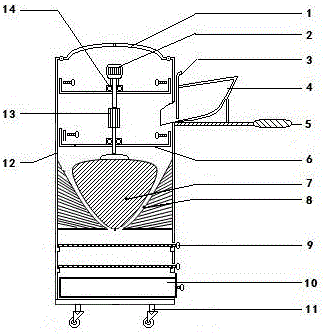

A soil analysis sample screening-grinding mobile all-in-one machine

An all-in-one, mobile technology, applied in the preparation of test samples, etc., can solve the problems of uneven crushing of soil analysis samples, high labor intensity, and low efficiency, and achieve low noise, good crushed soil quality, and simple manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

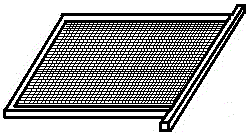

[0028] (1) Place the naturally dried soil sample on the feed hopper 4, and tap a large soil block with a rubber hammer. At this time, the mesh baffle plate 3 will block impurities such as plant roots, solid waste and stones in the sample. In the feed hopper 4, fine particles enter the integrated machine.

[0029] (2) Insert the 10-mesh screen 9, replace the corresponding coupling 13 according to the required soil particle size, turn on the servo motor 2 and control the running speed, and start grinding.

[0030] (3) After grinding, take out the sample collection box 10, check whether the ground soil sample meets the requirement of 2 mm, if it is qualified, pack it into a bag for the next step of experimental data determination; if the amount of ground sample does not meet the experimental requirements, Then repeat the above procedure for secondary grinding.

Embodiment 2

[0032] (1) Place the naturally dried soil sample on the feed hopper 4, and tap a large soil block with a rubber hammer. At this time, the mesh baffle plate 3 will block impurities such as plant roots, solid waste and stones in the sample. In the feed hopper 4, fine particles enter the integrated machine.

[0033] (2) Insert the 100-mesh screen 9, change the length of the corresponding coupling 13 according to the required soil particle size, turn on the servo motor 2 and control the running speed, and start grinding.

[0034] (3) After grinding, pull out the sample collection box 10 to check whether the ground soil sample meets the requirement of 0.15mm, if it is qualified, pack it into a bag for the next step of experimental data determination; if the amount of ground sample does not meet the experimental requirements , then repeat the above procedure for secondary grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com