the top end of the supporting frame. The rotary disc is cast at the top end of the rotating rod. The anti-loss molecular biology experimental sample grinder is scientific and reasonable in structure and safe and convenient to use; and the lifting mechanism is arranged and the rotary disc is rotated to drive the rotating rod to rotate, and the fixed base is pushed to slide up and down along the round groove through thecooperation of the slide groove and the slider, so that the heights of the fixed base, the rotating motor and the rotating shaft base are adjusted, then the gap between a grinding rod and a grindingpipe is adjusted according to needs, the grinding effect is improved, and biological experimental samples can be ground more sufficiently.

Owner:QINGDAO AGRI UNIV

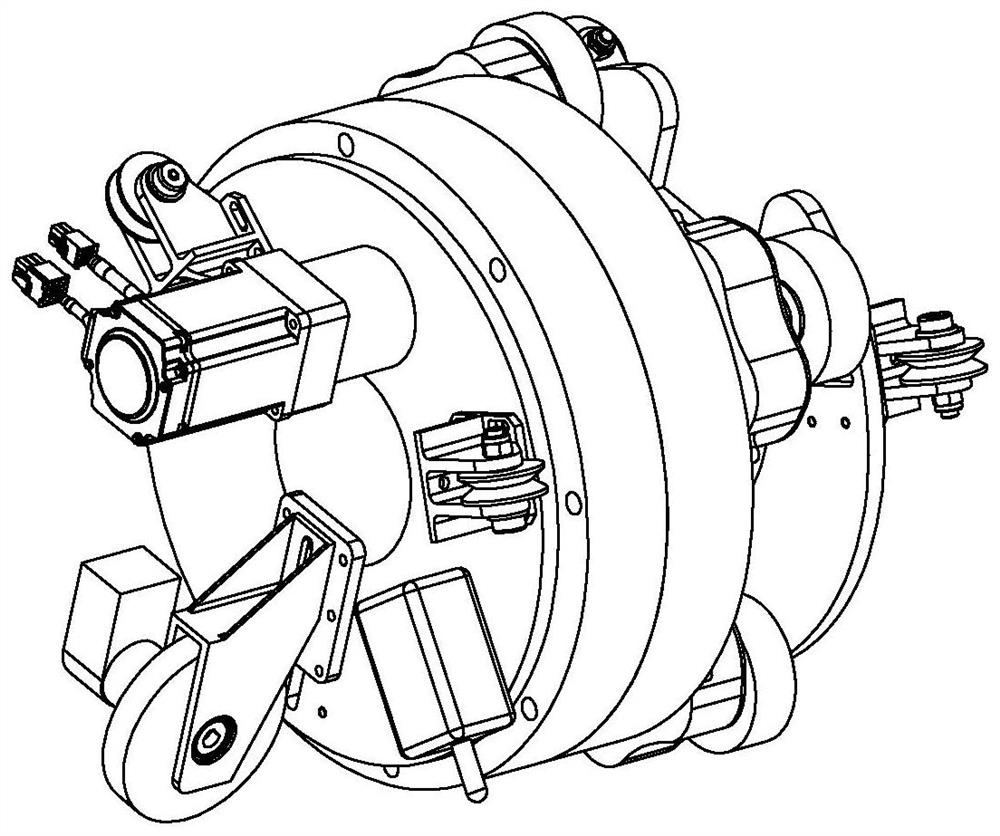

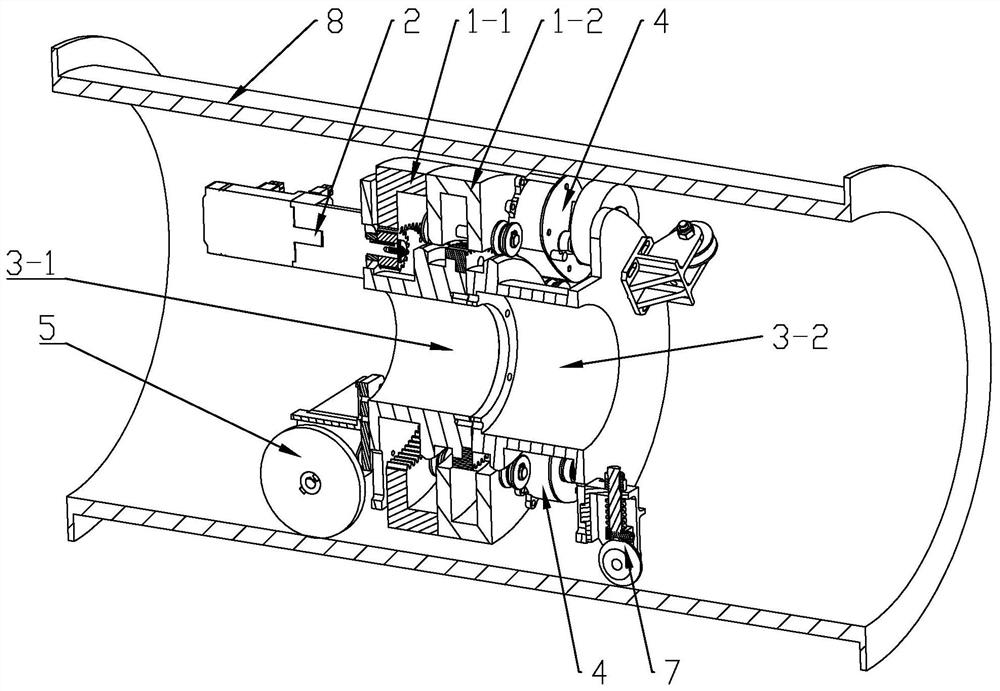

Automatic crawling grinding robot for inner wall of circular pipe

PendingCN111941246AShort structure lengthAvoid mechanical damageGrinding drivesGrinding machinesLinear motionGear drive

The invention provides an automatic crawling grinding robot for the inner wall of a circular pipe, and belongs to the technical field of descaling of relief pipelines. The automatic crawling grindingrobot comprises a shell, a main driving module, a driving base, grinding modules and a crawling module, the shell comprises a left shell body and a right shell body, and the driving base comprises a first driving base body and a second driving base body; the main driving module, the crawling module and a plurality of supporting wheels are installed on the outer end face of the driving base, the multiple grinding modules are evenly distributed between the outer end face of the right shell body and the opposite end faces of the second driving base body in the circumferential direction, and the crawling module drives a grinding device to do linear motion along the outer wall of the to-be-ground pipeline; and the main driving module drives the shell to drive the grinding modules to rotate in the circumferential direction of the inner wall of the pipeline through gear transmission. The device is wide in application range, dismounting, mounting and grinding work of the grinding machine can be completed through one-man operation, a detection device is arranged on the outer end face of the driving base, detection of the pipe wall thickness, cracks and the corrosion condition is achieved while the pipeline is ground, and one machine has multiple purposes.

Owner:苏州伸之助科技服务有限公司

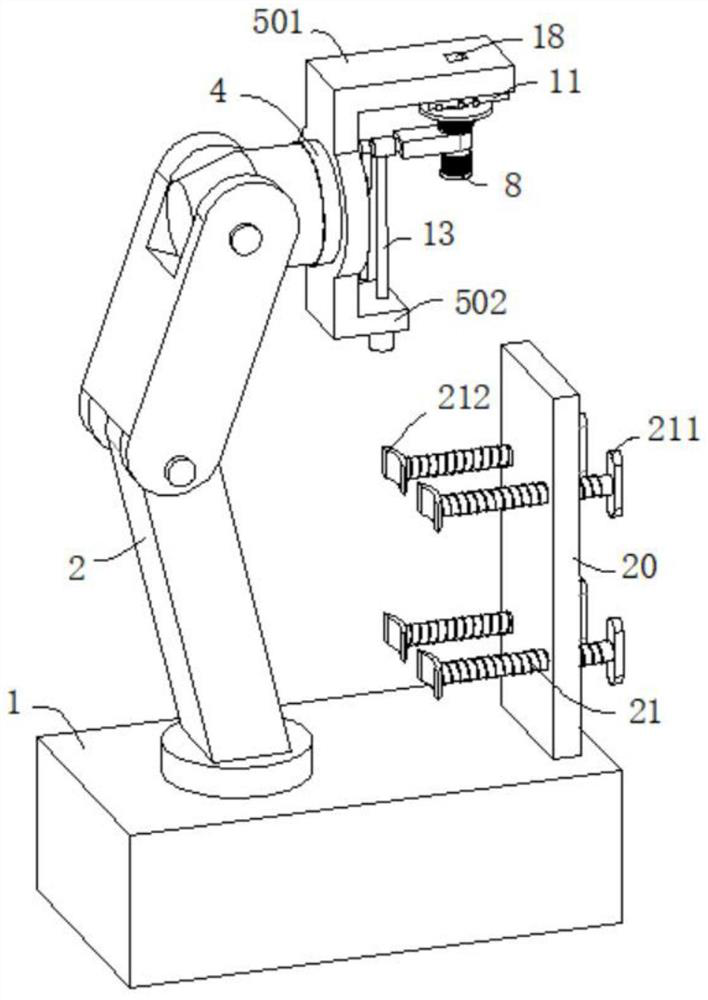

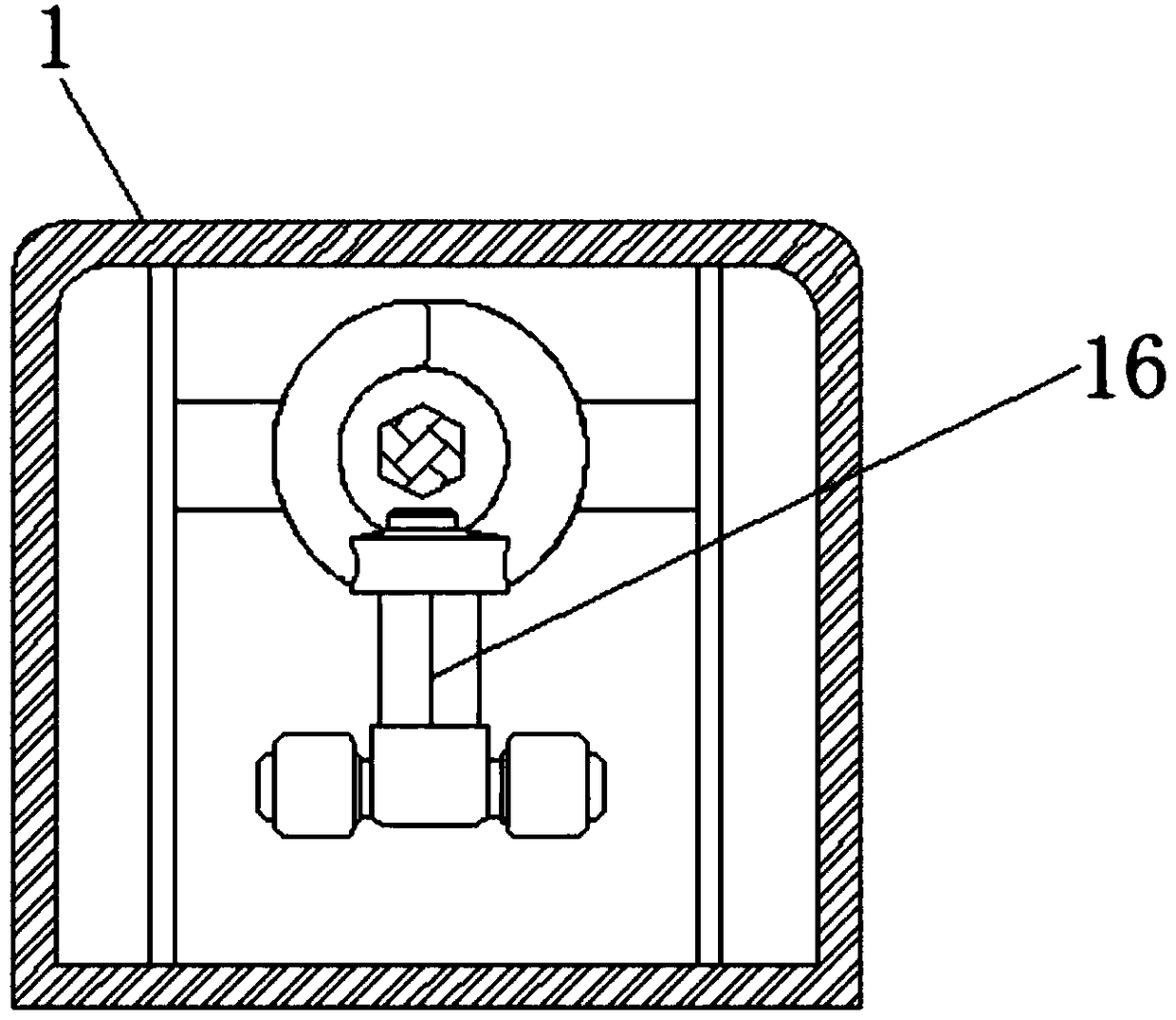

Robot grinding system and grinding clamp thereof

PendingCN113183027AFast replacementAvoid waiting in lineGrinding wheel securing apparatusGrinding machinesProduction lineEconomic benefits

The invention discloses a robot grinding system and a grinding clamp thereof, and belongs to the technical field of grinding. The robot grinding system comprises a grinding table, and the top of the grinding table is connected with a mechanical arm and the grinding clamp; the end, away from the grinding table, of the mechanical arm is connected with a rotating plate, and the outer wall of the rotating plate is connected with a working plate; the two sides of the outer wall of the working plate are connected with a first side plate and a second side plate separately, and the outer wall of the working plate is connected with a stroke plate through a connecting rod; a rail slot is formed in the outer wall of the stroke plate, and a movable rod is connected with the inner wall of the rail slot movably; a connecting plate is connected to the outer wall of the movable rod; a fixing rod is connected to the outer wall of the connecting plate; a fixing base is connected to one end, far away from the connecting plate, of the fixing rod; and a motor is connected to the outer wall of the fixing base. According to the robot grinding system, the replacement speed between grinding wheels can be increased, and it is ensured that normal grinding operation cannot be affected by the replacement operation of the grinding wheels; and the situation that an assembly line stops for waiting due to replacement of the grinding wheels is avoided, and the efficiency and economic benefits of a production line can be improved.

Owner:安徽精翔自动化科技有限公司

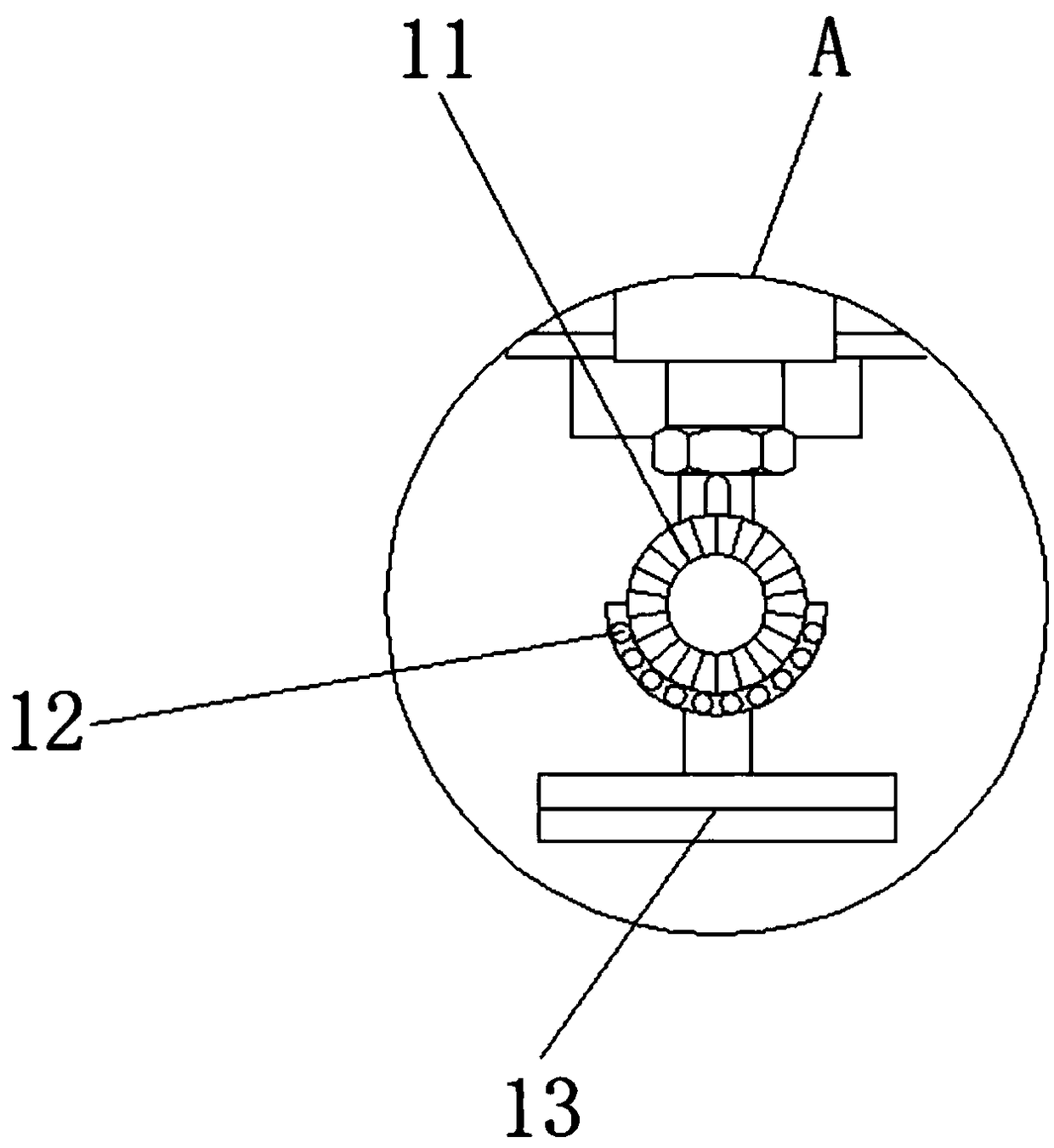

Sleeve grinding fixture

The invention relates to the technical field of work fixtures, and provides a sleeve grinding fixture. The sleeve grinding fixture comprises a cylindrical mandrel and two deformation mechanisms which are the same and are oppositely arranged on the mandrel. Each deformation mechanism comprises a gas bag, a nut, a plurality of supporting rods and a plurality of fixing plates. The nuts are connected with the mandrel in a threaded mode. The supporting rods are all hinged to the nuts and can rotate relative to the nuts. One ends of the fixing plates are hinged to the mandrel, and the other ends of the fixing plates are hinged to the supporting rods. The multiple fixing plates can form a cone around the mandrel and further be used for fixing a sleeve. The gas bags comprise gas inlets used for leading in gas and gas outlets used for blowing the gas to the outer circle of the sleeve, and the gas bags are arranged in the cone. According to the technical scheme, the sleeve grinding fixture provided by the invention is easy to operate, clamping and dismounting efficiency can be effectively improved, the range of application is wide, and grinding chips can further be cleared up in time.

Owner:张家港市宇安精密机械有限公司

Burr removing device for formed rubber sealing ring of petroleum machine

ActiveCN113386014AImprove stabilityAffect processing efficiencyEdge grinding machinesGrinding carriagesThermodynamicsMachine parts

The invention relates to the technical field of machining of petroleum machine parts, in particular to a burr removing device for a formed rubber sealing ring of a petroleum machine. The burr removing device comprises a base, a fixing unit and a grinding unit, wherein an annular groove is formed in the upper end of the base, the fixing unit is arranged in the annular groove, and the grinding unit is arranged on the fixing unit. The burr removing device can solve the following problems existing when burrs of rubber sealing rings are removed: most of traditional rubber sealing rings are manually trimmed, and workers cannot effectively fix the rubber sealing rings, so that the machining efficiency is influenced; existing freezing trimming equipment cannot effectively remove small burrs on the surface of a rubber sealing ring, thereby having limitation; the rubber sealing ring can be clamped and fixed in multiple directions, and therefore the stability of the rubber sealing ring can be improved; and according to the burr removing device, circumferential grinding treatment can be conducted on the rubber sealing ring through the grinding unit, chippings generated by grinding can be recycled, and resource waste can be avoided.

Owner:山东柏源技术有限公司

Automatic crawling polishing robot for outer wall of circular pipe

PendingCN111975480AShort structure lengthAvoid mechanical damageRevolution surface grinding machinesGrinding feed controlMachineRobot

The invention provides an automatic crawling polishing robot for the outer wall of a circular pipe, and belongs to the technical field of descaling of circular pipes. The automatic crawling polishingrobot comprises a shell, a main driving module, internal modules, a polishing module and a crawling module, wherein the shell comprises a left shell body, a middle shell body and a right shell body which are sequentially arranged from left to right; a to-be-polished pipeline penetrates through the shell in the axis direction; the main driving module, a spring pre-tightening wheel set and a supporting wheel set are mounted on the outer end face of the left shell body; the crawling module and the supporting wheel set are mounted on the outer end face of the right shell body; the internal modulesare mounted in the left shell body and the middle shell body; and the polishing module is mounted in the right shell body. The automatic crawling polishing robot is wide in application range, and thedismounting, mounting and polishing work of a polishing machine can be completed through one-man operation; and a detection device is arranged on the outer end face of the shell, the thickness, cracks and corrosion conditions of the pipe wall are detected while the pipeline is polished, and the automatic crawling polishing robot is multipurpose.

Owner:苏州伸之助科技服务有限公司

Fully-automatic feeding device for safe and efficient grinding machine

InactiveCN108747705AAvoid accumulationAvoid errorsCleaning using toolsGrinding machinesBench grinderIdler-wheel

The invention discloses a fully-automatic feeding device for a safe and efficient grinding machine. The fully-automatic feeding device comprises a main body, an electromotor and the grinding machine.The top of the main body is provided with a feeding opening in a penetrated manner, the feeding opening is internally and fixedly provided with a sieving net, the electromotor is installed inside themain body, and the periphery of the electromotor is provided with a conveyer belt in a tightly attaching manner. Fixing plates are fixedly arranged on the conveyer belt, the right side of the feedingopening is provided with hydraulic rods, the lower portions of the hydraulic rods are provided with rotary tables, and the lower portions of the rotary tables are connected with cleaning hair brushes.The grinding machine is installed on the right sides of the hydraulic rods, a round ball is arranged below the grinding machine, the outer wall of the round ball is provided with idler wheels in a tightly attaching manner, a grinding wheel piece is installed below the idler wheels, and a grinding groove is formed below the grinding wheel piece. The fully-automatic feeding device for the safe andefficient grinding machine is provided with an exhaust fan, through a communication structure of the exhaust fan and the grinding groove, ground debris can be cleaned rapidly, and the situation that grinding of a next ground part generates an error due to excessively much debris is prevented.

Owner:盐城市雷鸣电器制造有限公司

Silicon wafer processing device and processing technology for chip preparation

InactiveCN112838045AAvoid affecting the grinding effectAvoid affecting the sight of grindingSemiconductor/solid-state device manufacturingWaferingTransmission belt

The invention relates to the technical field of silicon wafer processing devices, and discloses a silicon wafer processing device and processing technology for chip preparation. A silicon wafer is polished through a polishing disc, a booster pump is started, water in a water tank is discharged into a water inlet pipe and then is discharged into the booster pump through the water inlet pipe, and cooling liquid is discharged into the water outlet pipe through the pressurization effect of the booster pump and finally is sprayed out through a porous nozzle, so the water cooling effect on the silicon wafer is realized during polishing. A coupling drives an input shaft to rotate, the input shaft drives a first driving belt wheel and a second driving belt wheel to rotate, a first driving belt wheel and a second driving belt wheel respectively drive a first driven belt wheel and a second driven belt wheel to rotate through a first transmission belt and a second transmission belt, so that a first rotating shaft and a second rotating shaft rotate, two cooling fans rotate, chippings generated during grinding can be treated through rotation of the cooling fans, and chippings are prevented from influencing the polishing sight.

Owner:六安优云通信技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com