Brick carving and tile surface carving and grinding machine

A technology for tile surface and brick carving, applied in work accessories, stone processing tools, stone processing equipment, etc., can solve problems such as low productivity, poor economic benefits, time-consuming and laborious, and achieve the effect of ensuring smoothness and aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

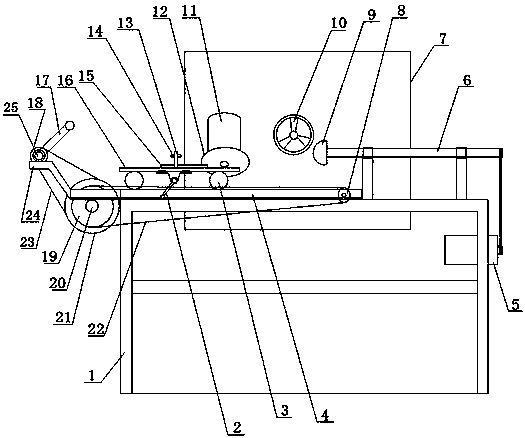

[0025] First put the bricks to be polished on the surface of the block 16, a right angle of the block is aligned with the right-angle block 15 on the block 16, and the movable rod 13 on the block 16 is pressed down by adjusting the handle 2, and the upper end of the movable rod 13 is connected The pressing plate 14 of brick is compressed.

[0026] Turn on the motor Ⅱ11, the motor Ⅱ11 drives the circular cutter 12 to rotate, the rotating shaft Ⅲ25 is driven to rotate by shaking the handle 17, the gear Ⅰ18 at one end of the rotating shaft Ⅲ25 rotates, the gear Ⅰ18 drives the gear Ⅱ19 to rotate through the chain Ⅱ23, and the coaxial gear with the gear Ⅱ19 Ⅲ21 rotates, the gear Ⅲ21 drives the chain Ⅰ22 to move, and the movement of the chain Ⅰ22 drives the pulley 16 to move forward. The bricks on the pulley 16 are cut off by the rotating circular cutter 12 during the forward movement, and the bevel surface of the masonry forming.

[0027] The pulley 16 continues to move forward, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com