Patents

Literature

161results about How to "Improve work continuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

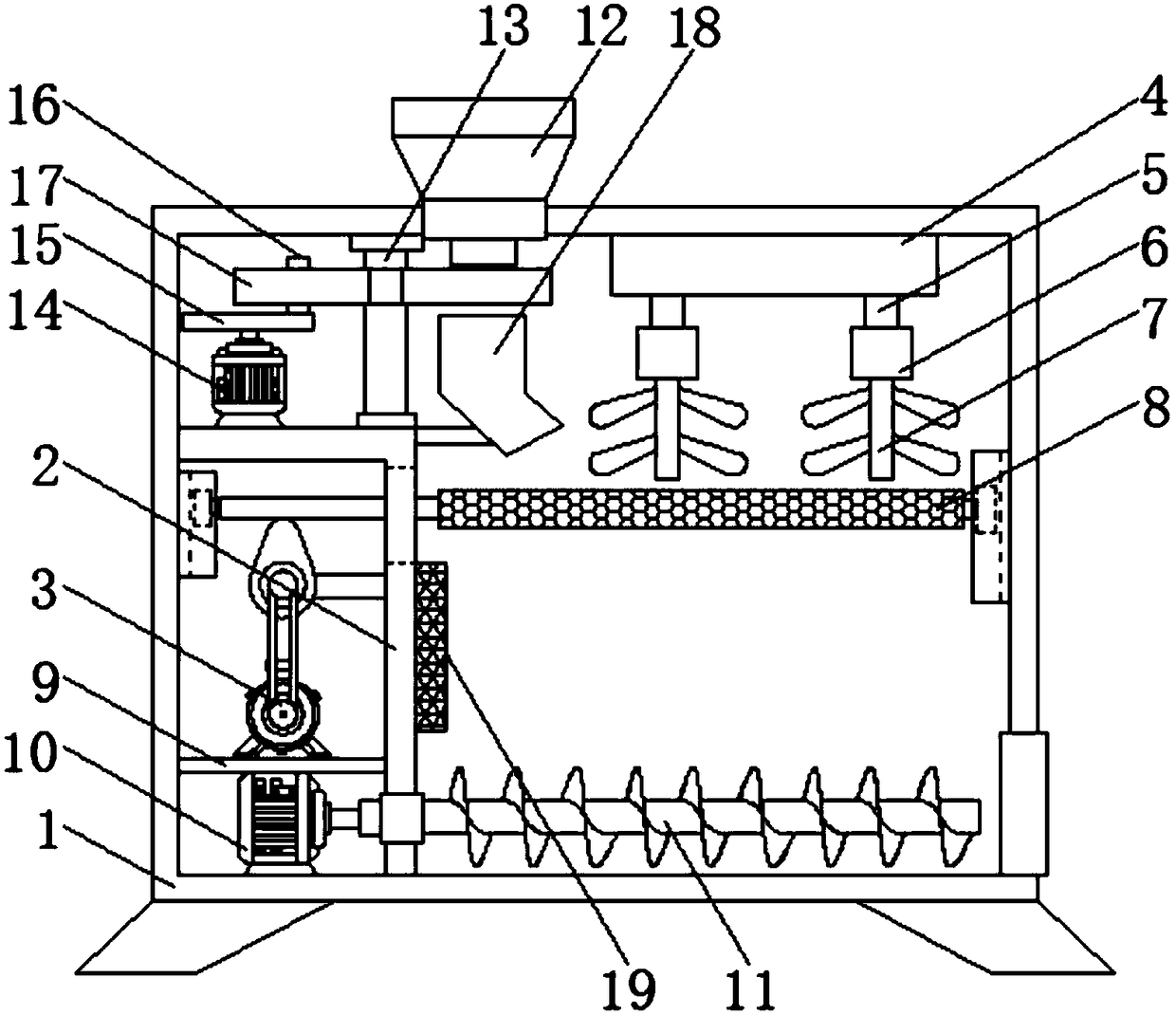

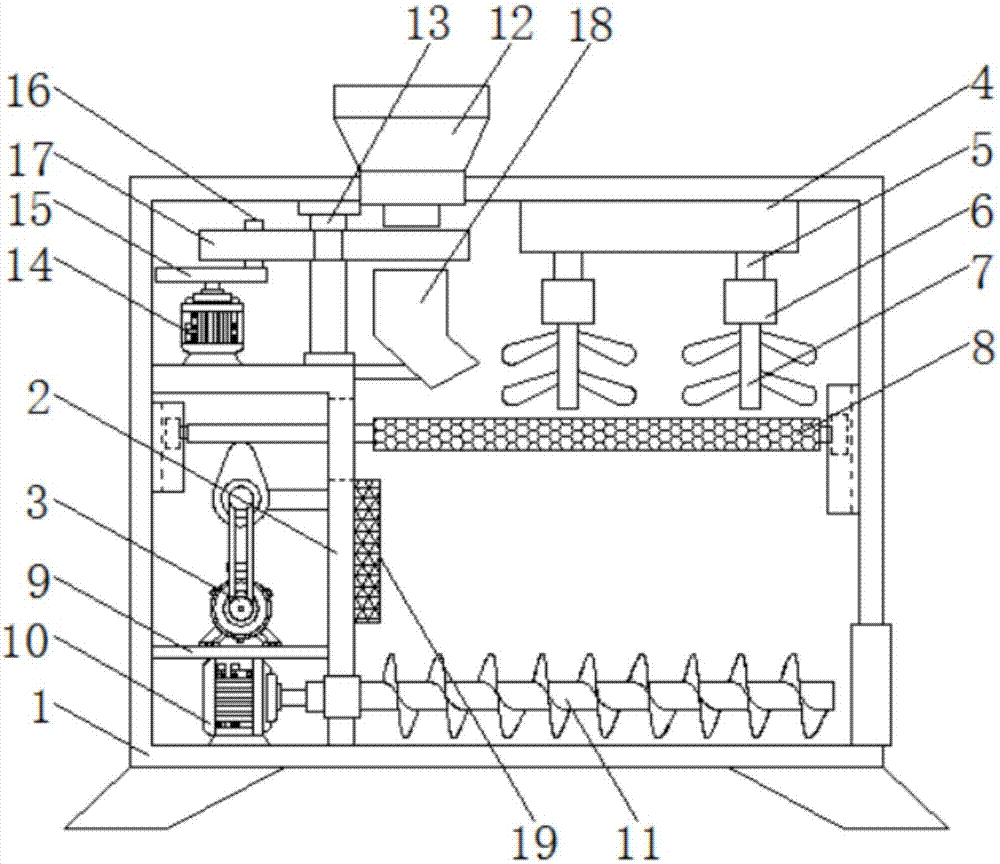

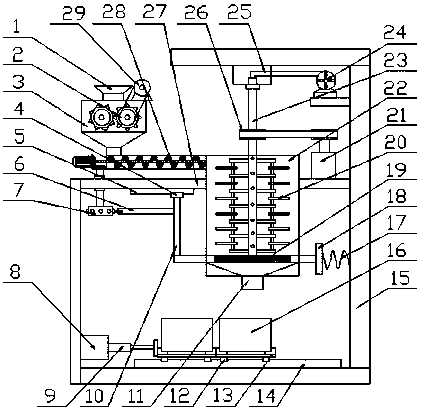

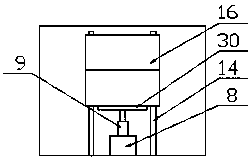

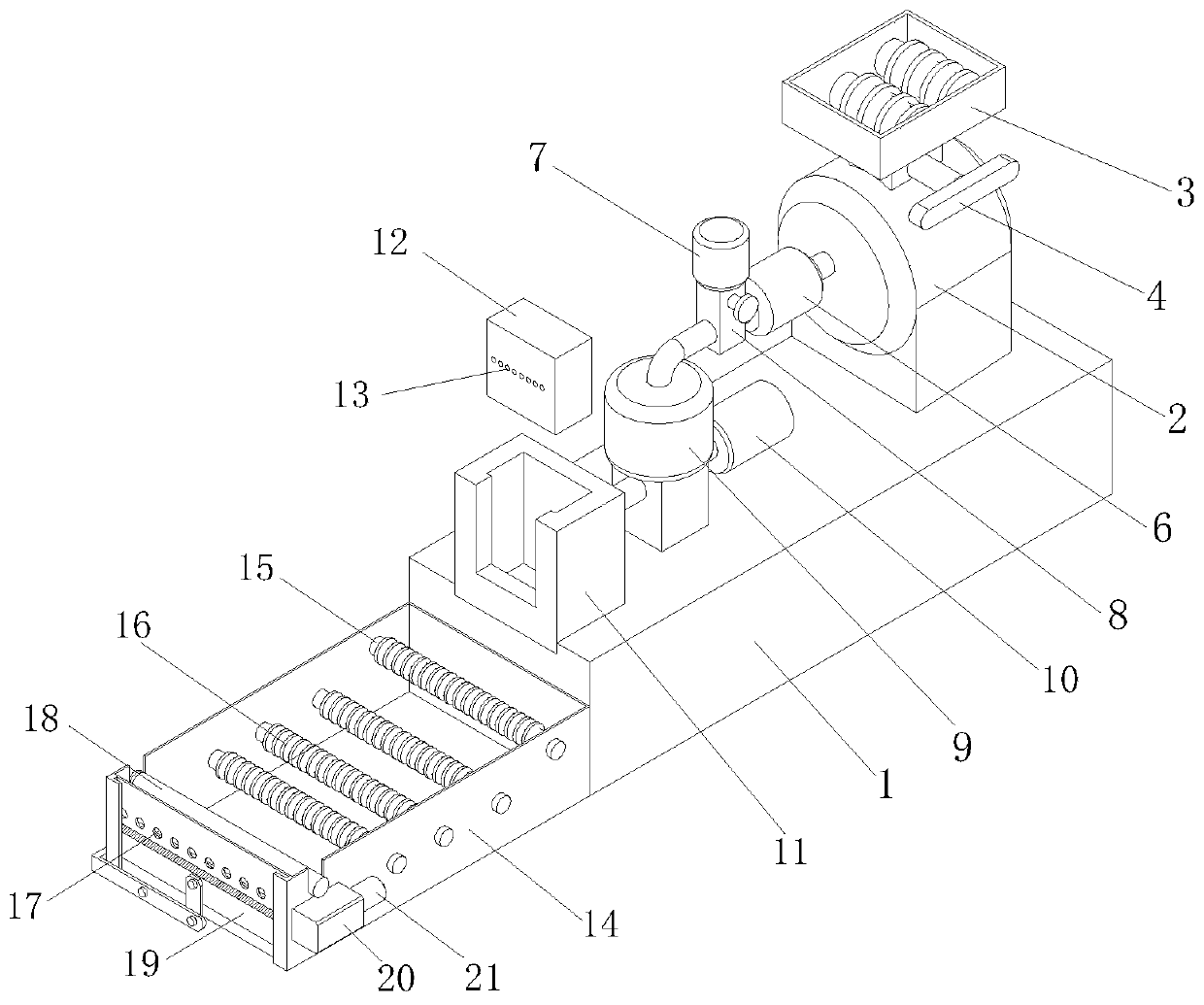

Soil analysis sample screening-grinding movable all-in-one machine

ActiveCN103487301AReduce workloadLow pricePreparing sample for investigationSoil scienceAgricultural engineering

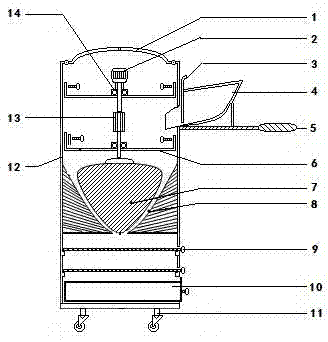

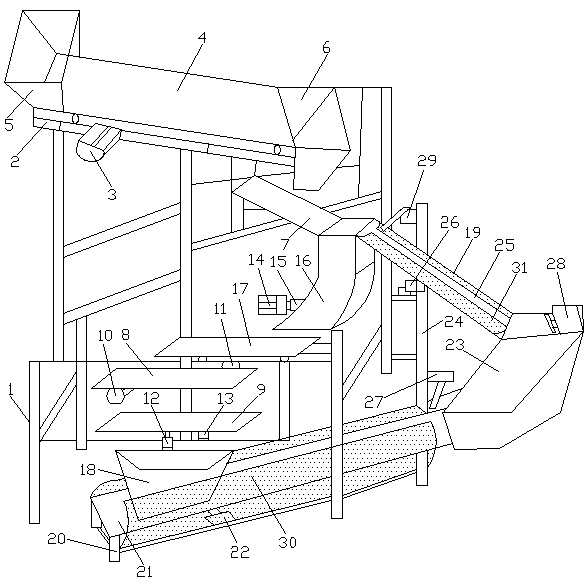

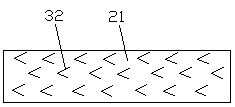

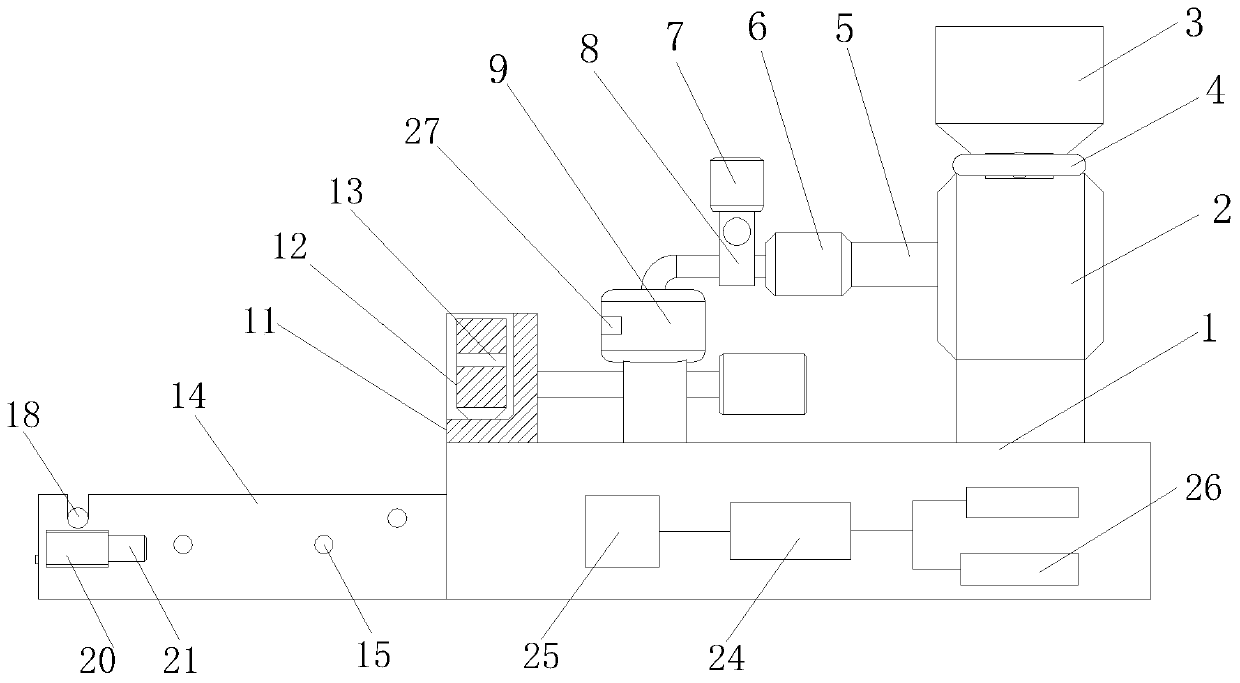

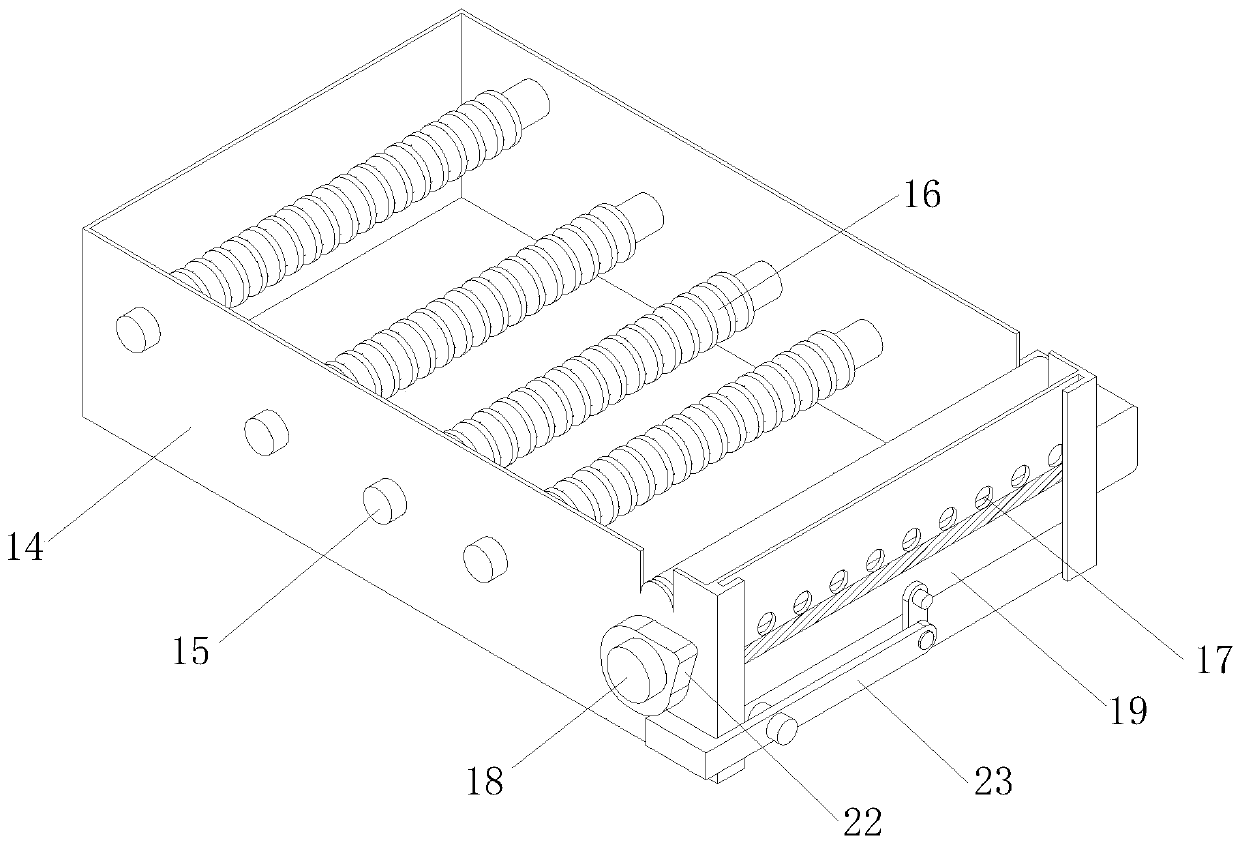

The invention relates to the technical field of soil sample screening-grinding equipment, particularly to a soil analysis sample screening-grinding movable all-in-one machine for laboratory analysis. The technical scheme of the machine is that the movable all-in-one machine includes a machine body, a feeding treatment system, a grinding system and a classified screening system, wherein the machine body is formed by a cuboid box body; a feeding treatment system is arranged at the upper part of the side wall of the box body; the classified screening system is positioned at the middle lower part of the box body; the grinding system is positioned at the middle upper part of the box body and is arranged in the middle part. Tests show that the all-in-one machine can one-step pulverize soil into particles not larger than 2 mm in diameter and counting for 85% above, and one-step pulverize soil into particles not larger than 0.15 mm in diameter and counting for 65% above, and the screening yield is 100%. The machine has the advantages that the obtained materials are common, the operation is simple, high quality and efficiency are realized, no pollution to a soil sample is caused, and the result is reliable.

Owner:FUJIAN NORMAL UNIV

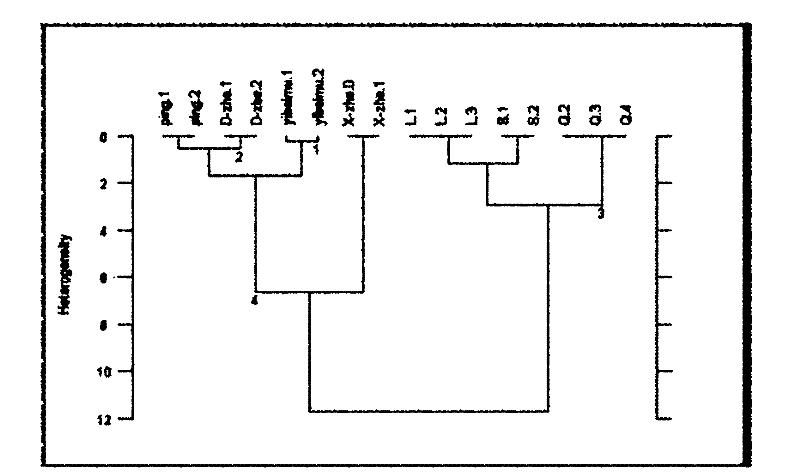

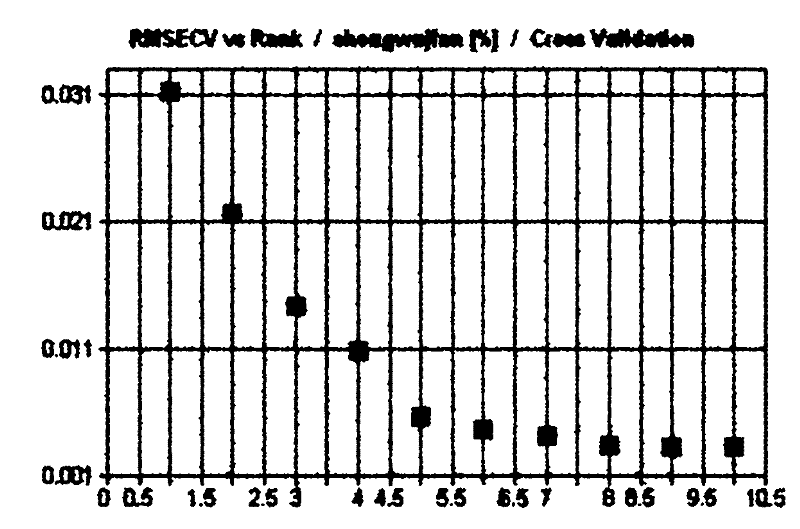

Method for distinguishing variety of fritillaria and detecting total alkaloid content of fritillaria by virtue of near infrared spectrum

InactiveCN102175648ASmall absorption coefficientEasy to collectScattering properties measurementsSample MeasurePrincipal component regression

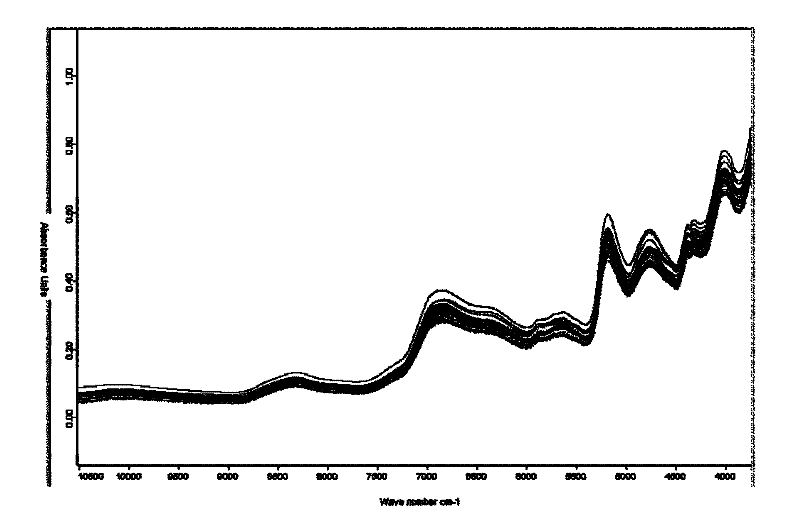

The invention provides a method for distinguishing variety of fritillaria and detecting total alkaloid content of the fritillaria by virtue of near infrared spectrum. The method provided by the invention comprises the following steps: (1) collecting a fritillaria sample; (2) measuring the near infrared diffuse reflection spectrogram of the fritillaria sample, preprocessing the 4000-5000cm<-1> wave band in the spectrogram, and performing cluster analysis on the pre-processed near infrared spectrogram to build a qualitative model; or preprocessing the 4000-7000cm<-1> wave band in the spectrogram, so as to obtain an absorbance, associating the absorbance with the alkaloid content of the sample measured by virtue of bromothymol blue colorimetry, and building a quantitative correction model for detecting alkaloid by one or more methods of a partial least squares method, a principal component regression method and a multiple linear regression method; (3) collecting the near infrared spectrogram of the sample to be measured, after the corresponding preprocessing is performed, distinguishing the variety of the fritillaria and detecting total alkaloid content of the fritillaria by utilizing the built qualitative model or quantitative correction model. The method provided by the invention has the characteristics of fast speed, no damage, environment friendliness and low cost.

Owner:DALIAN UNIV OF TECH

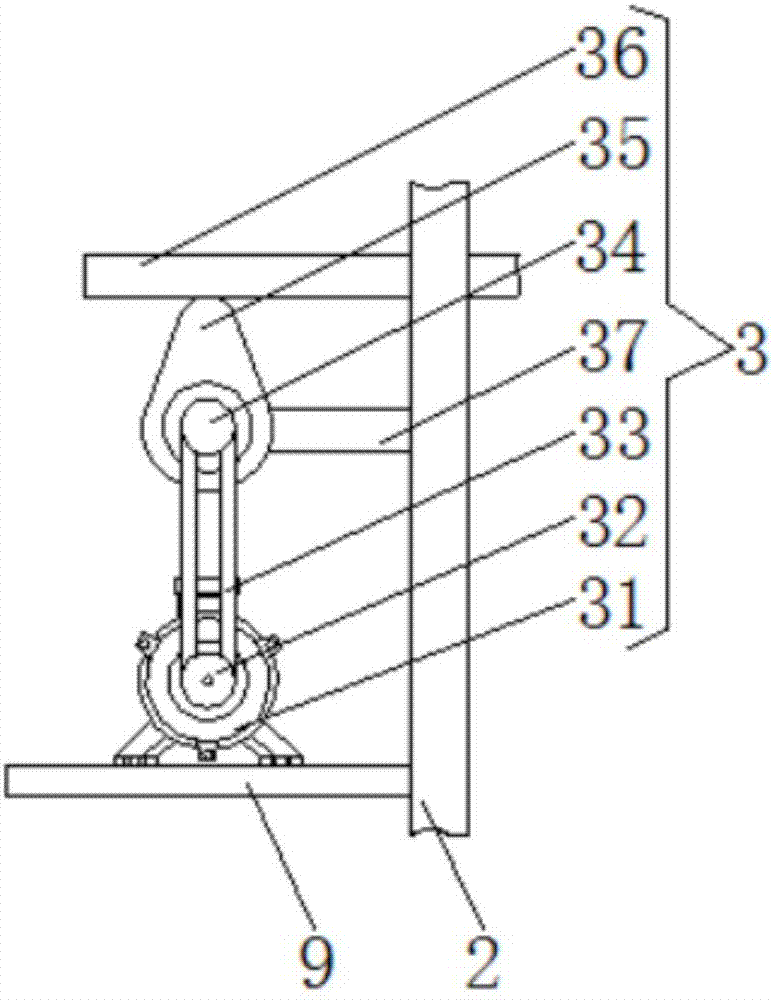

Sieving method for processing sweet potato powder

InactiveCN108188023AHigh speedReduce the amount of manual laborSievingScreeningEngineeringFeeding tube

The invention discloses a sieving method for processing sweet potato powder. The sieving method comprises the steps that the sweet potato powder is poured from a feeding hopper, and a rotary table isdriven by rotation of a motor to rotate; a rotating rod is driven by the rotation of the rotary table to perform circular motion, and a grooved pulley is driven by the rotating rod to perform intermittent rotation, so that the bottom of the feeding hopper is intermittently blocked; the sweet potato powder is fell down to the surface of a sieving mesh through a feeding tube, a first belt pulley isdriven by the work of a vibrating motor to rotate, and a second belt pulley is driven by the rotation of the first belt pulley to rotate through a belt. According to the sieving method for processingthe sweet potato powder, the sieving mesh is driven by the work of the vibrating motor to move and sieve the sweet potato powder, manual sieving is not required, the labor capacity is reduced, the speed of sieving is accelerated, and the working efficiency is improved; and the rate of feeding is controlled to enable the sweet potato powder to be intermittently and continuously fed, the stacking ofthe sweet potato powder due to too fast feeding is prevented to lead the device cannot work normally, and the use effect of the device is improved.

Owner:安吉县安信信息有限公司

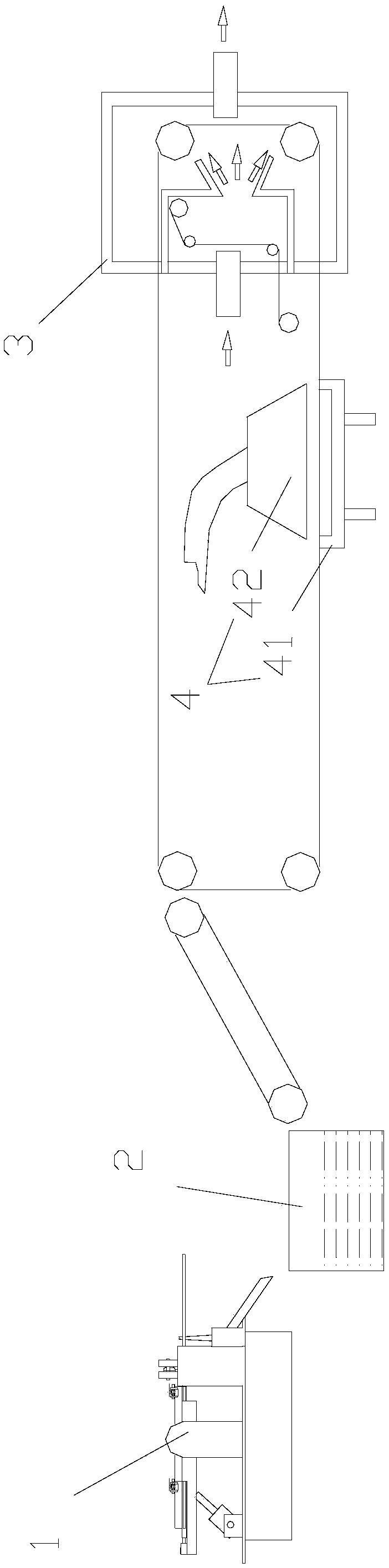

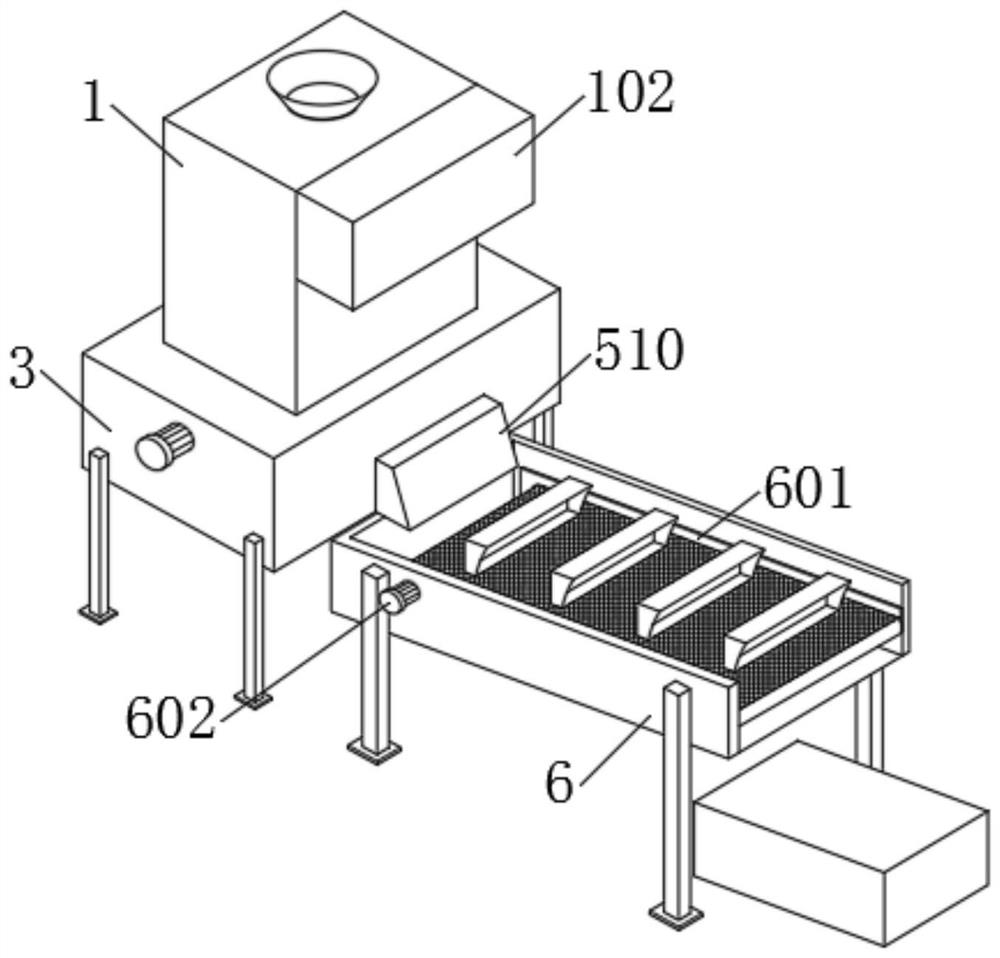

Roasted eel continuous processing production line system and roasted eel processing method

ActiveCN109007647AImprove fluidityImprove processing efficiencyFood ingredient as flavour affecting agentNatural extract food ingredientsEngineeringMouth shape

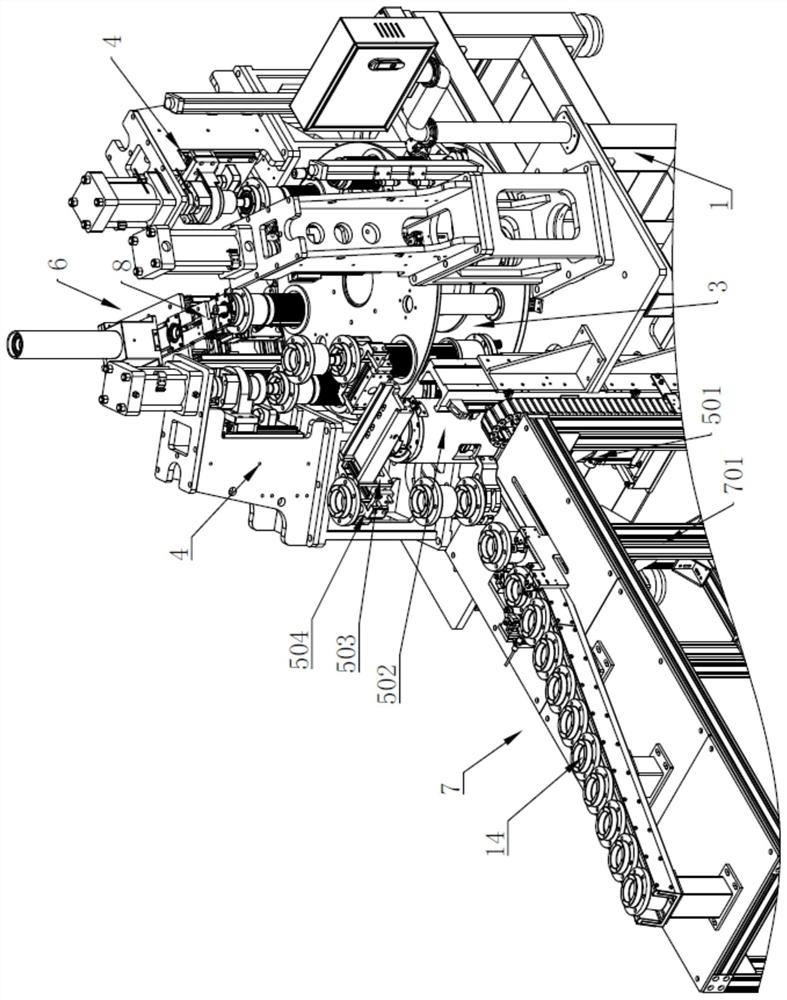

The present invention discloses a roasted eel continuous processing production line system. According to sequences of a process flow, the roasted eel continuous processing production line system successively comprises a slicing mechanism, a deodorizing pool, an air-drying device and a roasting device; the slicing mechanism is used for synchronous cutting of a plurality of eels in the same row along the length direction and can enable the cut eel blocks to slide into the deodorizing pool for deodorizing treatment; the air-drying device comprises a conveying device, a blowing device, an air-drying bin and filtering device; the conveying device is used for feeding the deodorized eel blocks into the air-drying bin; a conveying belt presents a mouth-shaped circulation structure and enters and exits the air-drying bin horizontally; the eel blocks can be turned over in the air-drying bin; and the roasting device is located on a conveying path of the conveying device and used for roasting theair-dried eel blocks. The present invention also discloses a processing method of the roasted eels. The roasted eel continuous processing production line system is strong in production and processingcontinuity, can realize continuous cutting of the eels, can conduct automatic turning-over in the air-drying stage, is high in air-drying cleaning degree and realizes circular material feeding.

Owner:FUJIAN FUMING FOOD

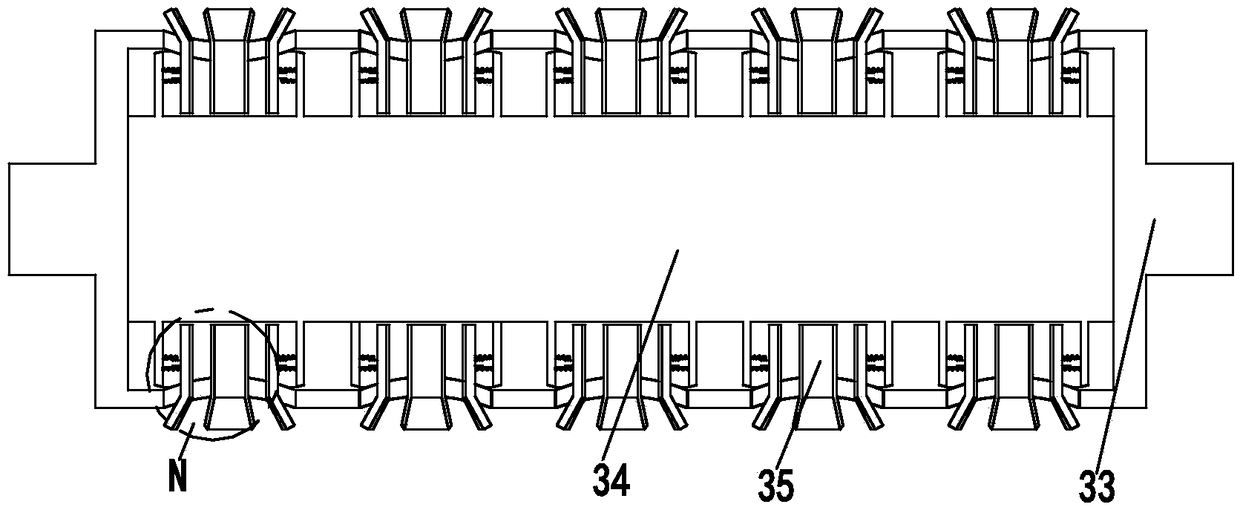

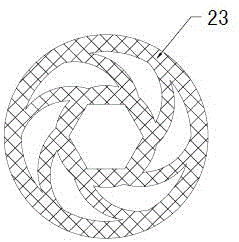

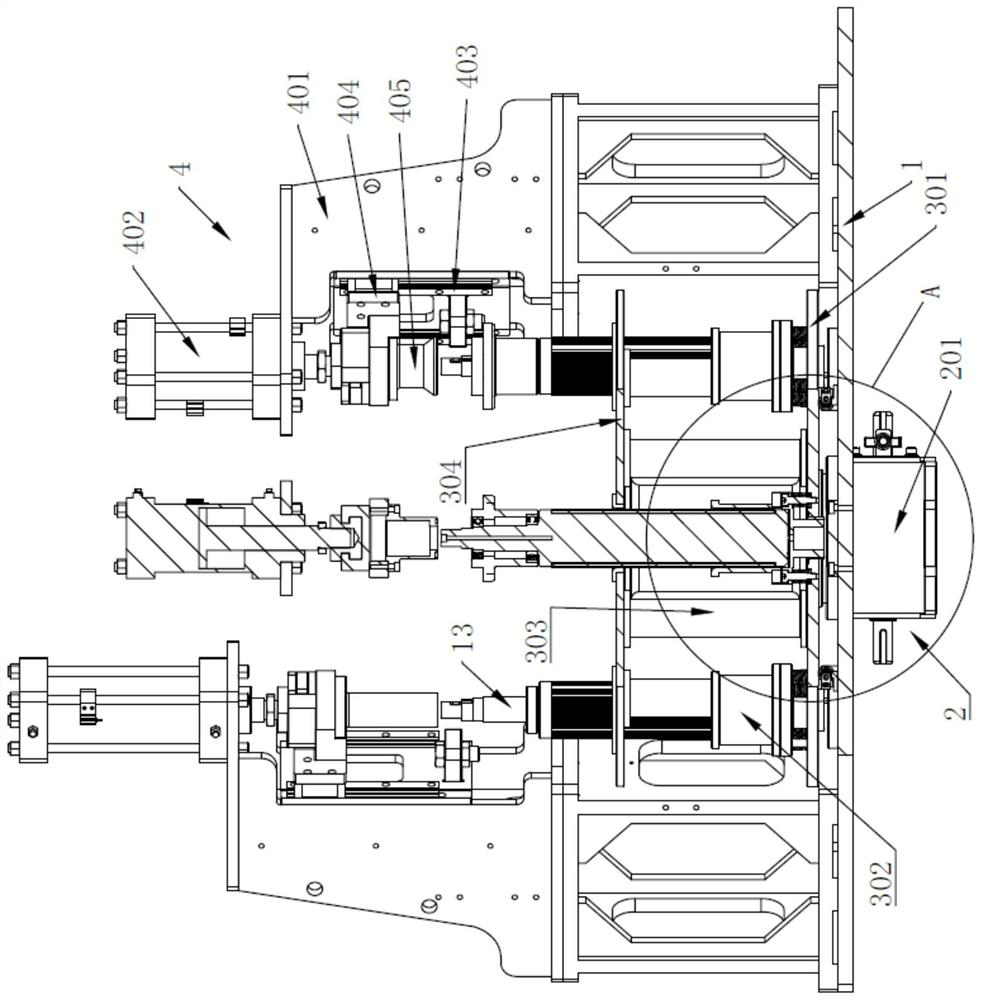

Hard rubber ring surface treatment equipment and rubber ring surface treatment technology

ActiveCN109318067AIncrease labor costImprove continuityRevolution surface grinding machinesGrinding drivesRubber ringFixed frame

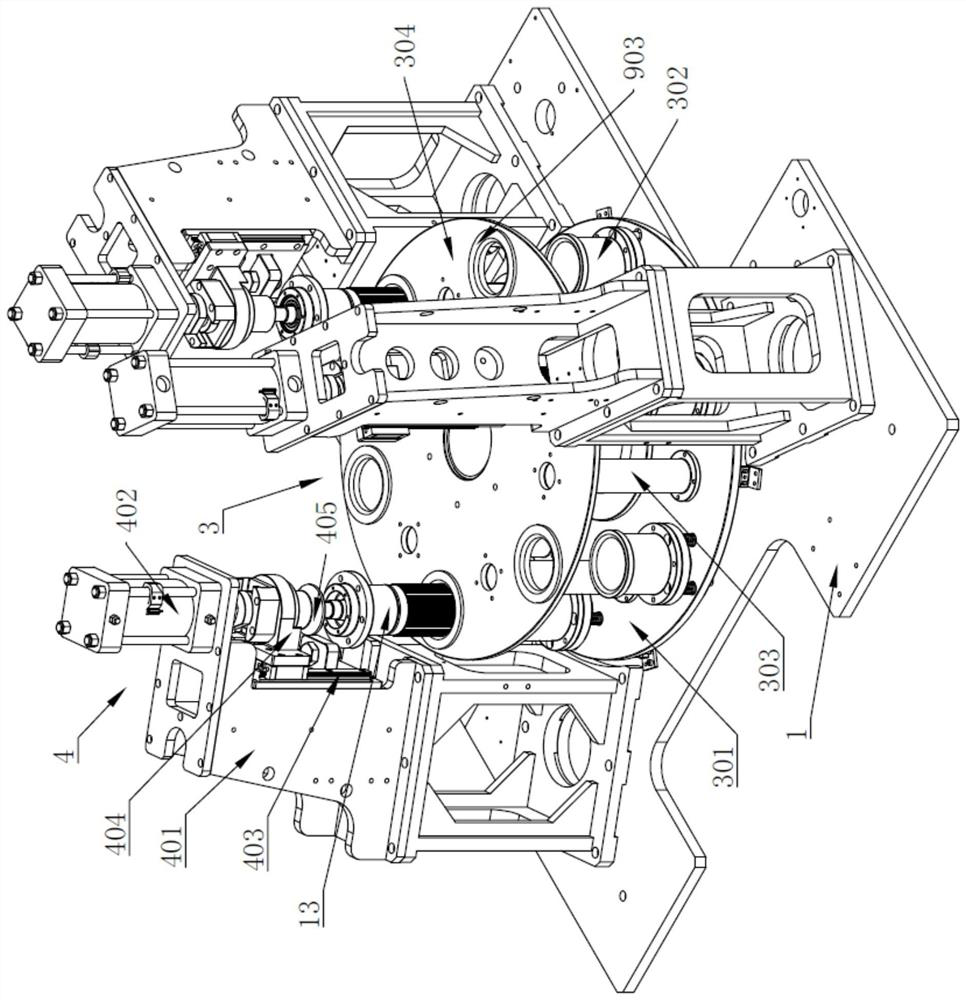

The invention relates to hard rubber ring surface treatment equipment and a rubber ring surface treatment technology. The equipment comprises a bed frame, a mounting rack, a grinding device and a holding device. A circular through hole is formed in the middle of the bed frame. The mounting rack is mounted on the bed frame. A circular hole is formed in the middle of the mounting rack. The grindingdevice is mounted in the circular hole. The holding device is arranged at the lower end of the grinding device and mounted on the bed frame. The grinding device comprises a fixing circular plate, an adjusting circular plate, an adjusting motor, a fixing frame, protruding columns, adjusting rods, connecting plates, sliding bars, limit plates and working plates. By means of the hard rubber ring surface treatment equipment and the rubber ring surface treatment technology, the problems that the manpower cost is high, the working efficiency is low, the application range is small, the working continuity and stability are poor and the like in an existing hard rubber ring surface treatment process can be solved, the functions that the surface of a hard rubber ring is automatically ground and wipedcan be achieved, and the equipment and the technology have the advantages of being low in manpower cost, high in working efficiency, wide in application range, good in working continuity, high in working stability and the like.

Owner:NANTONG HONGTU RUBBER & PLASTIC

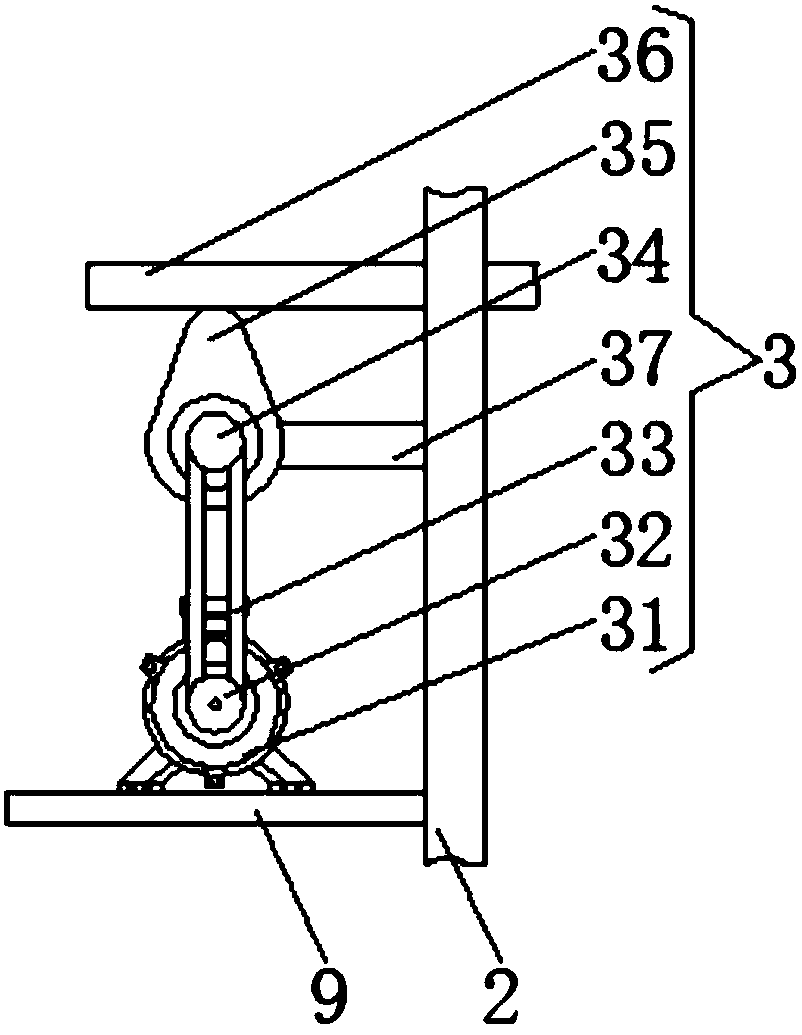

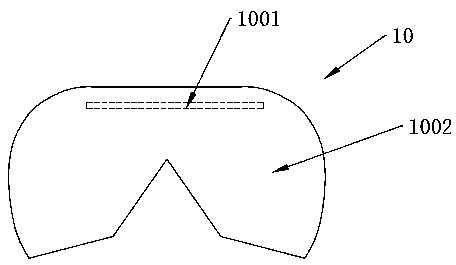

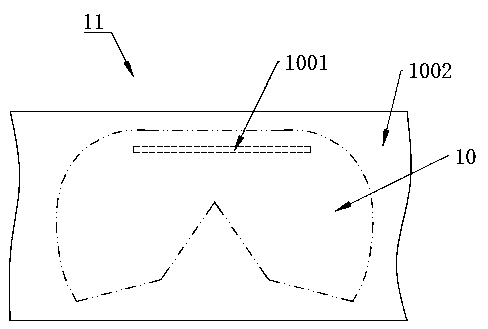

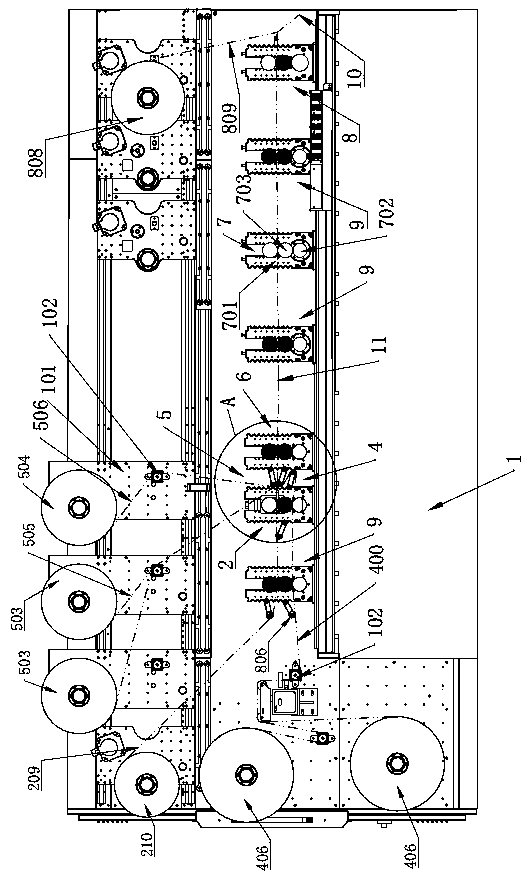

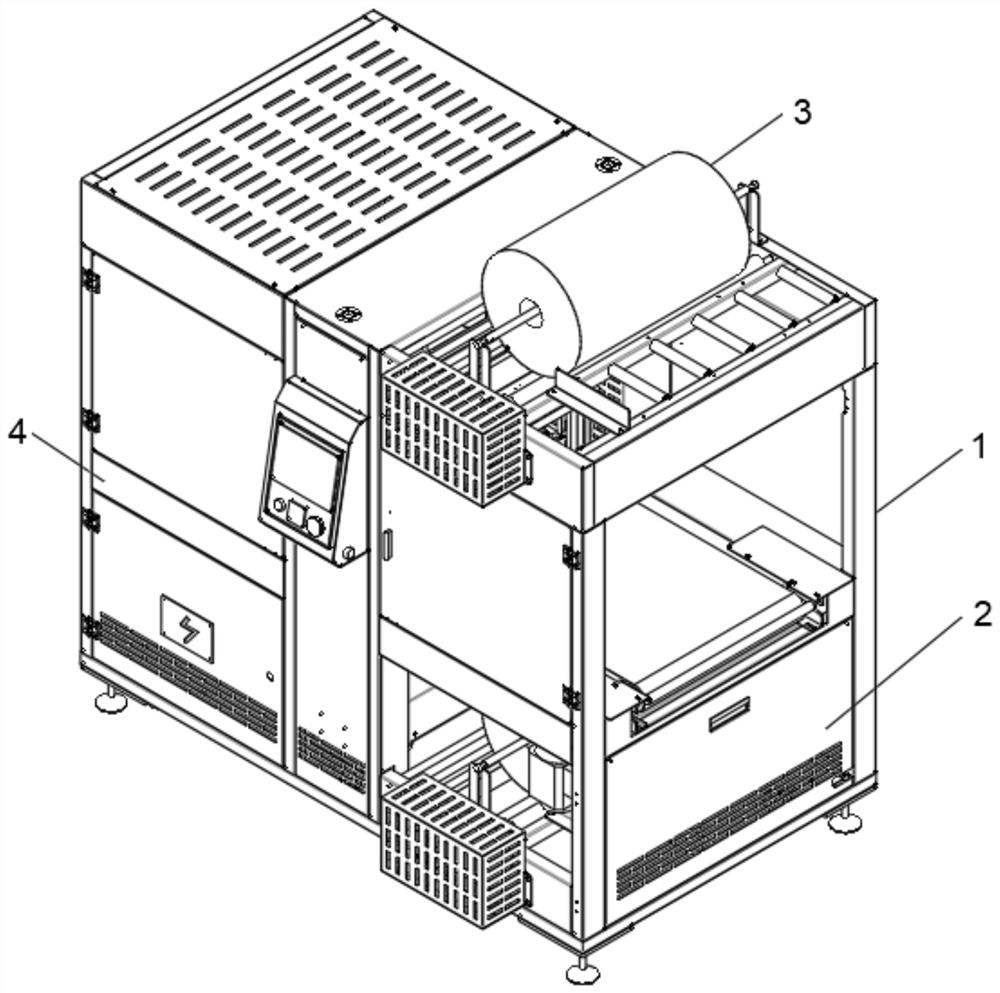

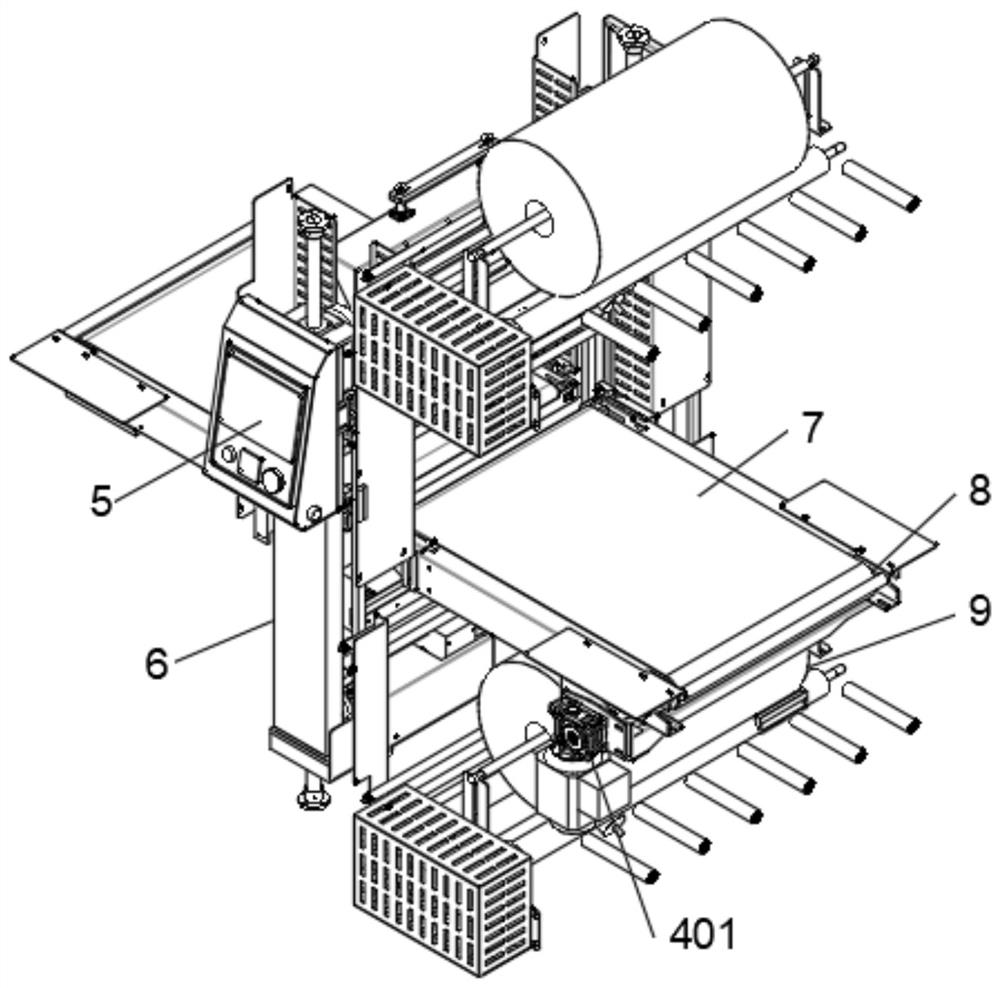

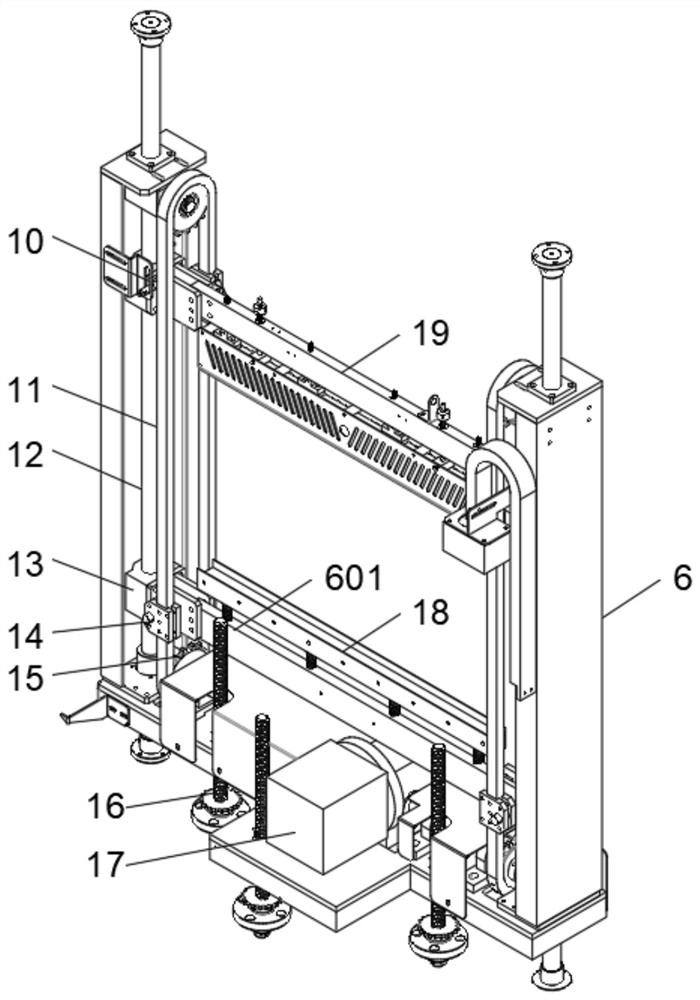

Sheet producer for masks

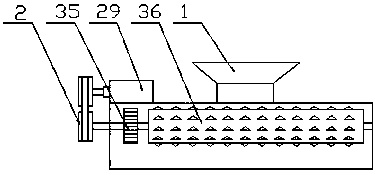

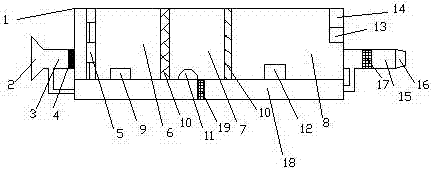

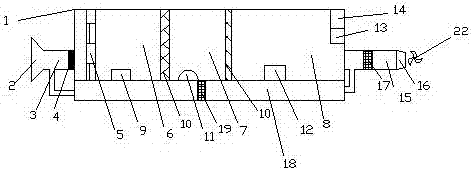

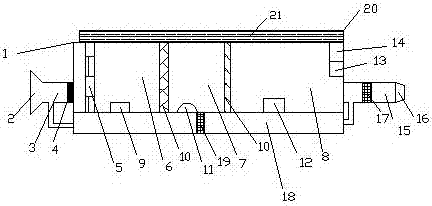

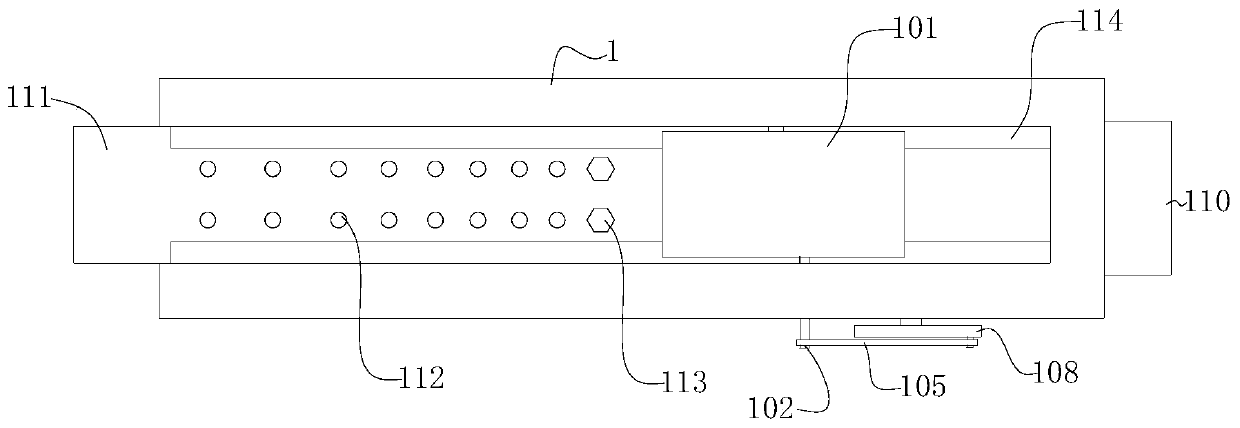

ActiveCN111376487AImprove aestheticsImprove work continuityDomestic articlesClothes making applicancesStructural engineeringNose bridge

The invention discloses a sheet producer for masks. The sheet producer for masks comprises a body of a nose bridge line loading and cutting mechanism. A nose bridge strip guiding and conveying mechanism is arranged on the downstream side of the nose bridge line loading and cutting mechanism. A first cloth layer loading and guiding and conveying mechanism is further arranged on the body and a guided and conveying first cloth layer passes below the nose bridge line loading and cutting mechanism. A second cloth layer loading and guiding and conveying mechanism is arranged on the body on the downstream side of the nose bridge strip guiding and conveying mechanism, and the tail ends of the first cloth layer loading and guiding and conveying mechanism and the second cloth layer loading and guiding and conveying mechanism extend to the direction of the nose bridge strip guiding and conveying mechanism. A traction compounding mechanism, a welding forming mechanism and a cutting and peeling mechanism are successively arranged on the downstream side of the second cloth layer loading and guiding and conveying mechanism. Divided synchronous conveyance, compounding, welding forming and waste and mask body separation of a nose bridge line, a first cloth layer and a second cloth layer are achieved, so that the sheet producer is high in working continuity and high in work efficiency. Meanwhile, the nose bridge line is compounded in the mask body, so that the step of processing the noise bridge strip independently is cancelled, and therefore, the work efficiency is improved favorably.

Owner:SHANDONG HOACO AUTOMATION TECH

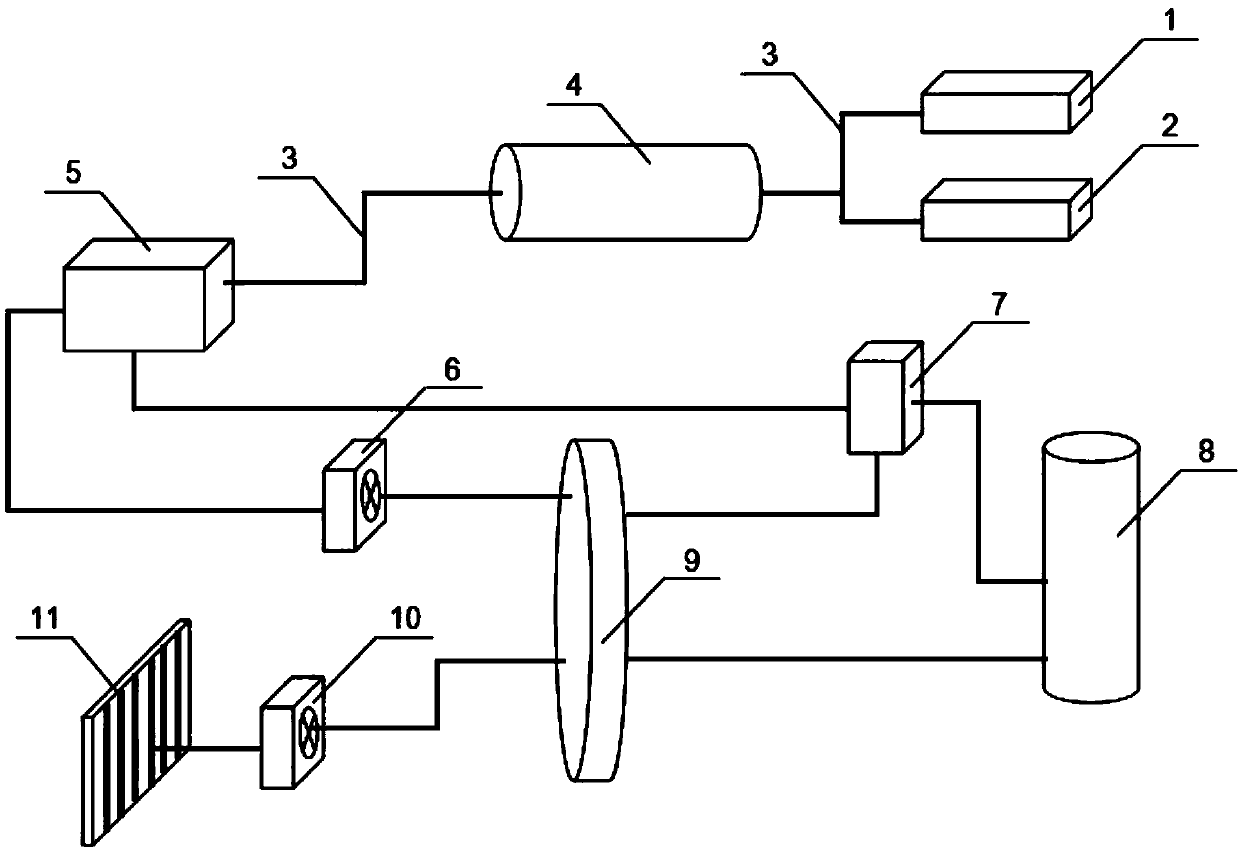

Novel volatile organic compounds (VOC) concentration treatment method

InactiveCN107551760ALow emission statusAccelerate emissionsDispersed particle separationIncinerator apparatusHigh concentrationDesorption

The invention discloses a novel volatile organic compounds (VOC) concentration treatment method. VOC waste gas enters a VOC concentration rotary wheel through a filter, zeolite adsorbs the VOC waste gas, and after treatment, waste gas enters a chimney to be discharged into air; VOC in the VOC concentration rotary wheel is concentrated to form a saturated zeolite region, desorption is performed byusing heat of a heat exchanger and a heat transfer, after desorption, the VOC concentration rotary wheel rotates to a cooling region and is cooled with room temperature air, and then rotates to a concentration region to repeat the operation; and the desorbed high-concentration VOC air flow is pumped to a burning device to be burned, so as to discharge carbon dioxide and vapor to the air. Comparedwith the prior art, the novel VOC concentration method has the advantages of easy operation, no extra complex operation tools, auto operation, high working continuity, high stability, less time and less effort, labor cost reduction, and high efficiency.

Owner:PURESCI ENVIRONMENTAL TECH CO LTD

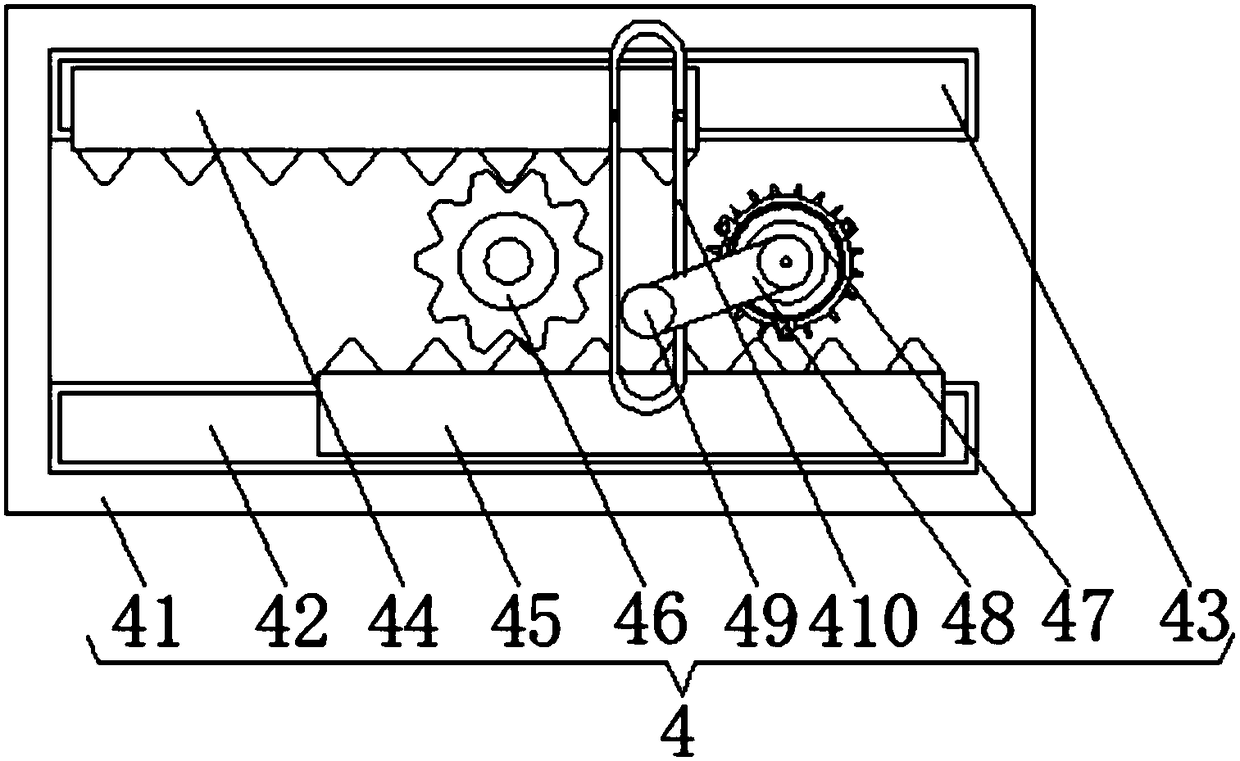

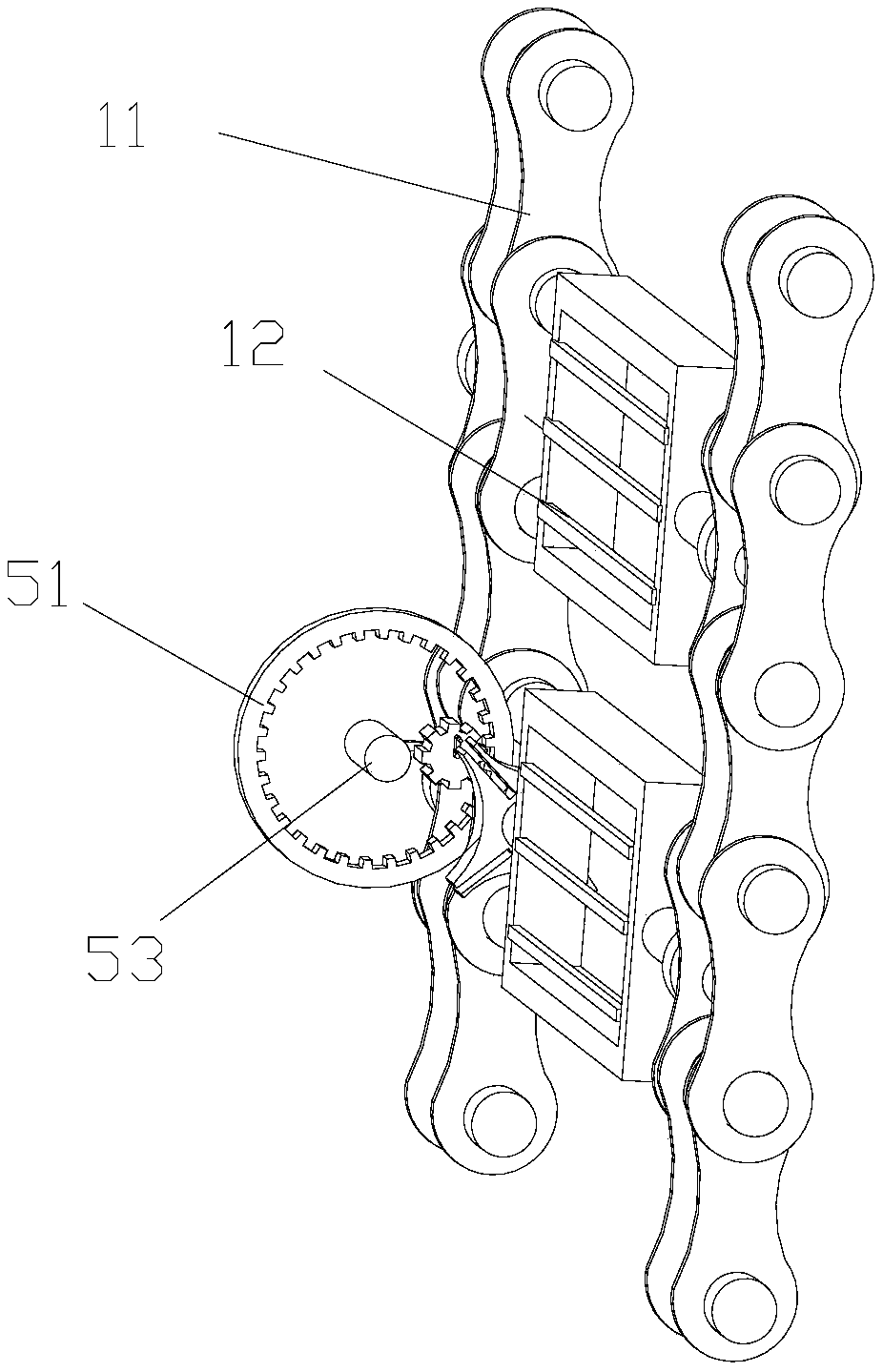

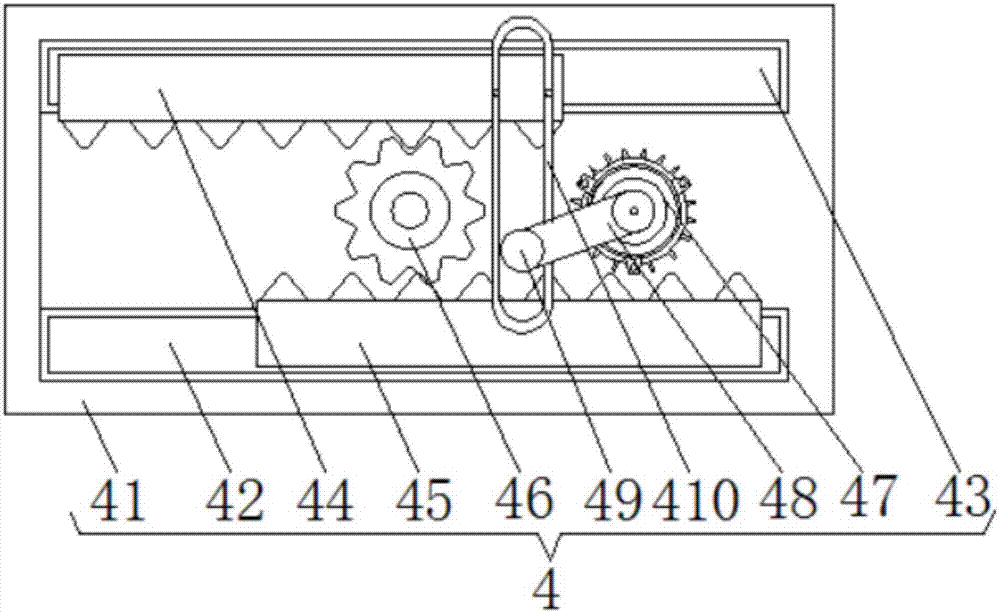

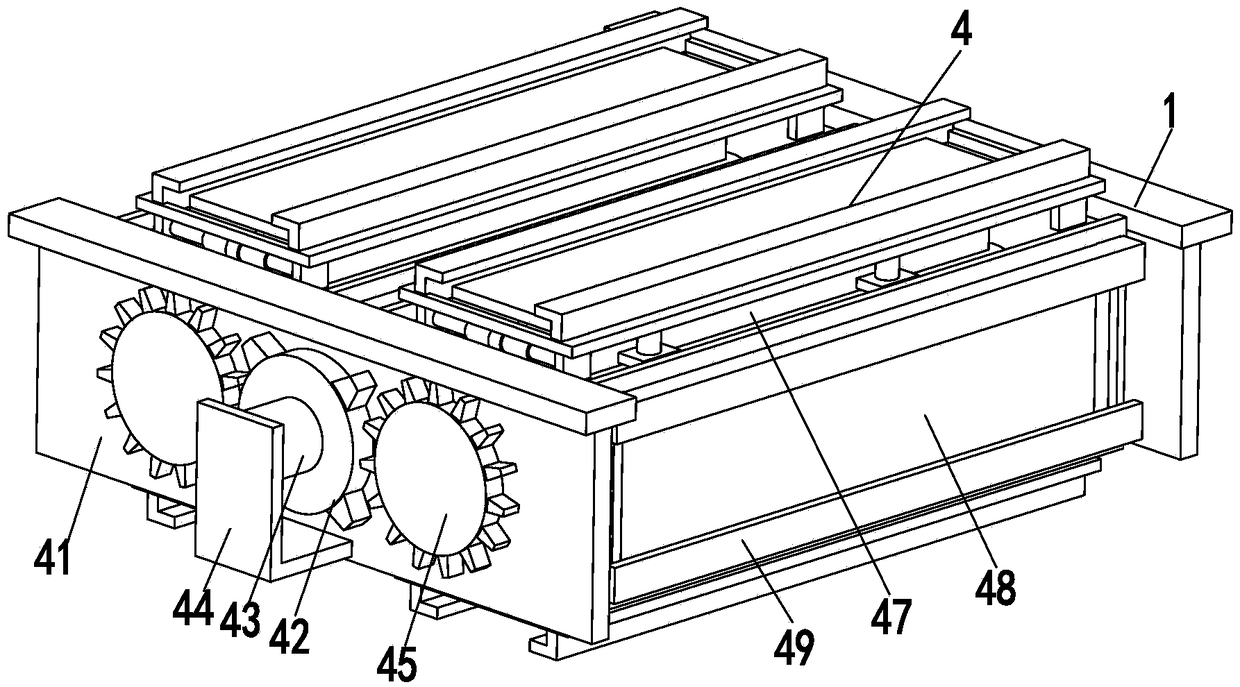

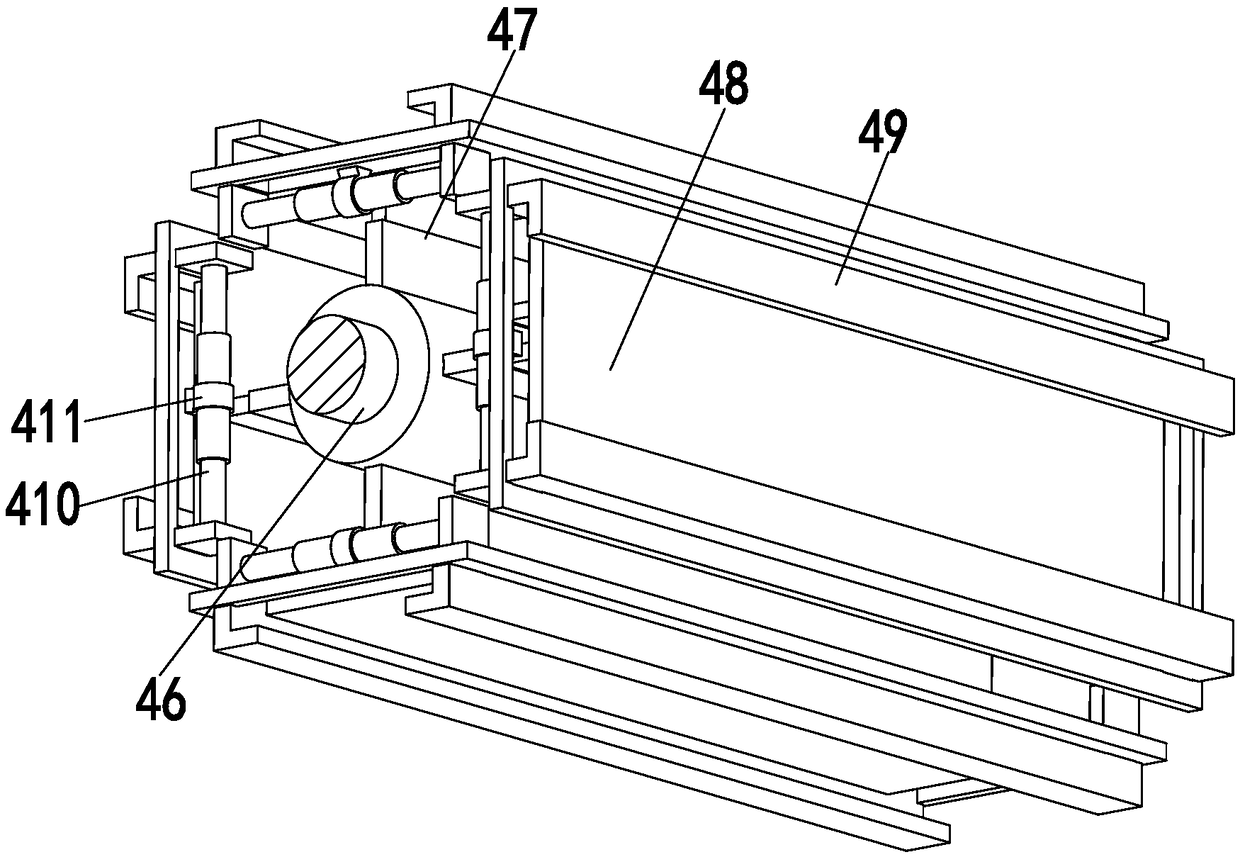

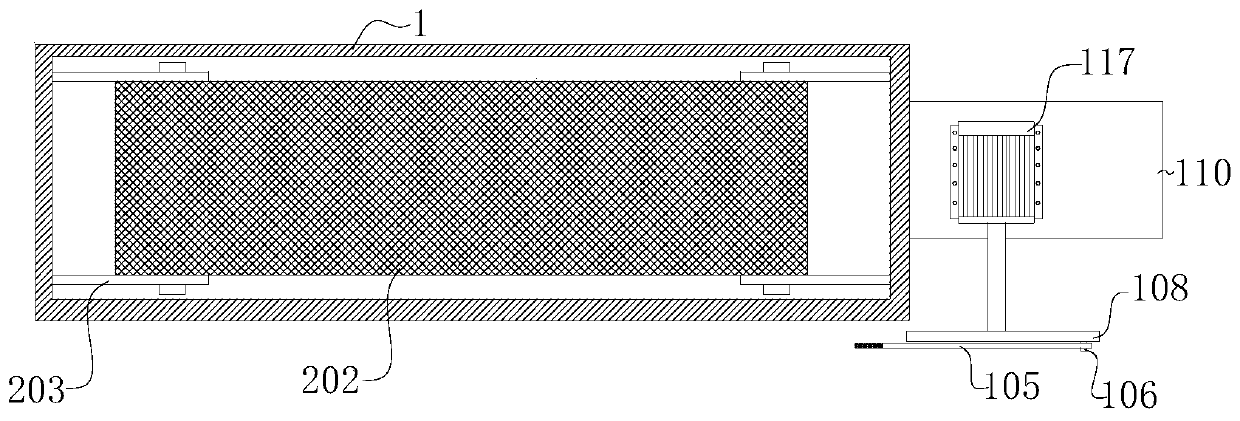

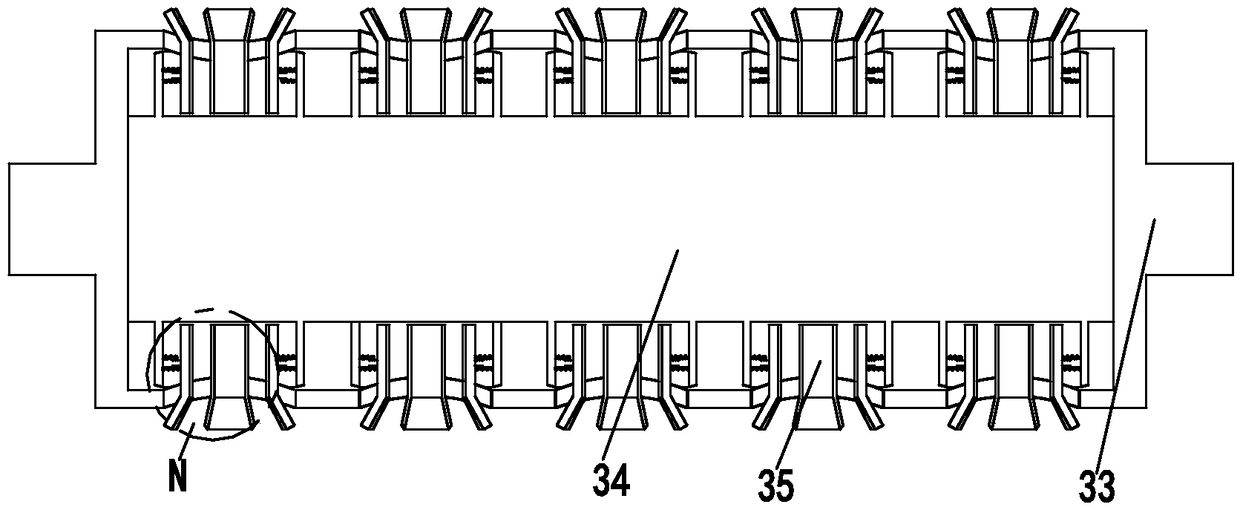

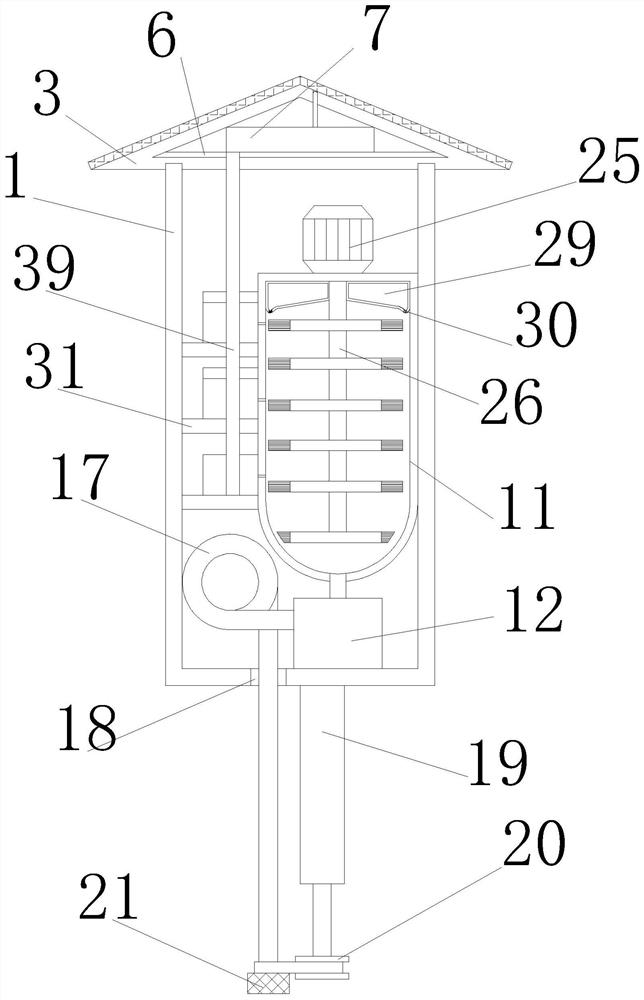

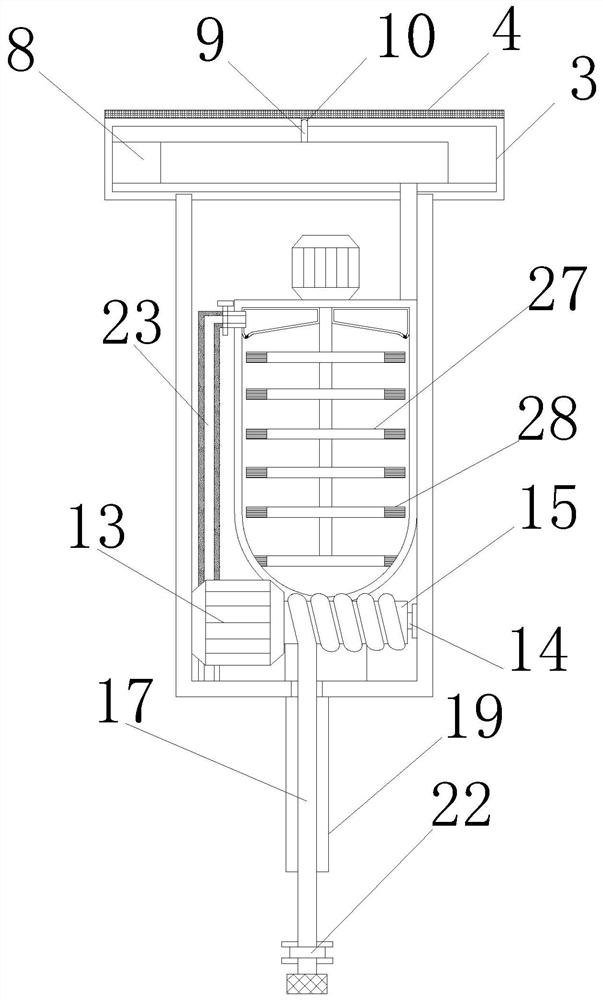

Continuous conveying double-face air drying device for eel roasting and hot air drying method

ActiveCN108955179AMechanizationSimple structureDrying gas arrangementsDrying solid materialsBlow outAir drying

The invention discloses a continuous conveying double-face air drying device for eel roasting. The continuous conveying double-face air drying device comprises a conveying device, an air blowing device, an air drying bin and a filtering device; the conveying device is used for feeding eels needing to be subjected to air drying into the air dying bin, and hot air blown out from the air blowing device conducts air drying treatment on the eels in the air drying bin after being filtered by the filtering device; the air drying bin comprises an air purifying and filtering bin and an air drying mainbin; the filtering device is arranged in the air purifying and filtering bin and comprises a feeding roller, a filter felt and a winding roller; and the air drying main bin is internally provided witha gear ring, a planet gear, a center shaft and a connection rod, the planet gear is provided with a protrusion, and the protrusion can rotate into guide grooves of a four-corner rotation piece and drive the four-corner rotation piece to do angular motion. The invention further discloses an eel air drying method. The continuous conveying double-face air drying device for eel roasting and the eel air drying method have the advantages that feeding is conducted, the air drying continuity is high, automatic turning over can be achieved, and the air drying cleanliness is high.

Owner:福建铭发水产开发有限公司

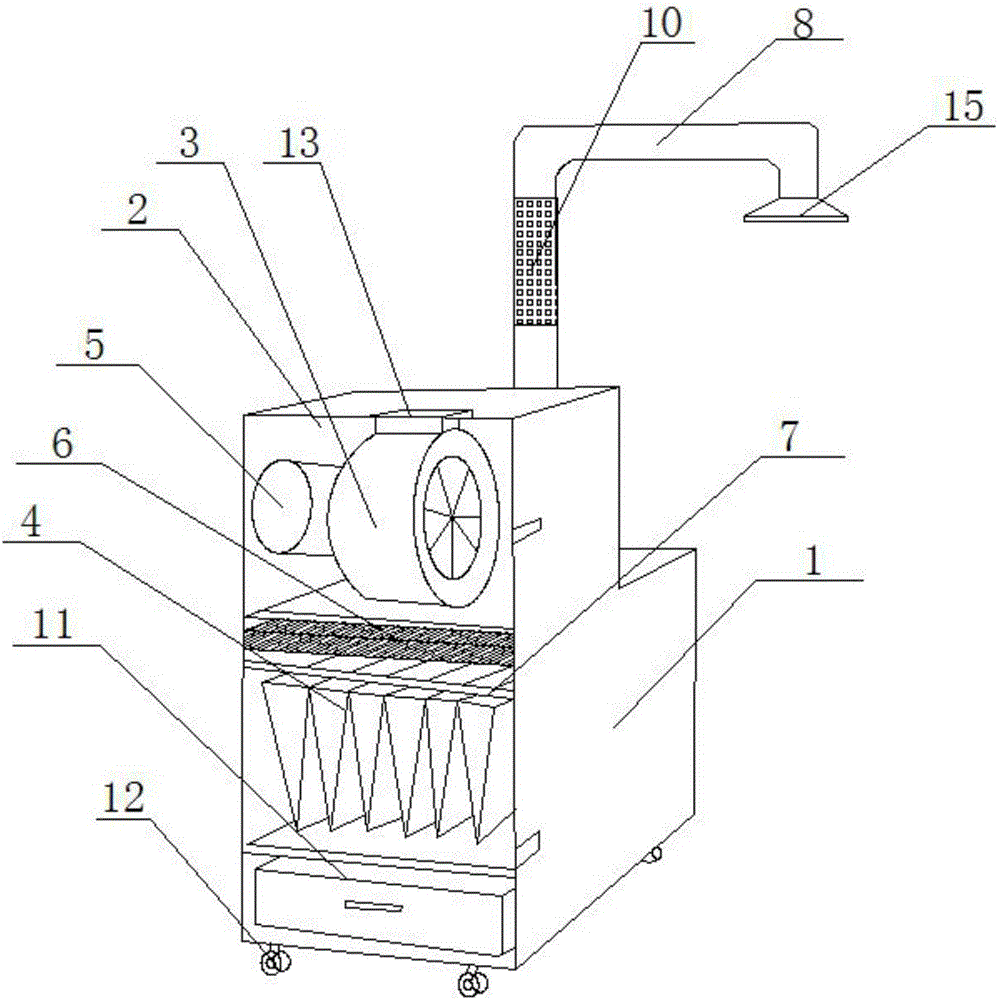

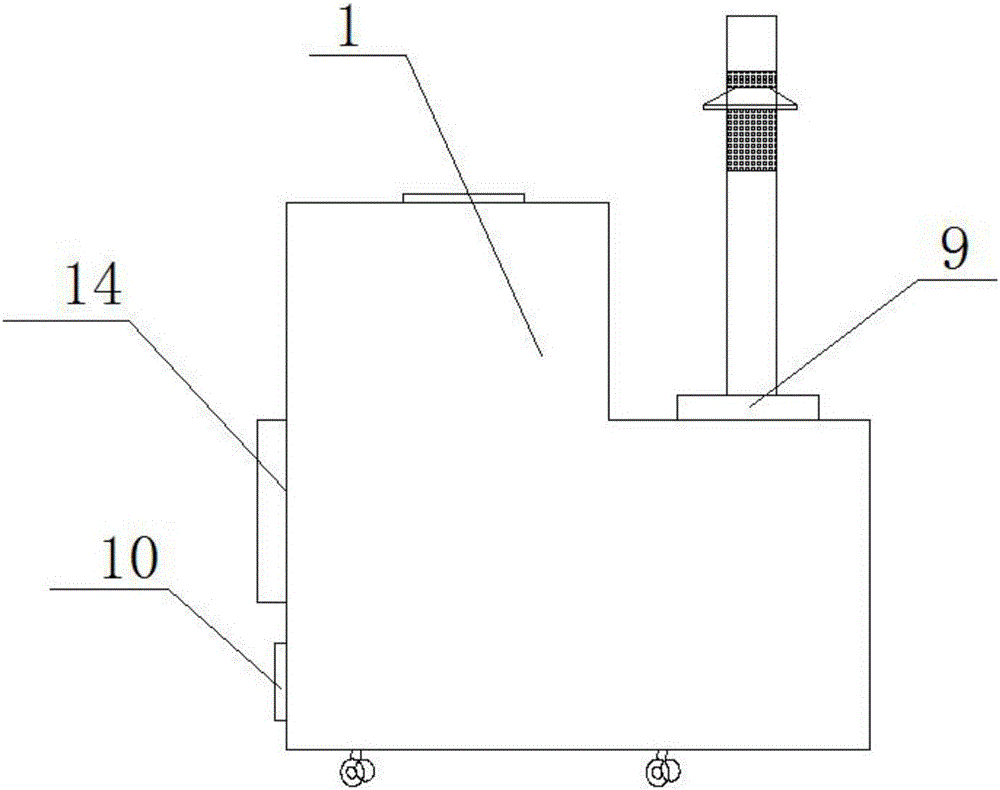

Mobile dust remover

InactiveCN105771437AEasy to cleanFlexible cleaningDispersed particle filtrationTransportation and packagingEngineering

The invention provides a mobile dust remover which comprises a tank body, a fan, a filter bag, a prefilter layer, a controller and a dust collection drawer.The tank body is divided into an upper tank body and a lower tank body.The fan is installed in the upper tank body.The controller is installed on one side of the fan.The prefilter layer and the filter bag are arranged in the lower tank body.The prefilter layer is located at the upper end of the filter bag.The lower end of the filter bag is connected with the dust collection drawer.The lower tank body is provided with a dust suction pipe.One end of the dust suction pipe is provided with an air suction cover.The mobile dust remover is compact in structure, convenient to operate and convenient and fast to move, has the excellent dust removal effect, and meanwhile is small in vibration, high in working continuity, stable in dust suction effect, capable of removing dust conveniently and flexibly and keeping comfort and health of working environment, convenient to maintain and strong in high temperature resistance, and the service life of the mobile dust remover is effectively prolonged.

Owner:苏州保酚环境科技有限公司

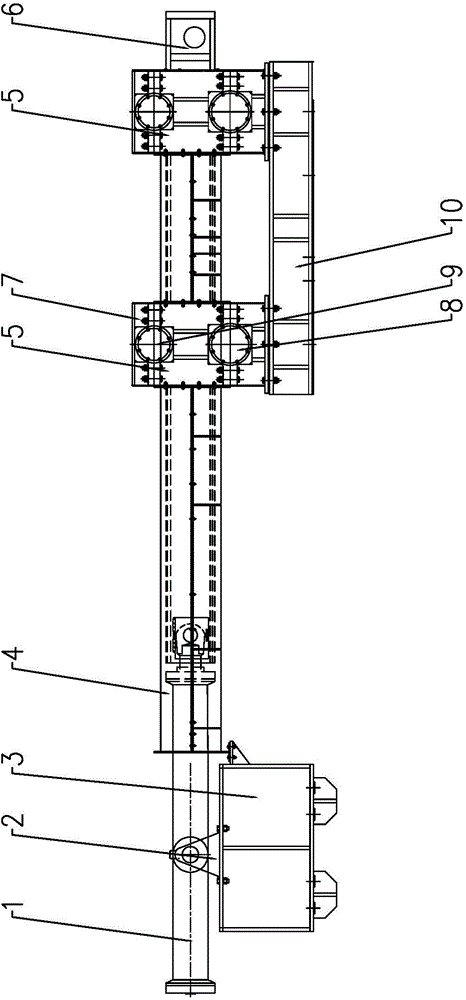

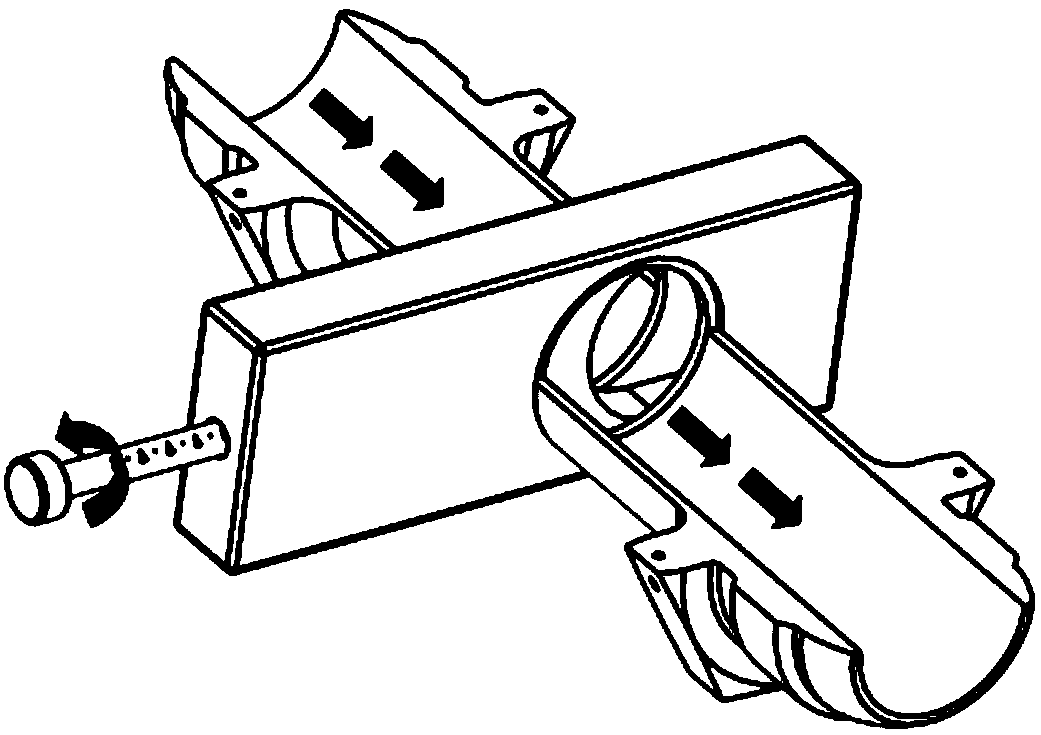

Pushing device

InactiveCN104357640AImprove protectionSimple structureCharge manipulationFurnace typesHydraulic cylinderAgricultural engineering

The invention relates to a pushing device, in particular to pushing equipment which can reliably protect a push rod, belonging to the technical field of pushing devices. The pushing device comprises a hydraulic cylinder, roller shaft components and a push rod, wherein the push rod is connected to the front end of the piston rod of the hydraulic cylinder; the front end of the push rod penetrates through two roller shaft components; the roller shaft components comprise roller shaft bases; pressing rollers and support rollers are arranged inside the roller shaft bases from top to bottom; the push rod penetrates through the pressing rollers and the support rollers. The pushing device is simple, compact and reasonable in structure, the push rod is reliably protected, the service life of the push rod is prolonged, and the working continuity is improved.

Owner:无锡晶瑜智能机械有限公司

Screening robot used for sweet potato flour processing

The invention discloses a screening robot used for sweet potato flour processing, and relates to the technical field of sweet potato flour processing. The screening robot used for sweet potato flour processing comprises a shell. A partition frame is fixedly connected to the left side of the bottom of the inner wall of the shell. A partition plate is fixedly connected between the right side of theinner wall of the partition frame and the left side of the inner wall of the shell. A vibrating device is fixedly connected to the top of the partition plate. The right side of the top of the vibrating device penetrates through the right side of the partition frame and extends out of the partition frame. The side, located outside the partition frame, of the vibrating device is fixedly connected with a sieve screen. According to the screening robot used for sweet potato flour processing, the sieve screen is driven by a vibrating motor to move to screen sweet potato flour, and manual screening is not needed, so that the workload of workers is reduced, the screening speed is increased, and the working efficiency is improved; and the discharging speed is controlled so that sweet potato four can be discharged intermittently and continuously, the situation that sweet potato flour accumulation is caused by an excessively high discharging speed, and consequentially, the screening robot cannotwork normally is avoided, and the using effect of the screening robot is improved.

Owner:安吉县安信信息有限公司

Gravel material multistage screening and crushing method

PendingCN109663637AThe crushing process is easy to controlImprove crushing efficiencySievingFouling preventionPrimary screeningContinuous production

The invention discloses a gravel material multistage screening and crushing method, and belongs to the technical field of gravel crushing. The gravel material multistage screening and crushing methodis characterized by comprising the following steps that a, gravel materials are conveyed to a screening work station; b, primary screening is carried out through a first-grade screening net, the gravel materials with the large particle size fall into a crushing station, the crushed gravel materials are conveyed to a second-grade screening net for horizontal swinging and screening, the screened gravel materials fall into a third-grade stage screening net, and the screened gravel materials are vibrated and screened through the third-grade screening net; and c, the gravel materials subjected to the third-stage screening fall into a material returning bin, the gravel materials falling from the material returning bin are conveyed into a crushing cylinder of a material crushing device through amaterial returning conveying part for circulation crushing. According to the method, the whole crushing process is easy to control, materials with different particle sizes can be crushed just by one material crushing device, the materials are conveyed into the material crushing device to be crushed through multistage screening, continuous production can be carried out, the crushing efficiency andthe yield are improved, and popularization and application are facilitated.

Owner:四川高路远长集团有限公司

Tidal wetland soil interstitial water in-situ layered collecting and filtering device

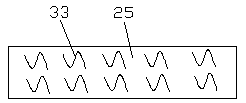

PendingCN107290183ASolve the problems of high labor intensity and high costImprove work efficiencyWithdrawing sample devicesPreparing sample for investigationSoil scienceWetland soils

The invention discloses a tidal wetland soil interstitial water in-situ layered collecting and filtering device, which comprises an equipment embedding system, a water sample layered collecting system, and a water sample pumping and collecting system. The provided collecting and filtering device guarantees the efficiency and quality of wild in-situ soil interstitial water sample collection, has the characteristics of simple manufacturing, low cost, and high performance / cost ratio, and assists the researchers and environmental scientists to carry out wild in-situ soil interstitial water sample layered collection and filtering.

Owner:FUJIAN NORMAL UNIV

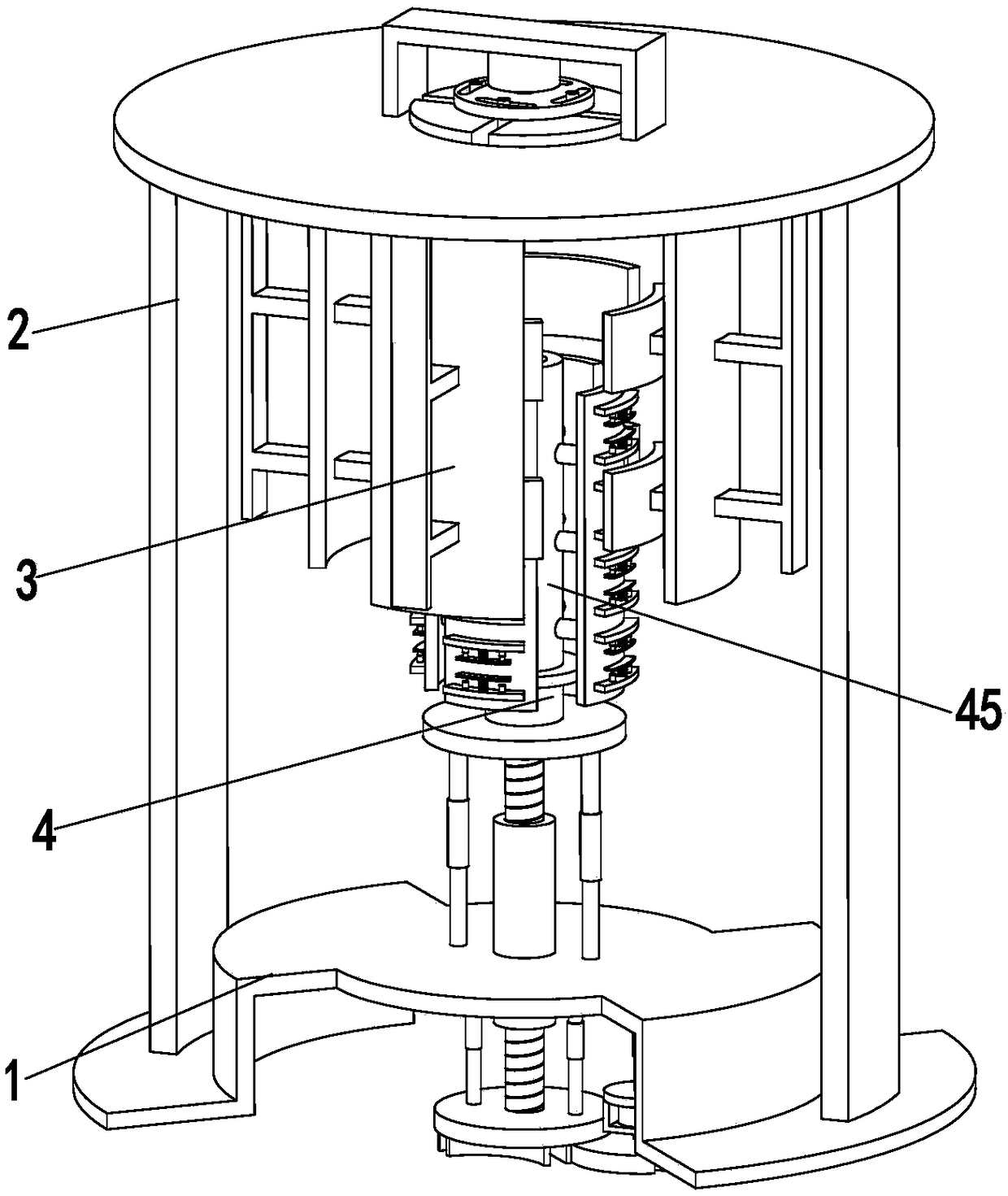

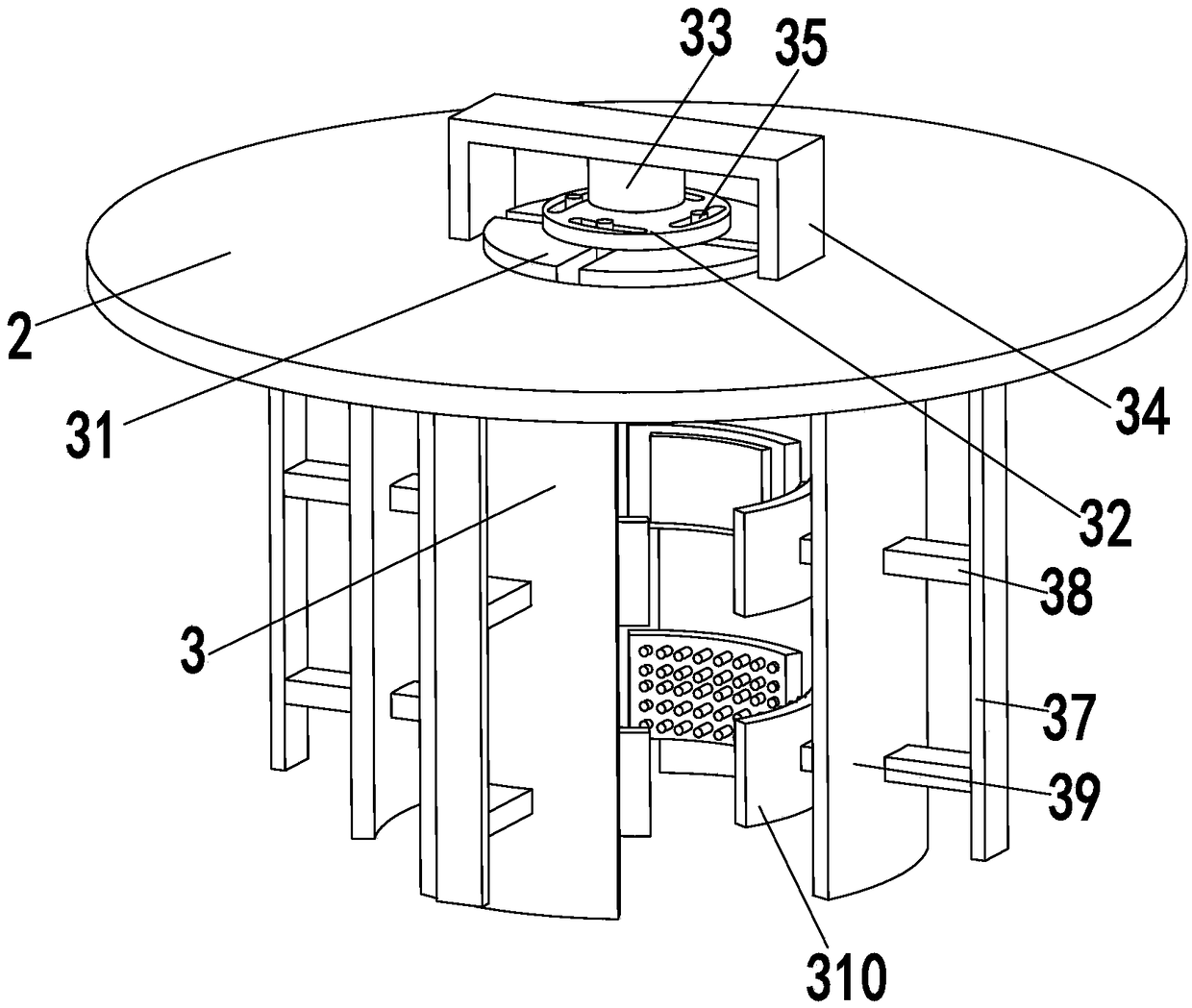

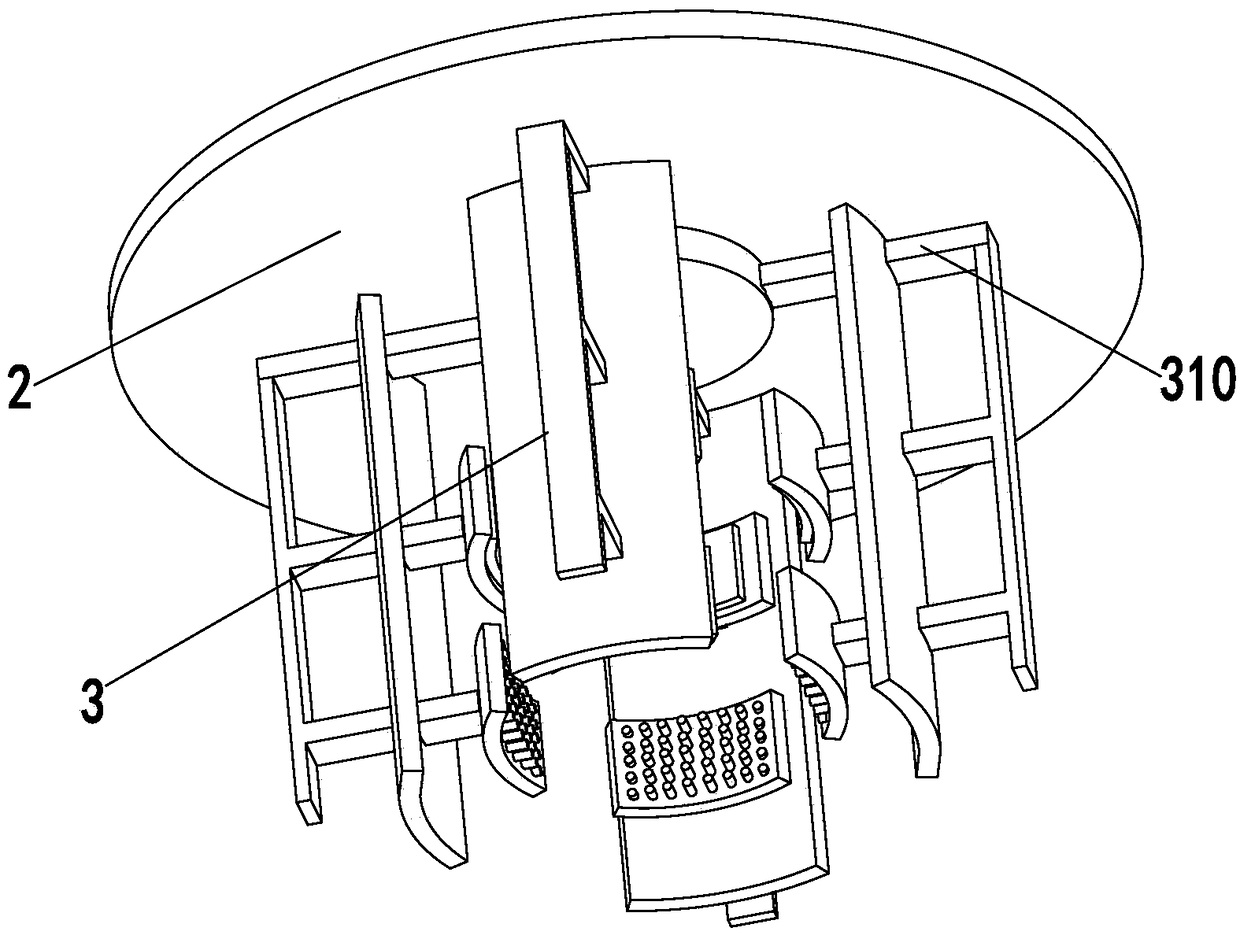

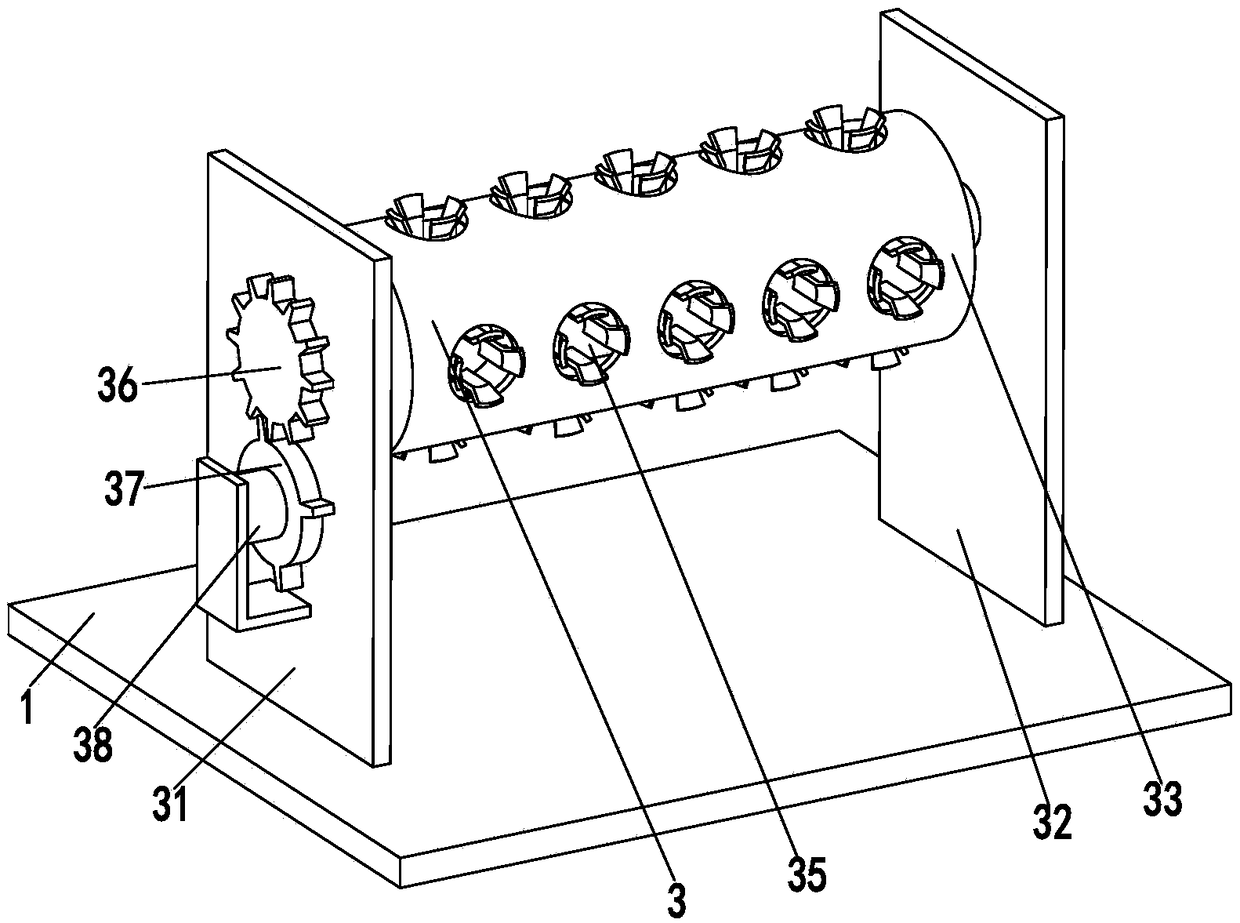

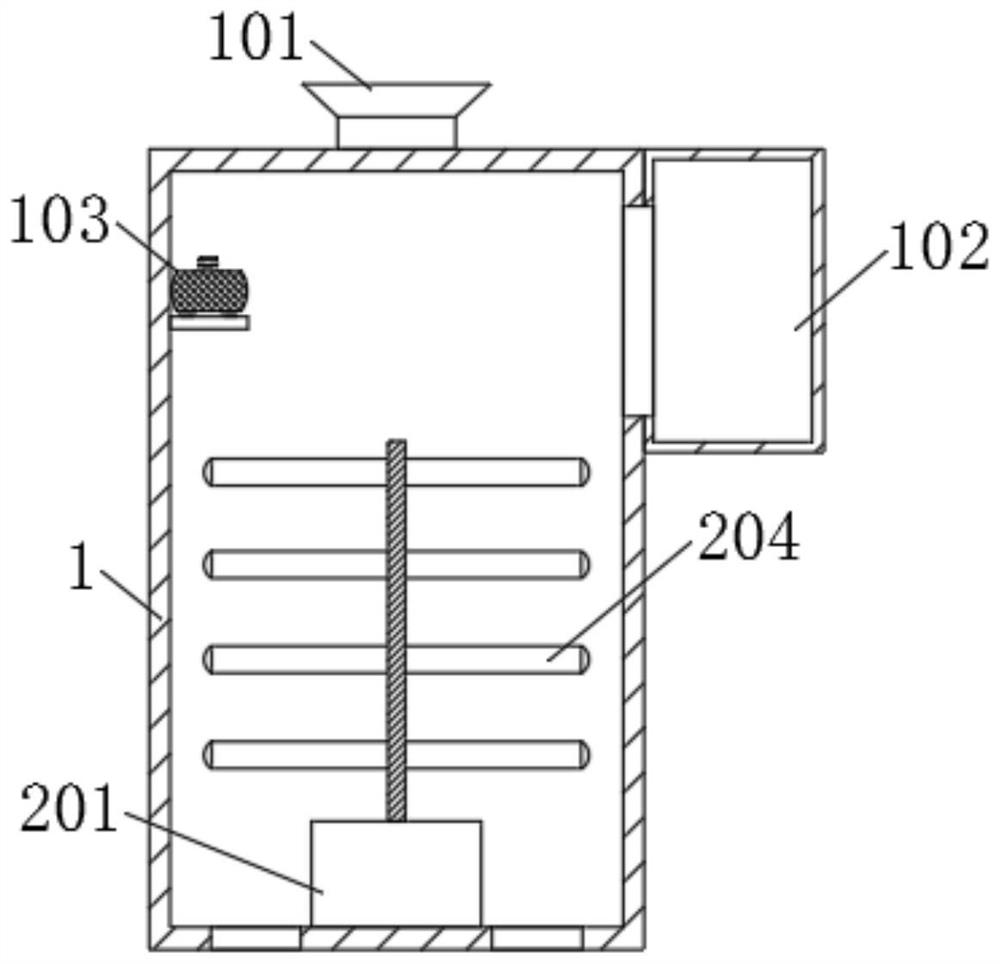

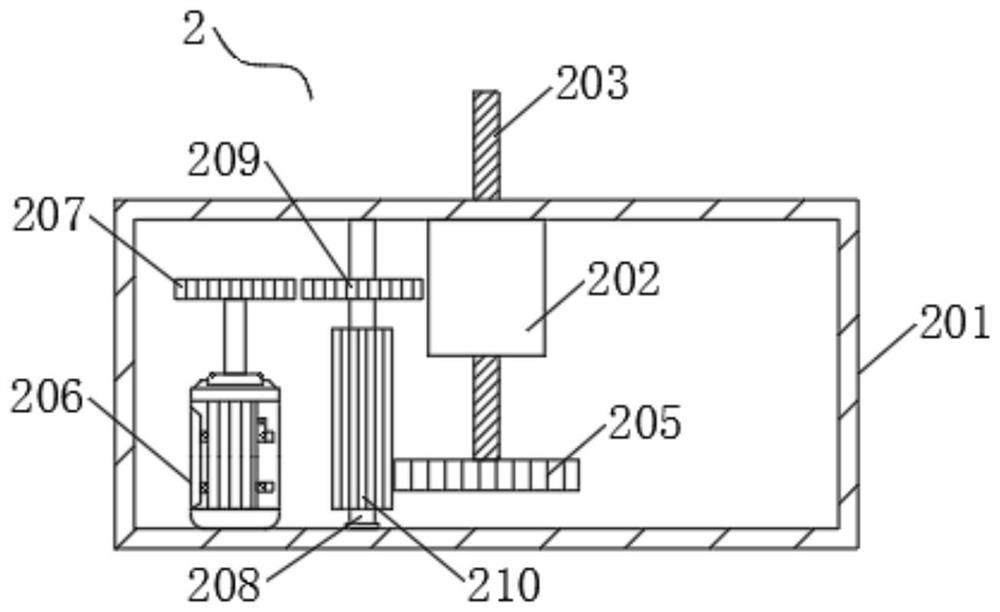

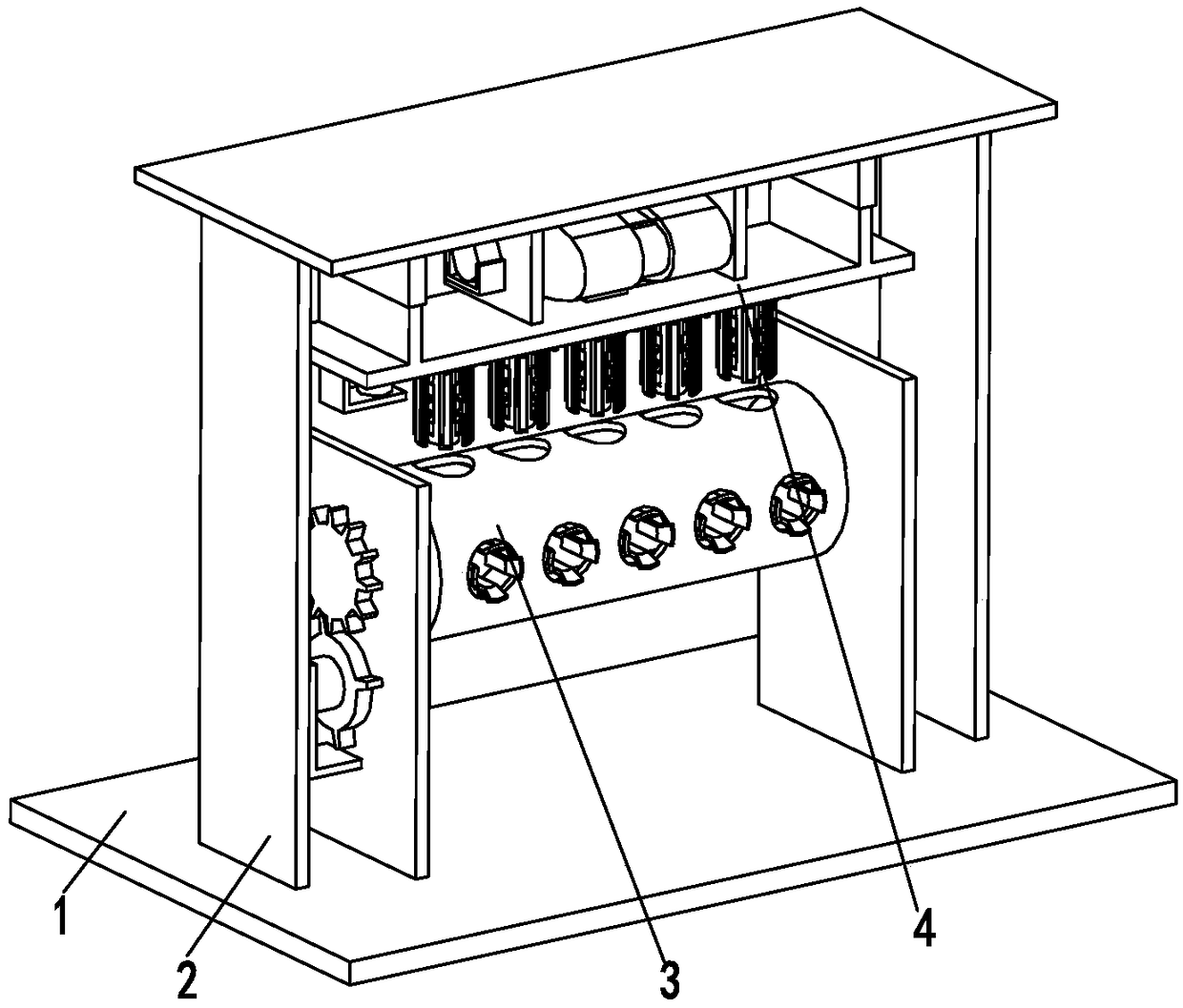

Raw material crushing and stirring device for brewing rice wine

InactiveCN109225432AImprove crushing efficiencyImprove work continuityGrain treatmentsEngineeringRaw material

The invention discloses a raw material crushing and stirring device for brewing rice wine. The raw material crushing and stirring device comprises a mounting frame, a grinding device, a crushing device and a transverse plate, wherein an air extractor is arranged on one side of the inside of the mounting frame; a sealed box is arranged on one side of the air extractor; a first rotating shaft is arranged at the lower end of the sealed box; a second belt wheel is arranged on the surface of the first rotating shaft; a plurality of crushing devices are arranged at the lower end of the second belt wheel; a plurality of crushing blades are arranged in the crushing device; a sieve plate is arranged under the lower ends of the crushing blades; a propping plate is arranged on one side of the sieve plate; a spring is arranged on one side of the propping plate; a discharging opening is formed in the lower end of the crushing device; the transverse plate is arranged on one side of the crushing device; a first rotating motor is arranged on one side of the upper end of the transverse plate; the grinding device is arranged at the upper end of the other side of the transverse plate. According to the raw material crushing and stirring device for brewing rice wine, the grinding device is arranged; a second grinding roller and a first grinding roller which are arranged in the grinding device rotate oppositely so as to grind and crush the raw rice in advance; the crushing efficiency is further improved.

Owner:叶彩英

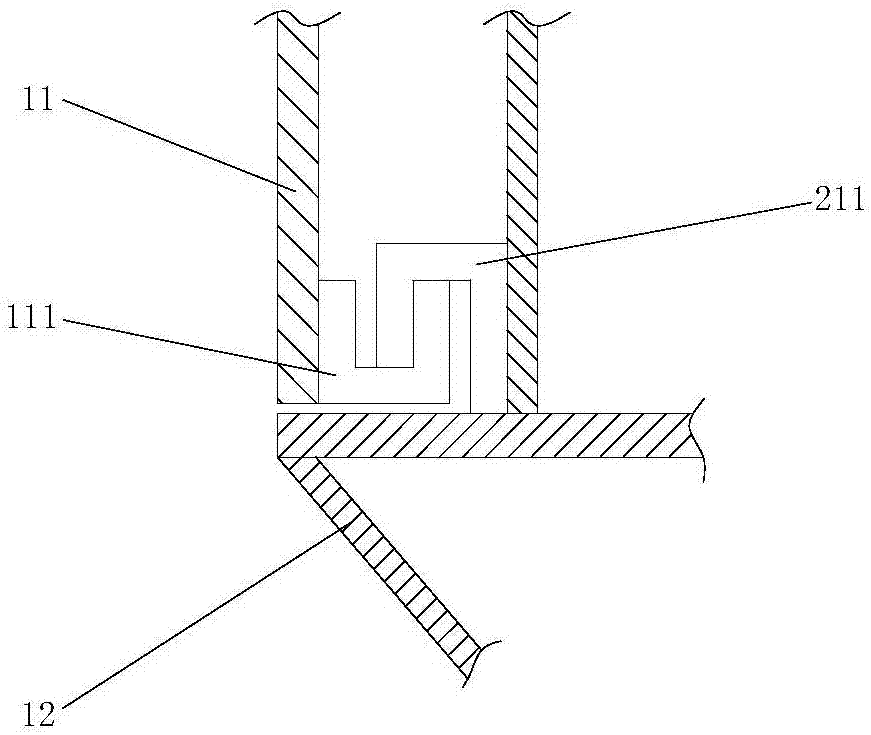

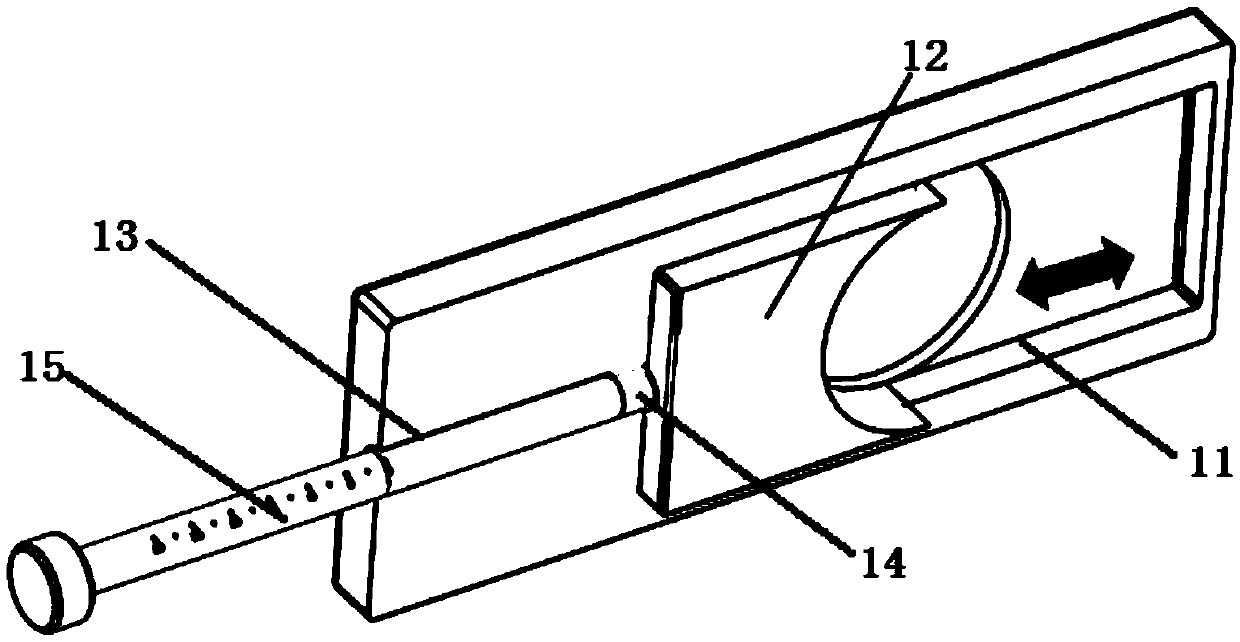

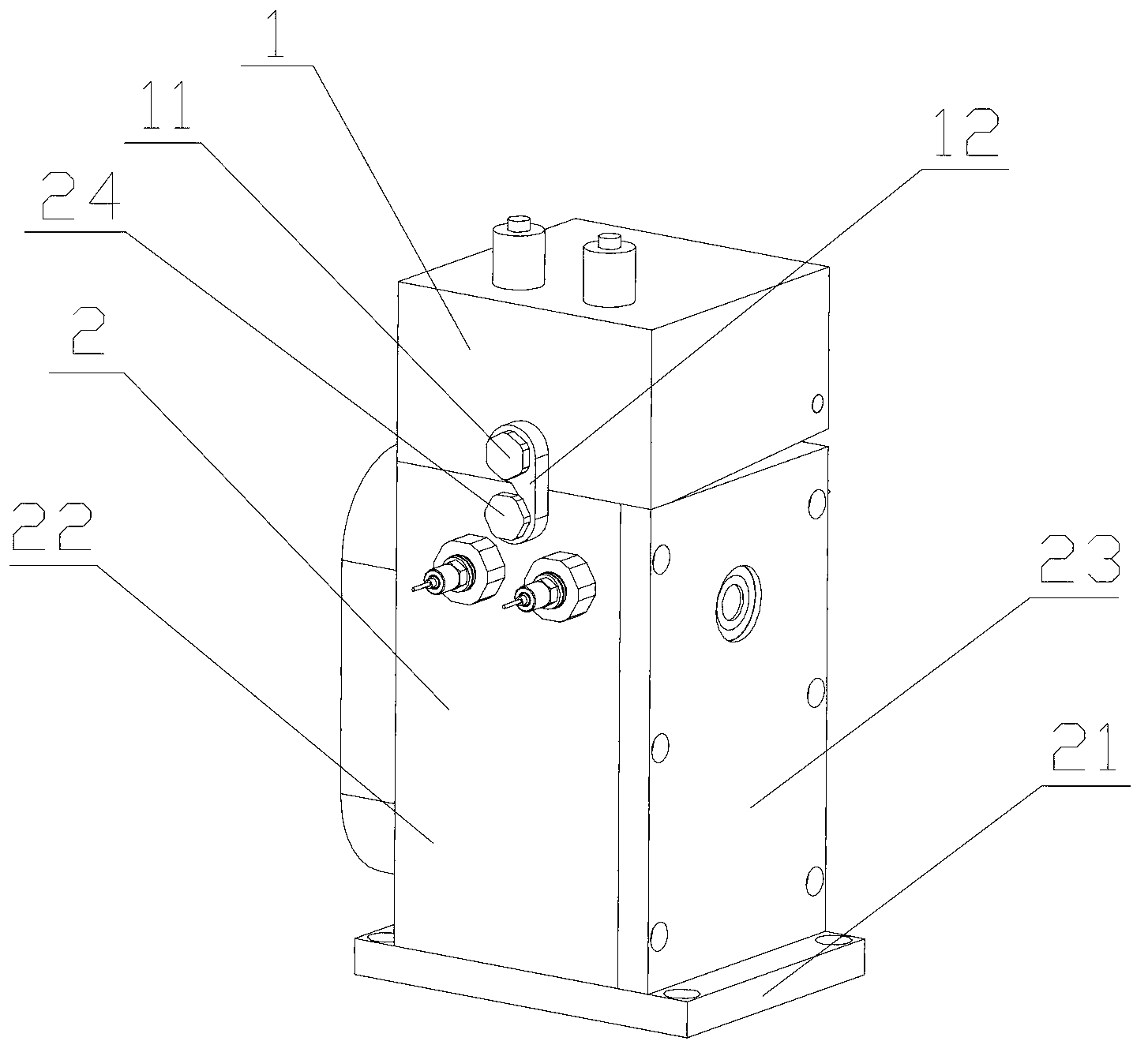

Device for adjusting areas of orifices of lubricating oil pipelines

InactiveCN109578604ATo achieve the purpose of throttlingShorten the timeSlide valveAviationThrottle control

The invention discloses a device for adjusting the areas of orifices of lubricating oil pipelines, and belongs to the technical field of design of aero-engine lubricating oil systems. The device comprises an adjusting pipeline arranged between the lubricating oil pipelines, and an adjusting valve. A channel is formed in the adjusting valve, a sliding way is arranged on the side portion of the channel, an adjusting plate (12) is slidingly arranged in the sliding way (11), when the adjusting plate (12) slides in the sliding way, the adjusting plate can at least partially block a through hole, athreaded hole (13) penetrating out of the adjusting valve is formed in one end of the sliding way in the sliding direction of the adjusting plate (12), a magnetic threaded rod (15) is screwed into thethreaded hole, a magnetic cylinder (14) is arranged at the end, stretching into the threaded hole (13), of the magnetic threaded rod (15), and the adjusting plate (12) is magnetic, and is attracted on the magnetic cylinder (14). Fluid in the lubricating oil system pipelines can be subjected to throttle control without splitting the lubricating oil pipelines in the test process, , and the purposeof throttling lubricating oil flow ways or air flow ways is achieved.

Owner:AECC SHENYANG ENGINE RES INST

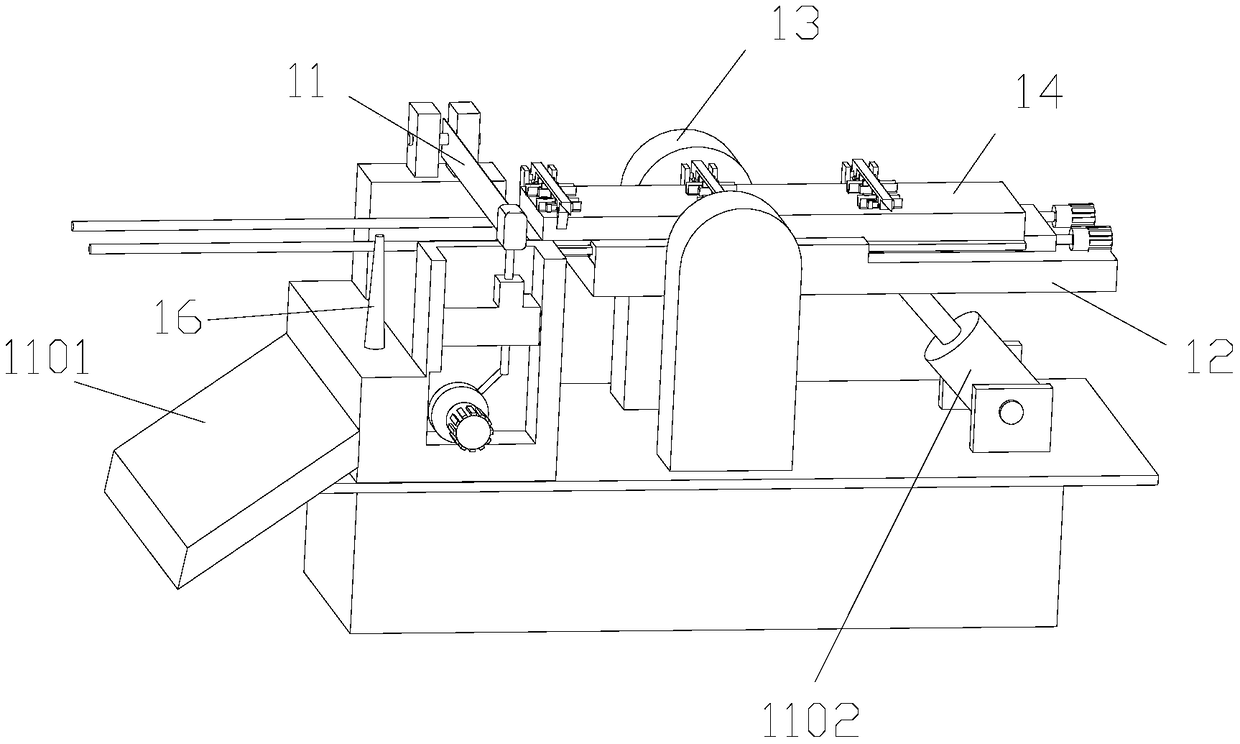

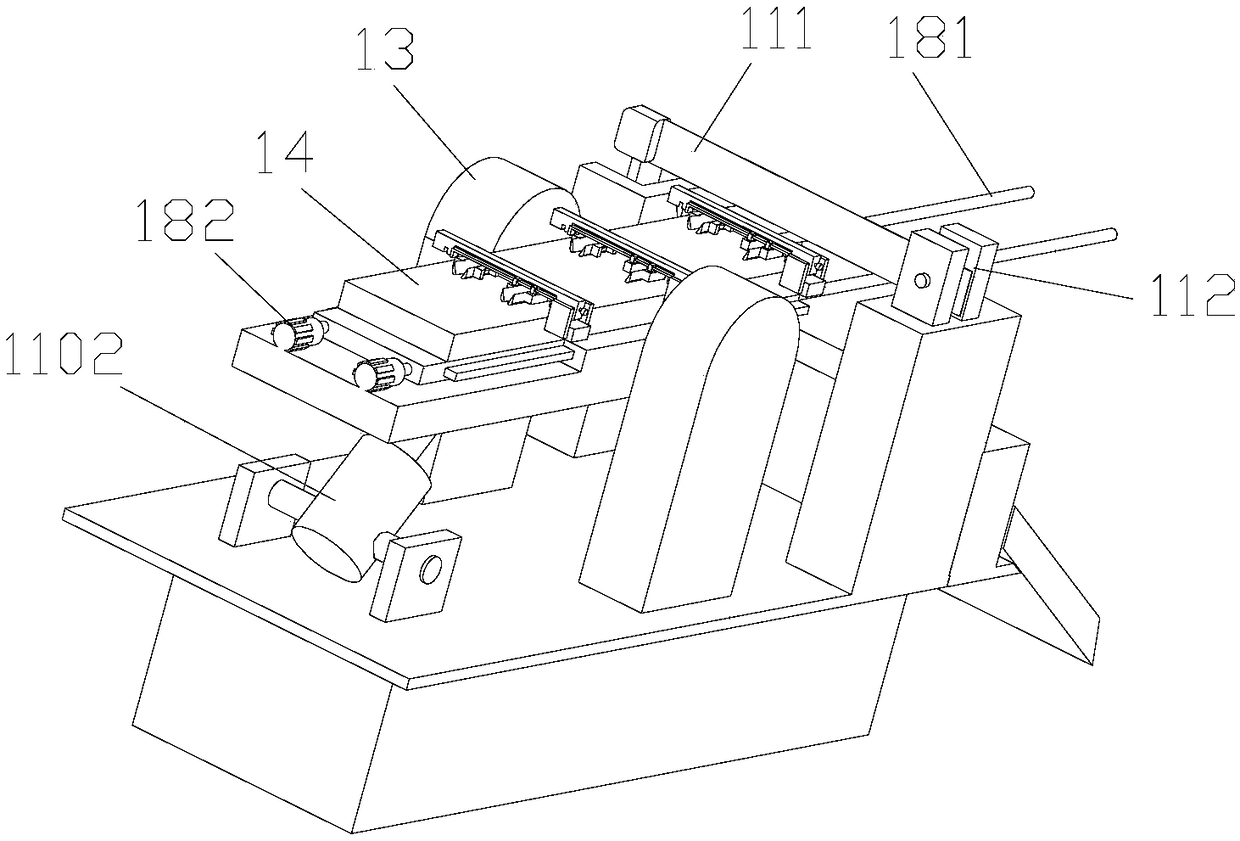

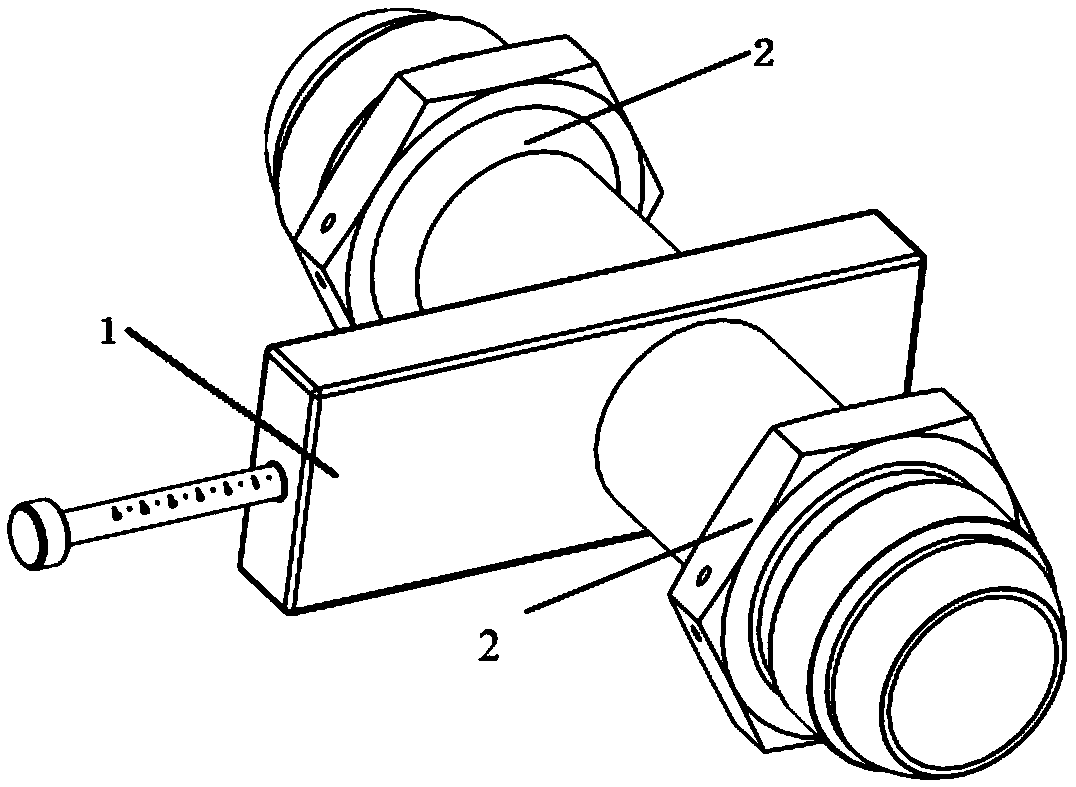

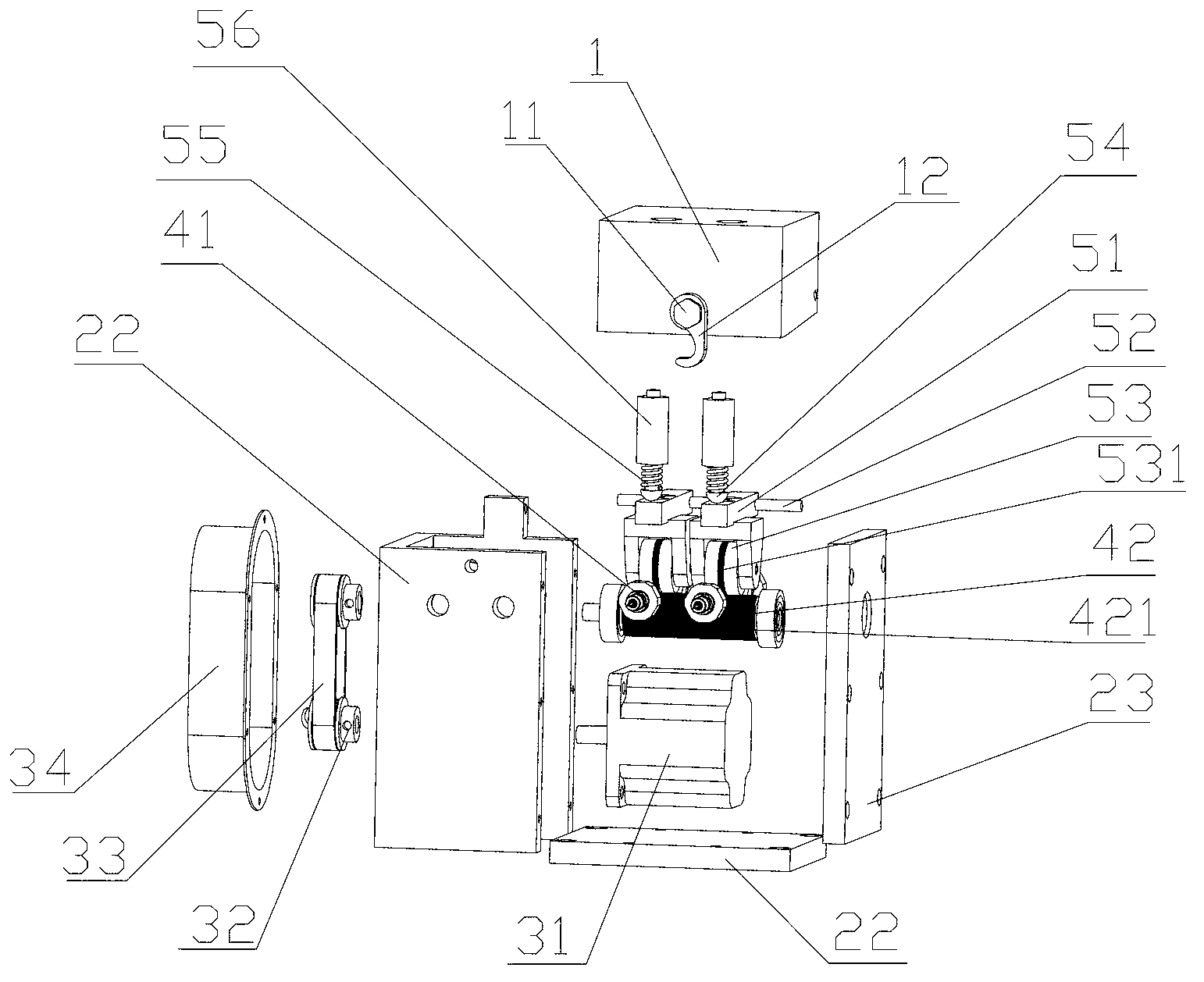

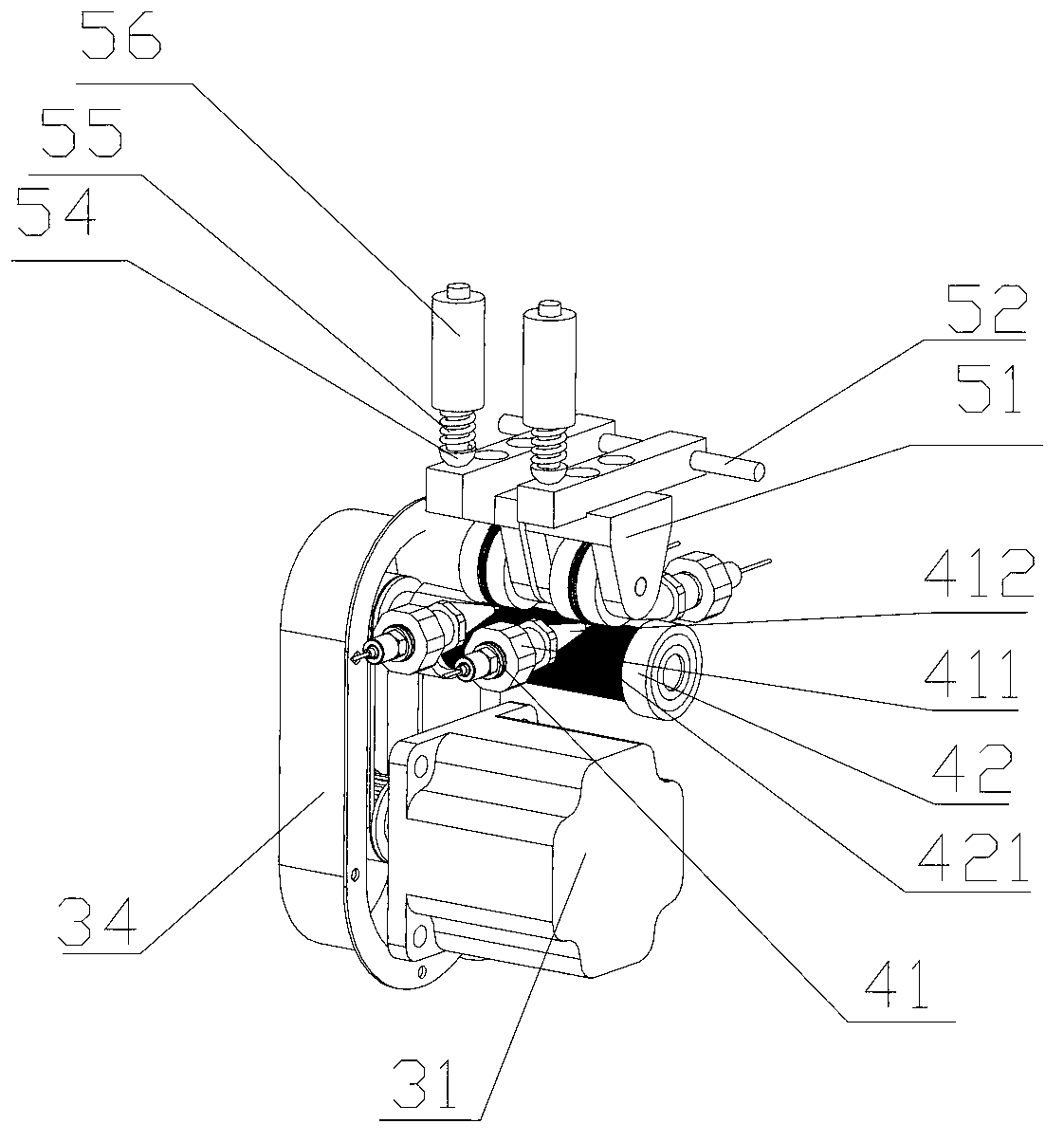

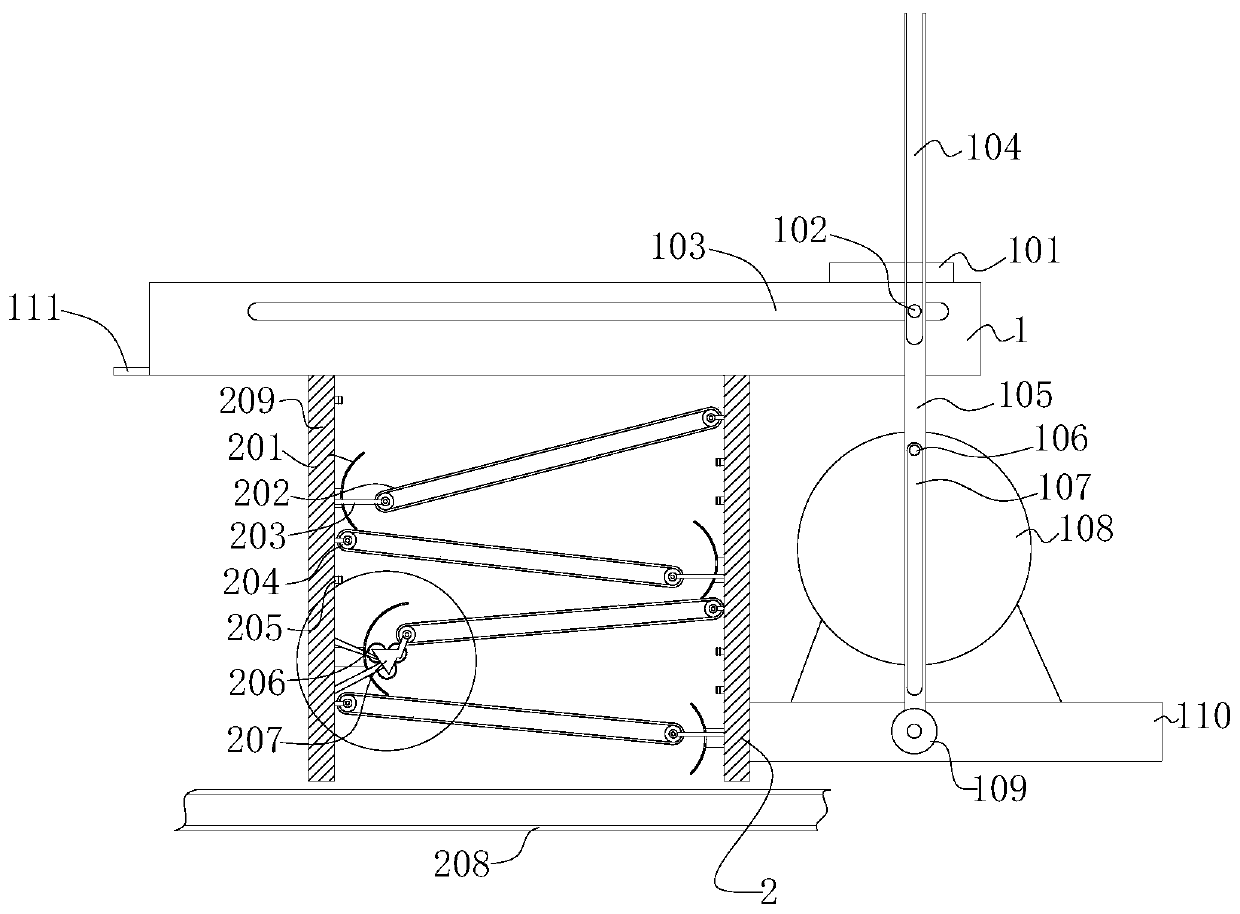

Wire feeder

InactiveCN103302425APrecisely determine the lengthRealize the function of fixed-length conveyingWelding/cutting auxillary devicesAuxillary welding devicesGear wheelHorizontal axis

The invention discloses a wire feeder which comprises an upper cover, a machine body, a stepping driving mechanism, wire feeder bodies and a positioning mechanism, wherein the stepping driving mechanism is mounted in the machine body; fixed-length output of a welding wire is realized by the aid of the arrangement of the stepping driving mechanism; the upper cover and the machine body are connected in an opening and closing manner; an opening and closing mechanism is arranged, so that the upper cover can be flexibly opened or closed, and auxiliary-penetration of welding wires at a wire feeding stage is realized; at least two wire feeder bodies are provided, and the wire feeder body comprises two wire guides fixed on the machine body and a wire feeding gear; through holes are formed in both wire guides; the through holes are located on the same horizontal axis after the wire guides are fixed; the wire feeding gear is arranged between the wire guides and connected with the stepping driving mechanism; the positioning mechanism is mounted in the upper cover and located above the wire feeding gear, and can be closely combined with the wire feeding gear during working; according to the wire feeder, the upper cover can be opened, wire penetration is facilitated, the work continuity is high, fixed-length output of the welding wires is realized, the production efficiency is improved, and waste is avoided.

Owner:DONGGUAN ZHUOLE PRECISION MACHINERY TECH

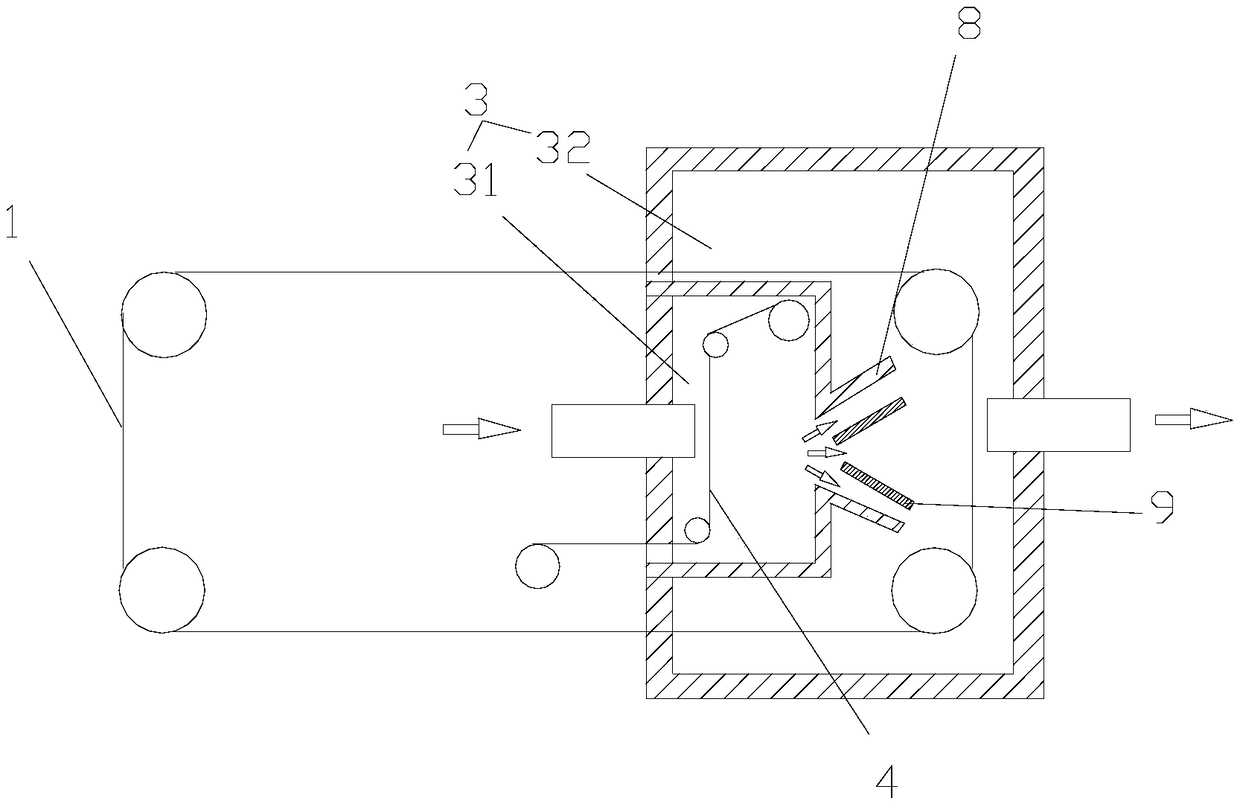

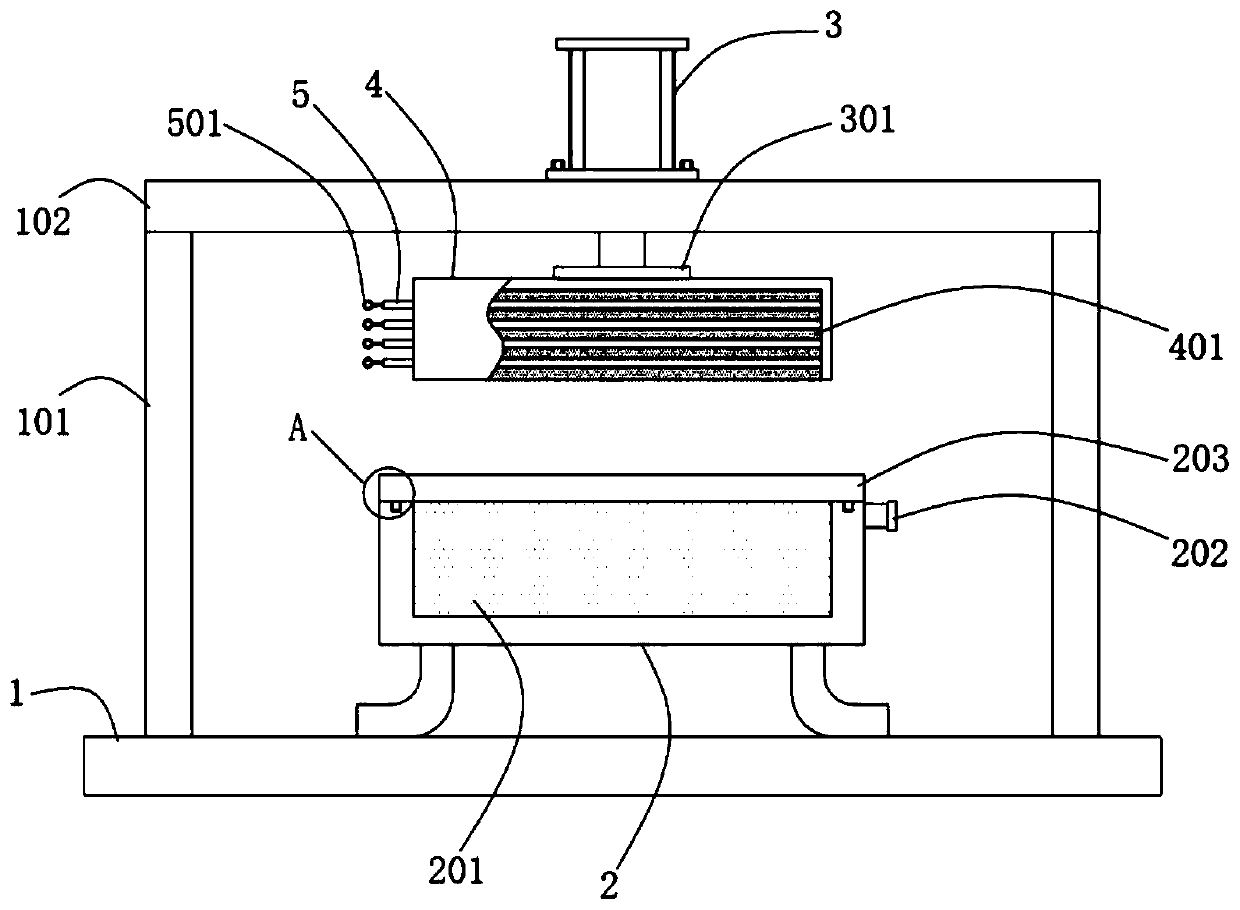

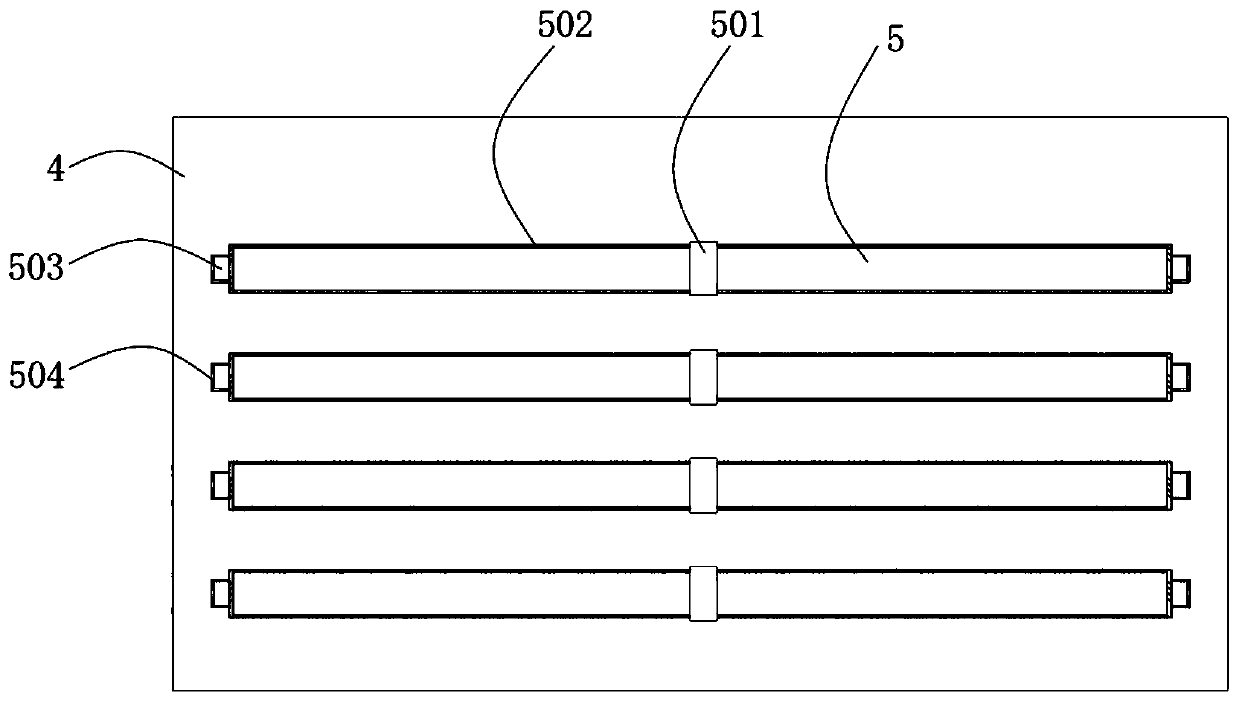

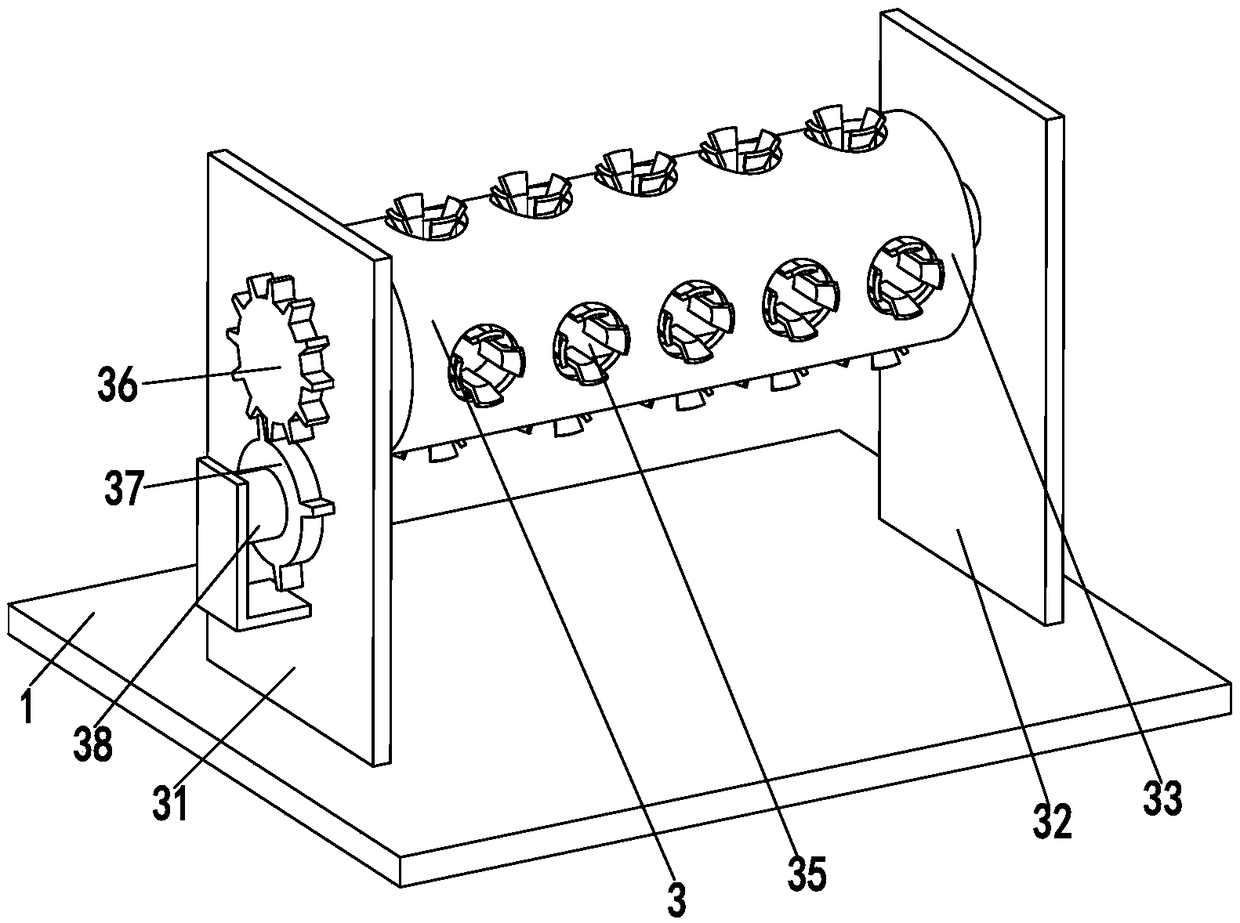

Device for oriented adding of steel fibers into concrete

ActiveCN110802738AImprove work continuityHigh tensile strengthCement mixing apparatusSold ingredients supply apparatusArchitectural engineeringStructural engineering

The invention discloses a device for oriented adding of steel fibers into concrete. The device comprises a base, supporting columns are fixedly connected to the four corners of the top of the base, supporting plates are fixedly connected between the tops of the supporting columns, telescopic air cylinders are fixedly mounted in the middles of the upper ends of the supporting plates, the output ends of the telescopic air cylinders penetrate to the bottoms of the supporting plates to be fixedly connected with fixed plates, feed boxes are fixedly mounted on the fixed plates through bolts, one side of each feed box is slidingly connected with bearing partition plates from top to bottom, the partition plates are evenly distributed, the middle of the base is fixedly provided with a mold base, the top of the mold base is clamped with a seal cover tightly, and the upper end of one side of the mold base is fixedly connected with an injection opening. According to the device, multiple layers ofsteel fibers can be conveniently and sequentially guided into concrete slurry, work continuity is high, loading is portable and rapid, work efficiency can be greatly improved, tensile strength and toughness of a concrete part are improved, and the product quality is ensured.

Owner:FOSHAN UNIVERSITY

Automobile air purifier

InactiveCN107303799AEfficient removalPracticalHuman health protectionAir-treating devicesGas pipelinePhotocatalysis

The invention discloses an automobile air purifier which comprises a shell, wherein an air inlet is formed on the left side of the shell; the air inlet is communicated with the interior of the shell through a first air pipeline; a filtering device, a first purifying chamber, a second purifying chamber and an air humidifying chamber are successively arranged in the shell from left to right; the filtering device is communicated with the first purifying chamber; an anion generator is arranged in the first purifying chamber; the first purifying chamber and the second purifying chamber are connected through a nanometer photo-catalyst net; an ultraviolet lamp is arranged in the second purifying chamber; the second purifying chamber and the air humidifying chamber are connected through a nanometer photo-catalyst net; the air humidifying chamber is connected with an air vent on the right side of the shell through a second air pipeline; and a circulating chamber is arranged on the lower parts of the filtering device, the first purifying chamber, the second purifying chamber and the air humidifying chamber. The automobile air purifier can effectively remove ash, organic gas and microorganism from air and is characterized by high practicability, simple structure, reasonable design and high working continuity.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

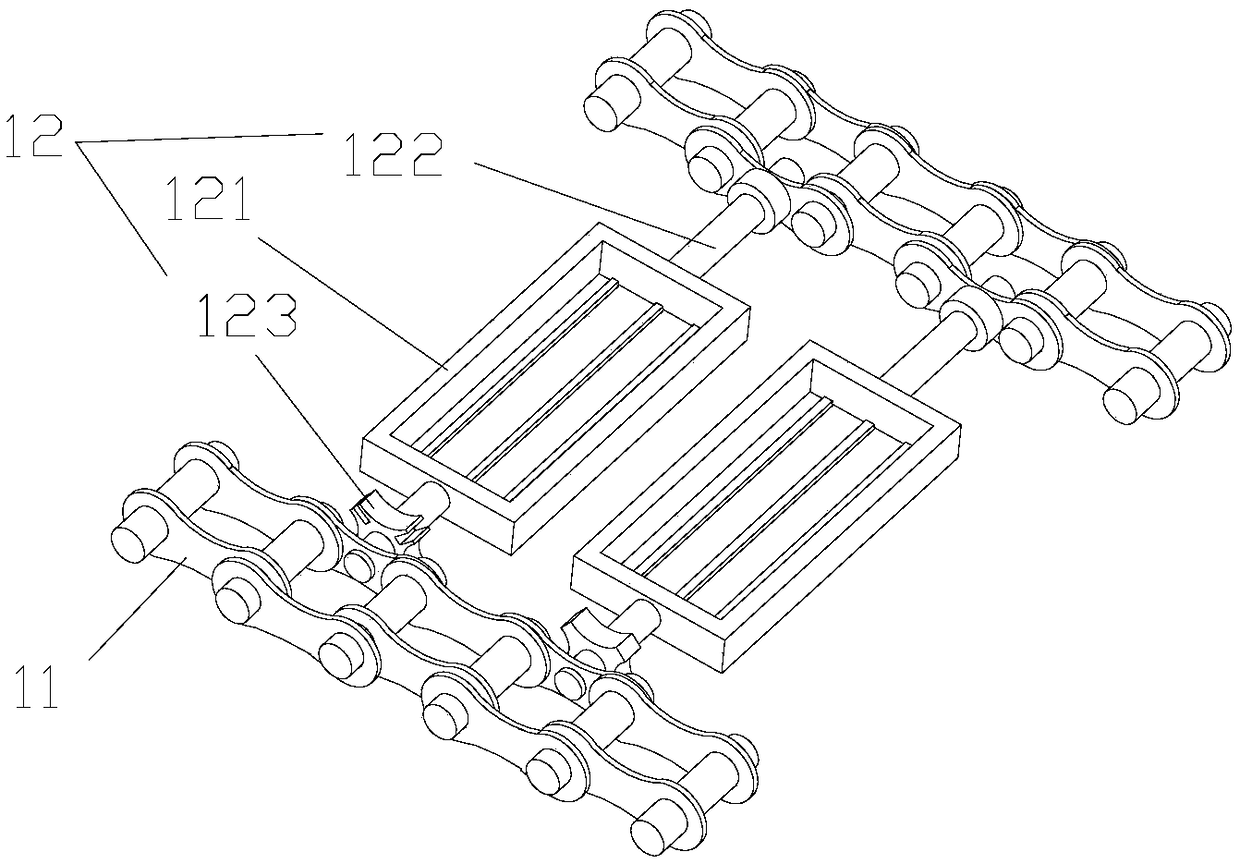

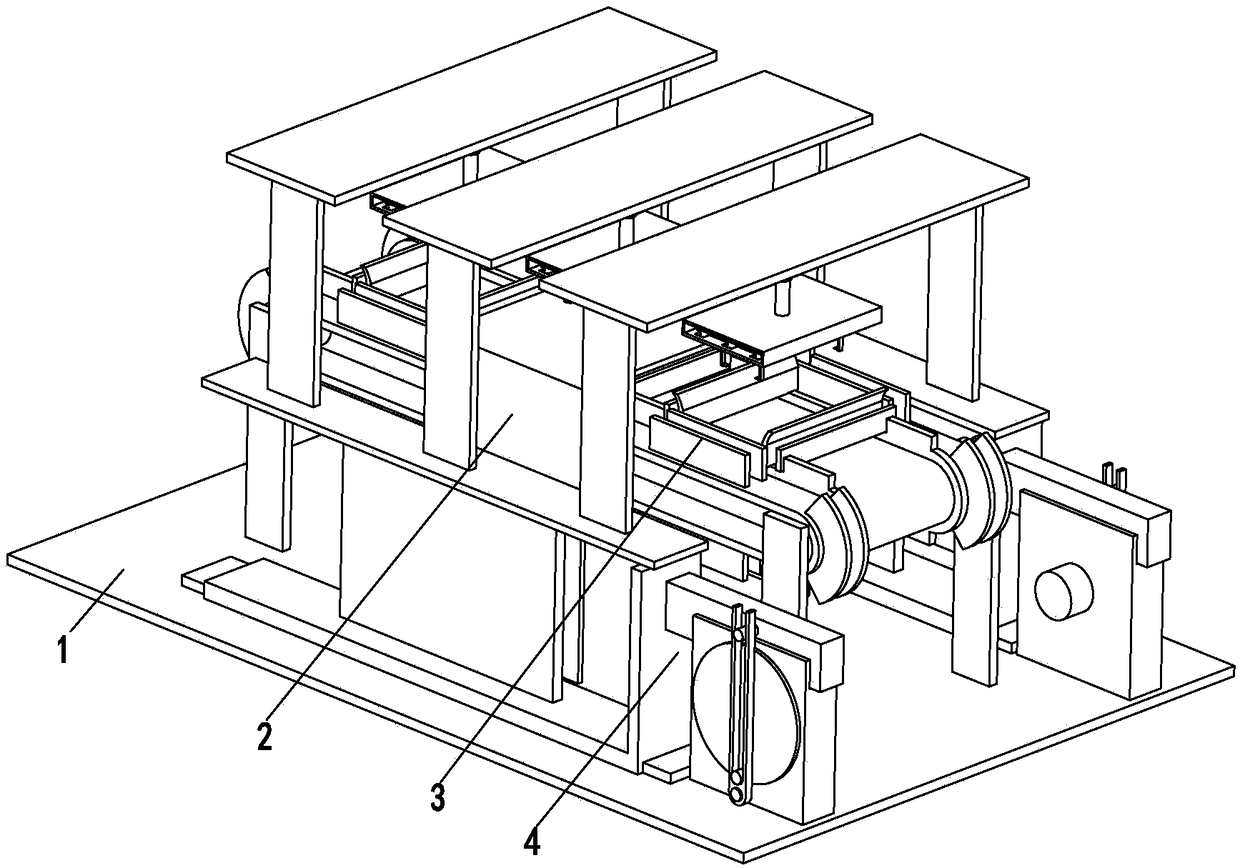

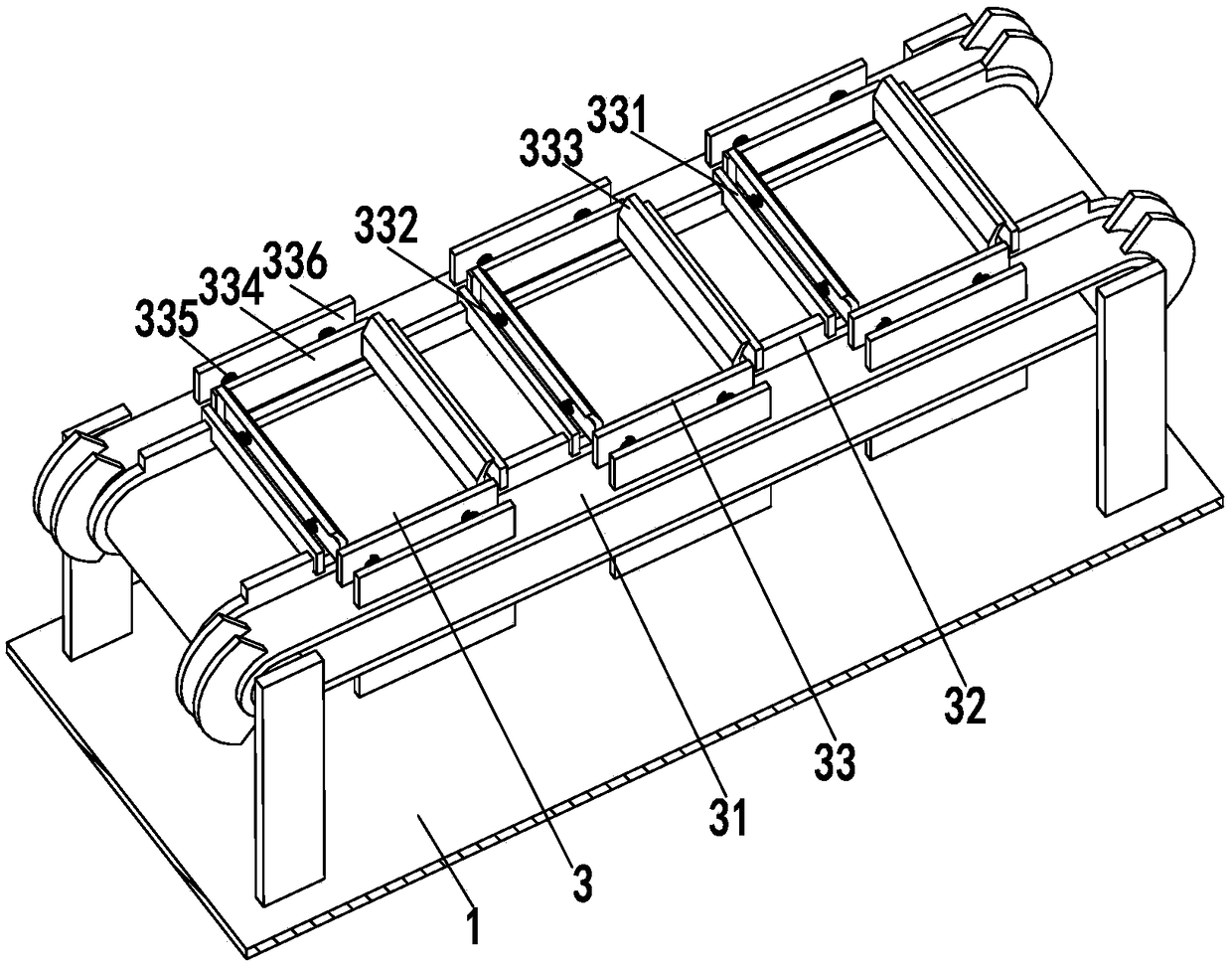

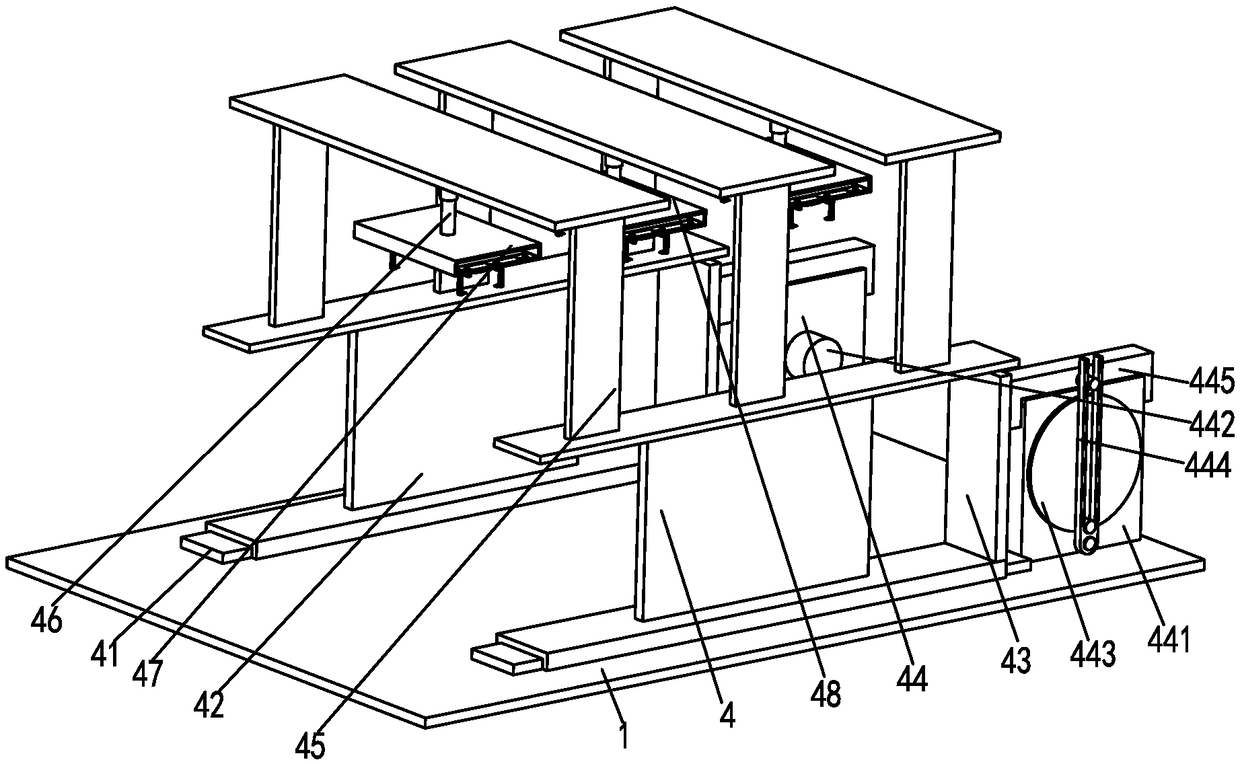

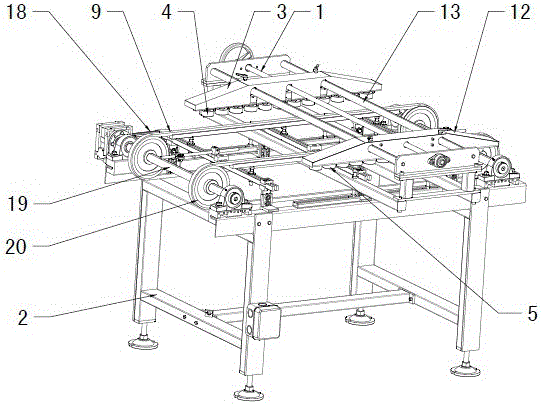

Filter screen production equipment for mobile air conditioner

The invention relates a filter screen production equipment for a mobile air conditioner. The filter screen production equipment for the mobile air conditioner comprises a bottom plate, a workbench, amaterial conveying device and a shifting device, wherein the middle part of the bottom plate is provided with the material conveying device, the shifting device is arranged on the front side of the material conveying device, the workbench is arranged at the upper end of the material conveying device, the workbench and the shifting device are installed on the bottom plate, the material conveying device comprises a belt type material conveying machine, a material placing frame and a positioning frame, the shifting device comprises a linear guide rail, a sliding frame, a pushing plate, a pushingmechanism, a mounting frame, a lifting air cylinder, a working frame and a shifting mechanism. The filter screen production equipment can solve the problems of high labor cost, high labor intensity, potential safety hazards exist, low working precision and prone to cause the filter screen to be scrapped and the like in the existing filter screen production process, so that the functions of automatically taking, placing and collecting the filter screen can be realized, the filter screen production equipment has the advantages that the manual cost is low, the labor intensity is low, the safety is high, the working precision is high, the rejection rate of the filter screen is low and the like.

Owner:ZHEJIANG OULUN ELECTRIC

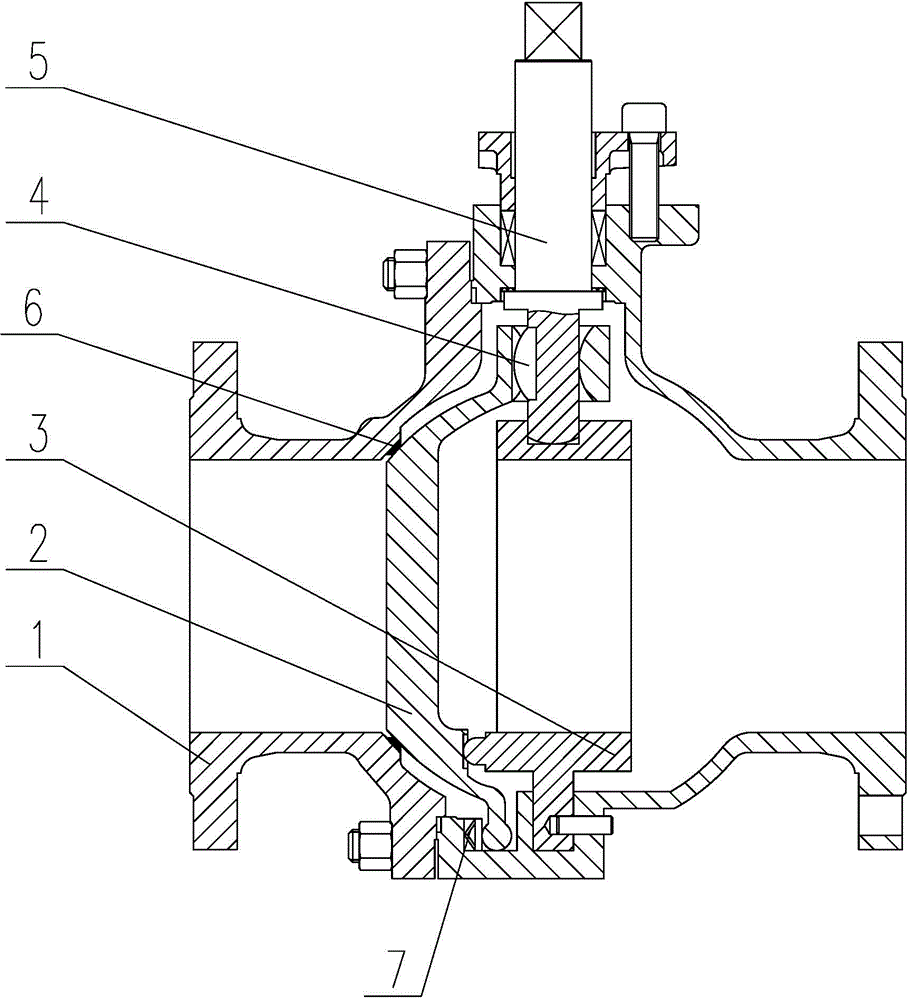

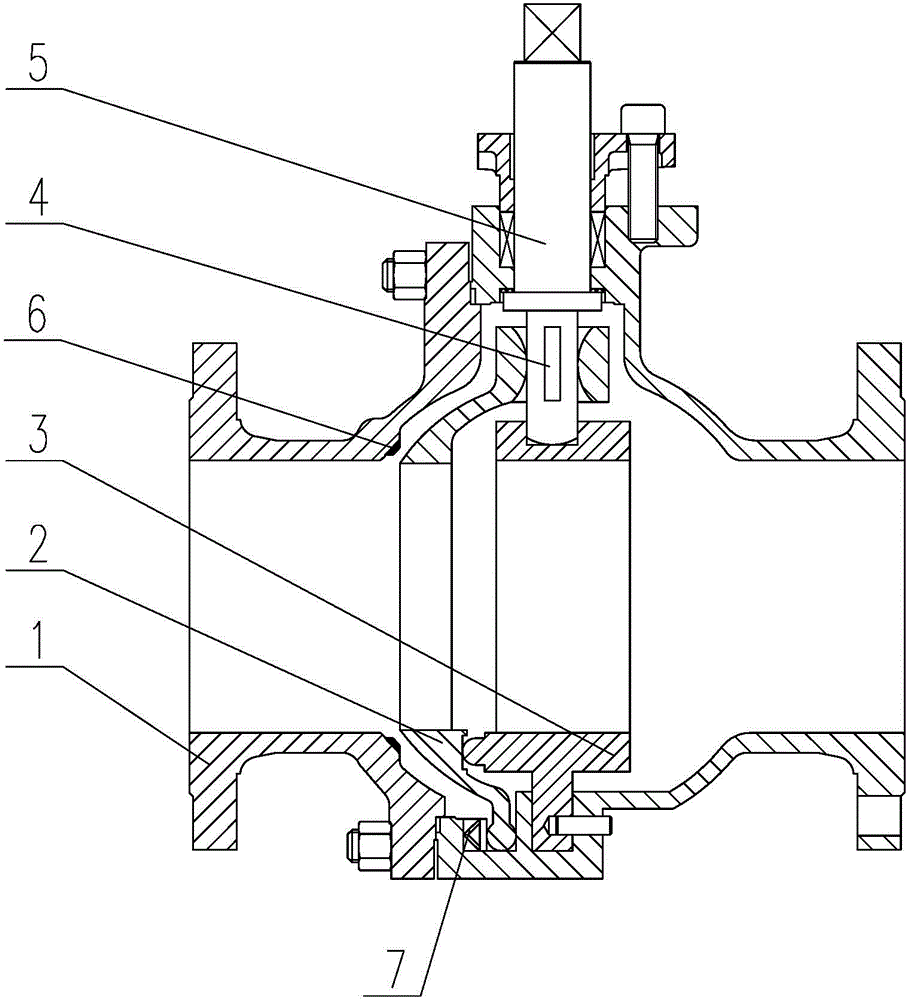

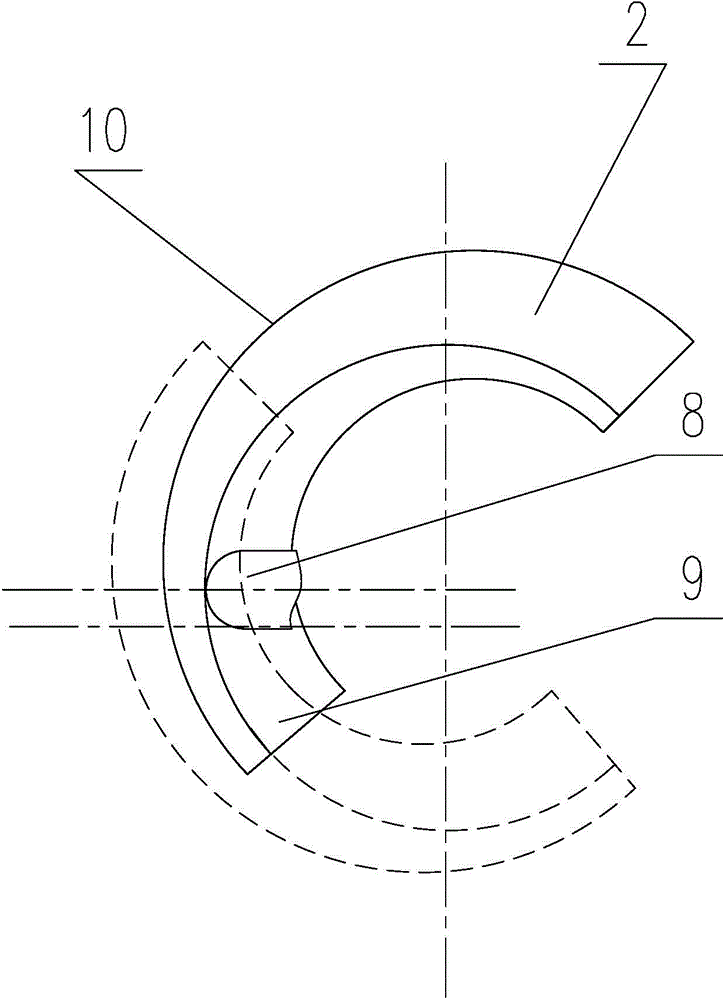

Rigidity-seal ball valve with guide rail

The invention discloses a rigidity-seal ball valve with a guide rail. The rigidity-seal ball valve with the guide rail is characterized in that a valve clack and an inner passage ring are arranged in a fluid passage of a valve body; the valve clack takes the shape of a hemispheroid; a rotating guide groove is formed in the inner side surface of the valve clack; the depth of the guide groove is gradually reduced from the start end to the tail end; the lower end of the inner passage ring is fixedly mounted on the inner wall of the valve body; a guide jacking block is arranged on the left side surface of the lower end of the inner passage ring; the jacking block is matched with the guide groove; a mounting hole is formed in the neck part of the valve flack; the inner wall of the mounting holes adopts a convex arc structure; the lower end of a valve rod is arranged in the mounting hole; the valve rod is in transmission with the valve clack to enable the valve clack to rotate to open or close; when the guide groove moves along the guide jacking block, the valve clack is enabled to be deviated to be separated from or to be in fit with a valve base; an elastic device is arranged between the outer side of the lower end of the hemispheroid valve clack and the valve body. The rigidity-seal ball valve with the guide rail is simple in structure, and convenient to use, can effectively reduce wear between the valve clack and the valve base, can make up a gap caused by wear through rotation offset of the valve clack, and the sealing performance keeps good.

Owner:常州亿米基电站辅机有限公司

Automatic cleaning system for environment-friendly drug bottle

ActiveCN109201679AAchieve the purpose of cleaningSolve the costHollow article cleaningDrying gas arrangementsDrive motorEngineering

The invention relates to an automatic cleaning system for an environment-friendly drug bottle, comprising a base plate, an installation rack, a conveying device, a bottle cleaning device and an auxiliary device; the installation rack is installed on the base plate; the installation rack is a structure capable of extending in left and right directions; the lower end of the installation rack is provided with the bottle cleaning device; the conveying device is arranged at the lower end of the bottle cleaning device; the auxiliary device is arranged at the lower end of the conveying device; the conveying device and the bottle cleaning device are installed on the base plate; and the conveying device comprises a No.1 fixing plate, a No.2 fixing plate, a conveying barrel, a material placing barrel, a material placing rack, a rotary gear, a drive gear and a drive motor. The automatic cleaning system for the environment-friendly drug bottle provided by the invention can solve the defects of high labor cost, low working efficiency, poor working continuity, incomplete cleaning and small using scope of the current environment-friendly drug bottle during the cleaning process; the automatic cleaning function of the environment-friendly drug bottle can be realized; and the automatic cleaning system has the advantages of low labor cost, high working efficiency, high working continuity, complete cleaning and wide using scope, etc.

Owner:SHANDONG XINHUA PHARMA CO LTD

Sorting and separating device for waste plastics

InactiveCN113601755AFit closelyFully sortedPlastic recyclingProcess engineeringMechanical engineering

Owner:界首市云锋再生资源有限公司

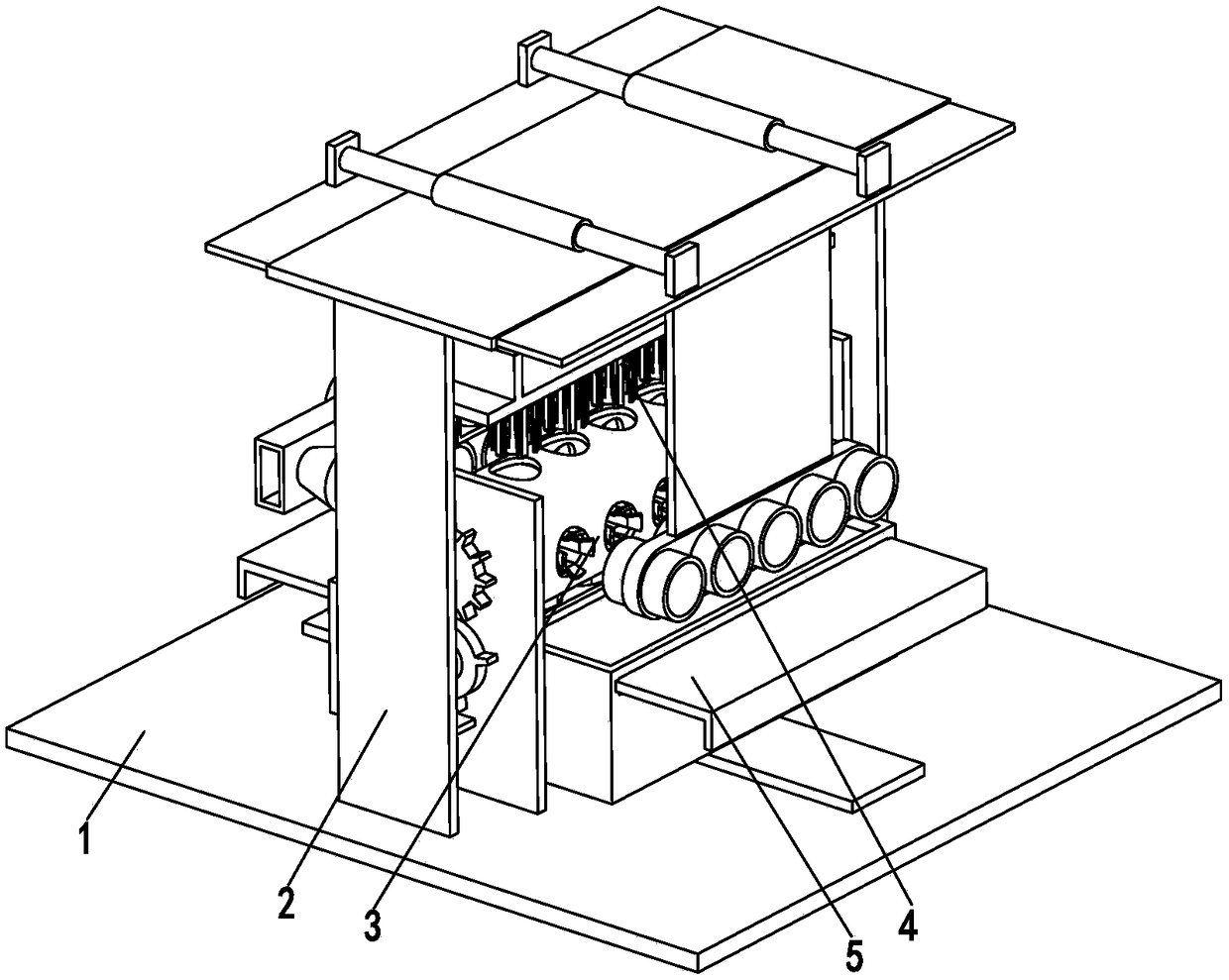

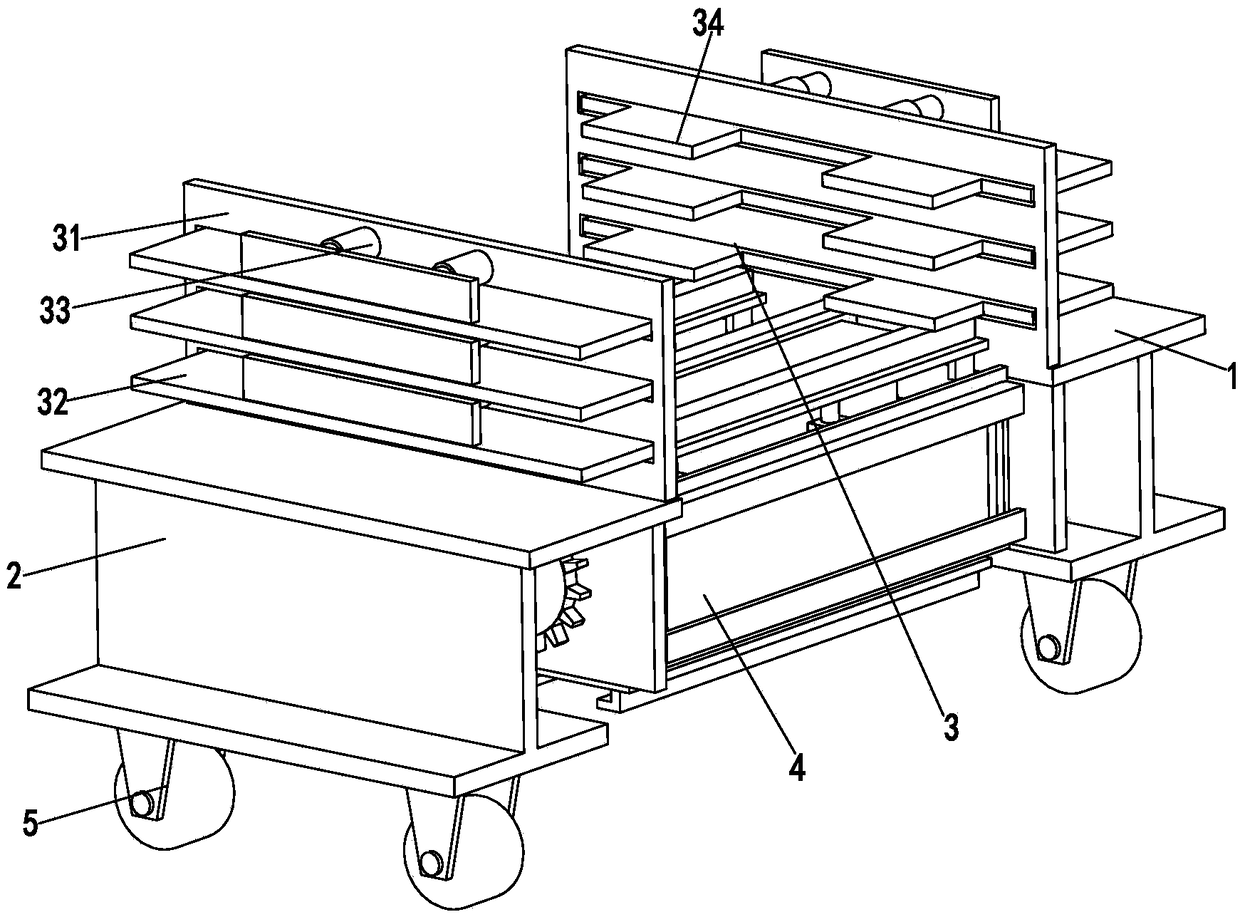

Sleeper automatic laying robot for railway emergency rescue and disaster relief

ActiveCN109281237ARealize automatic layingIncrease labor costRailway track constructionEmergency rescueEngineering

The invention relates to a sleeper automatic laying robot for railway emergency rescue and disaster relief. The sleeper automatic laying robot comprises two base plates, working frames, storing frames, a laying device and traveling wheels; the two base plates are arranged in a bilateral symmetry mode, and the working frames are mounted at the lower ends of the base plates; the traveling wheels aremounted at the lower ends of the working frames, and the storing frames are mounted at the upper ends of the base plates; the laying device is mounted between the two base plates, and the storing frames comprise mounting plates, adjusting frames, adjusting air cylinders and placing plates; and the laying device comprises a vertical plate, a rotating plate, a rotating motor, a mounting frame, a rotating gear, a rotating tube, a telescopic supporting plate, a bearing plate, a fixing plate, a fixing electric push rod and a fixing ring. The problems that in the existing process of sleeper layingfor railway emergency rescue, the labor cost is high, the working efficiency is low, the work continuity is poor, and large equipment works difficultly can be solved, the function of automatic layingon a sleeper can be achieved, and the sleeper automatic laying robot has the advantages of being low in labor cost, high in working efficiency, high in work continuity, small in size and the like.

Owner:胡佳威

Humidifying processing method for manufacture of shaving board material

ActiveCN110587743AImprove work continuityImprove continuous deliveryFlat surfacing machinesWood dampingMaterials processingMaterials science

The invention discloses a humidifying processing method for manufacture of a shaving board material, and relates to the technical field of board material processing. The method comprises the followingsteps: S1, planing processing: a regular wood surface is subjected to planing processing and processed into a sheet-like material by planing; S2, wet spraying processing: the surface of the sheet-like material obtained after planing in S1 is subjected to wet spraying processing, and humidity of the surface of the sheet-like material is uniform; S3, crush cutting: the sheet-like material with uniform humidity obtained after wet spraying in S2 is subjected to crush cutting, and finely broken wood shavings are obtained; S4, uniform spreading: the wood shavings obtained in S3 are uniformly spreadon a conveying belt, and conveyed to the next process through the conveying belt. A humidifying processing device is arranged at the bottom of a planing machine, the shaving board material is planedinto the sheet-like material by the planing machine conveniently and then falls into the humidifying processing device at the lower part, the material is automatically fed into the humidifying processing device, and therefore, working continuity of the humidifying processing device is improved.

Owner:亚丹生态家居(荆门)有限公司

Automatic cleaning robot of environmentally-friendly reagent bottle

ActiveCN109078950ASolve the costSolve efficiency problemsHollow article cleaningGear wheelEngineering

The invention relates to an automatic cleaning robot of an environmentally-friendly reagent bottle. The automatic cleaning robot comprises a bottom plate, a mounting frame, a conveying device and a bottle washing device, wherein the mounting frame is mounted on the bottom plate; the bottle washing device is mounted at the lower end of the mounting frame; the conveying device is arranged at the lower end of the bottle washing device; the conveying device is mounted on the bottom plate; the conveying device comprises a first fixed plate, a second fixed plate, a conveying barrel, a material placement barrel, a material placement barrel, a rotating gear, a drive gear and a drive motor; and the bottle washing device comprises a first mounting plate, a second mounting plate, a rotating motor, arotating shaft, a rotary adjustment block, a connection sliding block, a lifting frame, a driving motor, a driving gear, a driven gear and a bottle washing brush. The automatic cleaning robot can overcome the shortcomings of high labor cost, low working efficiency, low work continuity, incomplete cleaning, small use range and the like in an existing cleaning process of the environmentally-friendlyreagent bottle and can realize an automatic cleaning function for the environmentally-friendly reagent bottle.

Owner:江西省琪琪医疗器械有限公司

High speed straight cuff machine

The invention discloses a high-speed straight cuff machine, and relates to the technical field of packaging. The machine comprises a working bracket. The outer wall of the working bracket is fixed toa plurality of sealing plates, the middle of the outer wall of the working bracket is fixed to a fixed horizontal plate. An auxiliary column is embedded on the top two sides of the fixed horizontal plate, an operation panel is arranged on the front side of the auxiliary column, and a cutting lift slider is slidably arranged on the inner side of the auxiliary column near the top. By arranging a cutting lifting slider, a buffer bar, a buffer spring and a descending plate, the high-speed straight cuff machine can ensure that a cutting beam does not rise excessively while rising, and causing collisions with other parts. The machine improves the working stability of the device. By arranging a cutting table, a lifting screw rod, a reset spring and a reset rod, the machine can realize the rapid adjustment and buffering of the cutting table, avoiding direct contact between a blade and the cutting table, causing the problem of damage to packaging plastic. The working continuity of the device isimproved.

Owner:SHANGHAI KUKO PACKING MACHINERY

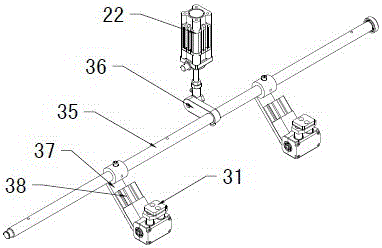

Centering adjustment mechanism and tile sorting device

InactiveCN106335776ASimple structureImprove work continuityConveyor partsEngineeringMechanical engineering

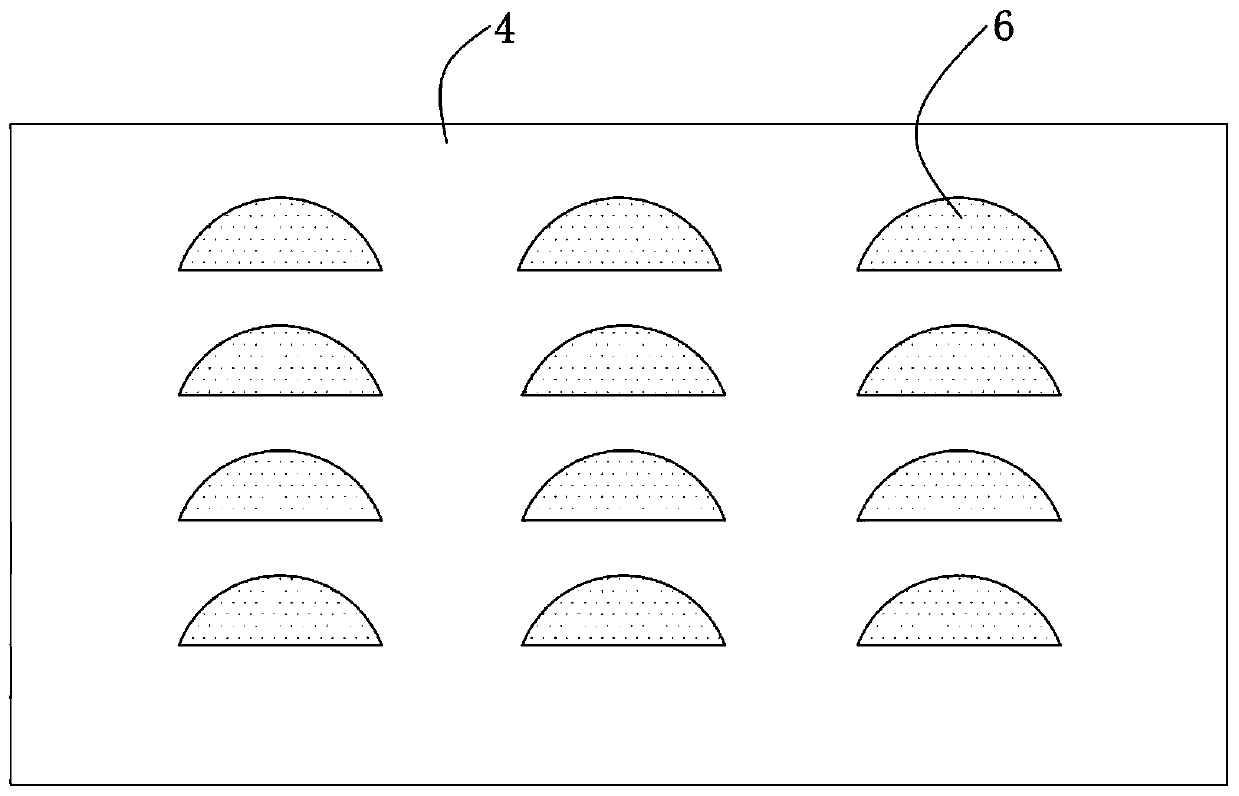

The invention discloses a centering adjustment mechanism, a device mechanism for adjusting the products and a device for classifying the tiles, including a row of fixed wheels (4), a row of adjusting wheels (5) and a conveying mechanism. The fixed wheel (4) is fixed radially and rotatably arranged on the fixed wheel frame (3). The adjusting wheel (5) is arranged on the adjusting wheel frame (12) through the elastic return mechanism, and the conveying mechanism is arranged between the fixed wheel (4) and the adjusting wheel (5). The elastic reset mechanism pushes the adjusting wheel (5) to swing to the fixed wheel (4) side. A ceramic tile classification device comprises an upper conveying mechanism, a damping mechanism, and a lower conveying mechanism, which are arranged in succession from top to bottom, and are provided with the centering adjusting mechanism at the input end of the sorting upper conveying mechanism. The present invention has the advantages of simple structure, enhanced work seriality, and high working efficiency.

Owner:山东爱而生智能科技有限公司

High-transparency recycled plastic formula, preparation method and granulator

The invention discloses a high-transparency recycled plastic formula, a preparation method and a granulator. The high-transparency recycled plastic formula comprises recycled polyethylene particles, recycled polypropylene particles, calcium carbonate powder, graphene powder, an antioxidant, a brightener, a stabilizer and a plasticizer. In the invention, the recycled polyethylene particles accountfor 60% of the total weight of the components, the recycled polypropylene particles account for 30% of the total weight of the components, the calcium carbonate accounts for 3% of the total weight ofthe components, the graphene accounts for 2% of the total weight of the components, the plasticizer accounts for 2% of the total weight of the components, the antioxidant accounts for 1% of the totalweight of the components, the brightener accounts for 1% of the total weight of the components, and the stabilizer accounts for 1% of the total weight of the components. Under the same use amount, therecycled plastic has the best transparency under the mixing ratio, and the mixed material has excellent toughness and good heat resistance. Thus, the component ratio adopted in the invention is an optimal scheme considering various properties of the recycled plastic. The granulator provided by the invention has the advantages of high production continuity, good effect and good economic benefit.

Owner:清远市佳易新材料科技有限公司

Rotating component assembling machine

ActiveCN113102991ASimple structurePush effect is goodAssembly machinesMetal working apparatusPhysicsEngineering

The invention discloses a rotating assembly assembling machine which comprises a rack, a positioning conveying device driven by an intermittent driving device is rotatably installed on the rack, and a plurality of pressure applying devices extending to the position above the positioning conveying device are arranged on the portion, located on the periphery of the positioning conveying device, of the rack. A transferring device and a bearing feeding device are further arranged on the machine frame on the periphery of the positioning conveying device, a shaft sleeve feeding device is arranged at the position corresponding to the transferring device, and a rotary clamping and conveying mechanism is arranged on the machine frame at the position corresponding to the bearing feeding device. The transferring device and the rotary clamping and conveying mechanism vertically slide along the rack and are distributed between the two adjacent pressure applying devices in the rotating direction of the positioning and conveying device. The assembling machine achieves mechanical feeding of bearings and shaft sleeves and mechanical assembling of the bearings, the shaft sleeves and air expansion shafts, is high in working continuity and working efficiency, and guarantees assembling precision. The problem of damage caused in manual assembly is avoided; and the labor intensity of workers is reduced, the labor amount is reduced, and the labor cost is low.

Owner:SHANDONG HOACO AUTOMATION TECH

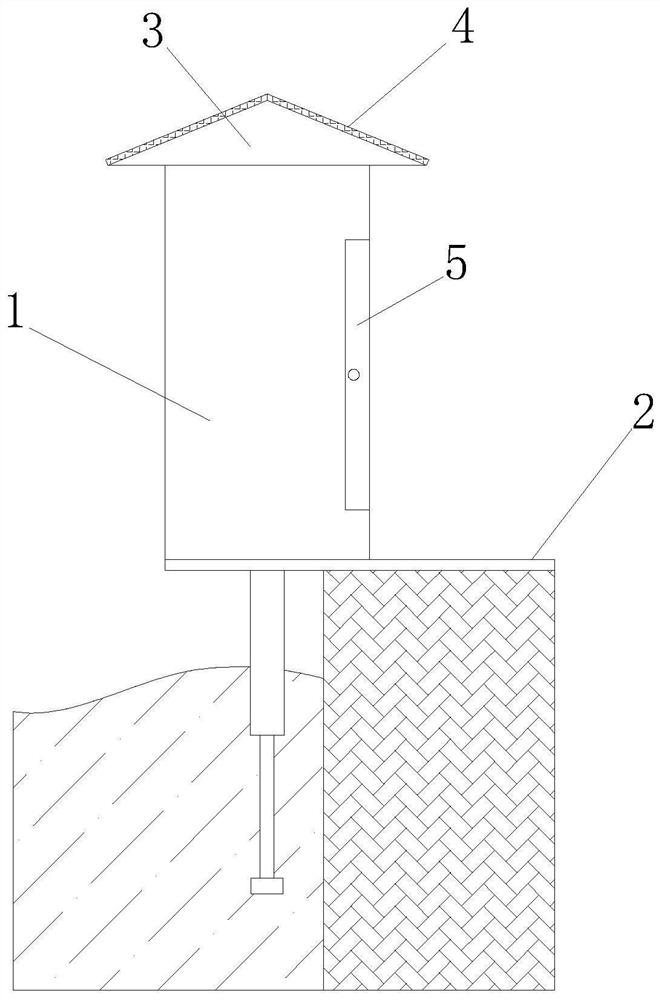

Water source pollution monitoring equipment

InactiveCN111679049AHave the effect of pollutingReduce mistakesTransmission systemsGeneral water supply conservationWater sourceTap water

The invention relates to the technical field of water quality detection, and discloses water source pollution monitoring equipment, which comprises a box body, a fixing plate, a tap water pipe and a cover top. According to the water source pollution monitoring equipment, the water quality is scientifically measured through a detection instrument; errors and inconvenience caused by manual measurement are reduced; and the reliability of measurement is improved. The water source pollution monitoring equipment collects a water sample on site; after monitoring and analysis, data in the automatic monitoring and analysis main body is transmitted to a central station through the communication network; the water quality environment is timely fed back, the monitoring efficiency of water source pollution is improved; treatment is timely, pollution is avoided, an electronic valve and a water bag are arranged to clean up the inside of the water tank after last sampling, a water pump with a bidirectional function is used to exhaust water out of the water tank, and thus, a next sampling result is more accurate. The water source pollution monitoring equipment is simple in structure, reasonable indesign, high in working efficiency, stable in working performance, high in working continuity and better in performance.

Owner:山东虎力机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com