Fine sueding and grinding machine

A sanding and sanding technology, which is applied to textiles and papermaking, roughening, fabric surface trimming, etc., can solve the problems of affecting the sanding effect, low processing precision, and affecting the strength of the fabric, so as to improve the sanding effect and improve the sanding effect. Flower precision, improve the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

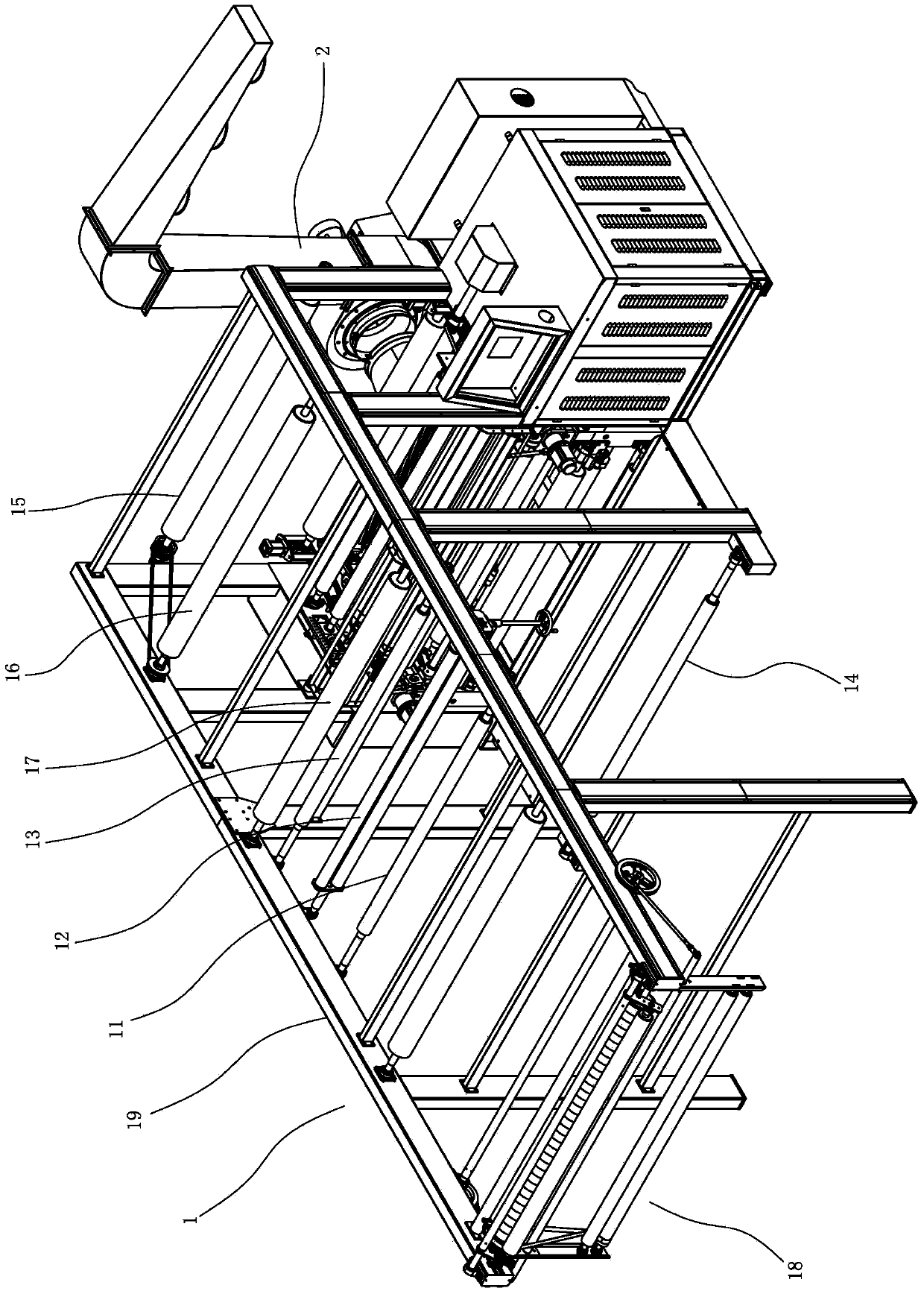

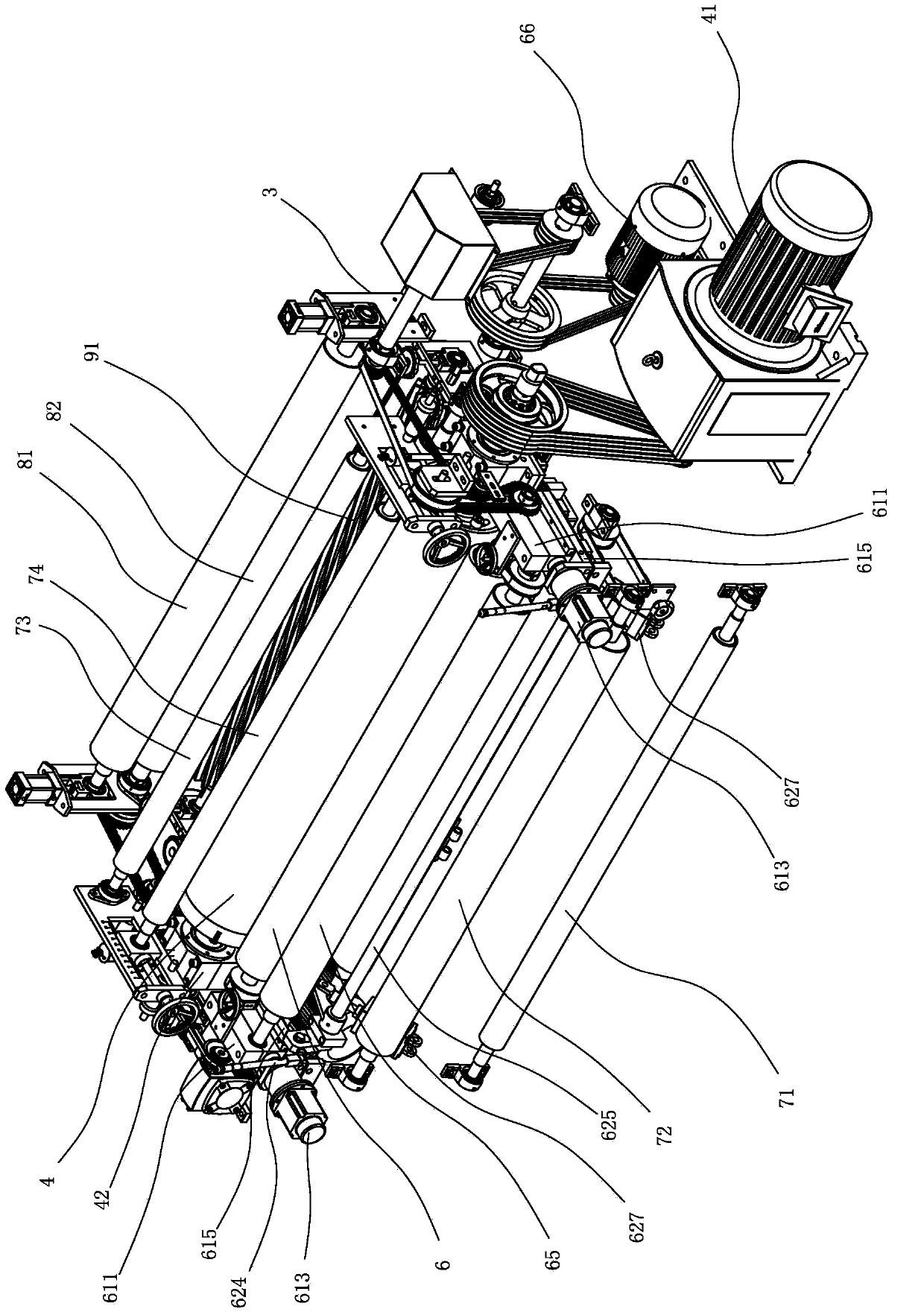

[0033] refer to Figure 1 to Figure 8 As shown, a fine sanding and grinding machine includes a cloth feeding and dropping mechanism 1, a frame 3, a grinding mechanism, a brushing mechanism, a cloth traction mechanism and a dust suction device 2 respectively arranged on the frame 3, and the working At this time, the cloth is guided by the cloth feeding and dropping mechanism 1 into the grinding mechanism for grinding, and after grinding, it enters the brushing mechanism to brush off the powder on the surface of the cloth. The cloth of the mechanism is pulled and exported by the cloth traction mechanism, and then guided and output by the cloth feeding and falling mechanism 1, and the cloth is dropped and folded into piles.

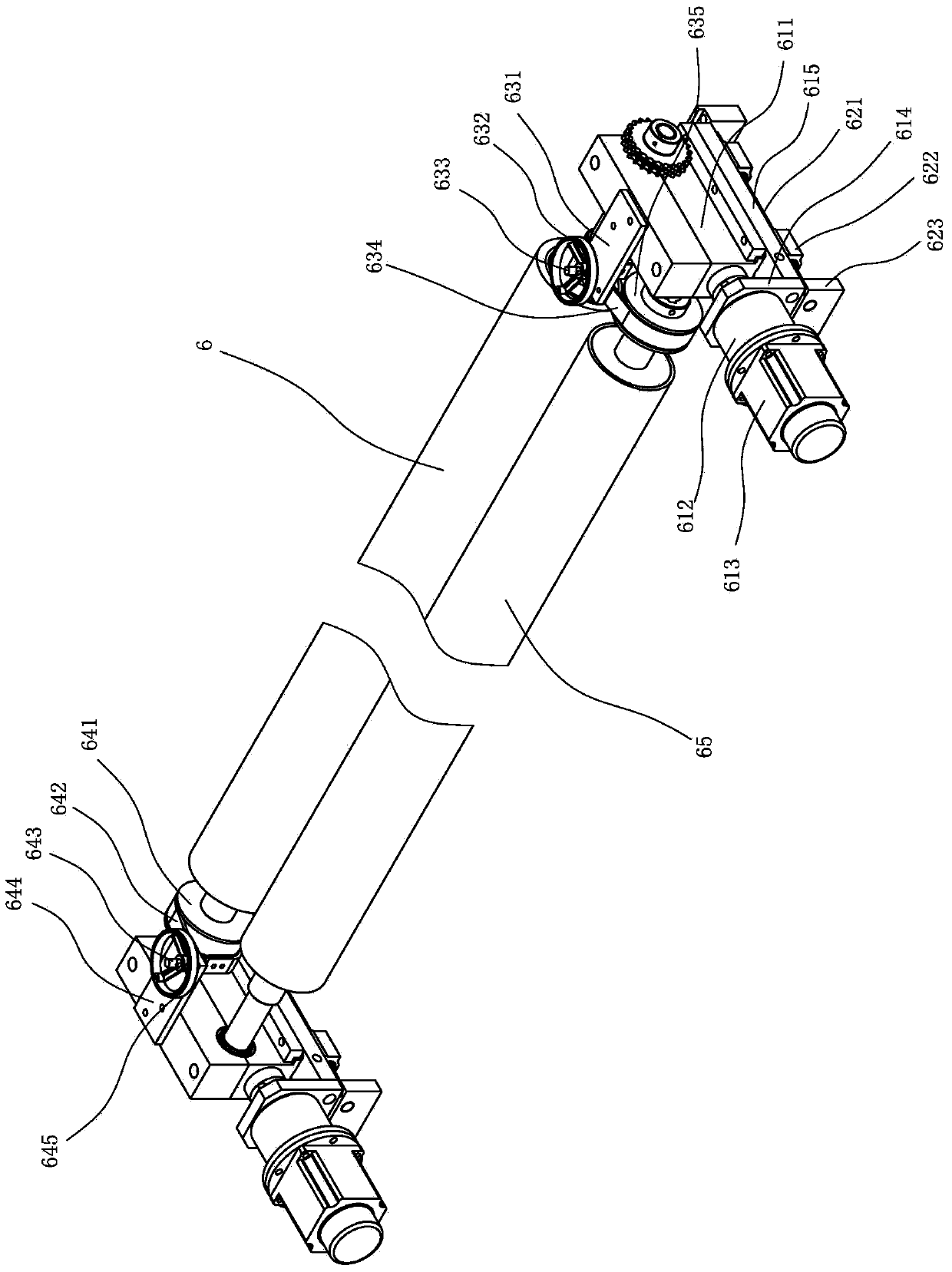

[0034] Detailed reference figure 2As shown, the embossing mechanism includes an embossing roller 4 that can move along its axial direction on the frame 3, and an embossing roller that can move relative to the embossing roller 4 between the working position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com