Automatic water supply and feed adding system for sheep farm

A technology for automatic water supply and feed addition, which is applied in the field of sheep breeding technology and equipment, can solve the problems of bacteria that are easy to breed, cannot be decomposed and mixed well, and cannot meet feeding needs well, so as to improve the efficiency of feeding and water intake, and improve the crushing and screening. effect, the effect of ensuring the grinding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

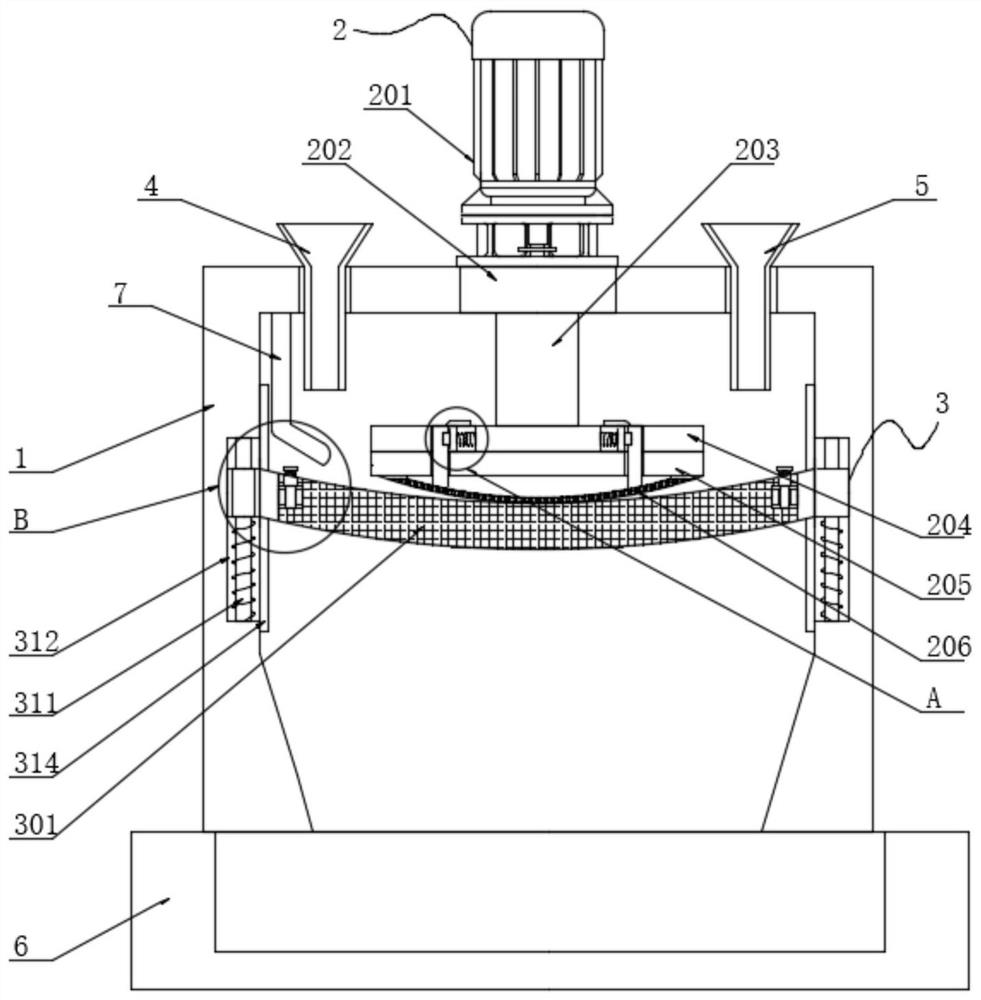

[0028] An automatic water supply and feed addition system for sheep farms, such as Figure 1-5 shown, including;

[0029] A box body 1, a grinding mechanism 2 is provided on the top of the inner cavity of the box body 1, a sieving mechanism 3 is attached to the bottom of the grinding mechanism 2, and a feeding tank 6 is provided on one side of the box body 1;

[0030] The grinding mechanism 2 includes a motor 201, the output shaft of the motor 201 is fixedly connected with a rotating shaft 203, the outer wall of the rotating shaft 203 is provided with a bearing 202, and the bearing 202 is embedded in the top of the inner cavity of the box body 1, and the rotating shaft The bottom end of the 203 is fixedly connected with a fixing seat 204 , the bottom of the fixing seat 204 is provided with a fixing plate 205 , and the bottom of the fixing plate 205 is attached with a grinding mesh plate 206 .

[0031] The sieve mechanism 3 includes a sieve plate 301, the top of the sieve plat...

Embodiment 2

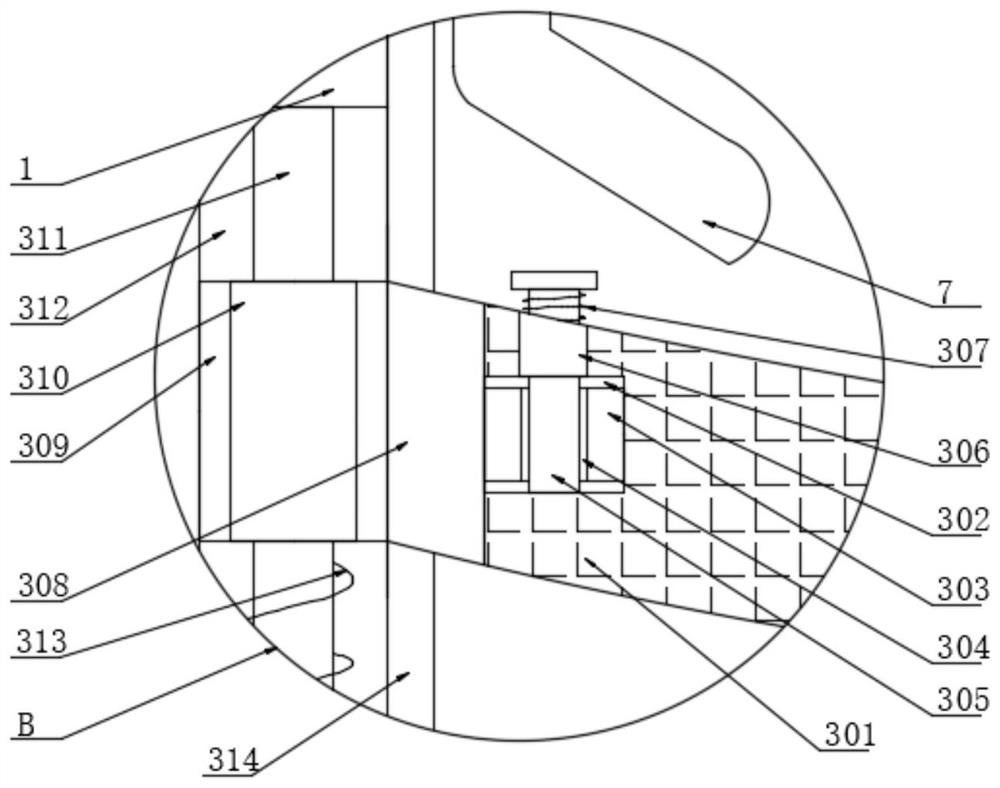

[0034] A kind of sheep farm automatic water supply and feed addition system, differs from embodiment 1 in that, as image 3As shown, both sides of the sieve plate 301 are fixedly connected with a second block 303, one side of the second block 303 is fixedly connected with a connecting block 308, and one side of the connecting block 308 is fixedly connected with a second slider 309, the top of the second sliding block 309 is embedded with a second sliding sleeve 310, the second sliding sleeve 310 is slidably connected with a second sliding rod 311, and both sides of the inner cavity of the box body 1 are provided with second chute 312, the second slider 309 is slidably connected in the second chute 312, the two ends of the second slide bar 311 are respectively fixedly connected with the two sides of the inner cavity of the second chute 312, and the second slide bar The outer wall of 311 is covered with a third spring 313 , and the two ends of the third spring 313 are respective...

Embodiment 3

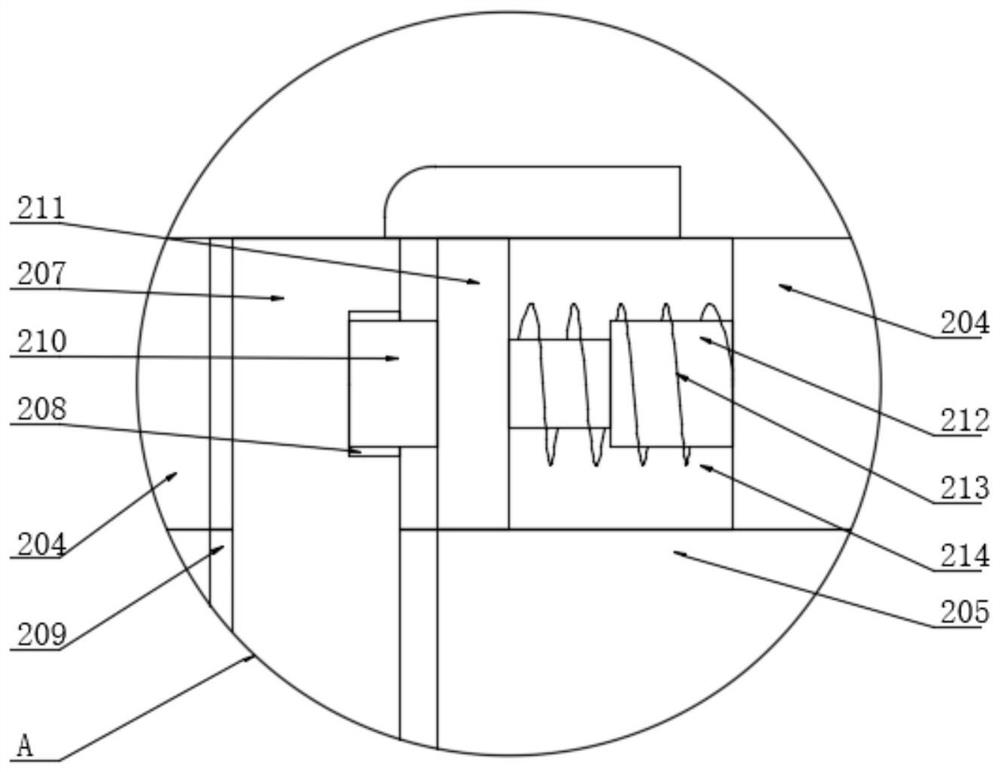

[0039] A kind of sheep farm automatic water supply and feed addition system, differs from embodiment 1 and 2 in that, as Figure 2-3 As shown, both sides of the top of the grinding screen 206 are fixedly connected with clamping rods 207, and the clamping rods 207 extend to the top of the fixing base 204 through the through holes 209 provided at the bottom of the fixing plate 205 and the fixing base 204. A first clamping hole 208 is opened on one side of the rod 207, and a first clamping block 210 is clamped in the first clamping hole 208, and a first sliding block 211 is fixedly connected to one side of the first clamping block 210. The other side of a slider 211 is fixedly connected with a telescopic rod 212, and one end of the telescopic rod 212 is fixedly connected with one side of the inner cavity of the first chute 214 provided on one side of the inner cavity of the through hole 209, and the first slider 211 slides Connected in the first chute 214, the outer wall of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com