Sleeve grinding fixture

A technology for grinding jigs and sleeves, which is applied in the field of tooling fixtures, can solve the problems of powder debris that cannot be cleaned in time, the diameter of the inner hole of the sleeve is limited, and the efficiency of clamping and dismounting is low, so as to improve the efficiency of clamping and dismounting and the scope of use. wide, improve the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

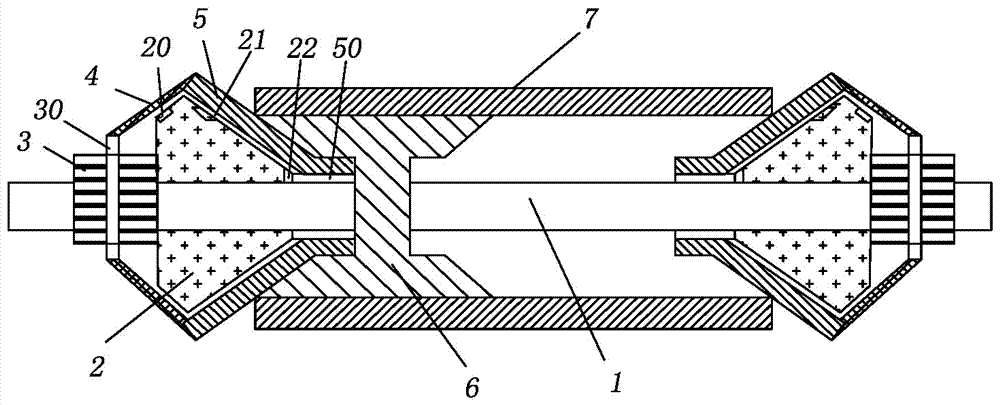

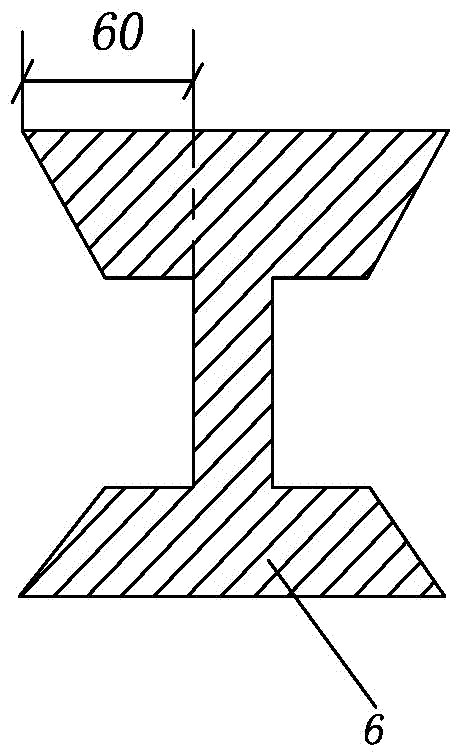

[0015] The reference signs in the drawings of the description include: mandrel 1, air bag 2, nut 3, support rod 4, fixed plate 5, air inlet 20, air outlet 21, air blowing hole 22, grinding head 6, grinding part 60, circle Ring 30, communication hole 50, sleeve 7.

[0016] The sleeve grinding fixture provided by this embodiment, such as figure 1 As shown, it includes a cylindrical mandrel 1, the middle section of the mandrel 1 is a smooth surface, and is slidably connected with a grinding head 6, and its structure is as follows figure 2 As shown, the disc in the middle of the grinding head 6 is set to grind the inner hole of the sleeve 7 in the circumferential direction, and both sides of the middle of the grinding head 7 are provided with protruding grinding parts 60 (when the fixed plate 5 and the sleeve 7 are in contact with each other) At this time, a cavity will be formed, and the grinding part 60 can enter this cavity, thereby grinding the two ends of the inner hole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com