Centering adjustment mechanism and tile sorting device

A centering adjustment and sorting device technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low level of mechanical operation of packers and many specifications and sizes, and achieve enhanced work continuity, faster speed, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

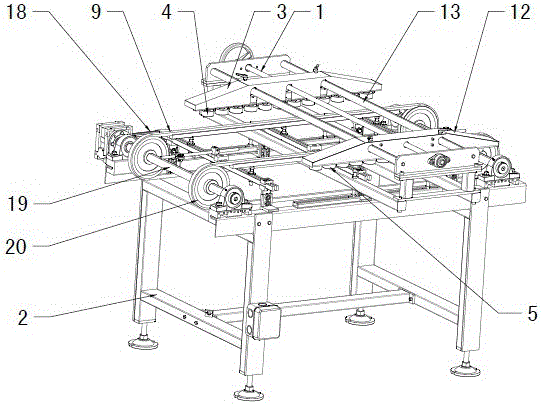

[0027] Embodiment 1 is the preferred embodiment of the present invention, below in conjunction with appended Figure 1~11 To further illustrate the technical solution of the present invention.

[0028] Example 1

[0029] to combine Figure 1~3 , a centering adjustment mechanism proposed in this embodiment, including a two-way lead screw 1, a support frame 2, a fixed wheel frame 3, a fixed wheel 4, an adjustment wheel 5, a rotating shaft 6, a tension spring 7, a swing plate 8, and a conveyor belt 9 , fixed shaft 10, adjusting shaft 11, adjusting wheel frame 12, balance bracket 13, first connecting hole 14, second connecting hole 15, motor 18, drive shaft 19, belt pulley 20, in the center hole of a plurality of fixed wheels 4 installation The bearings are assembled on a plurality of fixed shafts 10 fixed on a straight line on the fixed wheel frame 3, and the swing plate 8 is a triangular plate, wherein two corners are respectively provided with a first connecting hole 14 and a...

Embodiment 2

[0032] to combine Figure 4 The difference between embodiment 2 and embodiment 1 is that the spring of the elastic return mechanism of this embodiment is a compression spring 17, one end of the compression spring 17 is connected to the adjustment wheel frame 12, and the other end is connected to the wheel seat 16, and the adjustment wheel 5 is rotated and arranged on the wheel Seat 16.

[0033] When a power source motor 18 inputs a power through the pulley 20 on the driving shaft 19, when the product to be centered enters between the fixed wheel 4 and the regulating wheel 5 through the conveyor belt 9, the conveyor belt 9 drives the product to press the regulating wheel 5, compressing Spring 17 is compressed, and under the anti-deformation force effect of compression spring 17, the product on the adjusting wheel 5 presses conveyer belt 9 to move to fixed wheel 4 directions, makes product close to fixed wheel 4 direction centering.

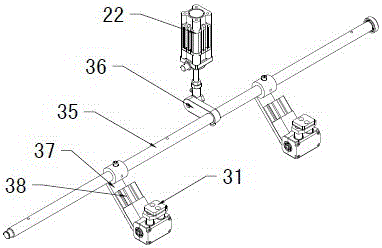

[0034] refer to Figure 5 , The present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com