Patents

Literature

48results about How to "Solve grinding problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

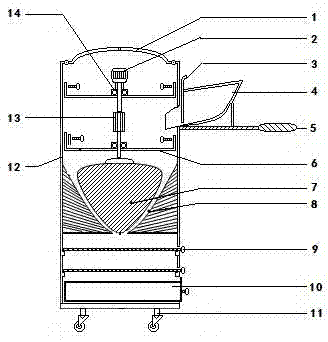

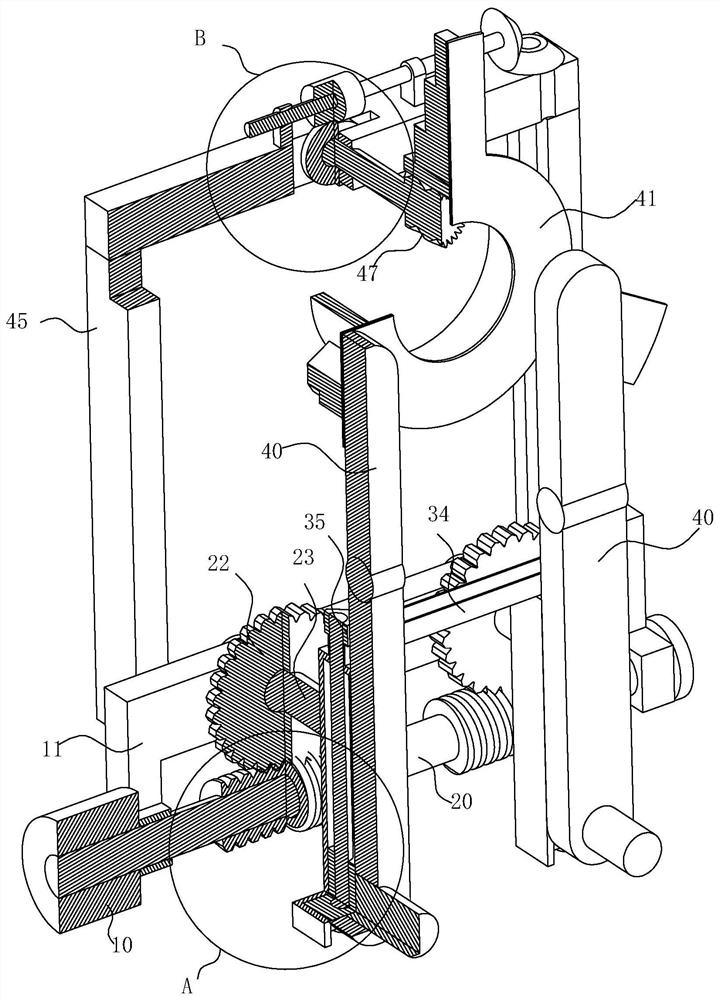

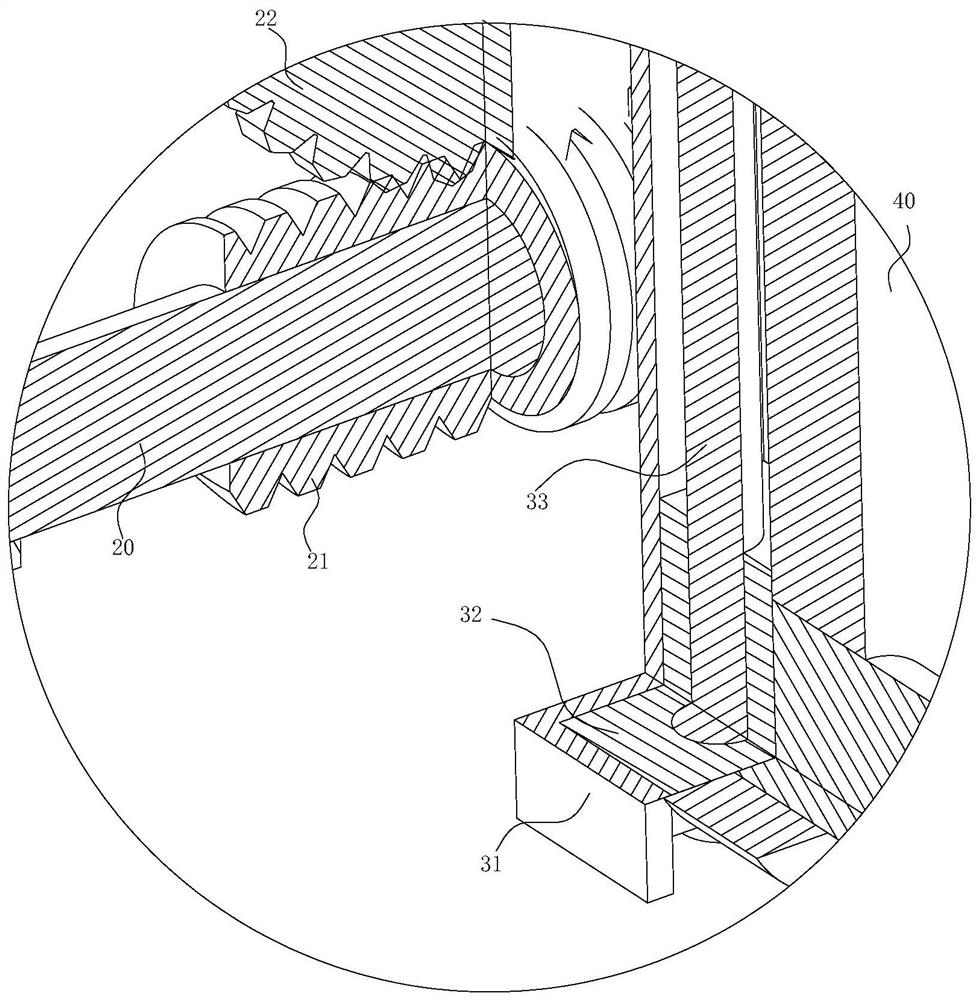

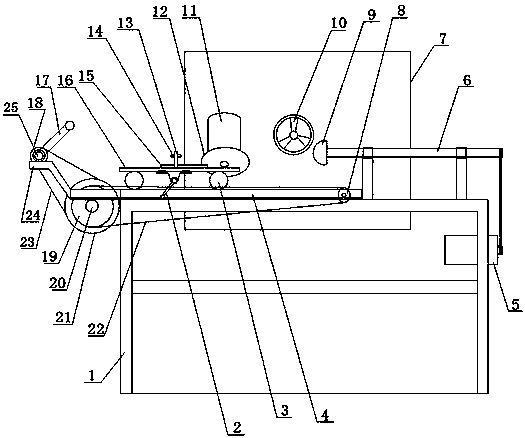

Soil analysis sample screening-grinding movable all-in-one machine

ActiveCN103487301AReduce workloadLow pricePreparing sample for investigationSoil scienceAgricultural engineering

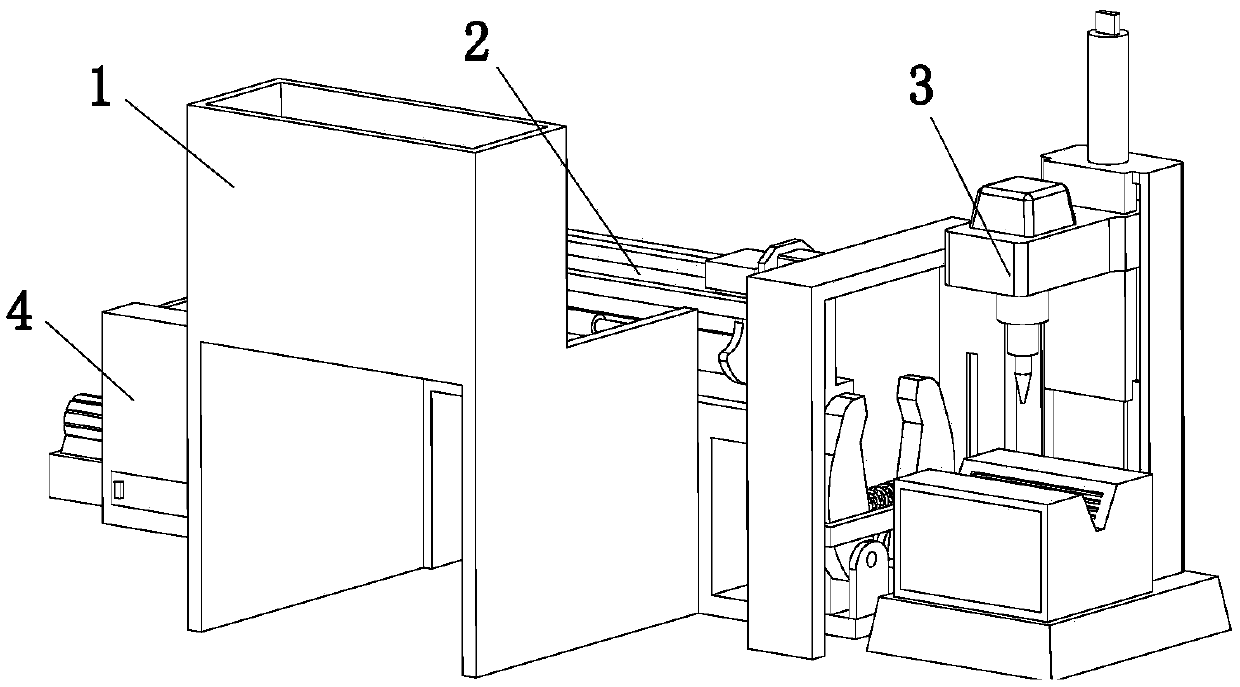

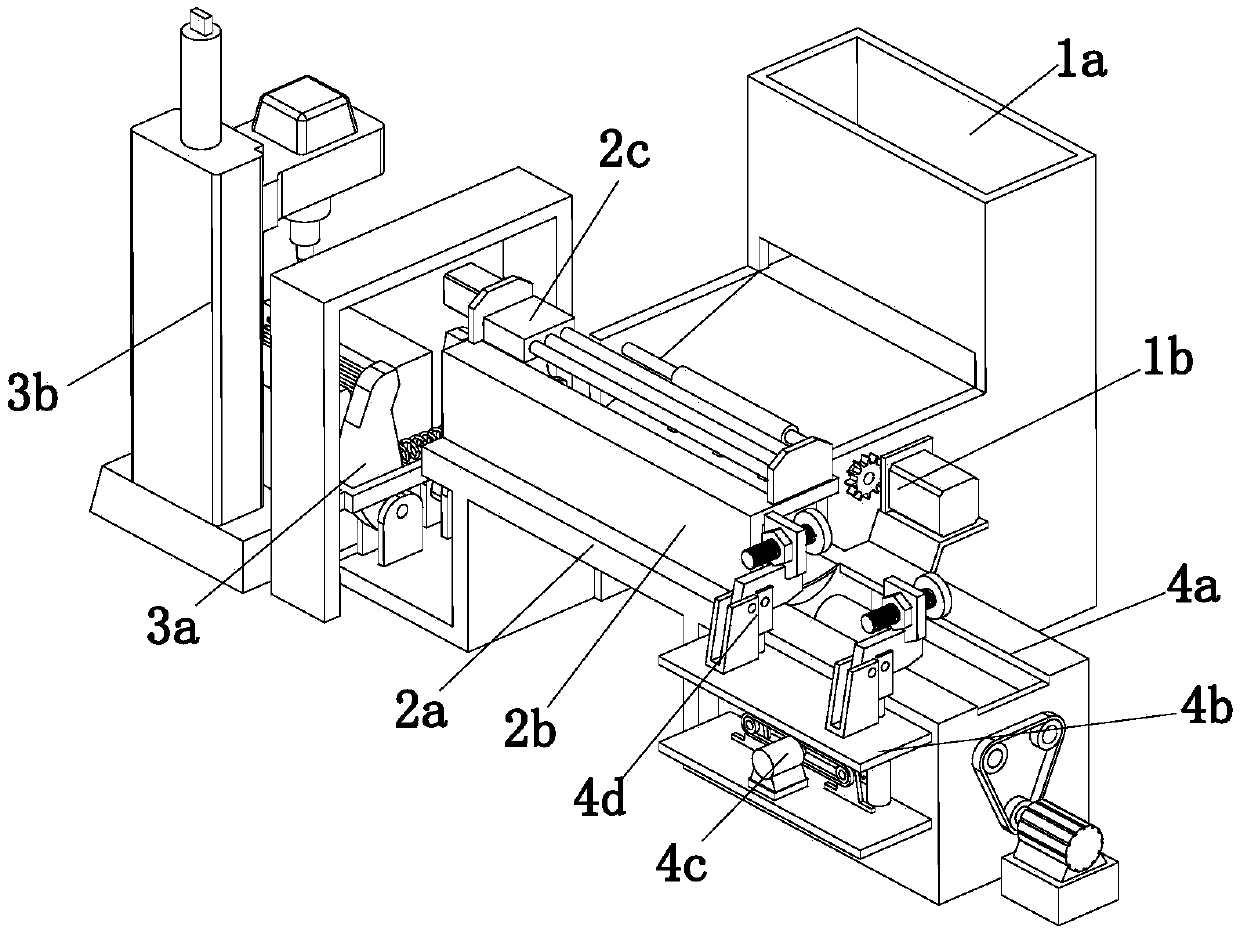

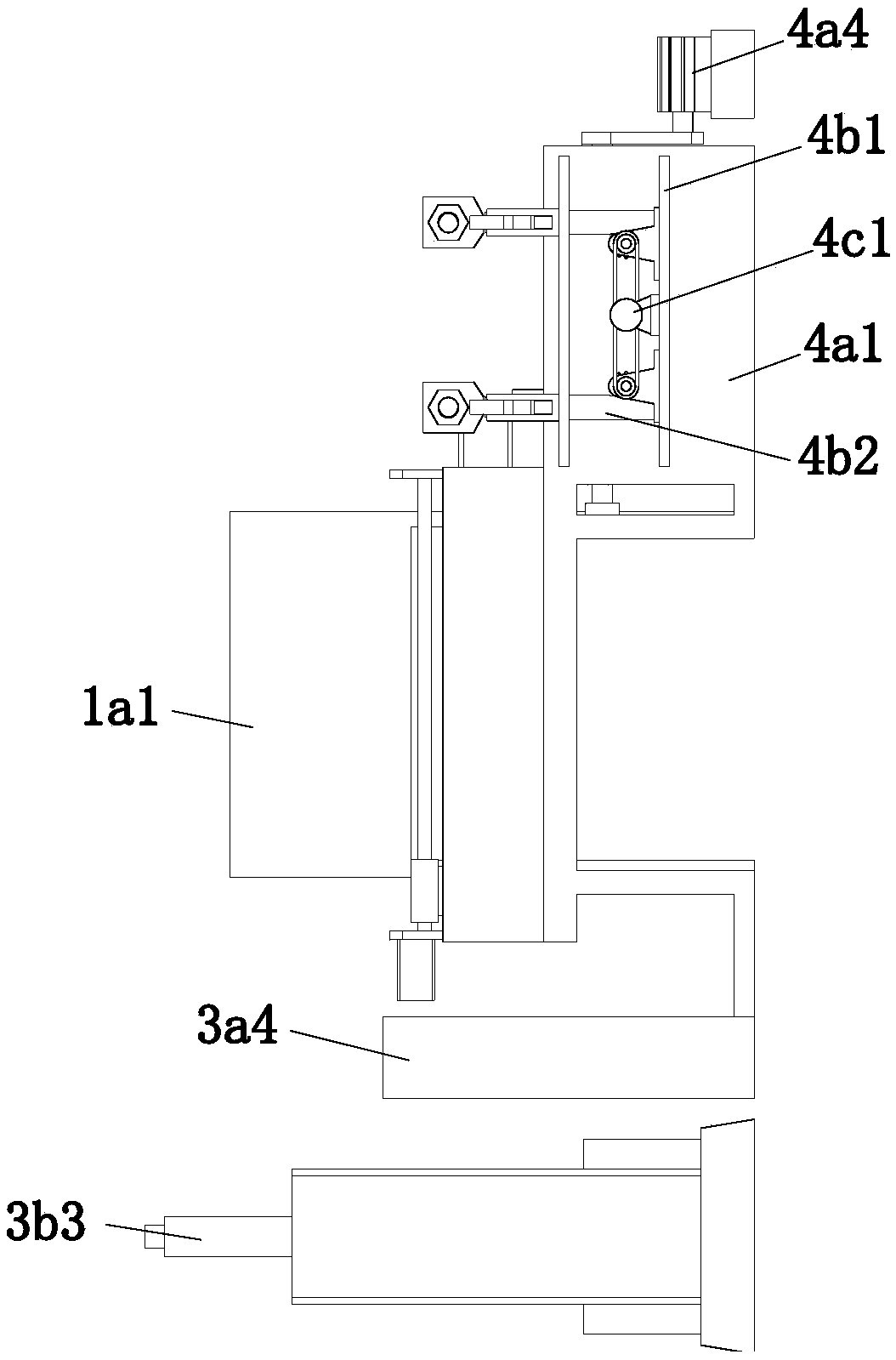

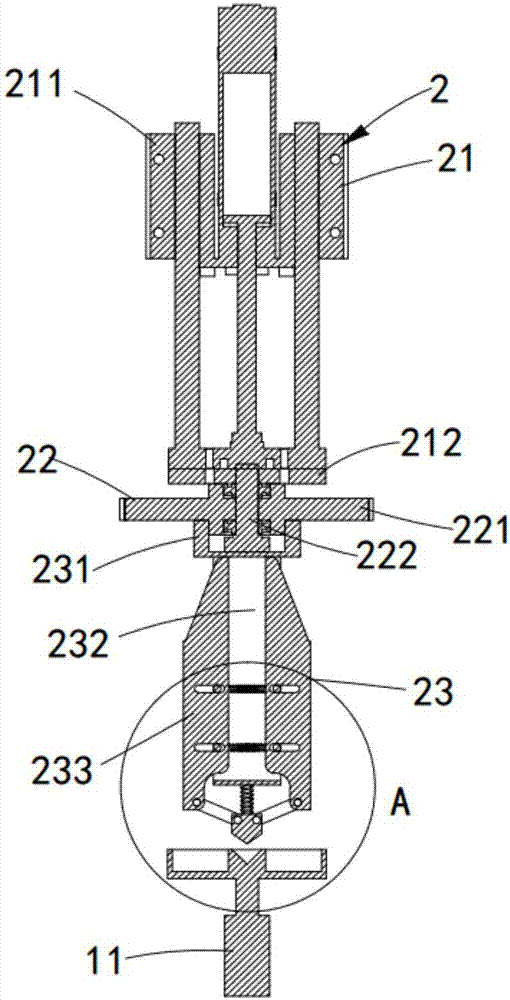

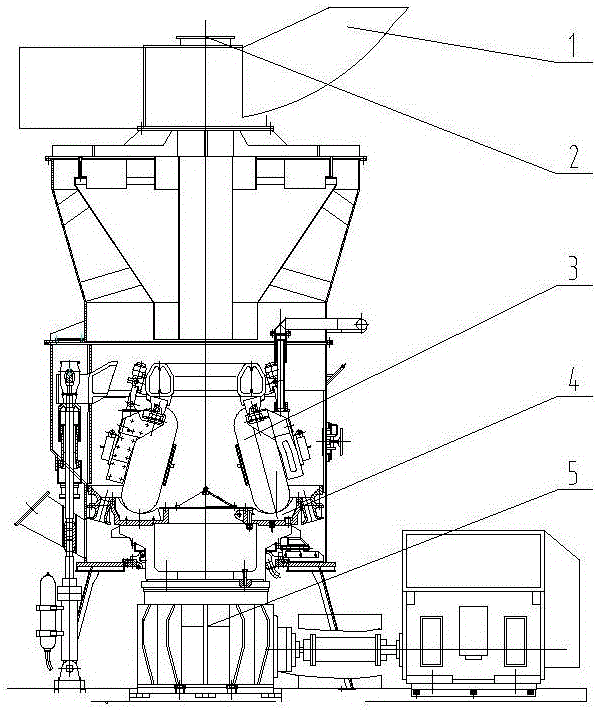

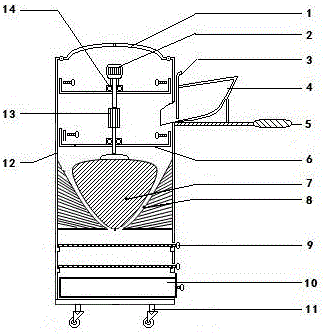

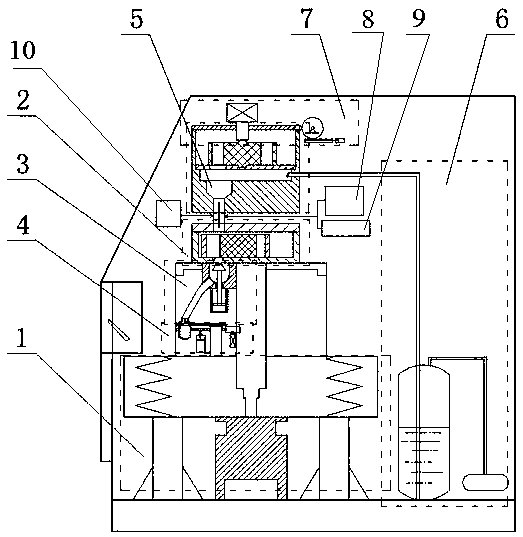

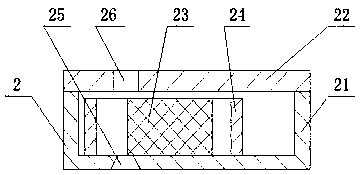

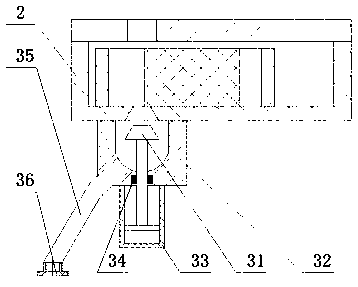

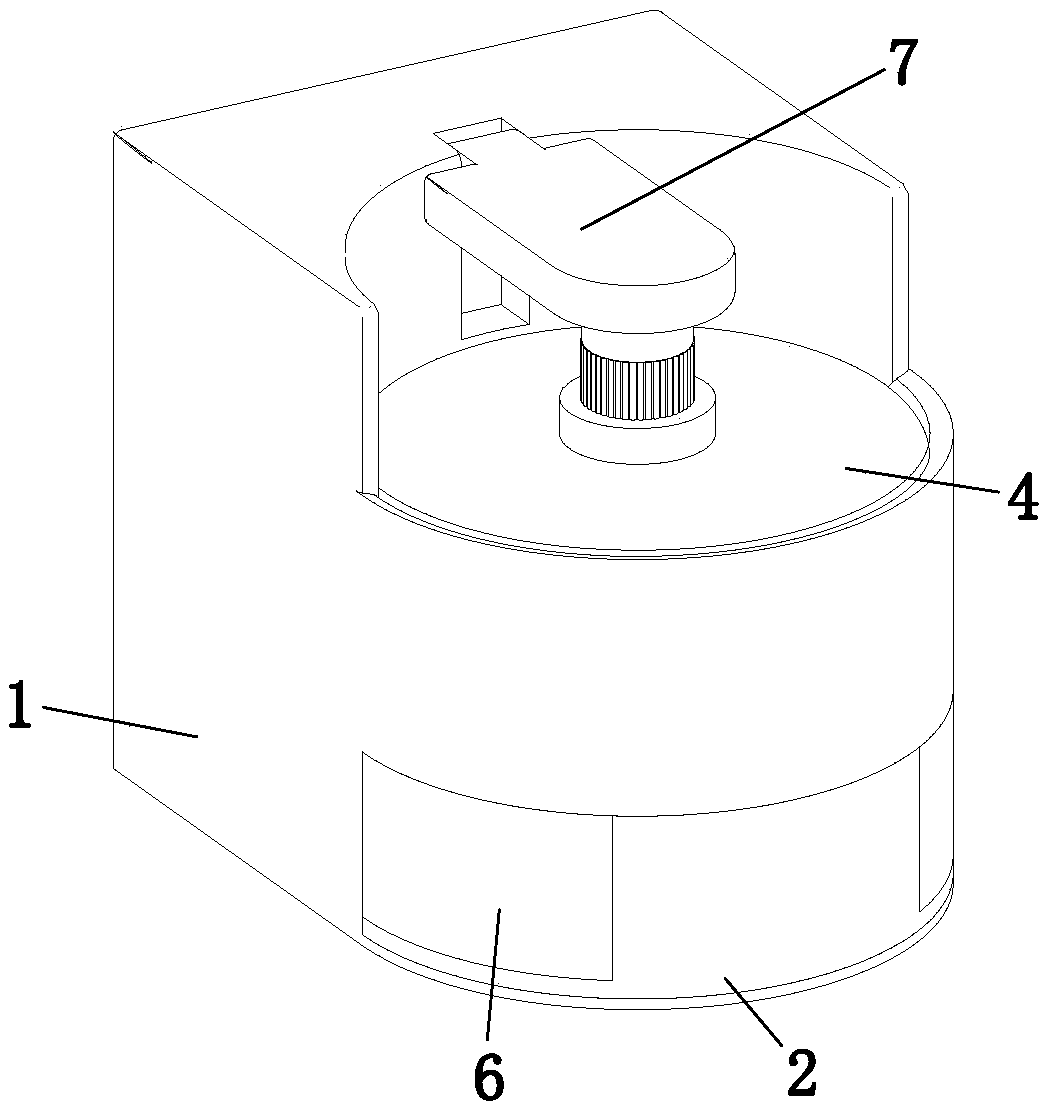

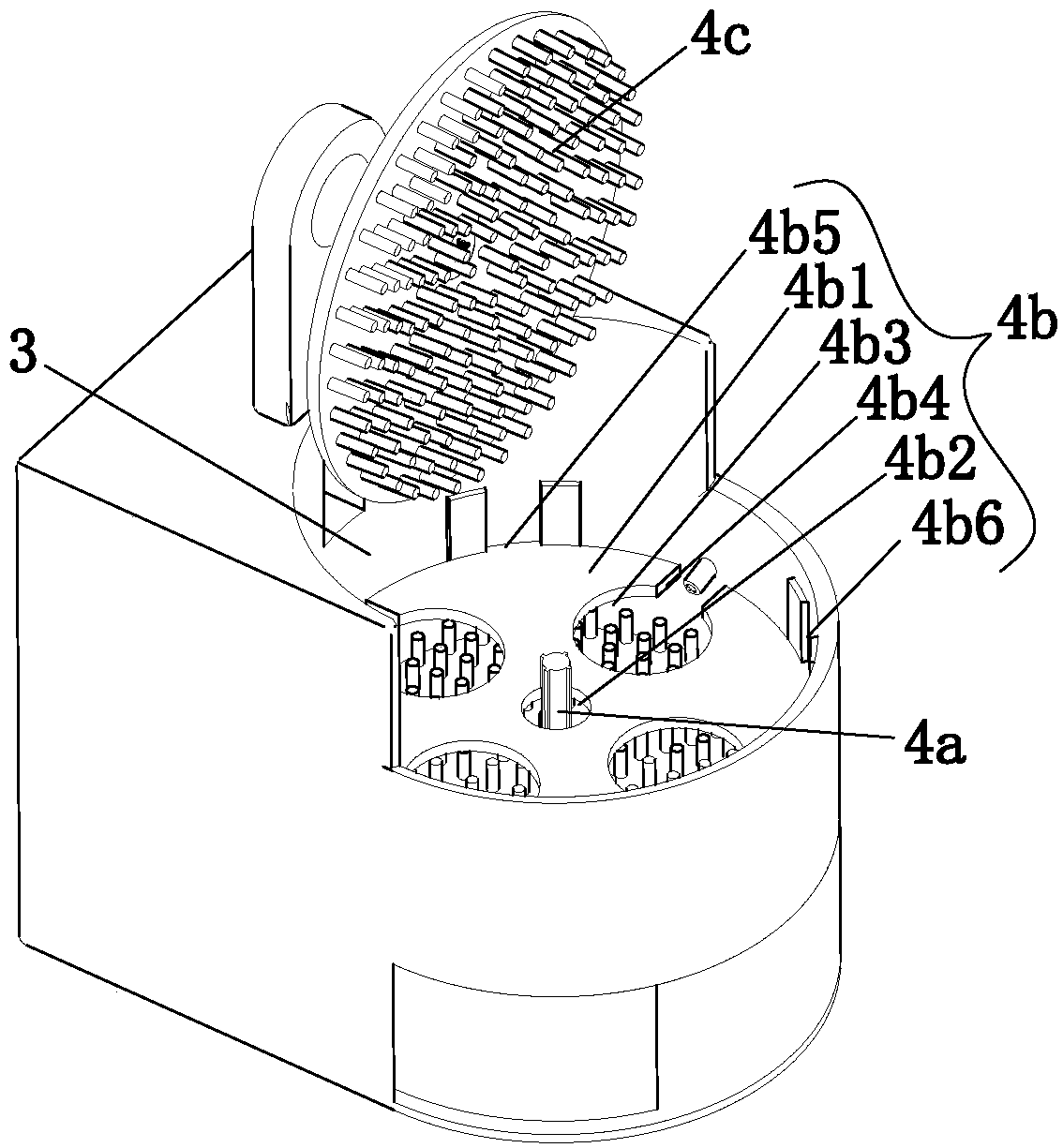

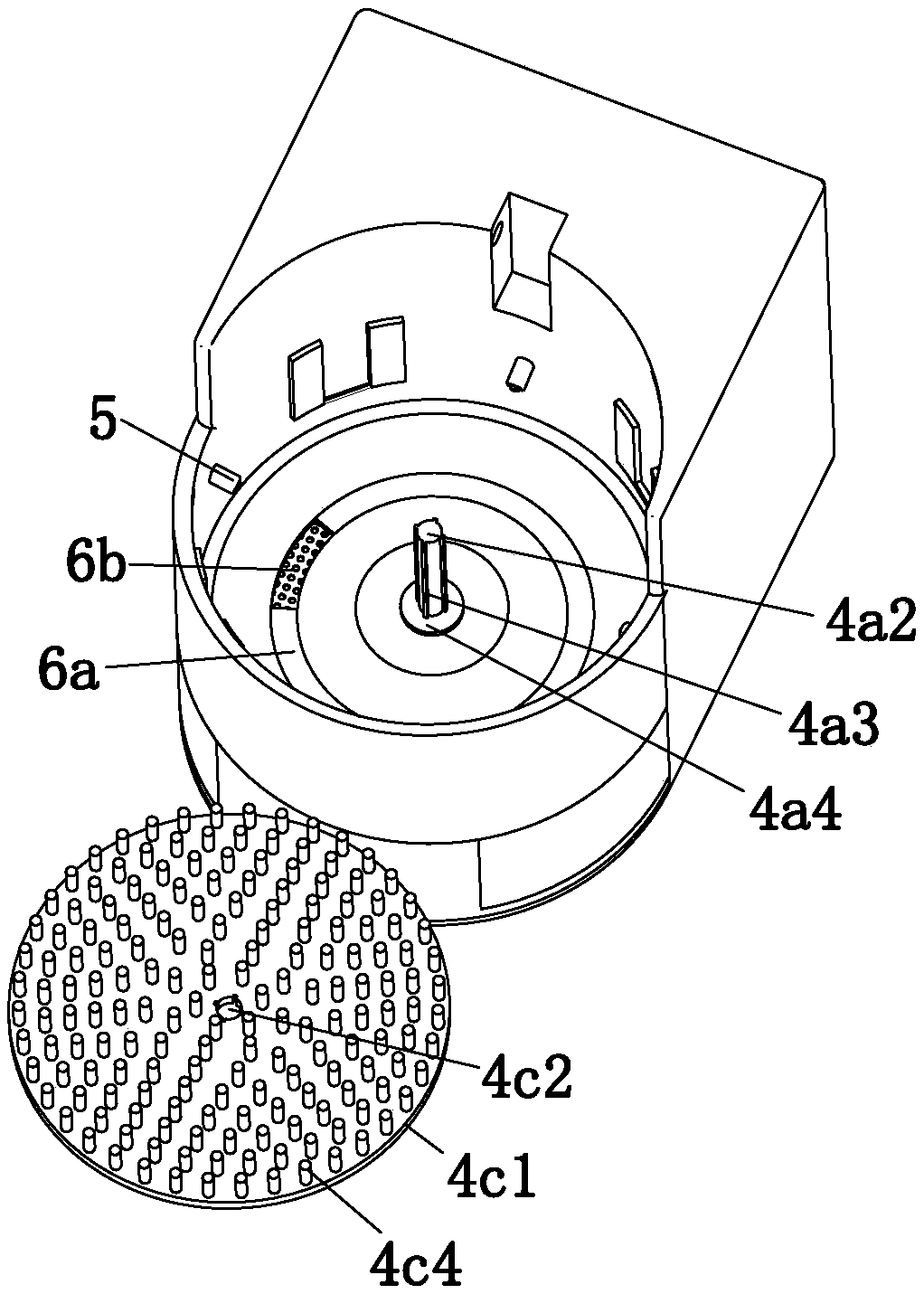

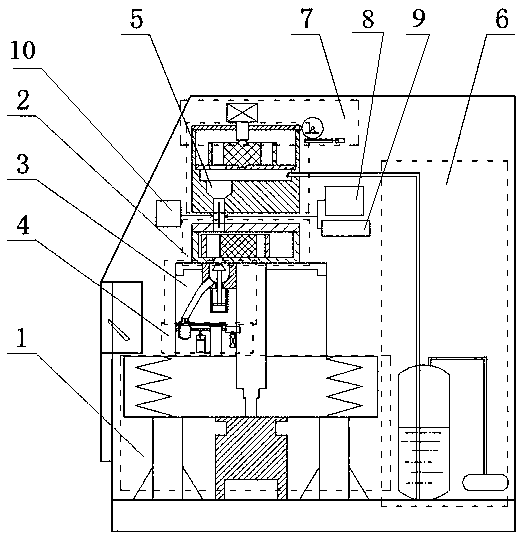

The invention relates to the technical field of soil sample screening-grinding equipment, particularly to a soil analysis sample screening-grinding movable all-in-one machine for laboratory analysis. The technical scheme of the machine is that the movable all-in-one machine includes a machine body, a feeding treatment system, a grinding system and a classified screening system, wherein the machine body is formed by a cuboid box body; a feeding treatment system is arranged at the upper part of the side wall of the box body; the classified screening system is positioned at the middle lower part of the box body; the grinding system is positioned at the middle upper part of the box body and is arranged in the middle part. Tests show that the all-in-one machine can one-step pulverize soil into particles not larger than 2 mm in diameter and counting for 85% above, and one-step pulverize soil into particles not larger than 0.15 mm in diameter and counting for 65% above, and the screening yield is 100%. The machine has the advantages that the obtained materials are common, the operation is simple, high quality and efficiency are realized, no pollution to a soil sample is caused, and the result is reliable.

Owner:FUJIAN NORMAL UNIV

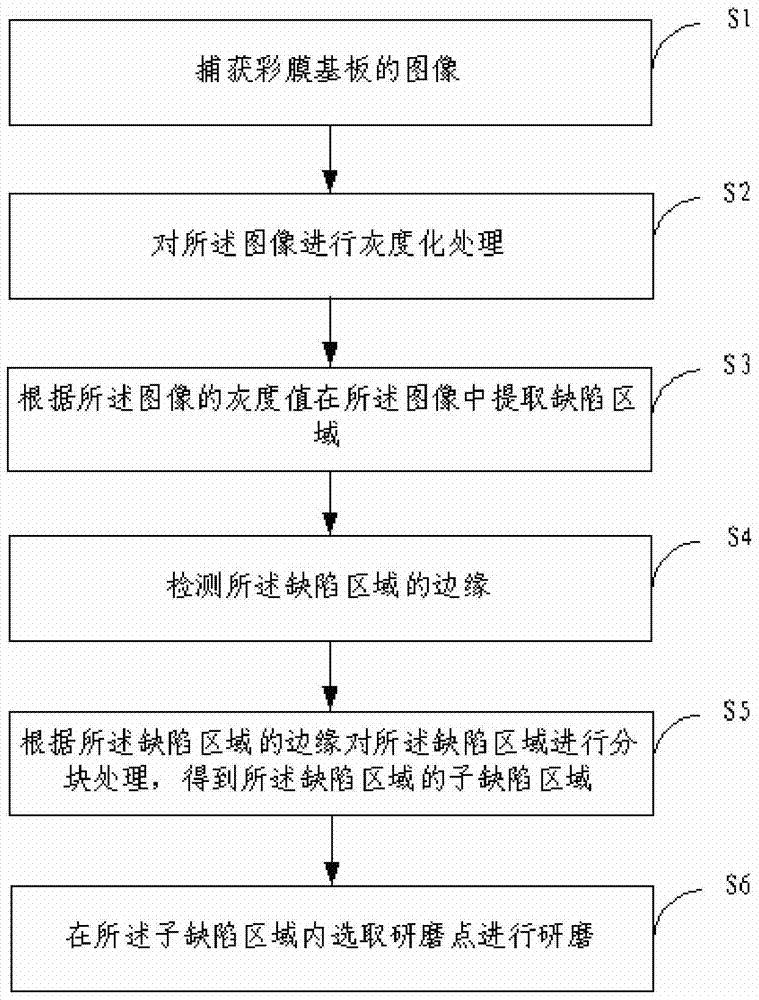

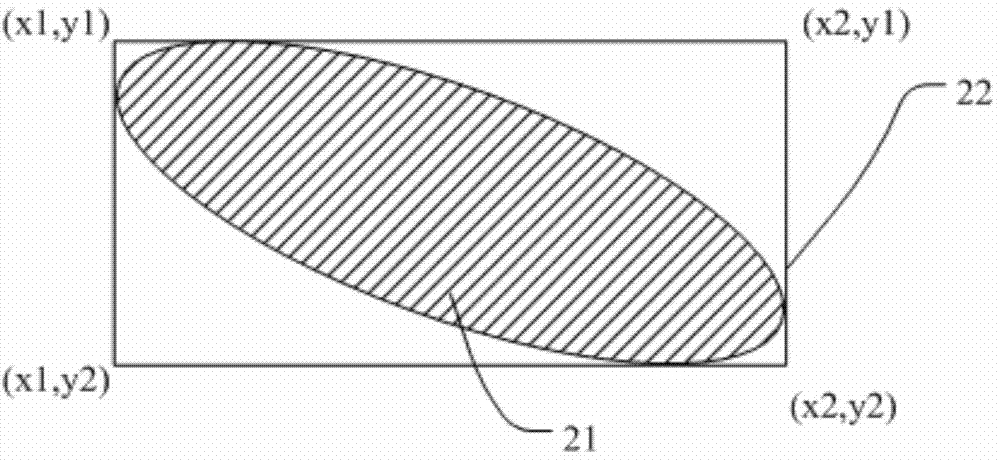

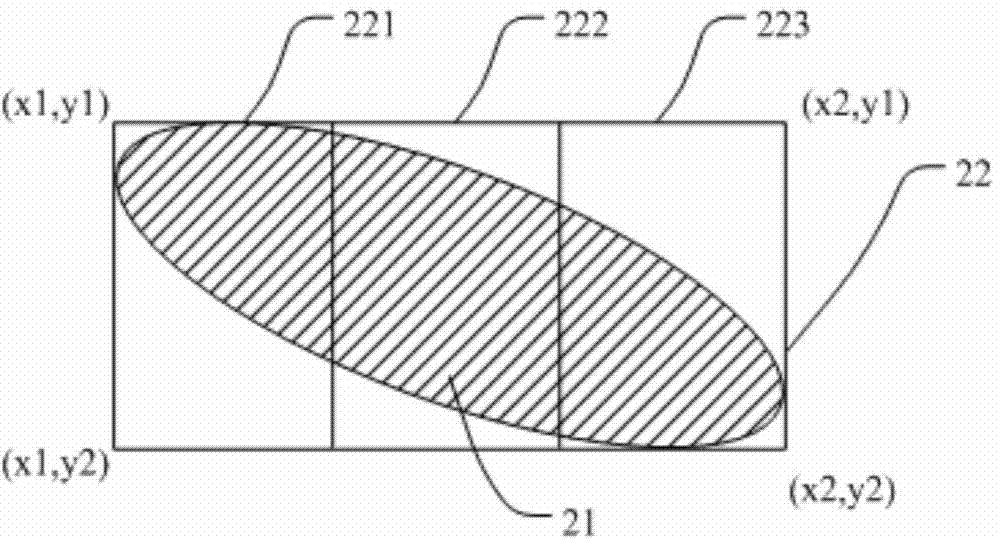

Color film substrate repairing method

The invention provides a color film substrate repairing method. The color film substrate repairing method comprises the steps of capturing a color film substrate image; performing graying treatment on the image; extracting a defect region from the image according to a gray value of the image; detecting the edge of the defect region; performing blocking treatment on the defect region according to the edge of the defect region to obtain sub-defect regions in the defect region; selecting grinding points from the sub-defect regions to performing grinding. The defects in a color film substrate are divided into a plurality of portions, then the portions are respectively subjected to height measurement and grinding, and accordingly the problem that large-sized defect points are grinded is solved.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

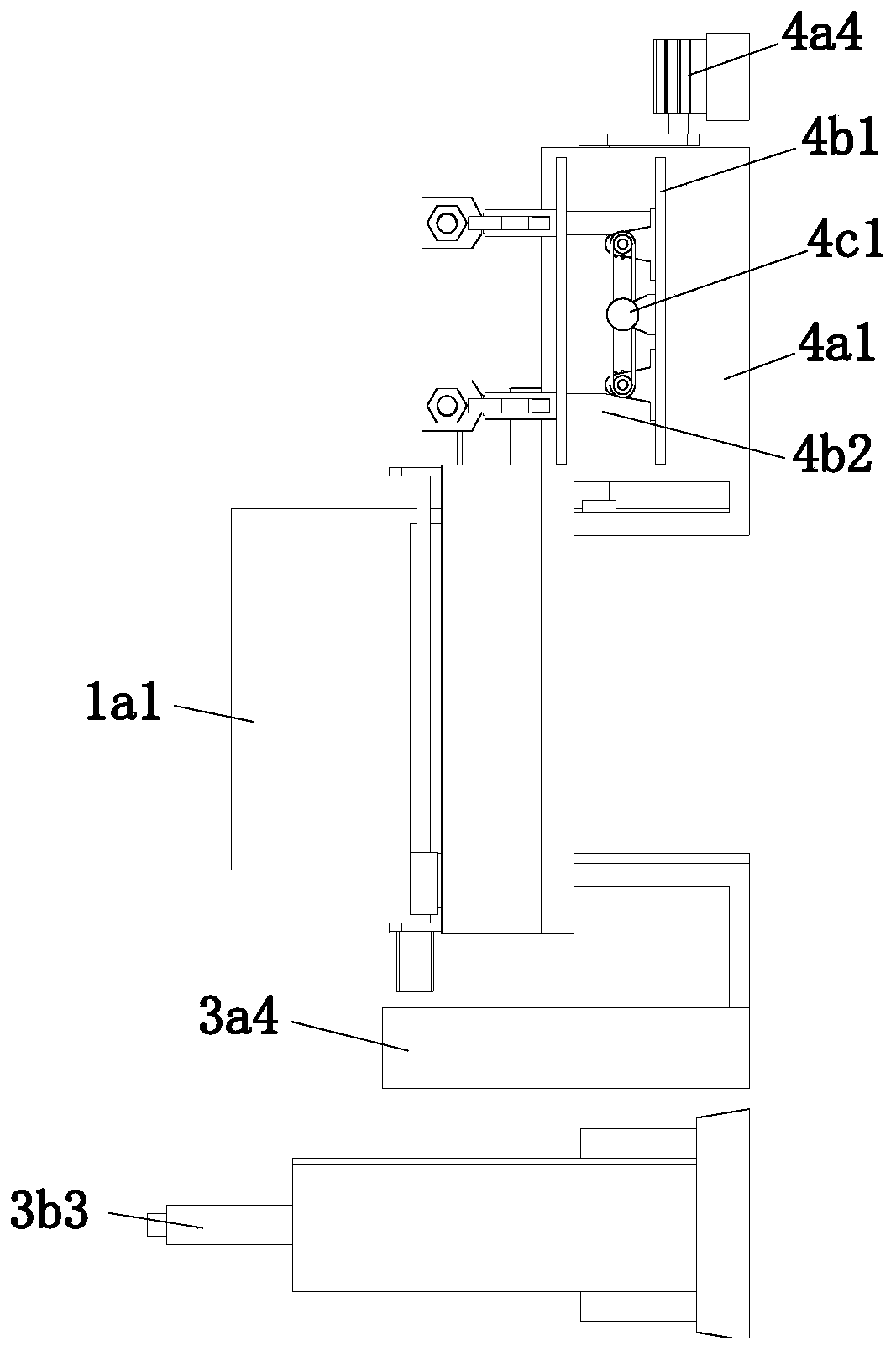

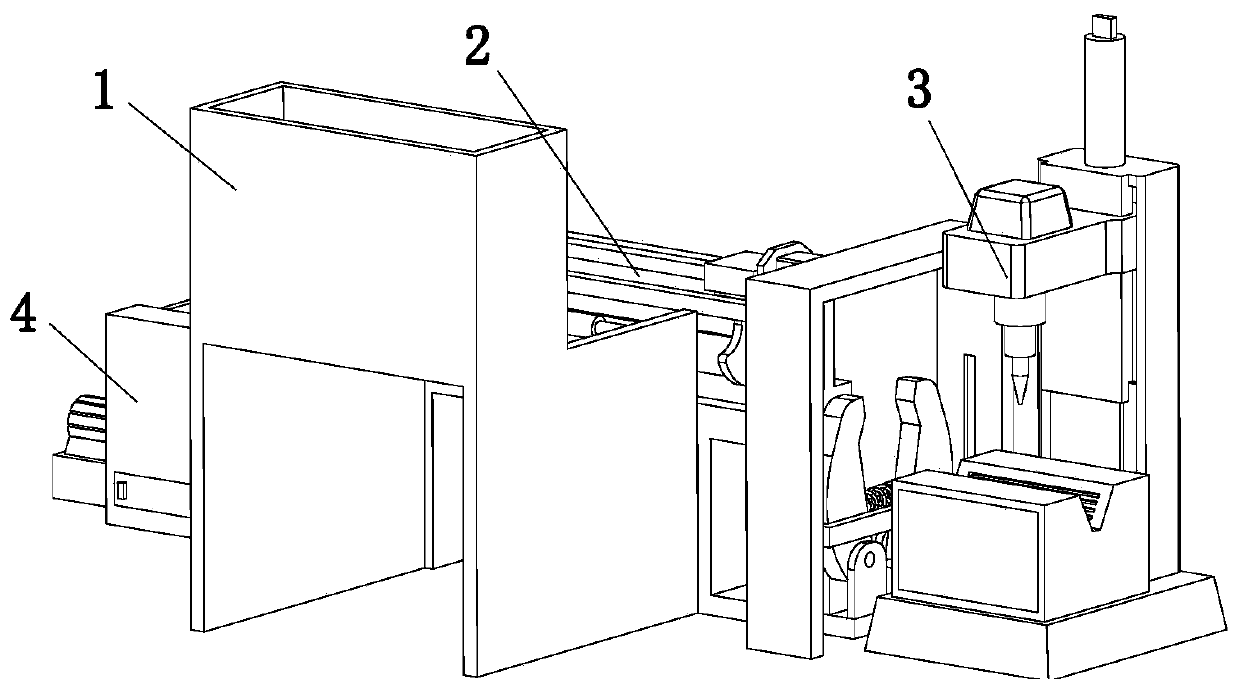

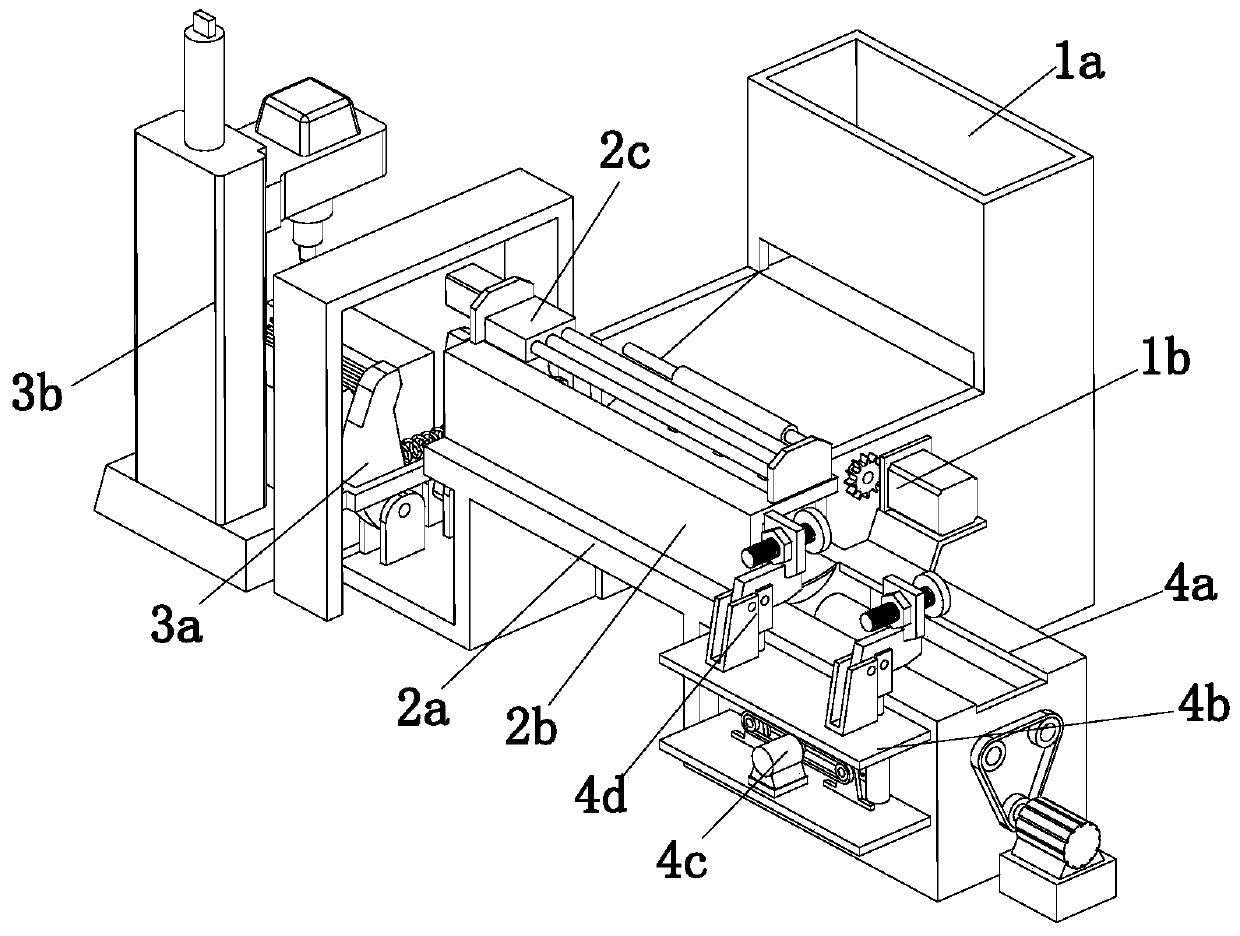

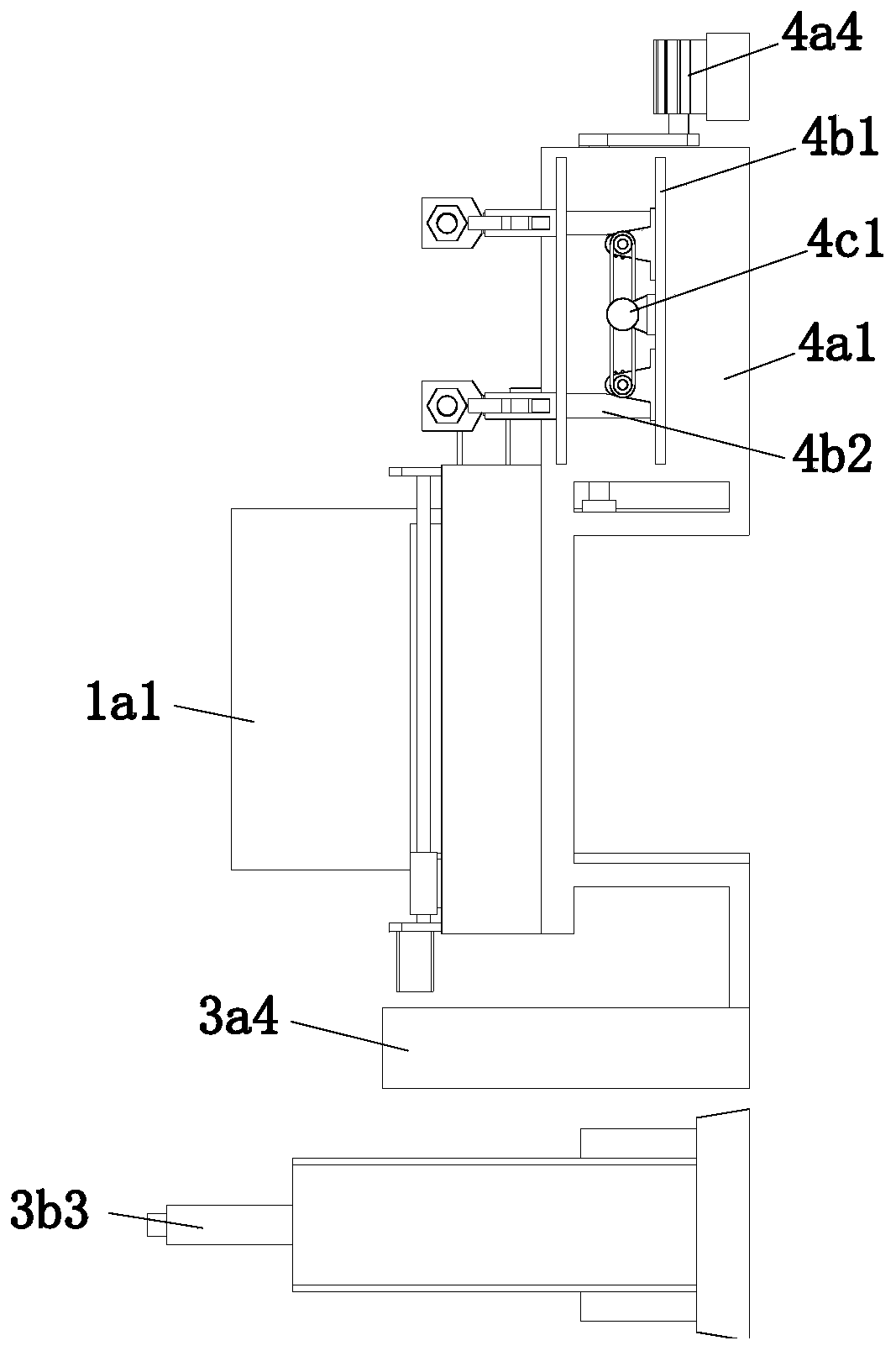

Working method of aluminum alloy bar processing equipment

ActiveCN109702495ASolve grinding problemsSolve processabilityOther manufacturing equipments/toolsPositioning apparatusAluminium alloyScrap

The invention discloses a working method of aluminum alloy bar processing equipment, and belongs to the field of aluminum alloy processing equipment. The processing equipment includes a feeding device, a transfer device, a drilling and milling device and a grinding device, the feeding device includes a feeding assembly and a material control assembly, the grinding device includes a bearing grinding assembly, a supporting assembly, a driving assembly and two pressing assemblies, the bearing grinding assembly is arranged at one end of the transfer device and is connected with the transfer device, the supporting assembly is installed on the side wall of the bearing grinding assembly, the driving assembly is installed on the supporting assembly and is connected with the two pressing assembliesin a transmission mode, the drilling and milling device includes a positioning assembly and a tapping and milling assembly, and the positioning assembly is arranged between the other end of the transfer device and the tapping and milling assembly. According to the working method of the aluminum alloy bar processing equipment, grinding and drilling and milling alternately processing for aluminum alloy bars can be realized, and waste can be centrally recycled while the aluminum alloy bars can be processed, so that overall practicability is improved.

Owner:帅翼驰新材料集团有限公司

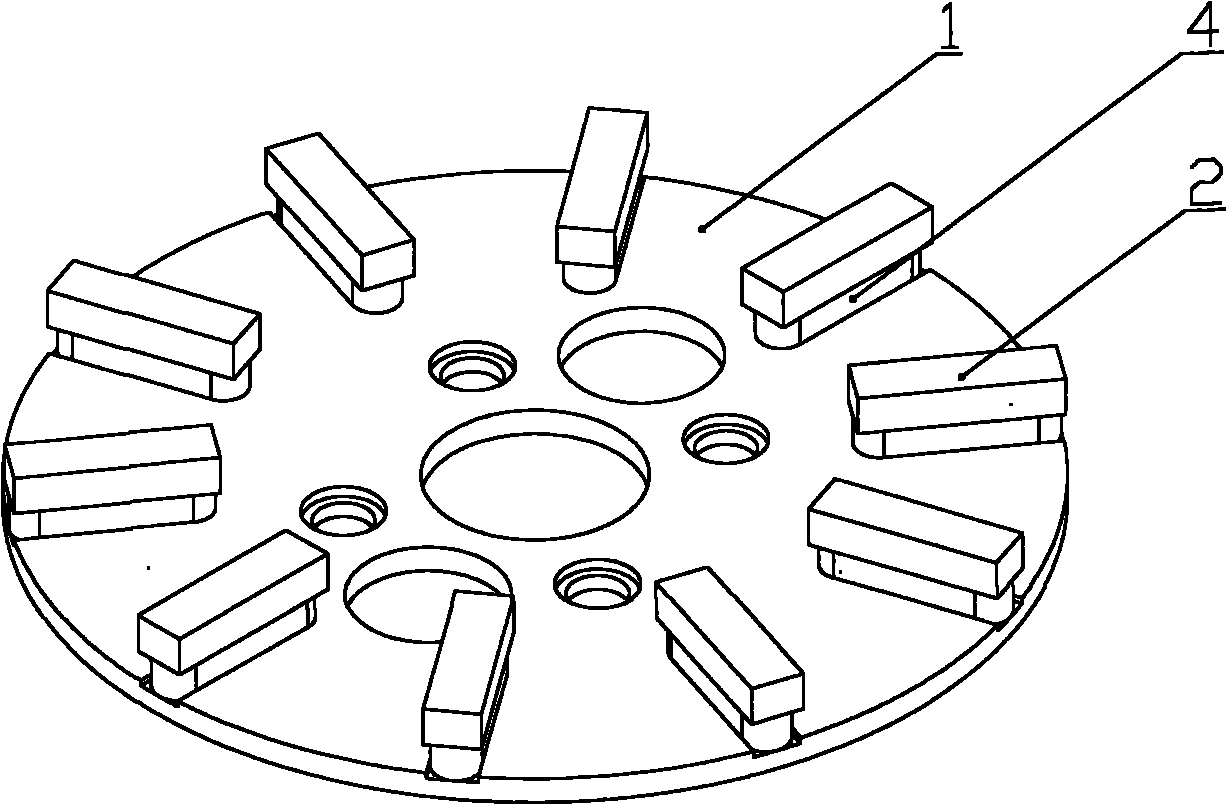

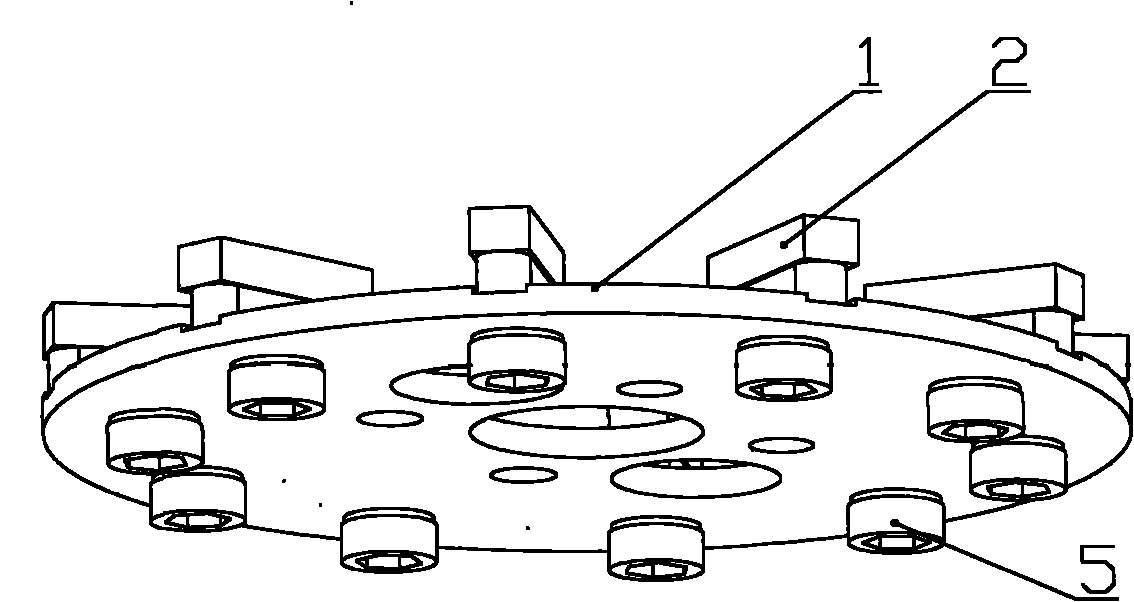

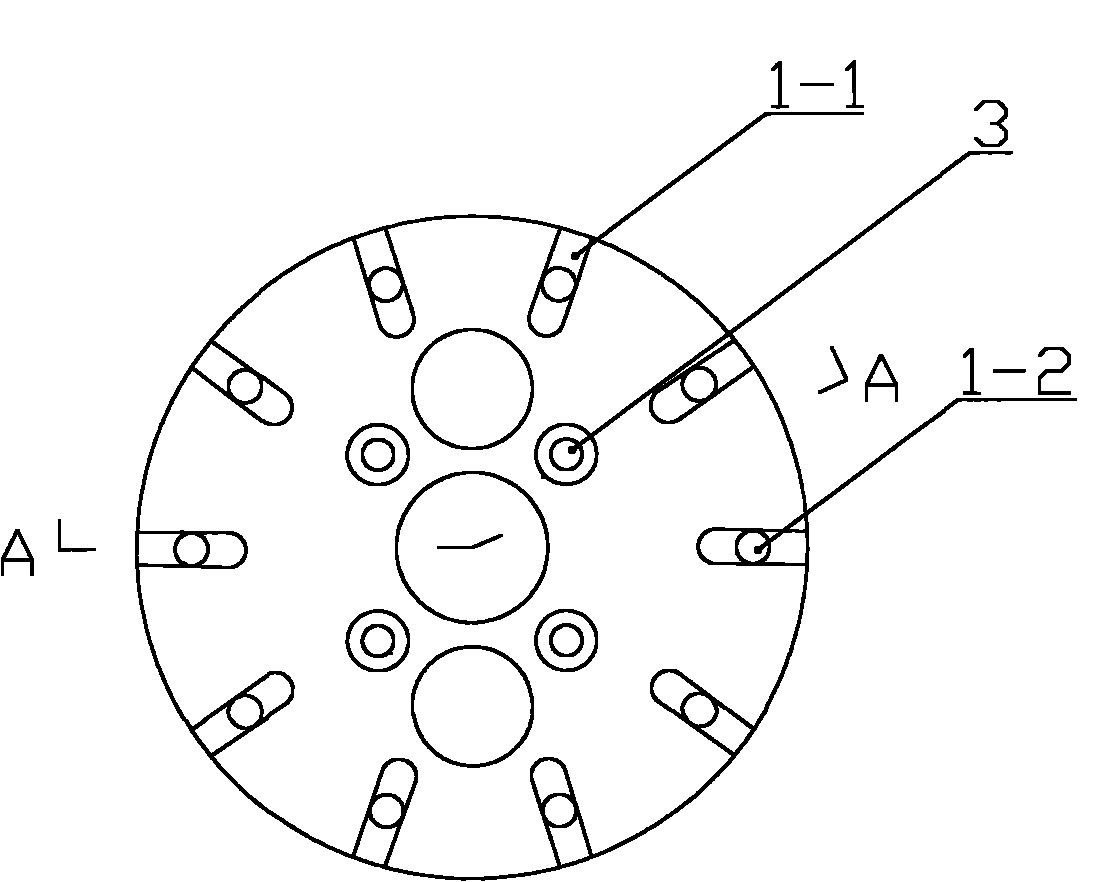

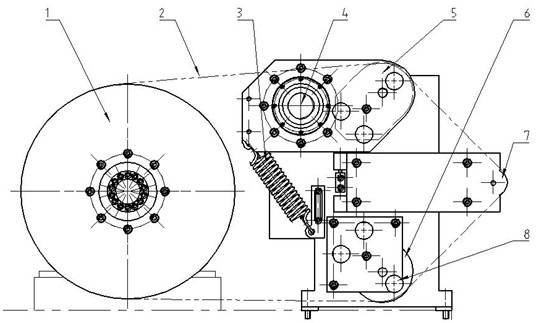

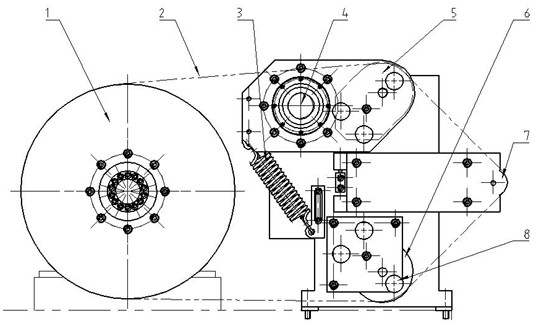

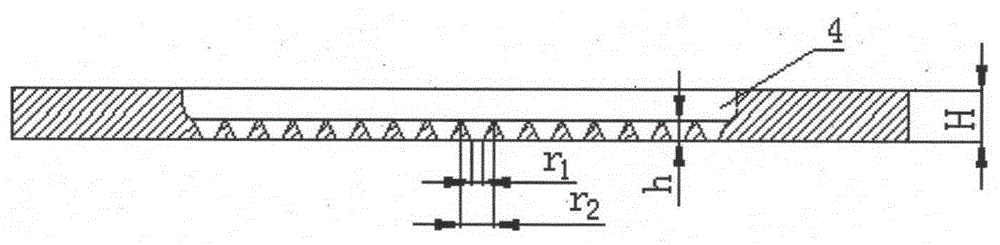

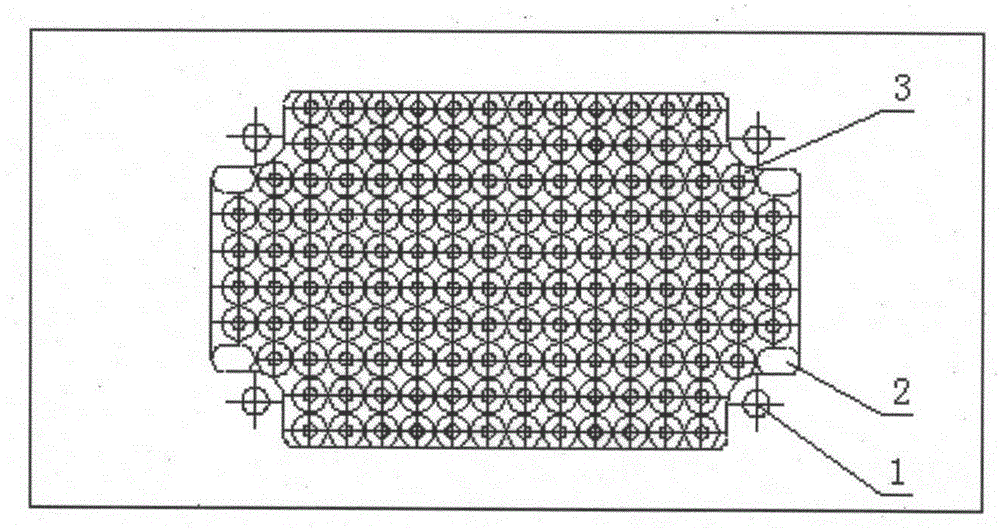

Grinding disc and high-speed rail bridge grinder provided with same

InactiveCN101934505APrevent slidingGuaranteed effective working performanceBonded abrasive wheelsPlane surface grinding machinesWork performanceMechanical engineering

The invention discloses a grinding disc for a high-speed rail bridge grinder. The grinding disc comprises a disc body, a grinding block and an anti-slip key, wherein the grinding block is arranged on the disc body; the disc body is provided with an anti-slip groove; the anti-slip key is embedded in the anti-slip groove and fixed with the disc body relatively; the grinding block is fixed on the top of the anti-slip key; the anti-slip key is provided with a screw hole; the bottom of the anti-slip groove of the disc body is provided with a corresponding positioning hole; and the anti-slip key is connected with the disc body through a screw. The grinding block and the disc body of the grinding disc do not need to be welded and are easy to install and convenient to operate; when the grinding block is fully worn, only the grinding block instead of the disc body needs to be replaced, so that cost is saved greatly; simultaneously, the disc body can be effectively prevented from being worn, the grinding block is prevented from sliding to the maximum extent and the effective working performance of the grinding block is ensured. The invention also discloses the high-speed rail bridge grinder provided with the grinding disc.

Owner:何轩

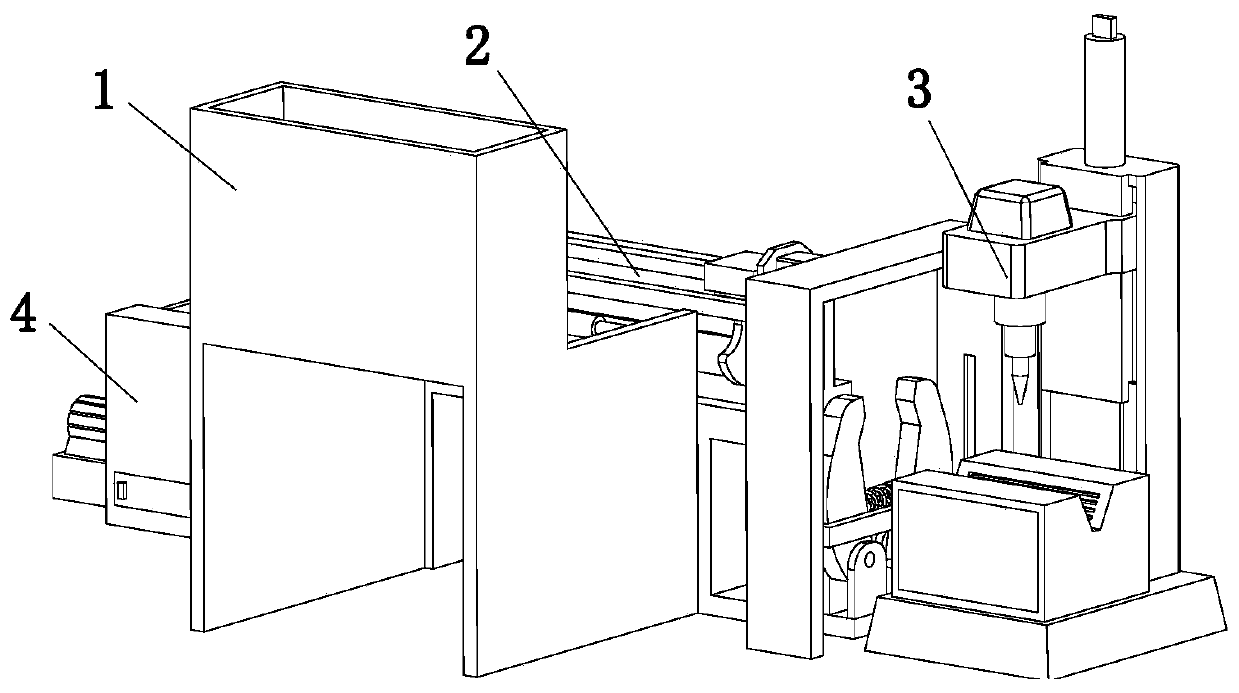

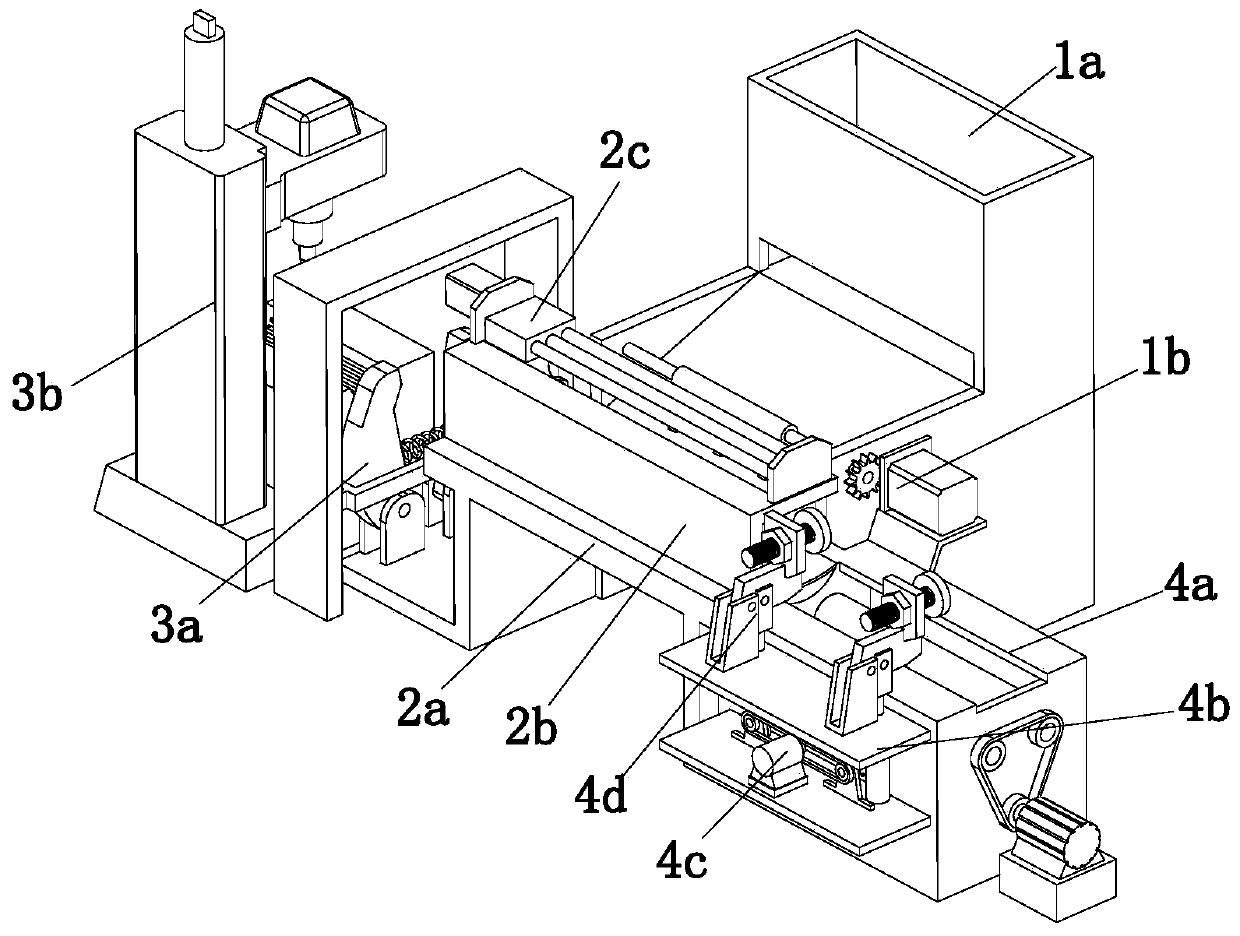

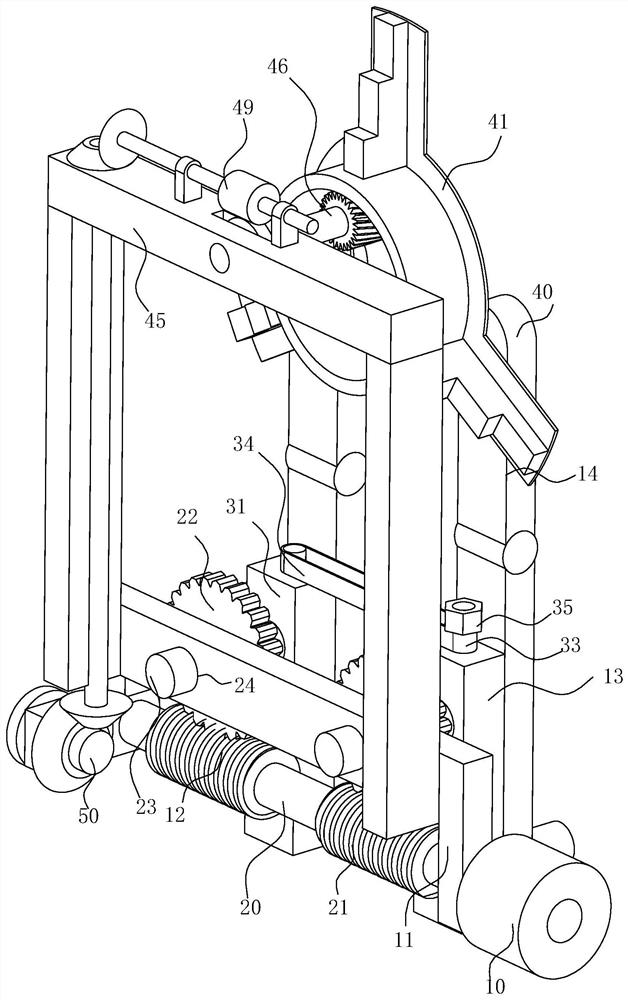

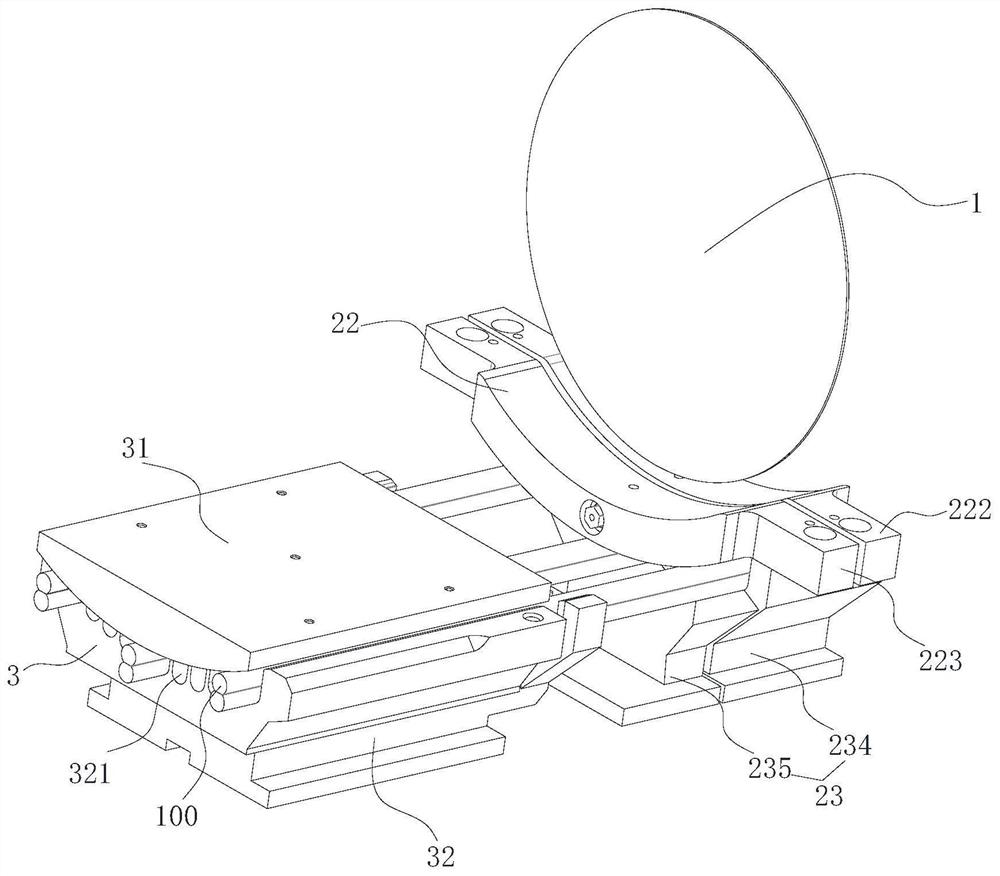

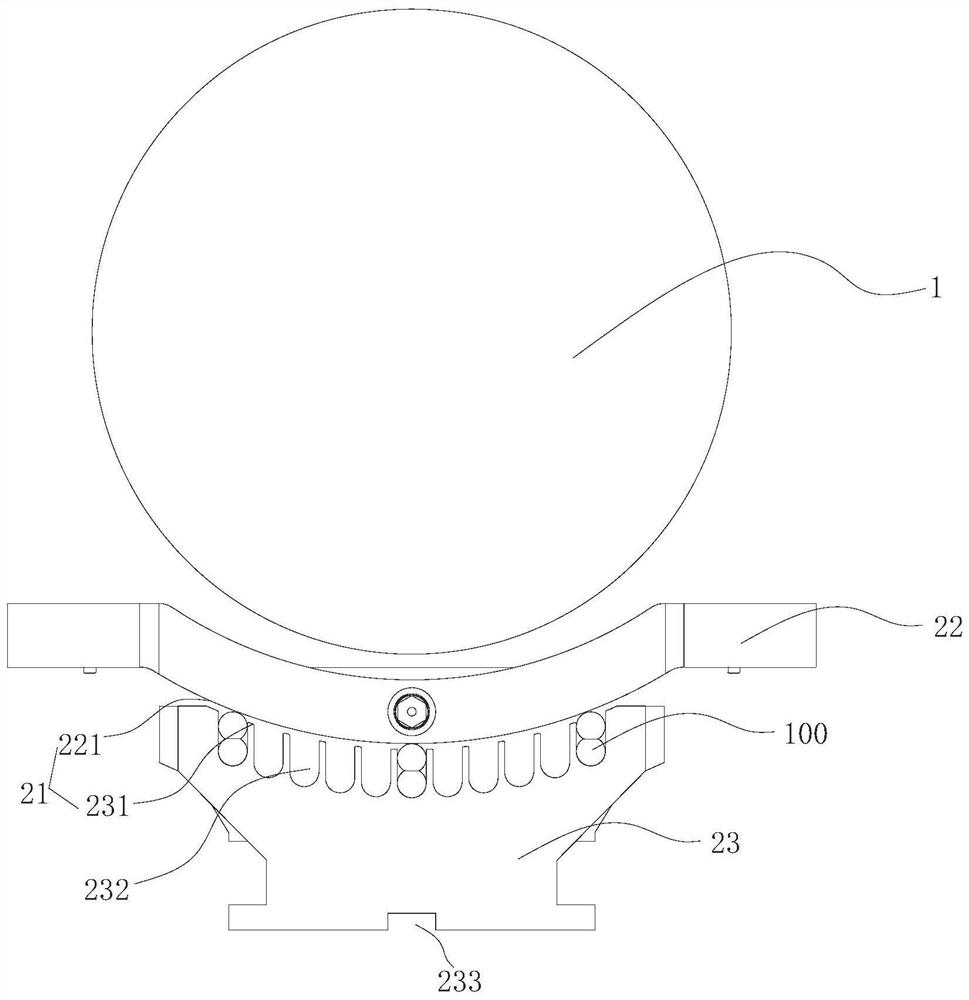

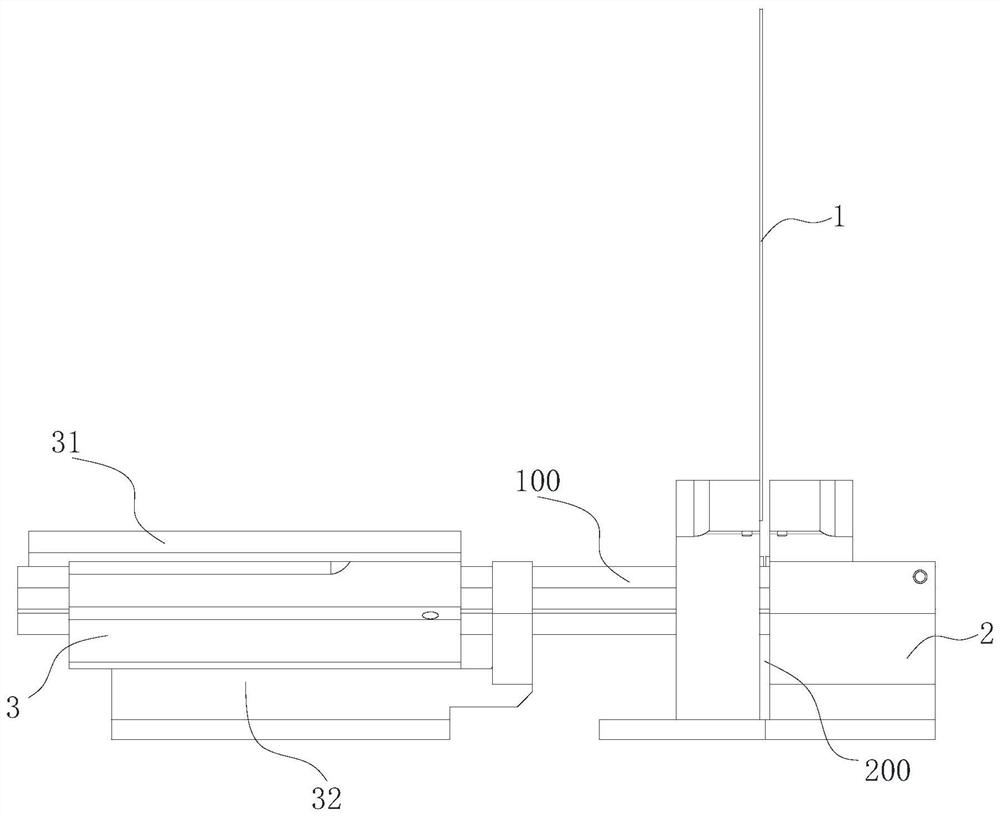

Machining equipment of aluminum alloy rods

ActiveCN109676450ASolve grinding problemsSolve processabilityRevolution surface grinding machinesGrinding drivesMaterial supplyAluminium alloy

The invention discloses machining equipment of aluminum alloy rods, and belongs to the field of aluminum alloy machining equipment. The machining equipment comprises a material supply device, a transfer device, a drilling and milling device and a grinding device. The material supply device comprises a material supply assembly and a material control assembly. The grinding device comprises a bearinggrinding assembly, a supporting assembly, a driving assembly and two pressing assemblies. The bearing grinding assembly is arranged at the position of one end of the transfer device and is in linkedcooperation with the transfer device, the supporting assembly is mounted on the side wall of the bearing grinding assembly, the driving assembly is mounted on the supporting assembly and is in transmission connection with the two pressing assemblies, the drilling and milling assembly comprises a positioning assembly and a tapping and milling assembly, and the positioning assembly is arranged between the other end of the transfer device and the tapping and milling assembly. The aluminum alloy rods can be ground and drilled and milled alternately, waste can be recycled and treated in a centralized manner while the aluminum alloy rods are machined, and therefore the overall practicality of the machining equipment is improved.

Owner:百色市彩虹铝业有限公司

Method for preparation of dimethyl ether

ActiveCN102125854AImprove particle finenessImprove performanceMetal/metal-oxides/metal-hydroxide catalystsEther preparationRare earthColloid

The invention relates to a method for the preparation of dimethyl ether, which comprises the steps of: using the intermediate product of a copper-zinc-aluminum methanol synthesis catalyst, i.e. the carbonate mixture, as the component of the methanol synthesis catalyst, using rare earth modified gamma-alumina with low temperature activity as the component of the methanol synthesis catalyst, sufficiently mixing the two components according to the method based on colloidal sedimentation and mechanical mixing, and activating the mixture to obtain dimethyl ether. The method of the invention is simple in process and ensures the repeatability in catalyst preparation; the catalyst prepared according to the method has small particle size and high specific surface area; and the catalyst has high activity owing to tight contact and strong synergistic effect between the components.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

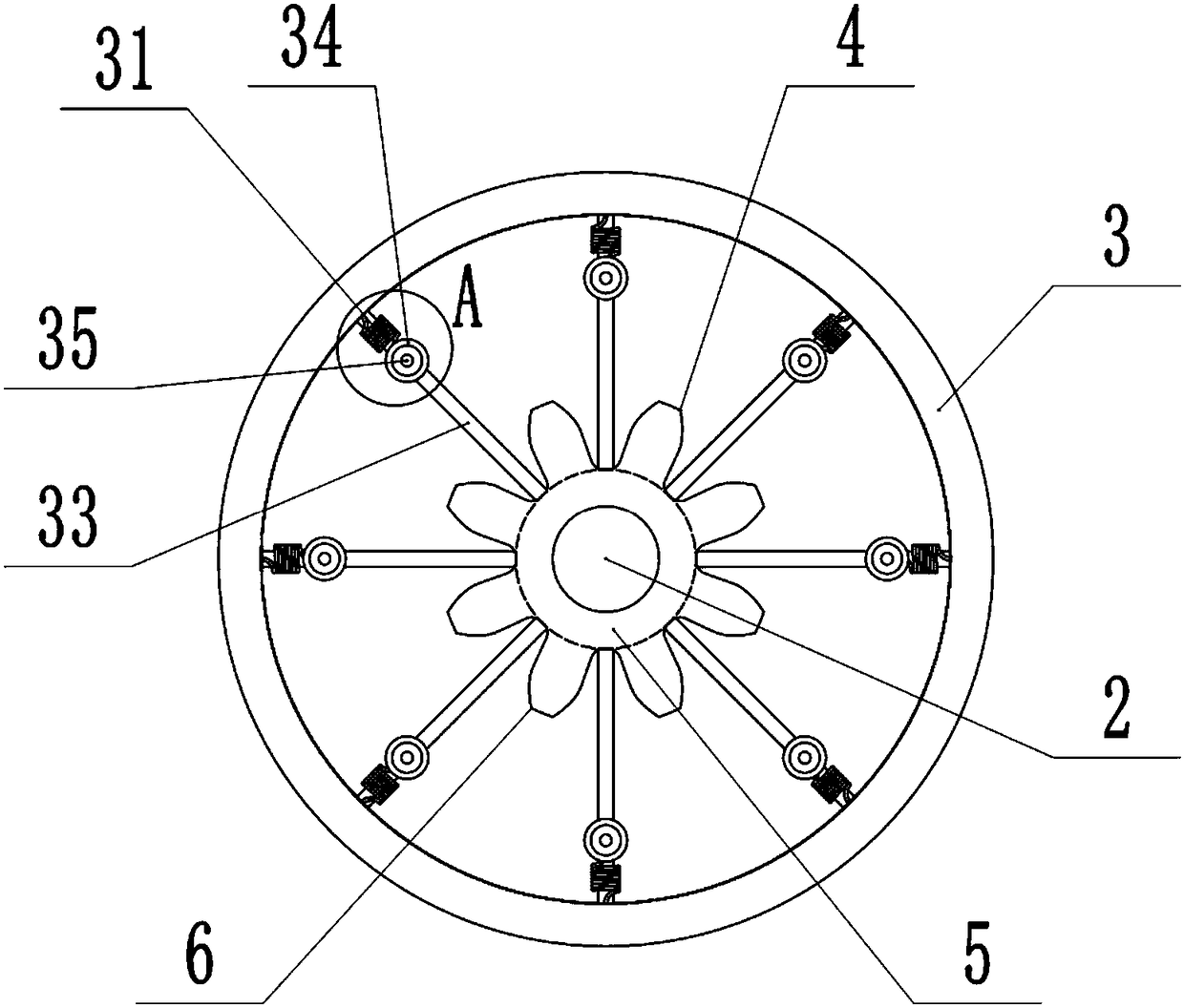

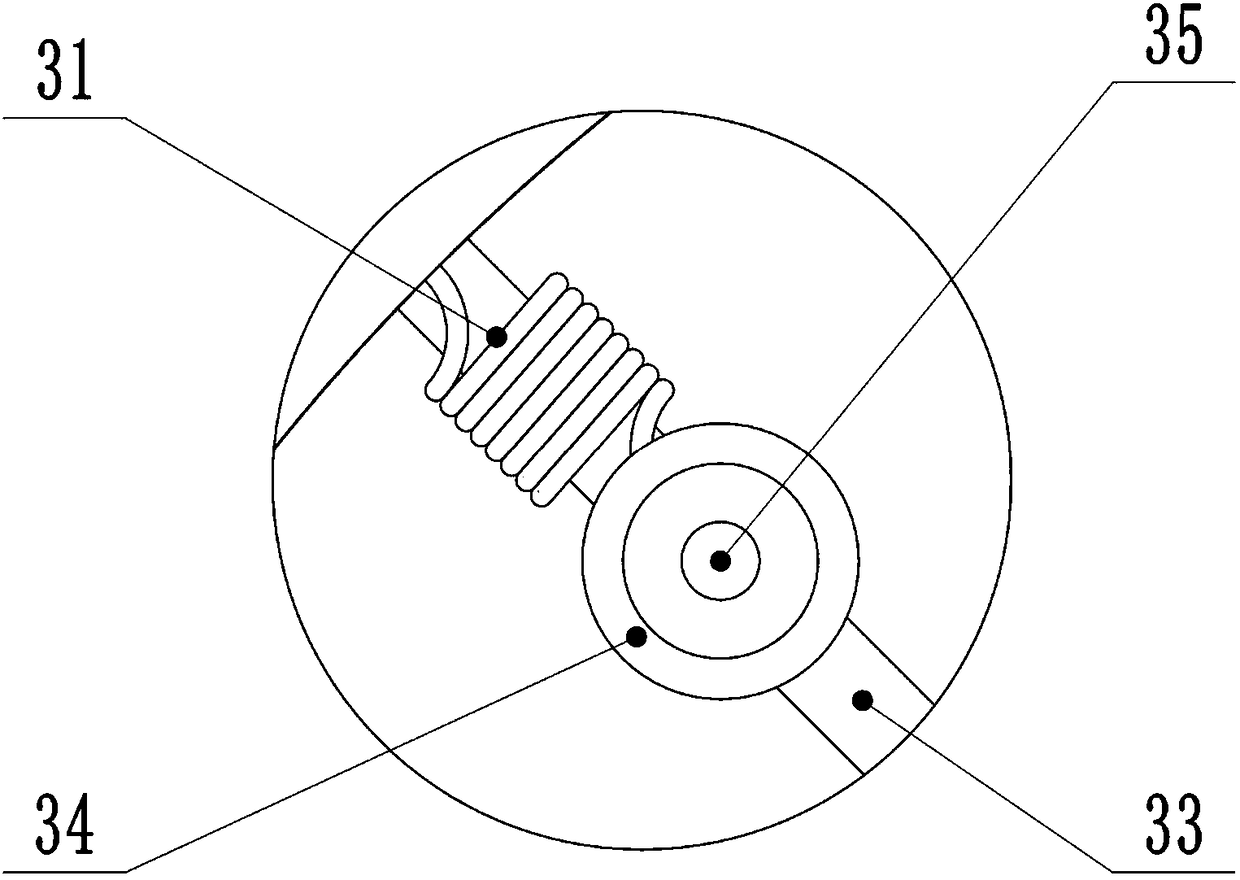

Automobile gear periphery polishing device

ActiveCN108296573ASolve grinding problemsSolve the problem of peripheral grindingGear teeth manufacturing toolsGear-cutting machinesMechanical engineeringEngineering

The invention relates to the field of metal product polishing, in particular to an automobile gear periphery polishing device. The automobile gear periphery polishing device comprises a first motor, afirst output shaft is arranged on the first motor and is fixedly connected with a rotating shaft, a polishing disc, a standard piece and a gear containing disc are connected to the rotating shaft from bottom to top, the polishing disc and the rotating shaft are rotationally connected, the standard piece is fixedly connected with the rotating shaft, the gear containing disc is fixedly connected with the rotating shaft, a cylindrical groove is formed in the polishing disc, a plurality of evenly-arranged sliding rods are arranged in the groove and are sleeved with springs, one ends of the springs are connected with the edge of the groove, the other sides of the springs are connected with sliding blocks connected to the sliding rods in a sliding manner, a second motor is fixedly connected tothe top faces of the sliding blocks, a second output shaft is arranged on the second motor, and a polishing roller is fixedly arranged on the second output shaft. Elasticity of the springs enables thesliding blocks to be attached to the standard piece all the time, the polishing roller is attached to a to-be-machined gear to achieve polishing, the first motor drives the rotating shaft to rotate,and full polishing of the periphery of the to-be-machined gear is achieved.

Owner:宁波隆锐机械制造有限公司

Piston pin grinding device for machining

InactiveCN113211200ASave time and costImprove grinding efficiency and qualityEdge grinding machinesRevolution surface grinding machinesPhysicsGrinding

The invention relates to the technical field of grinding devices, and particularly relates to a piston pin grinding device for machining. The piston pin grinding device for machining comprises a base, an air compressor is fixedly connected right above the base, a first supporting plate is arranged right above the base, the base is fixedly connected with the first supporting plate through a supporting rod, a second supporting plate is arranged right above the first supporting plate, and the first supporting plate is connected with the second supporting plate through a transmission rod. According to the piston pin grinding device for machining, through mutual cooperation of a first electromagnet, a second electromagnet, a third electromagnet, a pneumatic telescopic rod, a spring and the like, grinding of a chamfer of an inner ring of a piston pin is achieved, the problem that additional manual grinding is needed or special grinding equipment is independently used for grinding the chamfer of the inner ring of the piston pin is solved, the occupied space is reduced, and the equipment investment cost is reduced.

Owner:义乌市今朝创意设计有限公司

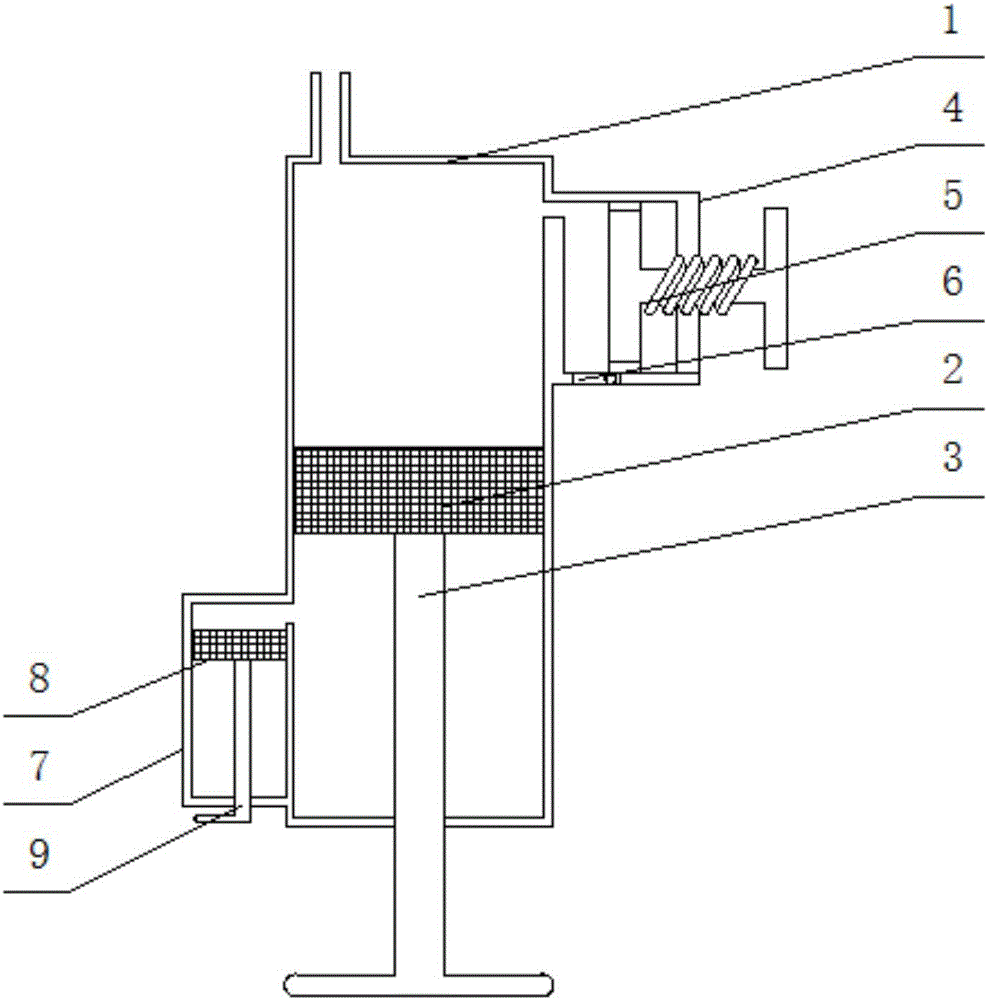

Drug feeding device with tablet crushing function

The invention discloses a drug feeding device with a tablet crushing function. The drug feeding device comprises a tube, a first push plug, a first push rod, a grinding device, a grinder, a baffle, a base, a secondary liquid suction device, a second push plug and a second push rod; the first push plug is arranged in the tube, the lower end of the first push plug is fixedly connected with the upper end of the first push rod, the lower end of the first push rod is located below the tube, and the grinding device is arranged on the right side of the tube. Compared with the prior art, the drug feeding device with the tablet crushing function has the advantages that the problems that an existing drug feeding device cannot directly grind tablets and is poor in dissolution effect are solved, the grinding device and the second liquid suction device are arranged, the tablets can be put in the grinding device to be directly ground into powder, the secondary liquid suction device can be used for repeated liquid suction, and drugs can be fully dissolved.

Owner:SUZHOU DERPIN MEDICAL SCI & TECH CO LTD

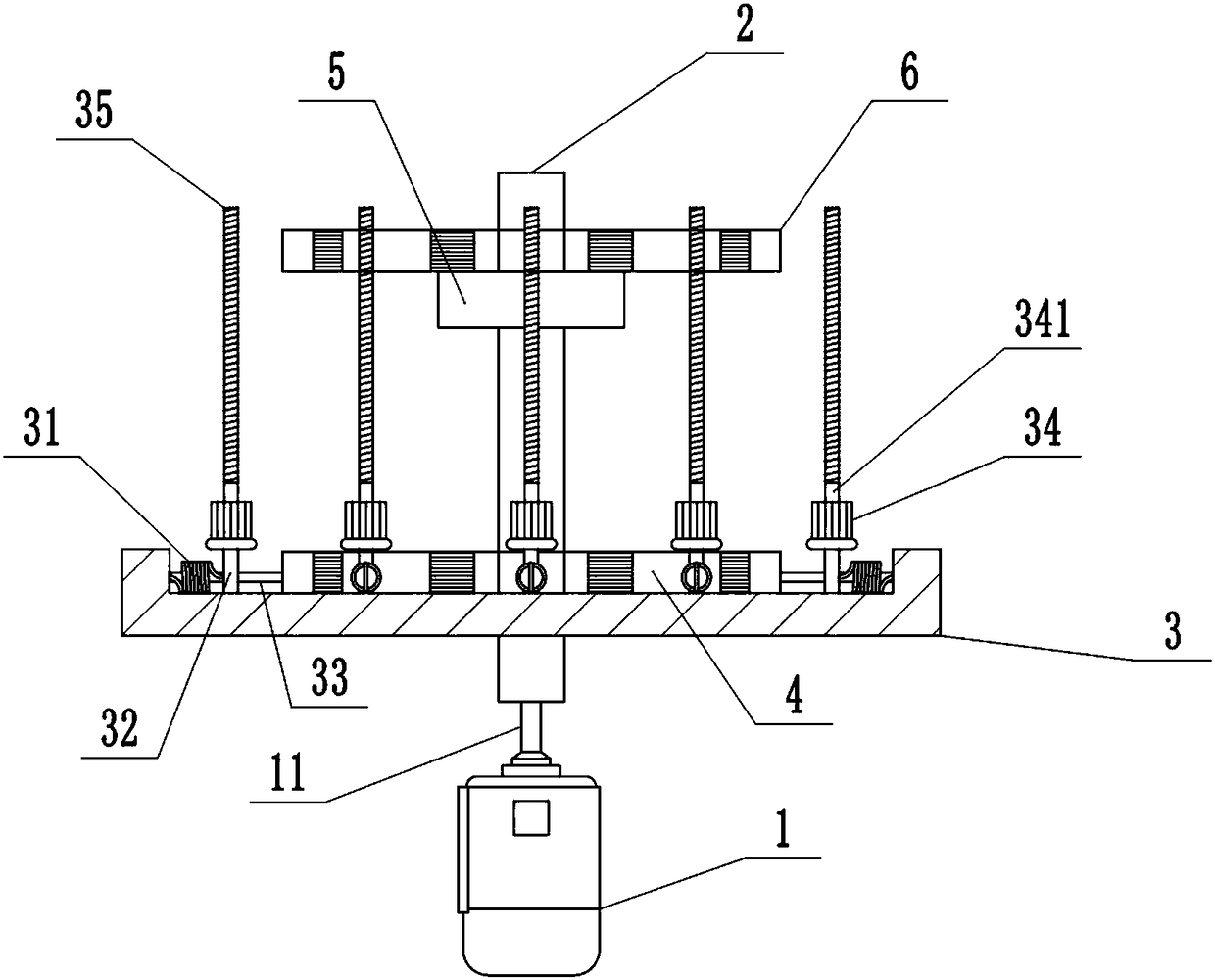

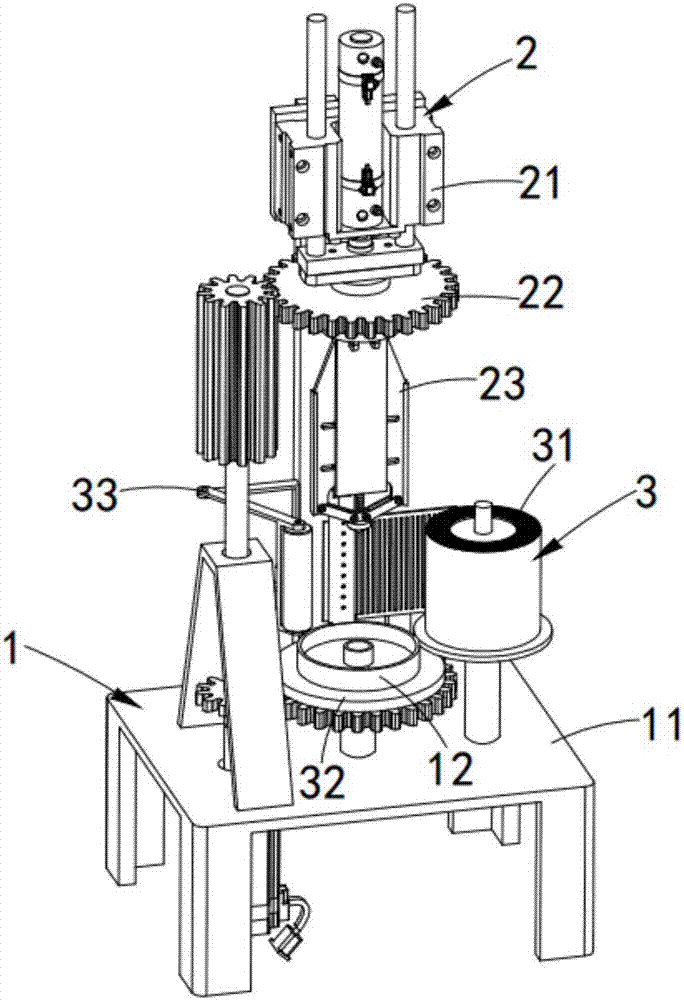

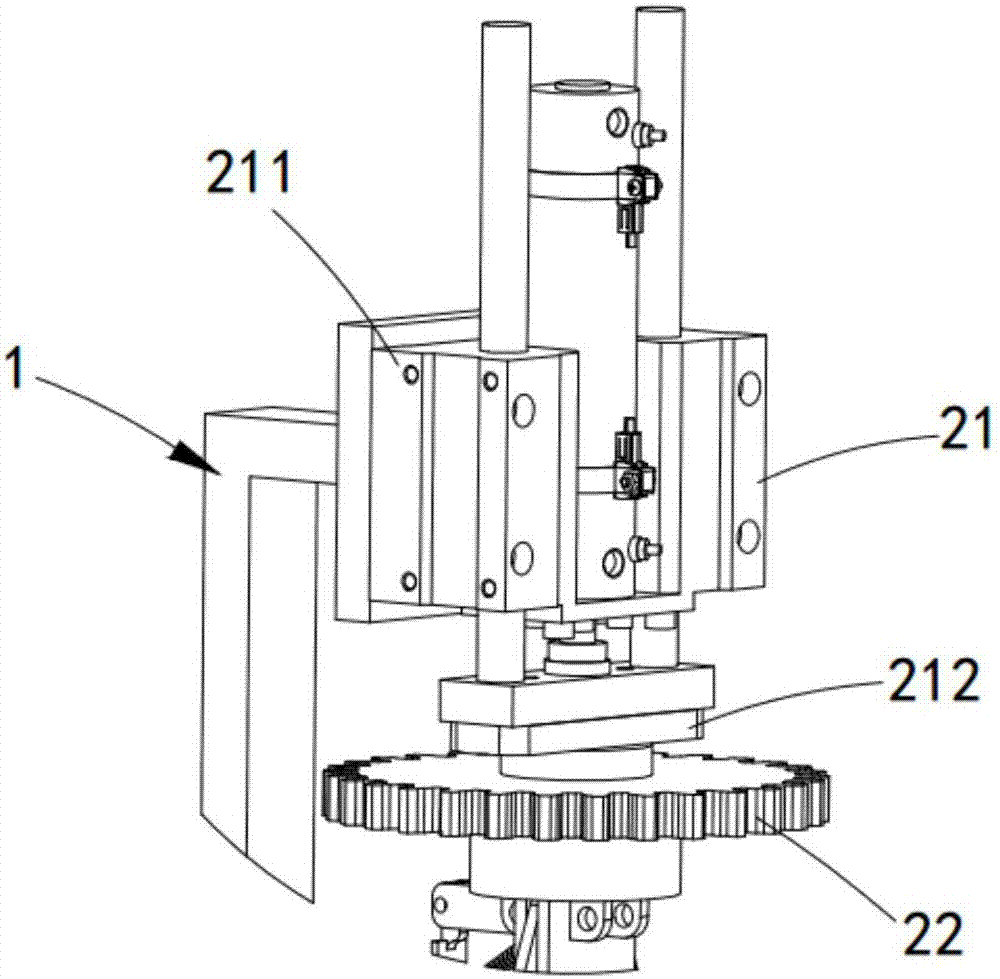

Dead head grinding and labeling device

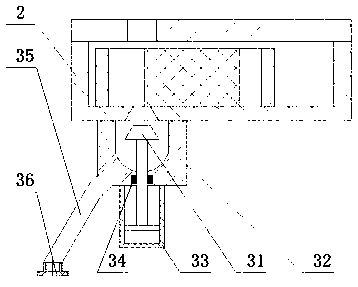

ActiveCN106881450ASolve grinding problemsImprove grinding accuracyMoulding toolsFoundry mouldsEngineeringGrinding process

The invention discloses a dead head grinding and labeling device. The dead head grinding and labeling device comprises a rack, a grinding mechanism, labeling mechanisms and a drive mechanism. The grinding mechanism is arranged on the top of the rack, can ascend and descend up and down along the rack and automatically grinds the inner wall of a dead head placed on a dead head positioning base at the bottom of the rack; and in the grinding process, the width of a grinding cutter in the grinding mechanism can be changed along with the diameter changes of the inner wall of the dead head in the grinding process. Meanwhile, the labeling mechanisms are arranged on the two sides of the dead head positioning base and automatically label the outer wall of the dead head, the purpose of thorough grinding of the inner wall of the dead head is achieved, automatic dead head outer wall label paper labeling is achieved, the dead head inner wall grinding precision is improved, the dead head label pasting speed is increased, and labeling consistency is guaranteed.

Owner:长兴鼎峰铸材科技股份有限公司

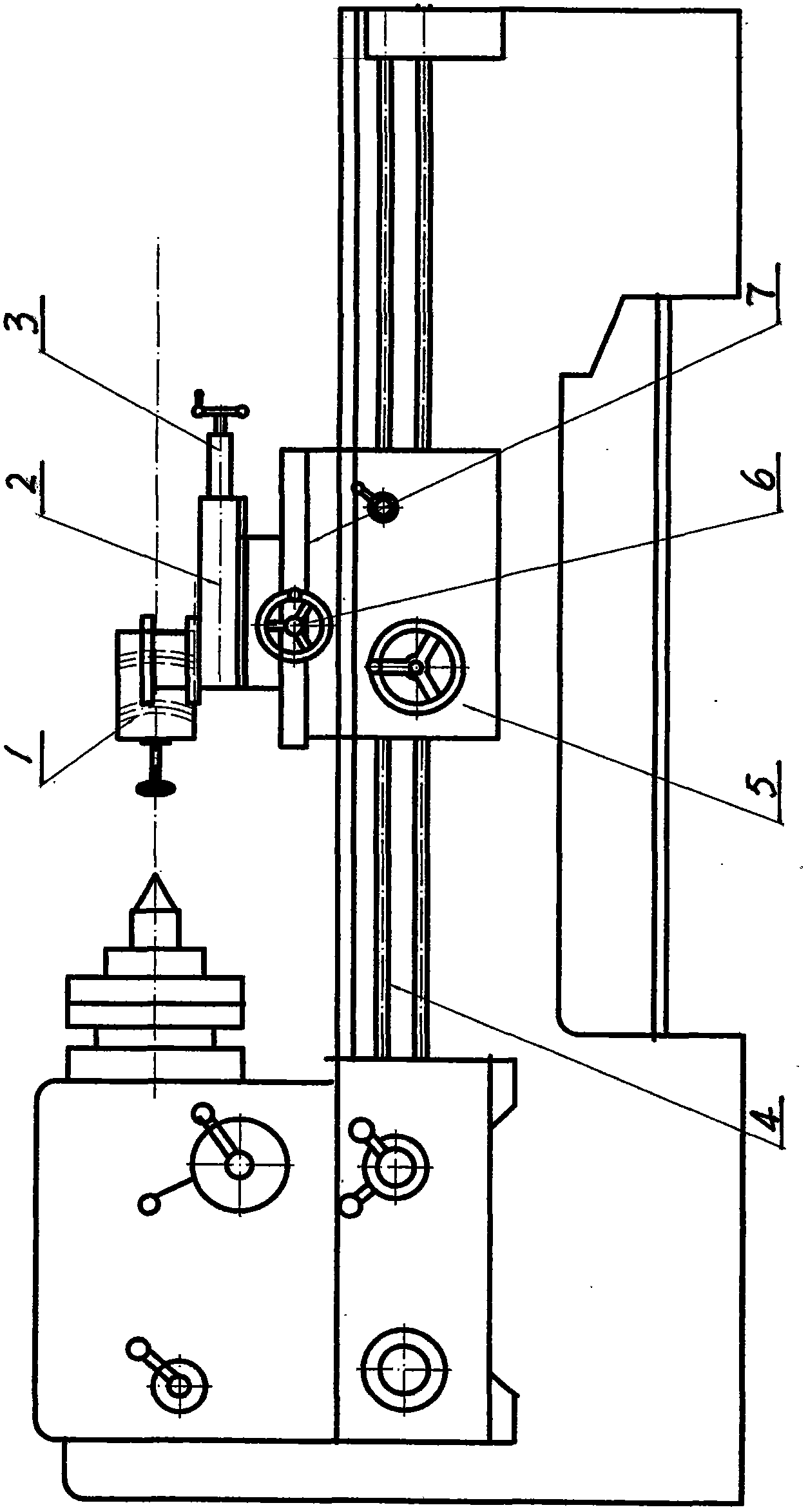

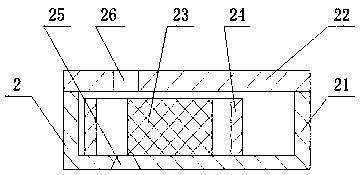

Accurate grinding method for tiny ball nuts

InactiveCN103419108ASolve grinding problemsAchieve precision machiningGrinding machinesBall screwSurface roughness

Disclosed is an accurate grinding method for tiny ball nuts. According to the method, the problems of the background technology that only ball nuts with pitch diameter larger than phi 16 can be machined even if a grinder is used, and the accuracy and the surface roughness cannot meet requirements even if the ball nuts can be machined. The method is characterized in that longitudinal lead screws 4, a transverse lead screw 6 and a knife rest T-shaped lead screw 3 on a common lathe are changed into precise ball screws. A large support plate 5, a small support plate 7 and a small support plate 2 are adjusted to be mutually matched. An electric spindle grinding head and a helix angle adjusting mechanism 1 are mounted on a knife rest. A grinding cooling lubrication system is arranged according to grinding requirements. The accurate grinding method has the advantages that the problem of grinding of tiny pitch-diameter ball nuts is solved, and the tiny pitch-diameter ball nuts are accurately machined; an internal thread grinder can be replaced, the internal thread grinding range is expanded; transformation costs for one grinder through the technology of the method is 6, 5000 yuan, but an internal thread grinder costs more than 300, 000 yuan; the method is used for grinding of ball nuts with pitch diameter larger than phi 16.

Owner:安顺虹特滚珠丝杠有限责任公司

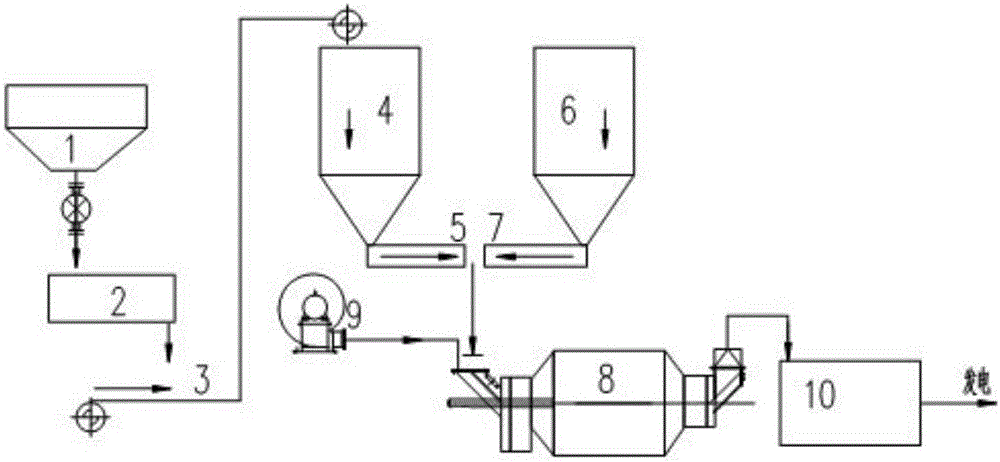

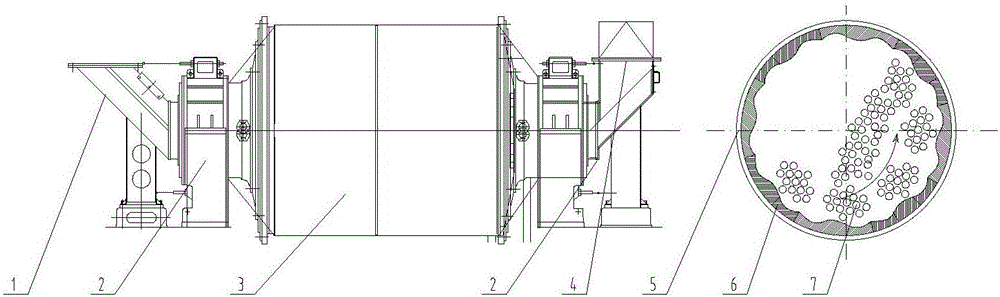

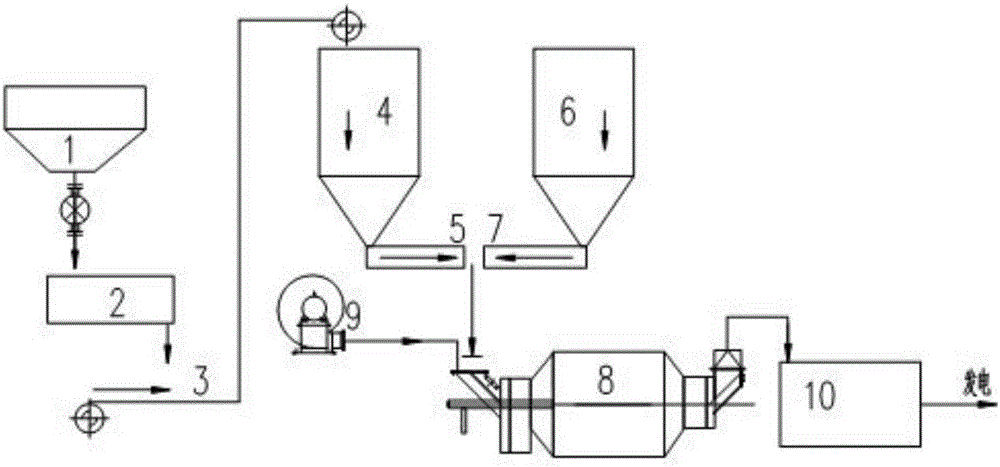

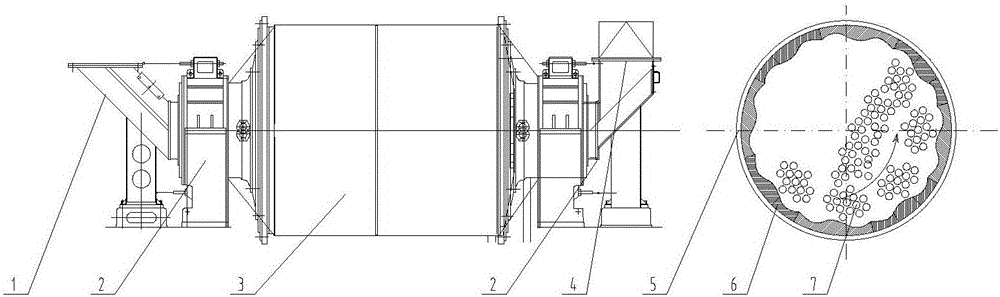

Semicoke grinding system and method

InactiveCN106513150ASimplify the production processReduce energy wasteGrain treatmentsLump/pulverulent fuel preparationPulverizerCoal

The invention discloses a semicoke grinding system and method. The semicoke grinding system comprises a pyrolyzing furnace, a high-temperature speed regulation feeder, a raw coal belt, a speed regulation coal feeder and a pulverizer. The high-temperature speed regulation feeder is arranged between the pulverizer and the pyrolyzing furnace. The speed regulation coal feeder is arranged between the pulverizer and the raw coal belt. The pulverizer comprises bearings and a barrel. The bearings are arranged on two sides of the barrel. The barrel comprises a feeding opening, a discharging opening, a housing, a lining plate and an insulating layer. The feeding opening and the discharging opening are respectively formed in two ends of the barrel. The housing is located on the surface layer of the barrel. The lining plate is arranged on the inner side of the housing, and is made of a high temperature resistant material. The insulating layer is arranged between the housing and the lining plate. The semicoke grinding system and method solve the grinding problem of high-temperature semicoke in a high temperature state, the high-temperature semicoke is ground into high-temperature coke powder through high temperature grinding, and high temperature coke powder is directly fed in a boiler for combustion through pneumatic transmission, so that the purpose that the high temperature semicoke is directly pulverized, and then the coal powder is transported for use is achieved.

Owner:北京神雾电力科技有限公司

Numerical-control-linkage-technology-based camshaft grinder abrasive belt grinding device

InactiveCN102107385AOvercoming easy blockageReduce grinding temperatureBelt grinding machinesBelt grindingEngineering

The invention relates to a numerical-control-linkage-technology-based camshaft grinder abrasive belt grinding device, which comprises a motor, a driving wheel and an abrasive belt, wherein the motor is directly connected with the driving wheel; and the abrasive belt is wound on the driving wheel, and is in contact connection with a tension wheel, a contact wheel and a transition wheel in turn and forms a closed cycle. The abrasive belt serves as a grinding medium, and the defect that blockage occurs easily in grinding wheel grinding is overcome; moreover, the abrasive belt has low grinding temperature, burn and other phenomena hardly occur on the surface of a workpiece, and high curvature can be achieved in a grinding area in case of sufficient abrasive particles due to high flexibility of the abrasive belt so as to solve the problem of grinding concave-convex wheels; moreover, the cam profile is more accurate, and the camshaft grinder has flexibility due to the adoption of the numerical control linkage technology.

Owner:SHANGHAI MACHINE TOOL WORK

High-temperature semicoke grinding system and grinding method

Owner:北京神雾电力科技有限公司

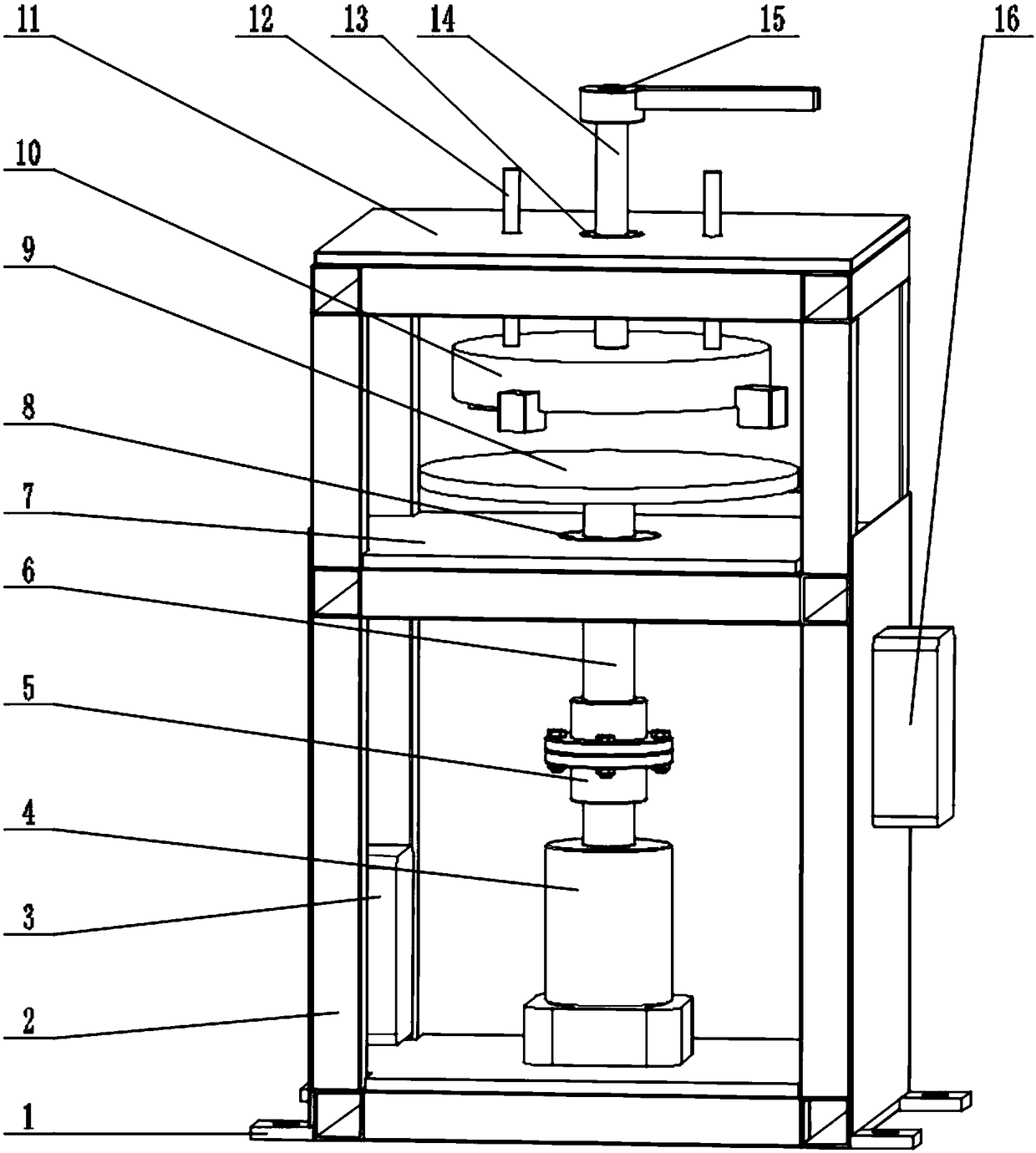

Grinding device for sealing surface of valve

InactiveCN108127548ASolve the accuracy problemSolve efficiency problemsGrinding drivesSeat surface grinding machinesDrive shaftEngineering

The invention discloses a grinding device for a sealing surface of a valve. The grinding device comprises a main bracket, wherein a motor is arranged in the main bracket; the motor is connected to a grinding disc through a transmission shaft; self-aligning four claws are arranged on the grinding disc in a matched manner; a guiding shaft and an adjusting screw are arranged on one surface, far fromthe grinding disc, of the self-aligning four claws; the motor is connected to a frequency converter and the frequency converter is connected to a control panel. The grinding device disclosed by the invention has the beneficial effects that the grinding device can solve the problem that the sealing surface of the valve ground by a company without a machining ability is low and the efficiency is low, and is controlled intelligently; and the grinding device solves the problem of grinding the sealing surfaces of a vale element of a safety valve, a valve clack of a stop valve, a flashboard of a sluice valve and the like.

Owner:SHANXI CHANGZHENG POWER TECH CO LTD

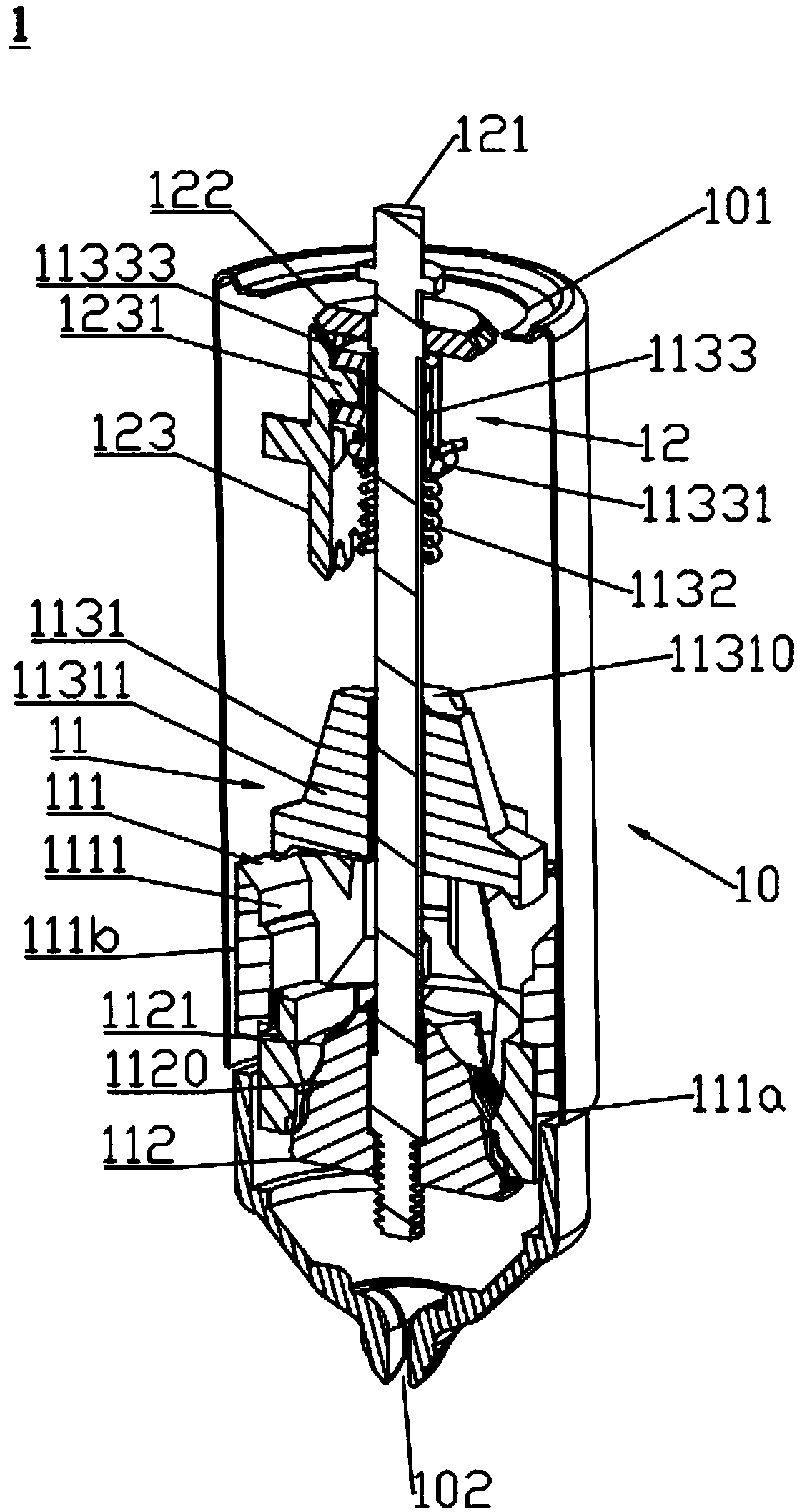

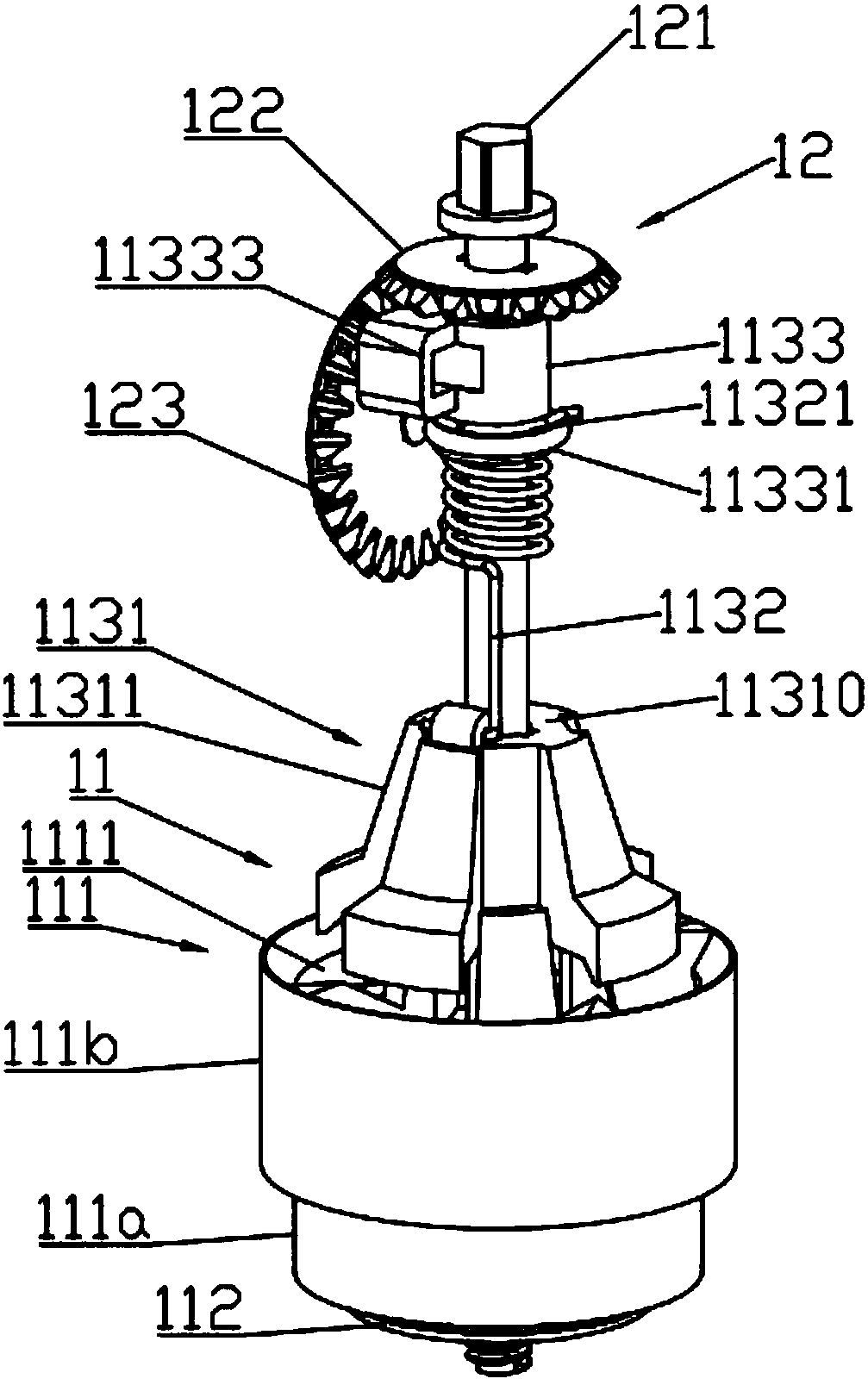

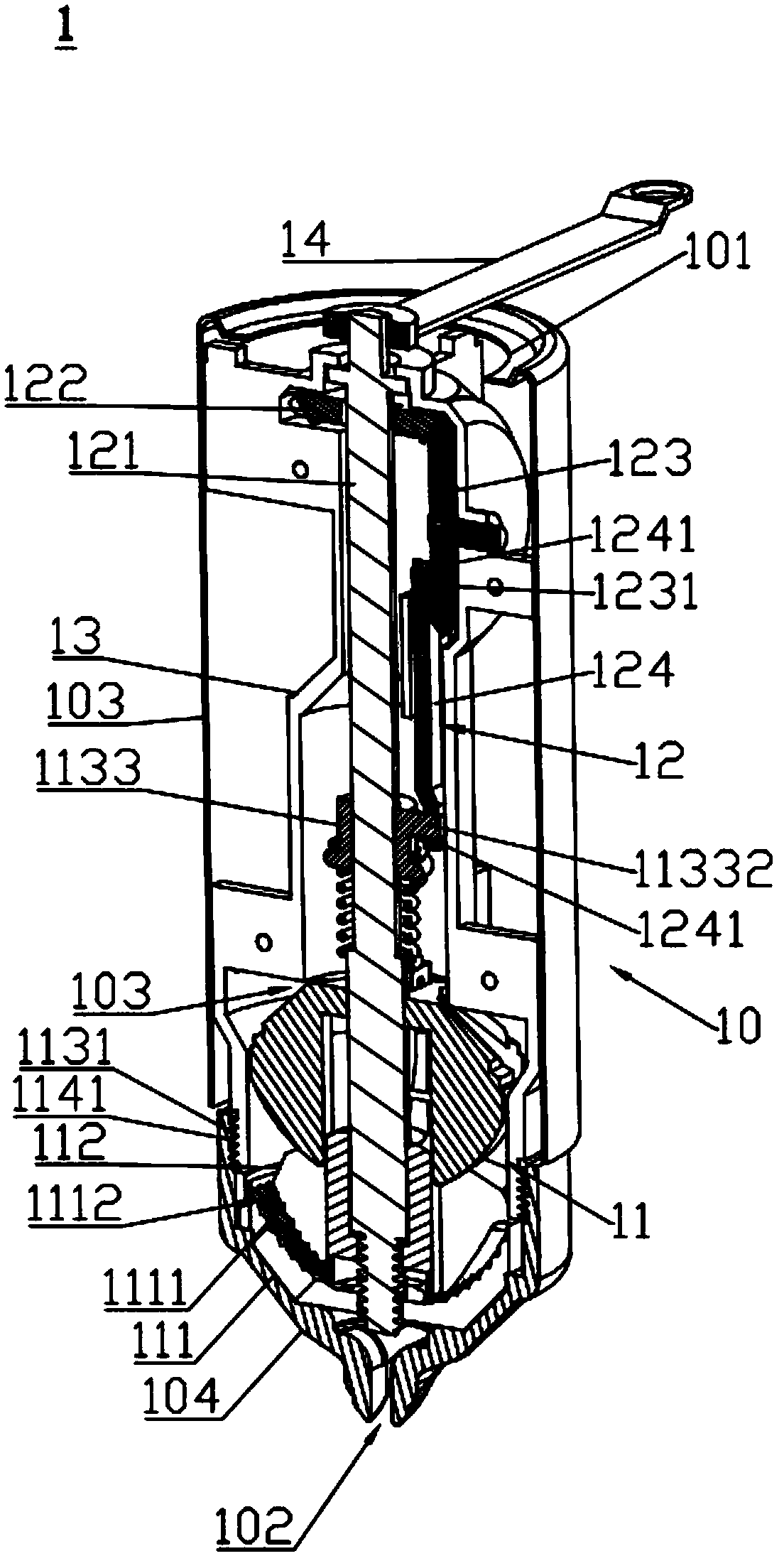

Grinder

PendingCN107669166ASolve grinding problemsImprove grinding efficiencyCoffee millsSpice millsEngineeringGrind

The invention relates to a grinder. The grinder comprises a grinding mechanism and a driving mechanism which drives the grinding mechanism; the grinding mechanism comprises a first grinding core, a second grinding core and a material pushing structure, the driving mechanism is connected with the first grinding core, the second grinding core and the material pushing structure, and the grinding surface of the first grinding core and the grinding surface of the second grinding core relatively rotate and drive the material pushing structure to move vertically. According to the grinder, the material pushing structure vertically moves to be near the grinding surface of the dynamic grinding core or the grinding surface of the static grinding core and constantly pushes materials to the portion between the grinding surface of the dynamic grinding core and the grinding surface of the static grinding core, and the dynamic grinding core and the static grinding core relatively rotate to grind the materials between the dynamic grinding core and the static grinding core, so that the purpose of grinding the oil materials is effectively achieved; moreover, the grinder has good grinding efficiency.

Owner:伍尚强

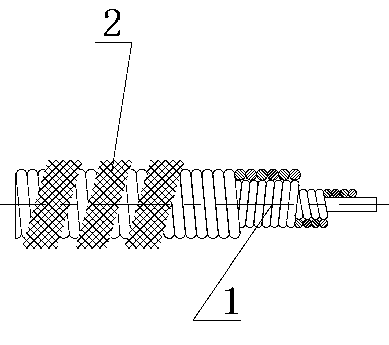

Tool for grinding S-shaped bent pipe

InactiveCN103659497ASolve grinding problemsSimple structureGrinding machine componentsRevolution surface grinding machinesEngineeringConductor Coil

The invention discloses a tool for grinding an S-shaped bent pipe. The tool comprises a grinding head and a flexible shaft. The grinding head is wrapped at one end of the flexible shaft, and the other end of the flexible shaft is connected with a driving device. The grinding head is a non-woven abrasive bandlet with a nylon base layer, and the non-woven abrasive bandlet with the nylon base layer is attached to and wrapped on the surface of one end of the flexible shaft through glue. The flexible shaft is provided with at least two steel wire winding layers, 4 to 12 steel wires are wound side by side to form each steel wire winding layer, and the steel wires are one of flat steel wires and round steel wires. By means of the tool for grinding the S-shaped bent pipe, the characteristics of the flexible shaft are used, the non-woven abrasive bandlet with the nylon base layer of the grinding head is combined with the flexible shaft, and therefore the problem of grinding the inner wall of a pipe which is in a non-linear shape or has a small inner diameter ranging from 6mm to 12mm and is of a long structure can be effectively solved, and the tool for grinding the S-shaped bent pipe is simple in structure, convenient to operate, high in automation degree and suitable for production.

Owner:SUHNER SUZHOU IND TECH

A soil analysis sample screening-grinding mobile all-in-one machine

ActiveCN103487301BReduce workloadLow pricePreparing sample for investigationSoil scienceAgricultural engineering

The invention relates to the technical field of soil sample screening-grinding equipment, in particular to a soil analysis sample screening-grinding mobile integrated machine for laboratory analysis. Its technical solution is: a mobile all-in-one machine, which is composed of a body, a feed processing system, a grinding system and a grading and screening system. The system is located in the middle and lower part of the box, and the grinding system is located in the middle and upper part of the box and is set in the center. According to the test, the all-in-one machine has more than 85% of the soil particles with a one-time crushed soil ≤ 2mm, and more than 65% of the soil particles with a crushed soil ≤ 0.15mm, and the screening pass rate is 100%. The invention uses common materials, is simple to operate, high in quality and high in efficiency, has no pollution to soil samples, and has reliable results.

Owner:FUJIAN NORMAL UNIV

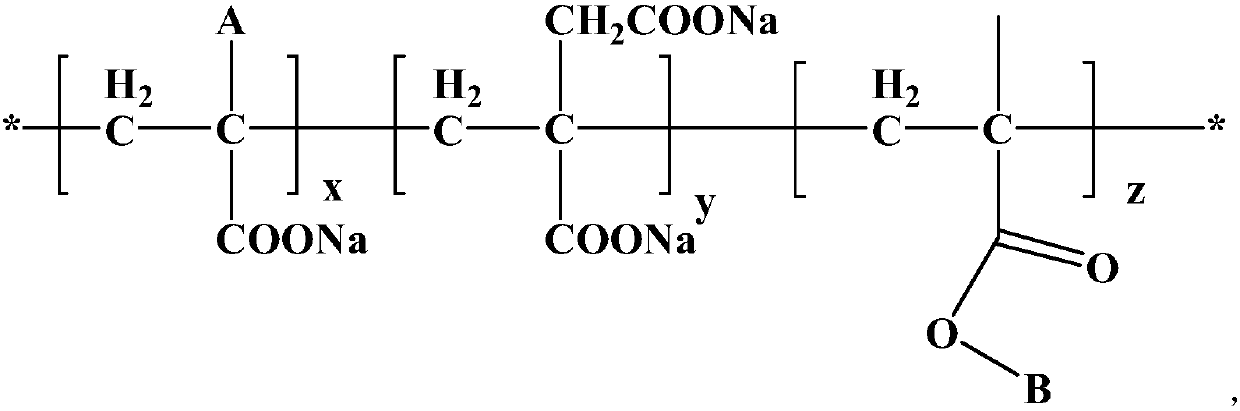

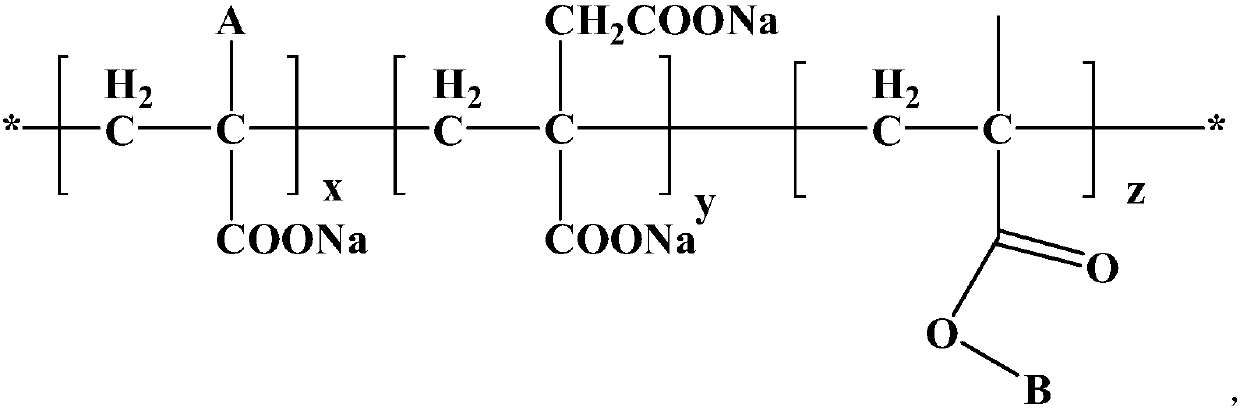

Waterborne high molecular ceramic pigment grinding aid dispersing agent as well as preparation method and application thereof

The invention discloses a waterborne high molecular ceramic pigment grinding aid dispersing agent as well as a preparation method and application thereof. According to the method, (methyl)acrylic acid, itaconic acid and monomer molecules (glycerol monomethyl acrylate or methacrylic acid D-pentadigalloylglucose amino ethyl ester) are dissolved into water to obtain a mixed solution; under the nitrogen gas protection condition, initiators are dripped into the mixed solution; after the dripping of the initiators is completed, constant temperature reaction is performed at 60 to 90 DEG C; after thereaction is completed, the temperature is lowered; then, the reaction liquid is regulated to the neutral state under the ice bath condition; the waterborne high molecular ceramic pigment grinding aiddispersing agent with the number-average molecular weight being 8000 to 15000 is obtained. The invention aims at providing the waterborne dispersing agent which can be used as the grinding aid for grinding and can also be used for well and stably dispersing particles.

Owner:SOUTH CHINA UNIV OF TECH

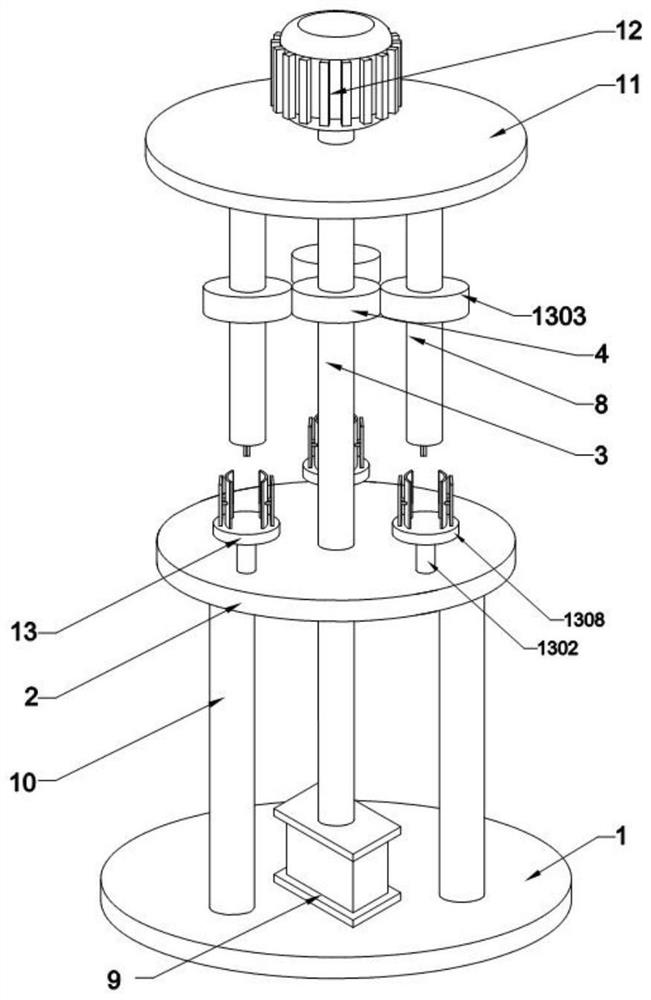

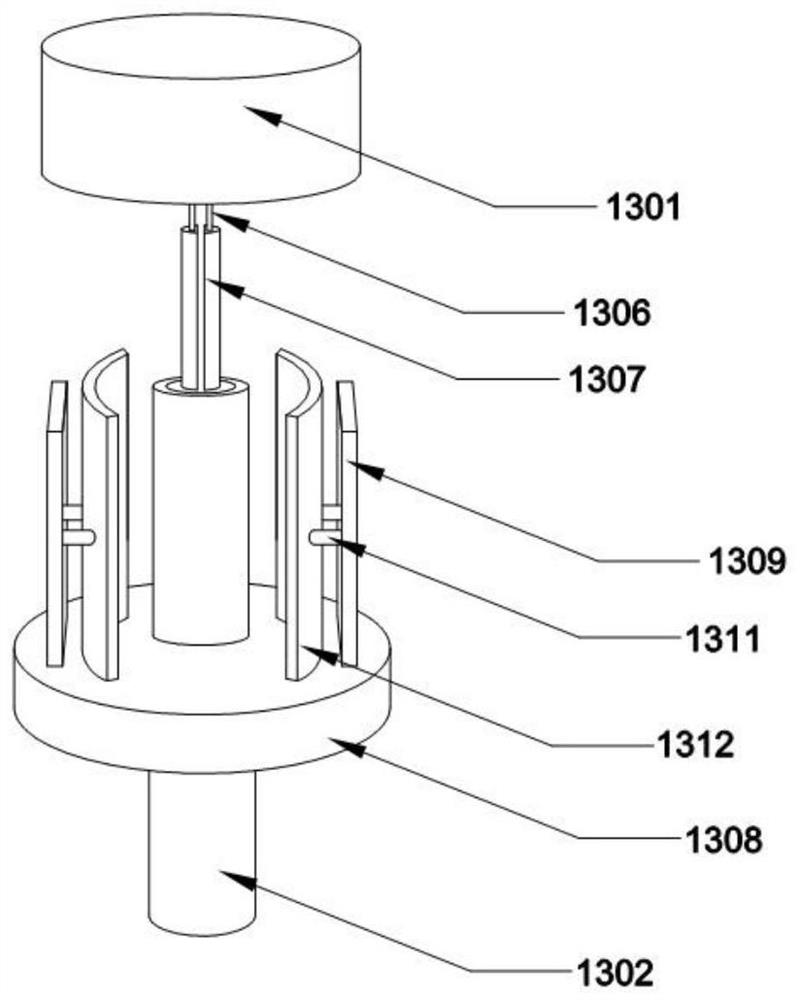

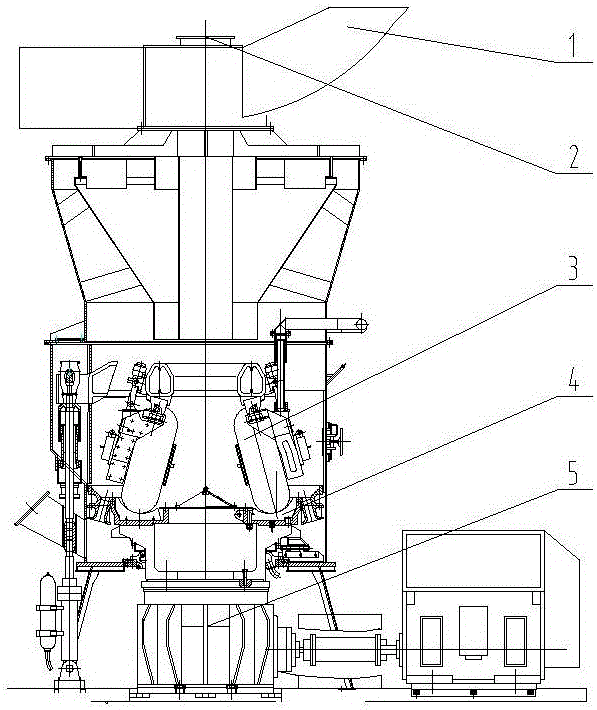

Step feeding and sample grinding machine with function of automatically cleaning and drying grinding apparatus with wet method

ActiveCN108722566AImprove work efficiencySolve grinding problemsHollow article cleaningGrain treatmentsEngineeringHigh pressure water

The invention relates to a step feeding and sample grinding machine with a function of automatically cleaning and drying grinding apparatus with a wet method. The step feeding and sample grinding machine comprises a grinding mechanism, a feed bowl, a discharging mechanism, a switching mechanism, a feeding mechanism, a high-pressure water supply mechanism, a compressing mechanism, a temperature sensing module, a control module and a drying module. According to the step feeding and sample grinding machine, multiple sample filling vessels are arranged on a feeding turnplate, the same or differentsamples can be continuously and automatically supplied in order for grinding, and the working efficiency is improved; furthermore, joint parts of the elements are of a sealing structure, so that cross contamination of the samples is prevented. With the adoption of the step feeding and sample grinding machine, the problem that only one sample can be ground through one-time feeding at present is solved, and after one-time automatic circulating operation of multiple samples, the feeding turnplate is replaced or cleaned for reuse.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

Method for preparation of dimethyl ether

ActiveCN102125854BImprove particle finenessImprove performanceMetal/metal-oxides/metal-hydroxide catalystsEther preparationRare earthColloid

The invention relates to a method for the preparation of dimethyl ether, which comprises the steps of: using the intermediate product of a copper-zinc-aluminum methanol synthesis catalyst, i.e. the carbonate mixture, as the component of the methanol synthesis catalyst, using rare earth modified gamma-alumina with low temperature activity as the component of the methanol synthesis catalyst, sufficiently mixing the two components according to the method based on colloidal sedimentation and mechanical mixing, and activating the mixture to obtain dimethyl ether. The method of the invention is simple in process and ensures the repeatability in catalyst preparation; the catalyst prepared according to the method has small particle size and high specific surface area; and the catalyst has high activity owing to tight contact and strong synergistic effect between the components.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Polishing and washing device of collection walnuts

ActiveCN109366308AStrong applicabilitySolve grinding problemsGrinding machinesGrinding work supportsHigh pressureLiquid waste

The invention provides a polishing and washing device of collection walnuts, and belongs to the technical field of collection treating equipment. The polishing and washing device structurally comprises a base, two recovering tanks, a polishing cavity, a polishing mechanism, a washing mechanism and recovering mechanisms, wherein the two recovering tanks are arranged at the lower part of the base; each recovering mechanism is arranged in the corresponding recovering tank; the polishing cavity is formed in the middle part of the base; the polishing mechanism is arranged in the polishing cavity; the washing mechanism is arranged in the base; the polishing mechanism comprises a driving assembly, a fixing assembly and a polishing assembly; the driving assembly is arranged in the base; the fixingassembly and the polishing assembly are arranged in the polishing cavity; the washing mechanism comprises a washing assembly and a mixing assembly; and the washing assembly and the mixing assembly are arranged at the rear part of the base, and communicate with each other. Through the adoption of the polishing and washing device disclosed by the invention, the polishing efficiency of the collection walnuts can be improved; and through high-pressure water spraying, impurities in cracks of walnuts can be thoroughly washed, and besides, oil and water in waste liquid can be separated for recycling.

Owner:马鞍山建腾新型建材有限公司

Novel gear machining deburring machine

InactiveCN113681390ASolve grinding problemsImprove applicabilityEdge grinding machinesGrinding carriagesElectric machineryManufacturing engineering

Owner:黄林枢

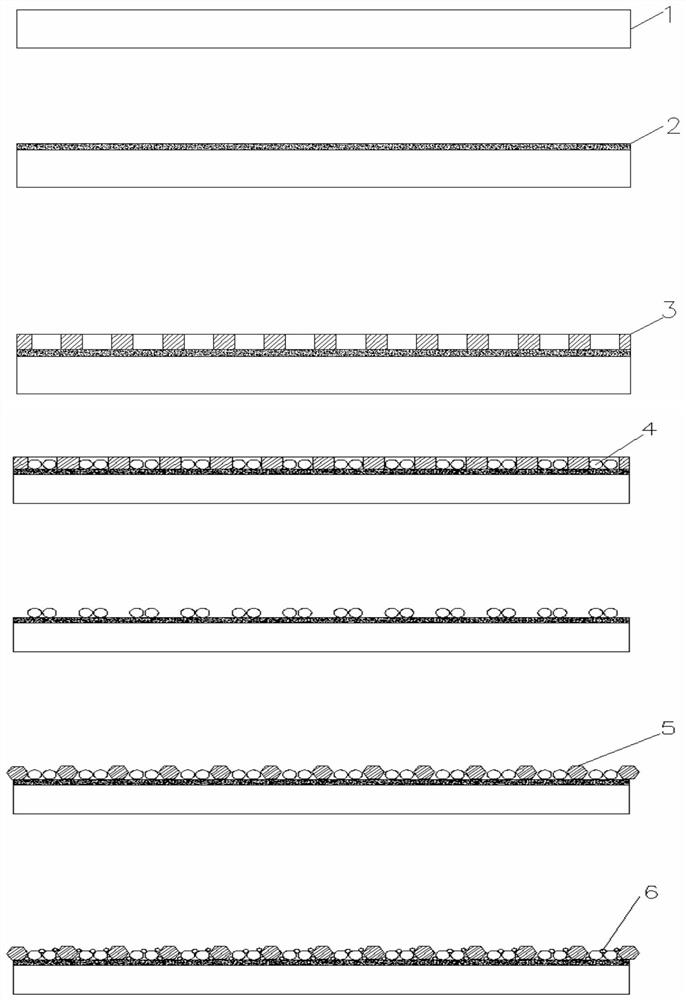

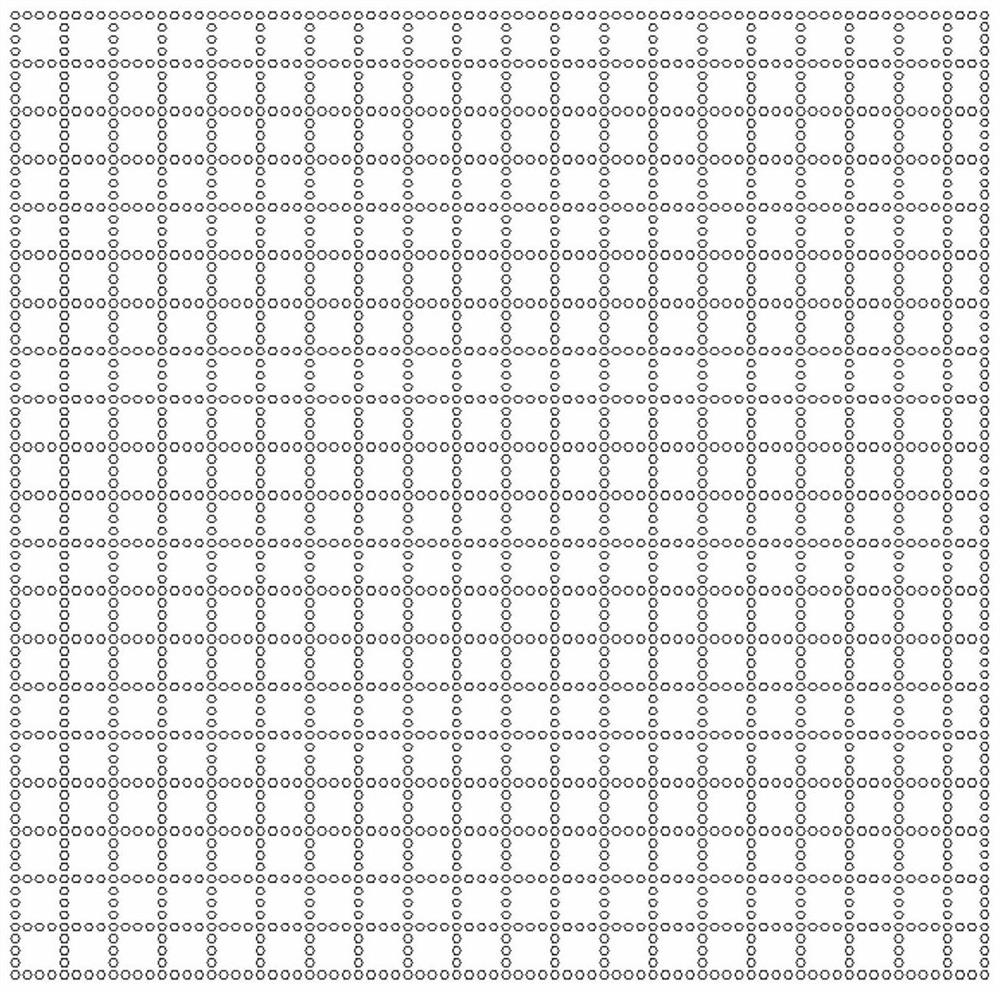

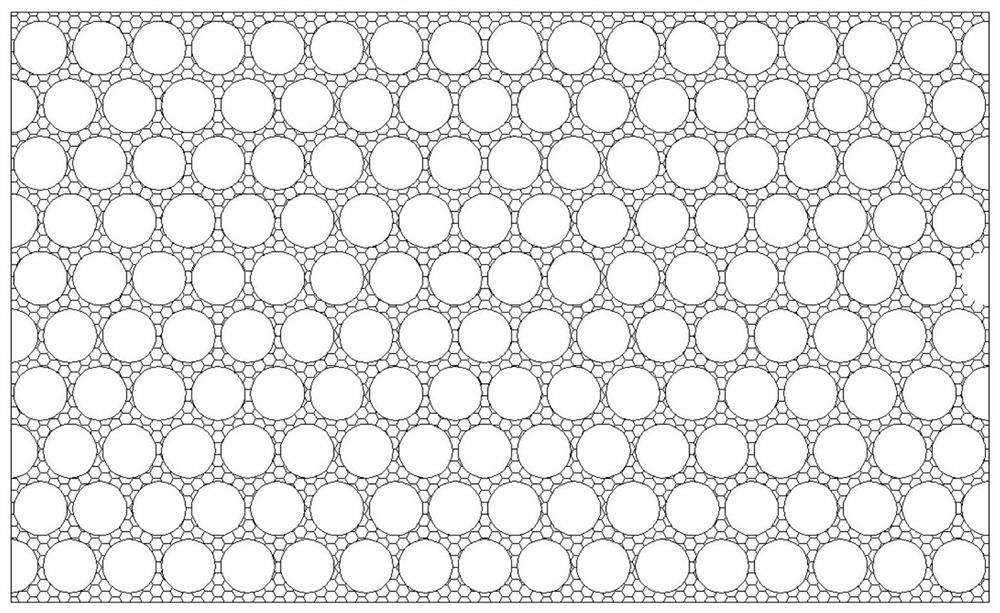

Special abrasive particle landform for steel grinding abrasive disk and diamond abrasive disk and preparation method of special abrasive particle landform

ActiveCN112677062AEasy to removeSolve grinding problemsGrinding machine componentsBonded abrasive wheelsMachiningDiamond

The invention discloses a special abrasive particle landform for a steel grinding abrasive disk and a diamond abrasive disk and a preparation method of the special abrasive particle landform. Abrasive particles are diamond abrasive particles, the diamond abrasive particles are arranged and distributed in a continuous linear or strip shape, and the adjacent linear or strip-shaped diamond abrasive particles form two or more closed heat dissipation areas in a surrounding manner. The shapes of the heat dissipation areas are axisymmetric. The heat dissipation areas are evenly distributed around the axis of the steel grinding abrasive disk. According to the special abrasive particle landform for the steel grinding abrasive disk, the arrangement of the diamond abrasive particles on the surface of the abrasive disk can be optimized, when steel is machined, the high heat dissipation effect is achieved, abrasive particle adhesion wear and the graphitization degree are reduced, the machining efficiency can be improved easily, and the diamond abrasive disk has higher economical efficiency and high economic value when applied to steel machining.

Owner:江苏韦尔博新材料科技有限公司

A kind of processing equipment of aluminum alloy bar

ActiveCN109676450BSolve grinding problemsAvoid affecting the grinding effectRevolution surface grinding machinesGrinding drivesMaterial supplyWaste material

The invention discloses machining equipment of aluminum alloy rods, and belongs to the field of aluminum alloy machining equipment. The machining equipment comprises a material supply device, a transfer device, a drilling and milling device and a grinding device. The material supply device comprises a material supply assembly and a material control assembly. The grinding device comprises a bearinggrinding assembly, a supporting assembly, a driving assembly and two pressing assemblies. The bearing grinding assembly is arranged at the position of one end of the transfer device and is in linkedcooperation with the transfer device, the supporting assembly is mounted on the side wall of the bearing grinding assembly, the driving assembly is mounted on the supporting assembly and is in transmission connection with the two pressing assemblies, the drilling and milling assembly comprises a positioning assembly and a tapping and milling assembly, and the positioning assembly is arranged between the other end of the transfer device and the tapping and milling assembly. The aluminum alloy rods can be ground and drilled and milled alternately, waste can be recycled and treated in a centralized manner while the aluminum alloy rods are machined, and therefore the overall practicality of the machining equipment is improved.

Owner:百色市彩虹铝业有限公司

Cutting device and clamping device

PendingCN111958455AImprove cutting accuracyIncrease contact areaGrinding machinesGrinding feedersPhysicsEngineering

The invention discloses a cutting device and a clamping device. The cutting device comprises a cutting wheel and a clamping device body, the clamping device body comprises a first clamping piece and asecond clamping piece, a first surface of the first clamping piece and a second surface of the second clamping piece opposite to the first surface form a clamping surface, and the cutting wheel is perpendicular to the clamping surface; the first surface and the second surface are arc-shaped, and the curvature of the first surface, the curvature of the second surface and the curvature of the cutting surface of the cutting wheel are the same. According to the cutting device and the clamping device, the clamping surface of the clamping device body is arc-shaped, and the curvature of the clampingsurface is the same as that of the cutting surface of the cutting wheel, so that the cutting wheel makes contact with multiple products at the same time when cutting the products clamped on the clamping surface, cutting is completed at the same time, the problem that the multiple products are ground by the cutting wheel due to different cutting time when being cut at the same time is solved, therefore, the cutting precision and cutting efficiency are improved, and the service life of the cutting wheel is prolonged; meanwhile, the cutting wheel is always in contact with the multiple products during cutting, so that the contact area is large, and the swinging of the cutting wheel is reduced.

Owner:SHENZHEN TATFOOK FANGYUAN MOLDING TECH CO LTD

Mirror finishing process method for piston pin for locomotive

The invention relates to the technical field of piston pins, in particular to a mirror finishing process method for a piston pin for a locomotive. The process route for machining the mirror surface of the piston pin comprises the following steps: forging a blank, annealing, roughly turning the appearance, semi-finely turning the appearance, drilling an oil hole and pre-drilling, carburizing, finely turning two ends, drilling the oil hole, quenching, correcting central holes at two ends, roughly grinding an outer circle, finely turning the appearance, semi-finely grinding the outer circle, grinding an inner hole, polishing the oil hole, marking, finely grinding the outer circle, machining the outer circle by a mirror surface, and packaging and warehousing after flaw detection. The process route is reasonable in process allowance design, balanced in production takt, high in machining efficiency, low in cost and high in generalization performance, and machining equipment is universal equipment. After quenching, the allowance of the outer circle and the inner hole is removed, and then the oil hole is polished, so that the influence of the oil hole on the roughness of the whole outer cylindrical surface during mirror processing of the outer circle can be effectively ensured. The oil hole polishing tool is self-made according to product characteristics, the problem that small holes are not polished by standard polishing accessories is solved, and the oil hole polishing tool has extremely high practicability and economical efficiency.

Owner:CRRC QISHUYAN CO LTD

Brick carving and tile surface carving and grinding machine

ActiveCN106113282BSolve grinding problemsQuick sandingWorking accessoriesStone-like material working toolsBrickEngineering

The invention provides a carving and polishing machine for a brick carved tile face. The carving and polishing machine comprises a frame, a pulley, gears, motors, a dust cover, a circular cutter and a cambered millstone. The two motors are arranged at the rear part of the frame. The circular cutter is driven by one motor to rotate, and the cambered millstone is driven by the other motor to rotate. A right-angle side of a brick face is cut off by the circular cutter. A slope formed after cutting-off is polished into a cambered surface by the cambered millstone. Quick polishing and molding of the brick carved tile face are realized through mechanical movement, and mechanical movement replaces conventional manual polishing and molding, so that labor is liberated, and the labor cost is reduced; and the tidy tile face and the smooth and clean curved surface can be ensured when batch production is completed.

Owner:积石山县禹王砖雕有限公司

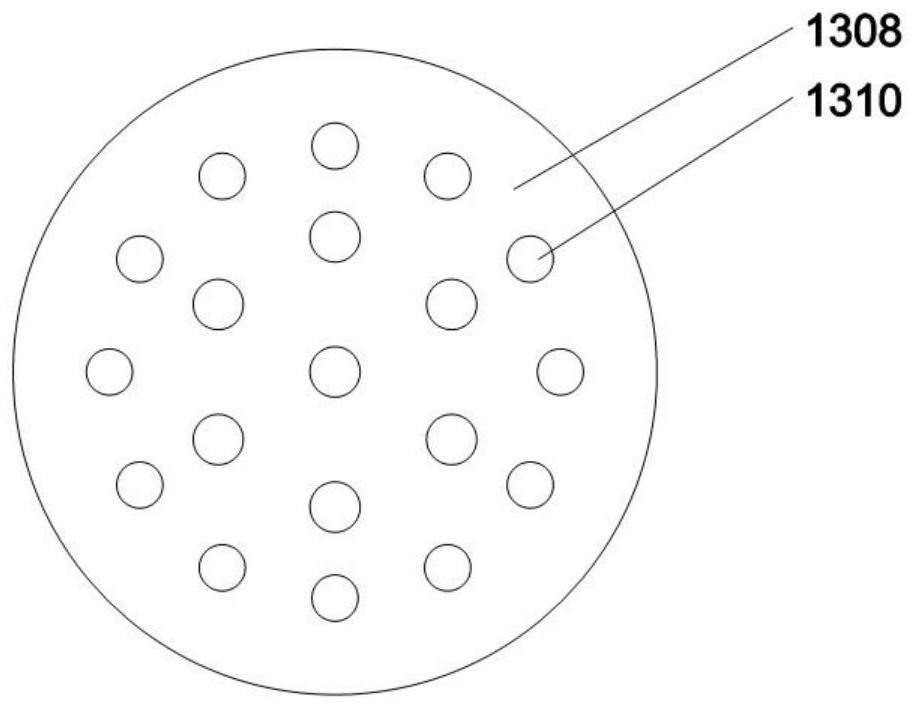

Pouring transformer mold honeycomb hole cover

The invention discloses a honeycomb hole cover board of a pouring transformer mold. The honeycomb hole cover board is characterized in that a storage groove corresponding to a filling port in shape is formed in the cover board; honeycomb holes are evenly distributed in the bottom of the storage groove. By adopting the honeycomb hole cover board, the problems of polishing and repairing a transformer casting body are solved; the product quality and the production efficiency of the pouring transformer are improved; the honeycomb hole cover board has the advantages of being environment-friendly and the like.

Owner:陕西正泰智能电气有限公司

A step-feed mill prototype for automatic wet cleaning and drying of abrasive tools

ActiveCN108722566BImprove work efficiencySolve grinding problemsHollow article cleaningGrain treatmentsProcess engineeringIndustrial engineering

The invention relates to a step feeding and sample grinding machine with a function of automatically cleaning and drying grinding apparatus with a wet method. The step feeding and sample grinding machine comprises a grinding mechanism, a feed bowl, a discharging mechanism, a switching mechanism, a feeding mechanism, a high-pressure water supply mechanism, a compressing mechanism, a temperature sensing module, a control module and a drying module. According to the step feeding and sample grinding machine, multiple sample filling vessels are arranged on a feeding turnplate, the same or differentsamples can be continuously and automatically supplied in order for grinding, and the working efficiency is improved; furthermore, joint parts of the elements are of a sealing structure, so that cross contamination of the samples is prevented. With the adoption of the step feeding and sample grinding machine, the problem that only one sample can be ground through one-time feeding at present is solved, and after one-time automatic circulating operation of multiple samples, the feeding turnplate is replaced or cleaned for reuse.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com