High-temperature semicoke grinding system and grinding method

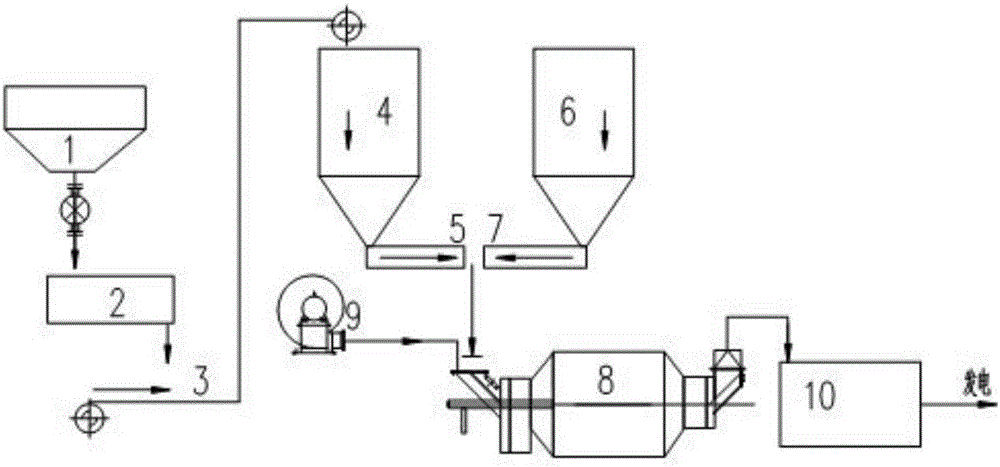

A high-temperature semi-coke and high-temperature technology, which is applied in the field of high-temperature semi-coke grinding systems, can solve the problems of large cooling water consumption, increase semi-coke production costs, and limit material temperature, so as to simplify the production process, improve grinding efficiency, Reduce the effect of intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

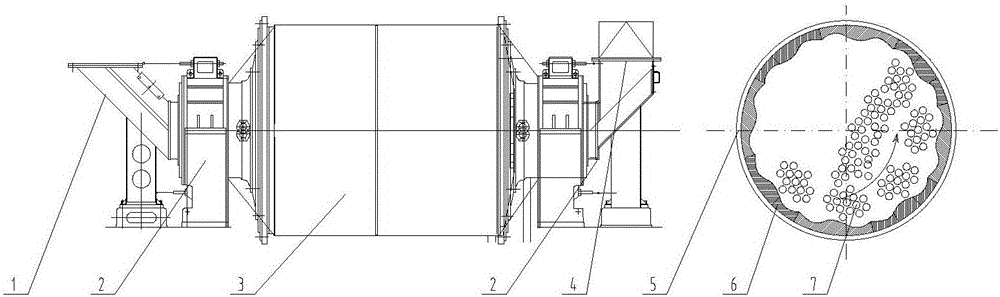

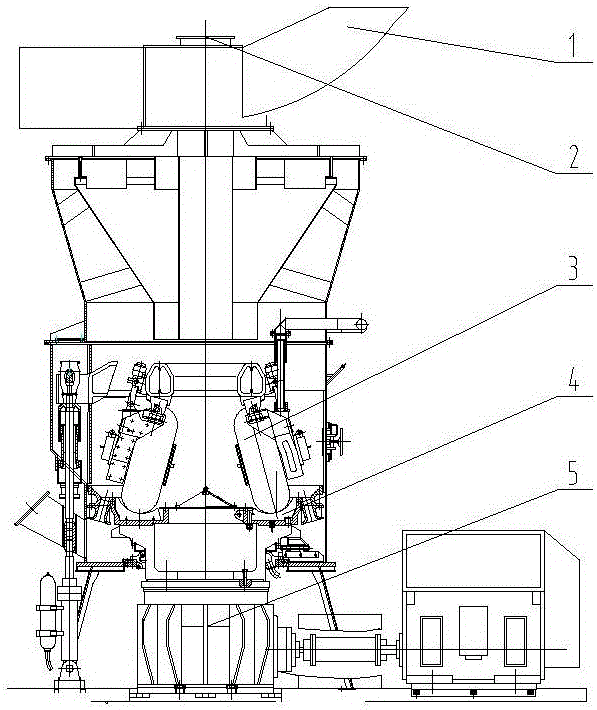

Method used

Image

Examples

Embodiment 1

[0090] This embodiment proposes a high-temperature semi-coke grinding system and grinding method. The lignite is dried and then enters the pyrolysis furnace to generate semi-coke. After the powder enters the pulverized coal boiler for combustion, steam is sent to the steam turbine to generate electricity. The technical data of lignite are shown in Table 1:

[0091] Table 1: Technical data of lignite:

[0092]

[0093] The amount of lignite coal is designed to be 120t / h, and it enters the dryer through the feeder. After drying, the moisture Mt of the lignite is ≤ 10%, and then enters the pyrolysis furnace for pyrolysis.

[0094] Semi-coke is produced after lignite pyrolysis, the output is 65t / h, the semi-coke outlet temperature is 700°C, and the semi-coke parameters are as follows:

[0095] Table 2: High temperature semi-coke parameters

[0096]

[0097] The high-temperature semi-coke and the raw coal in the raw coal bunker enter the coal mill according to the ratio of 2...

Embodiment 2

[0104] This embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as described below. The technical data of lignite are shown in Table 1:

[0105] Table 1: Technical data of lignite:

[0106]

[0107] The amount of lignite coal is designed to be 110t / h, and it enters the dryer through the feeder, and the moisture Mt of the dried lignite is ≤ 10%, and then enters the pyrolysis furnace for pyrolysis.

[0108] Semi-coke is produced after lignite pyrolysis, the output is 60t / h, the semi-coke outlet temperature is 900°C, and the semi-coke parameters are as follows:

[0109] Table 2: High temperature semi-coke parameters

[0110]

[0111] The high-temperature semi-coke and the raw coal in the raw coal bunker enter the coal mill at a ratio of 1:1. The raw coal parameters in the raw coal bunker are as follows:

[0112] Table 3 Basic data of raw coal in raw coal bunker

[0113]

[0114] After entering the c...

Embodiment 3

[0118] This embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as described below. The technical data of lignite are shown in Table 1:

[0119] Table 1: Technical data of lignite:

[0120]

[0121] The amount of lignite coal is designed to be 100t / h, and it enters the dryer through the feeder, and the moisture Mt of the dried lignite is ≤ 10%, and then enters the pyrolysis furnace for pyrolysis.

[0122] Semi-coke is produced after lignite pyrolysis, the output is 60t / h, the semi-coke outlet temperature is 700°C, and the semi-coke parameters are as follows:

[0123] Table 2: High temperature semi-coke parameters

[0124]

[0125] The high-temperature semi-coke and the raw coal in the raw coal bunker enter the coal mill at a ratio of 1:2. The raw coal parameters in the raw coal bunker are as follows:

[0126] Table 3 Basic data of raw coal in raw coal bunker

[0127]

[0128] After entering the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com