Rotary grinding equipment for iron plate weld mark of hardware

A welding mark and rotary technology, which is applied in metal processing equipment, grinding/polishing equipment, and machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of waste damage to work efficiency and low efficiency, and achieve good grinding effect, Increases safety and prevents damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

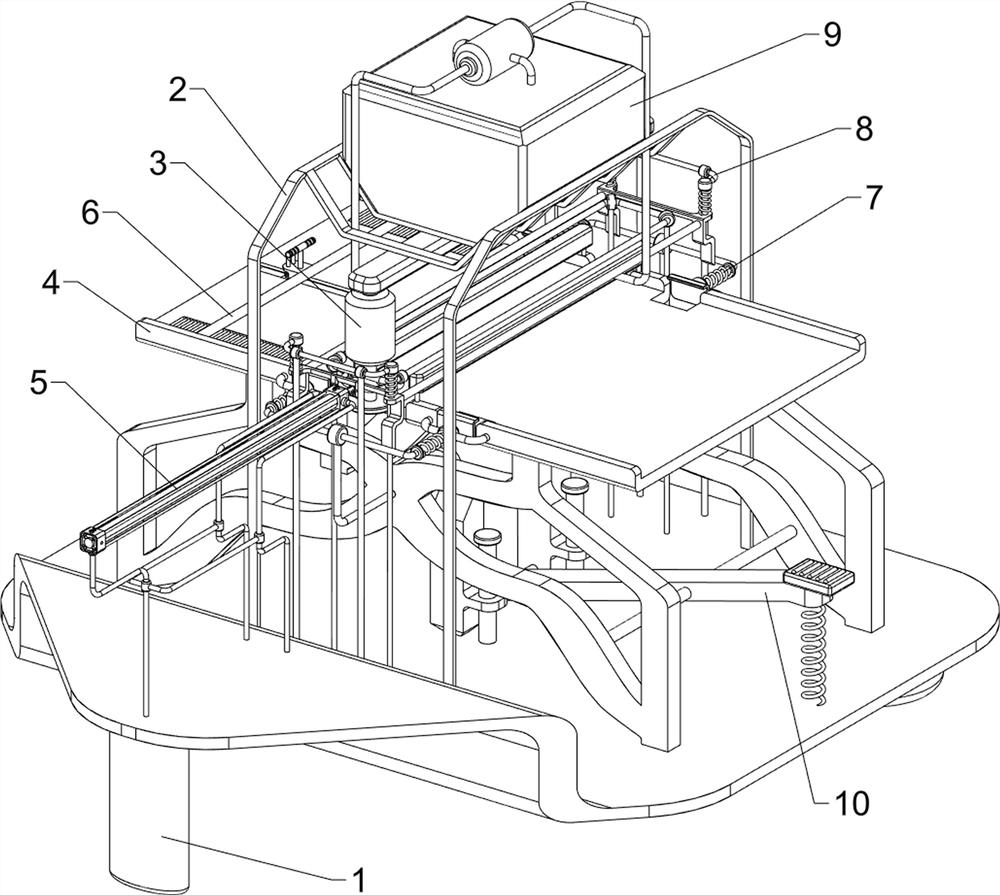

[0074] A kind of rotary grinding equipment for welding marks of iron plates for hardware, such as figure 1 As shown, it includes a base 1, a first support frame 2, a motor 3, a placement assembly 4 and a grinding assembly 5, a first support frame 2 is provided in the middle of the top of the base 1, and a motor 3 is slidingly provided on the top of the first support frame 2. A placement component 4 is provided on the top right side of the base 1, and a grinding component 5 is provided between the top left side of the base 1 and the output shaft of the motor 3.

[0075] When people need to polish the welding mark on the iron plate, first put the welded iron plate on the placement assembly 4, then start the motor 3, and the output shaft of the motor 3 drives a certain part of the grinding assembly 5 to rotate, so that the grinding assembly 5. Grind the welding marks. After the grinding is completed, turn off the motor 3 and remove the polished iron plate.

Embodiment 2

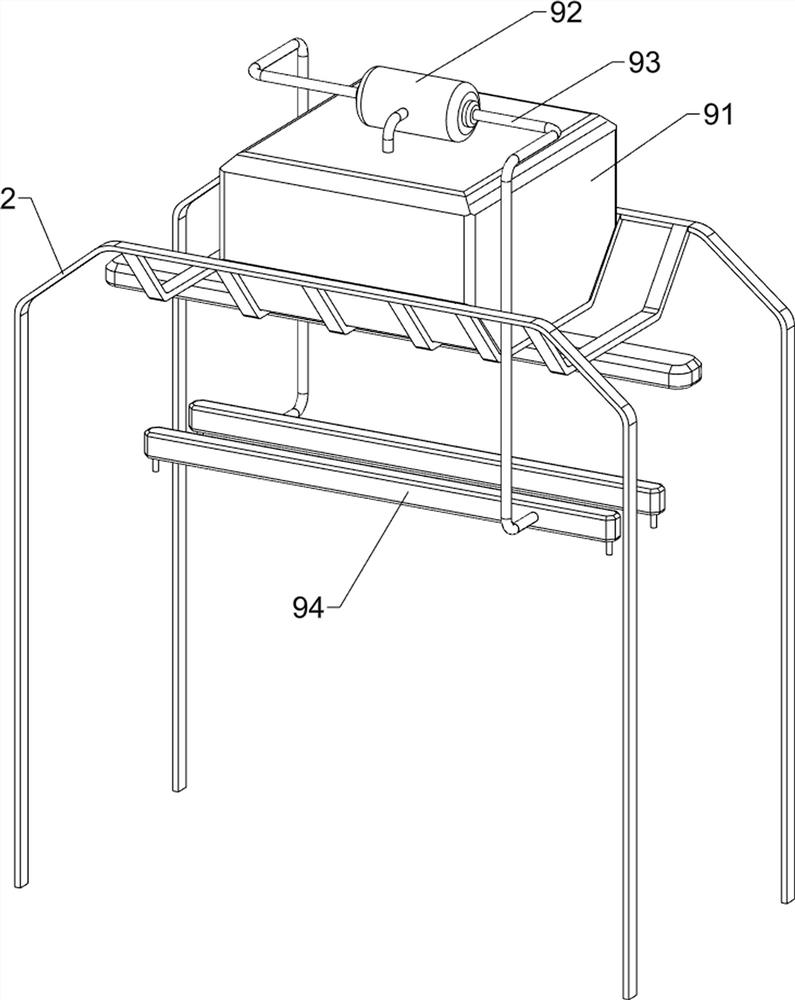

[0077] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the placement assembly 4 includes a support plate 41, a placement plate 42 and a first baffle plate 43, a support plate 41 is arranged symmetrically on the right side of the top of the base 1, and a placement plate 42 is provided between the tops of the support plates 41, and the placement plate 42 First baffles 43 are provided on both left and right sides.

[0078] When people need to polish the welding marks on the iron plate, the welded iron plate can be placed on the front side of the top of the placement plate 42, and then the iron plate can be pushed back to a suitable position. Under the action, prevent the iron plate from falling.

[0079] The grinding assembly 5 includes a first support rod 51, a first connecting rod 52, a diamond 53, a second support frame 54, a cylinder 55 and a push rod 56, the middle of the top of the base 1 is provided with a first ...

Embodiment 3

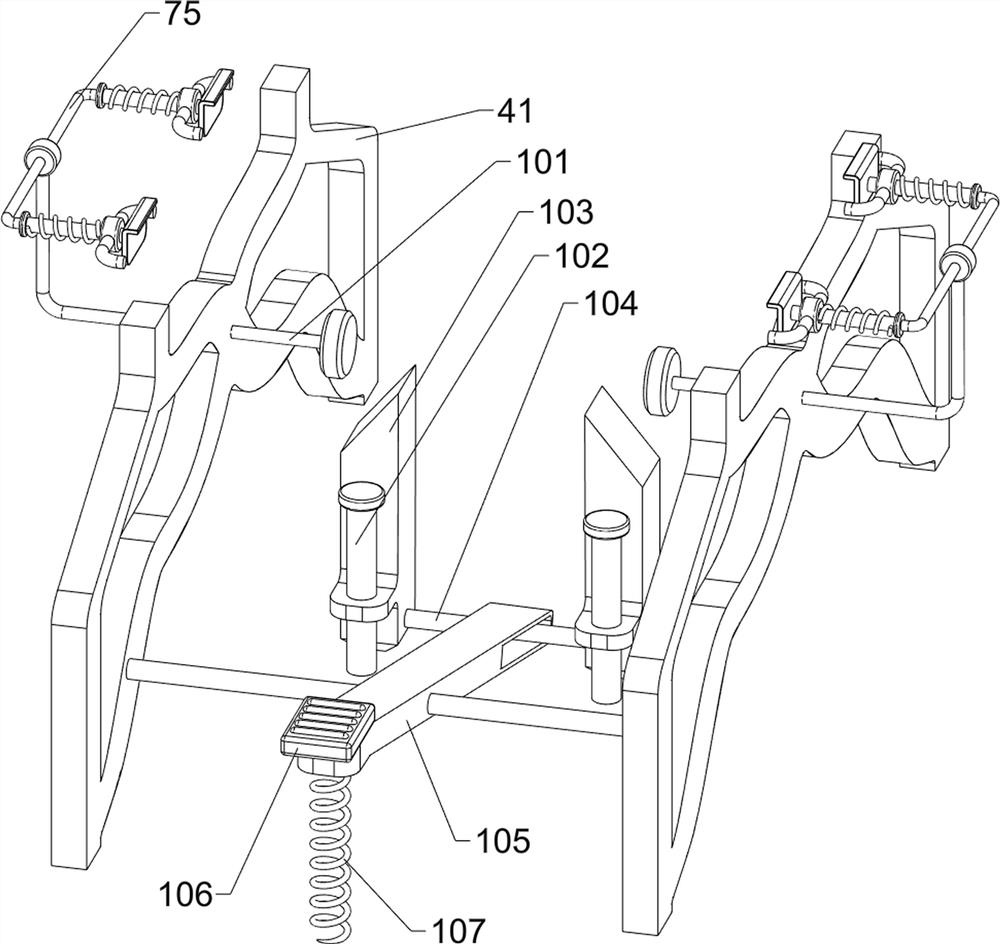

[0086] On the basis of Example 2, such as Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a locking assembly 8 is also included, and the locking assembly 8 includes a third support rod 81, a third guide rod 82, a block 83, a third connecting rod 84, a third spring 85, a second wedge block 86, a fourth Connecting rod 87 and torsion spring 88, base 1 top left and right sides middle parts are all provided with the 3rd support rod 81, the inner side of the 3rd support rod 81 upper part is equipped with the 3rd guide rod 82 symmetrically before and after, the 3rd guide rod 82 of the same side All sliding type is provided with clamping block 83 between the bottom, and clamping block 83 cooperates with the second connecting rod 75, is provided with the third connecting rod 84 symmetrically front and back between the upper part of the inner side of clamping block 83, and both sides of clamping block 83 top front and back are all with the same. A third spring 85 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com