Metal material surface rust removal device convenient to clamp

A technology of metal materials and splints, applied in the direction of grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc., can solve the problems of poor rust removal effect, inconvenience, and low work efficiency, and achieve a wide range of rust removal , simple and fast operation, and the effect of improving efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

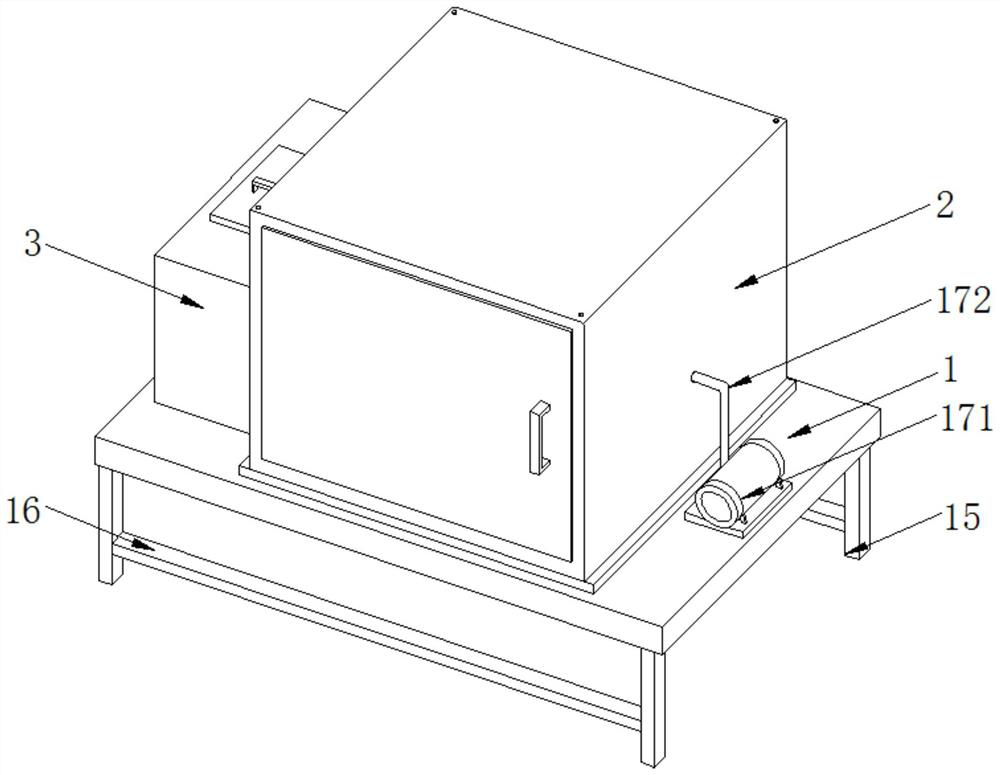

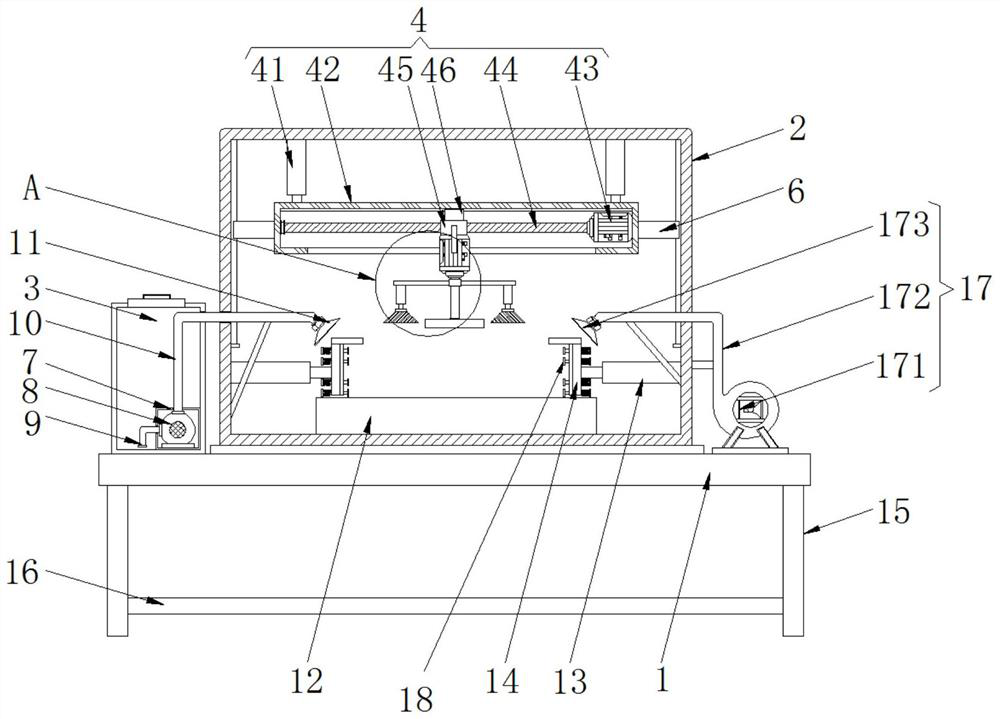

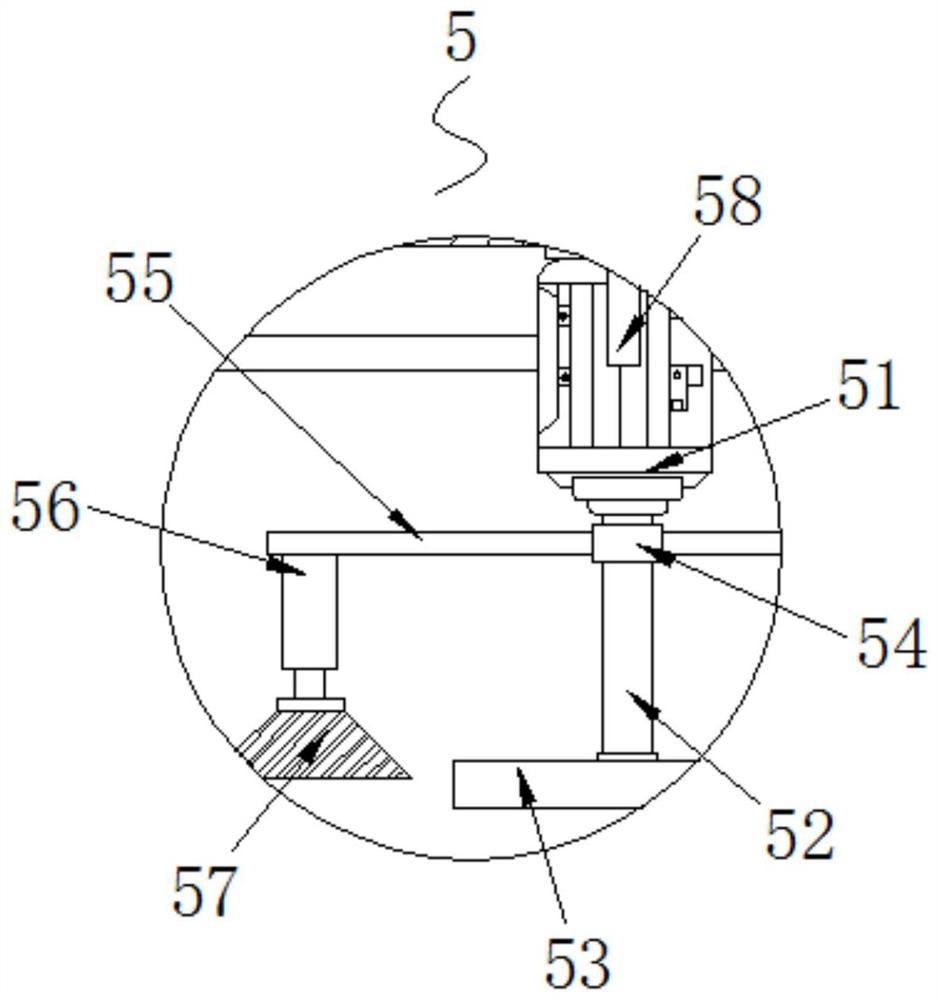

[0033] A metal material surface derusting device that is easy to clamp, including a workbench 1, a box body 2, and a water tank 3. The top of the water tank 3 is provided with a door for easy water filling. The surface of the box body 2 is hinged with a box door. The setting of body 2 and box door is in order to prevent the residue of grinding during derusting from splashing around and causing harm to the surrounding staff. The four corners of the bottom of workbench 1 are fixedly connected with support legs 15, and the bottom of two support legs 15 is opposite to each other. The sides are fixedly connected with a horizontal plate 16, the right side of the top of the workbench 1 is fixedly connected with the bottom of the box body 2, the left side of the top of the workbench 1 is fixedly connected with the bottom of the water tank 3, and the top of the inner wall of the box body 2 is fixedly connected with The adjustment mechanism 4 and the setting of the adjustment mechanism 4...

Embodiment 2

[0035] A metal material surface derusting device that is easy to clamp, including a workbench 1, a box body 2, and a water tank 3. The top of the water tank 3 is provided with a door for easy water filling. The surface of the box body 2 is hinged with a box door. The setting of body 2 and box door is in order to prevent the residue of grinding during derusting from splashing around and causing harm to the surrounding staff. The four corners of the bottom of workbench 1 are fixedly connected with support legs 15, and the bottom of two support legs 15 is opposite to each other. The horizontal plates 16 are fixedly connected between the sides, and the bottom of both sides of the inner wall of the box body 2 is fixedly connected with the second electric telescopic rod 13, which is controlled by an external control mechanism. The model of the second electric telescopic rod 13 It is YNT-02, and one end of the output shaft of the second electric telescopic rod 13 is fixedly connected ...

Embodiment 3

[0038] A metal material surface derusting device that is easy to clamp, including a workbench 1, a box body 2, and a water tank 3. The top of the water tank 3 is provided with a door for easy water filling. The surface of the box body 2 is hinged with a box door. The setting of the body 2 and the box door is to prevent the grinding residue from splashing around during rust removal and causing harm to the surrounding staff. The right side of the top of the workbench 1 and the right side of the box body 2 are fixedly connected with a drying mechanism 17, The setting of the drying mechanism 17 makes it possible to dry the cleaned metal material through the drying mechanism 17 after cleaning the metal material after rust removal, which saves the time for workpiece processing and improves work efficiency. 17 includes a hot air blower 171, which is controlled by an external control mechanism. The model of the hot air blower 171 is HAM-G3A-11. One end runs through the box body 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com